The forged steel lift check valve stands at the forefront of flow control innovations—meeting the highest demands of reliability, pressure containment, and corrosion resistance in critical pipeline applications. Leveraging advanced forging and precision CNC techniques, contemporary check valve lift type products (such as the API 602 Pattern Forged Lifting Check Valve) deliver robust performance across petrochemical, metallurgy, water treatment, and power sectors.

1. Industry Trends: Market Dynamics for Forged Steel Lift Check Valves

Global demand for forged steel lift check valve solutions is surging, driven by stringent safety standards (ISO 9001:2015, API, ANSI), increasing operating pressures (up to 420 Bar), and the transition towards environmentally friendly, leakage-proof flow systems.

- 2023 global industrial valve market size: $85.9 billion (Statista, 2023)

- Projected CAGR of lift type check valves (2024–2029): 5.1% (MarketsandMarkets, 2024)

- Main growth sectors: Petrochemical, Power Generation, Water & Wastewater Management, Oil & Gas, Metallurgy

2. Technical Parameters: Deep Dive Into Lift Check Valve Design & Performance

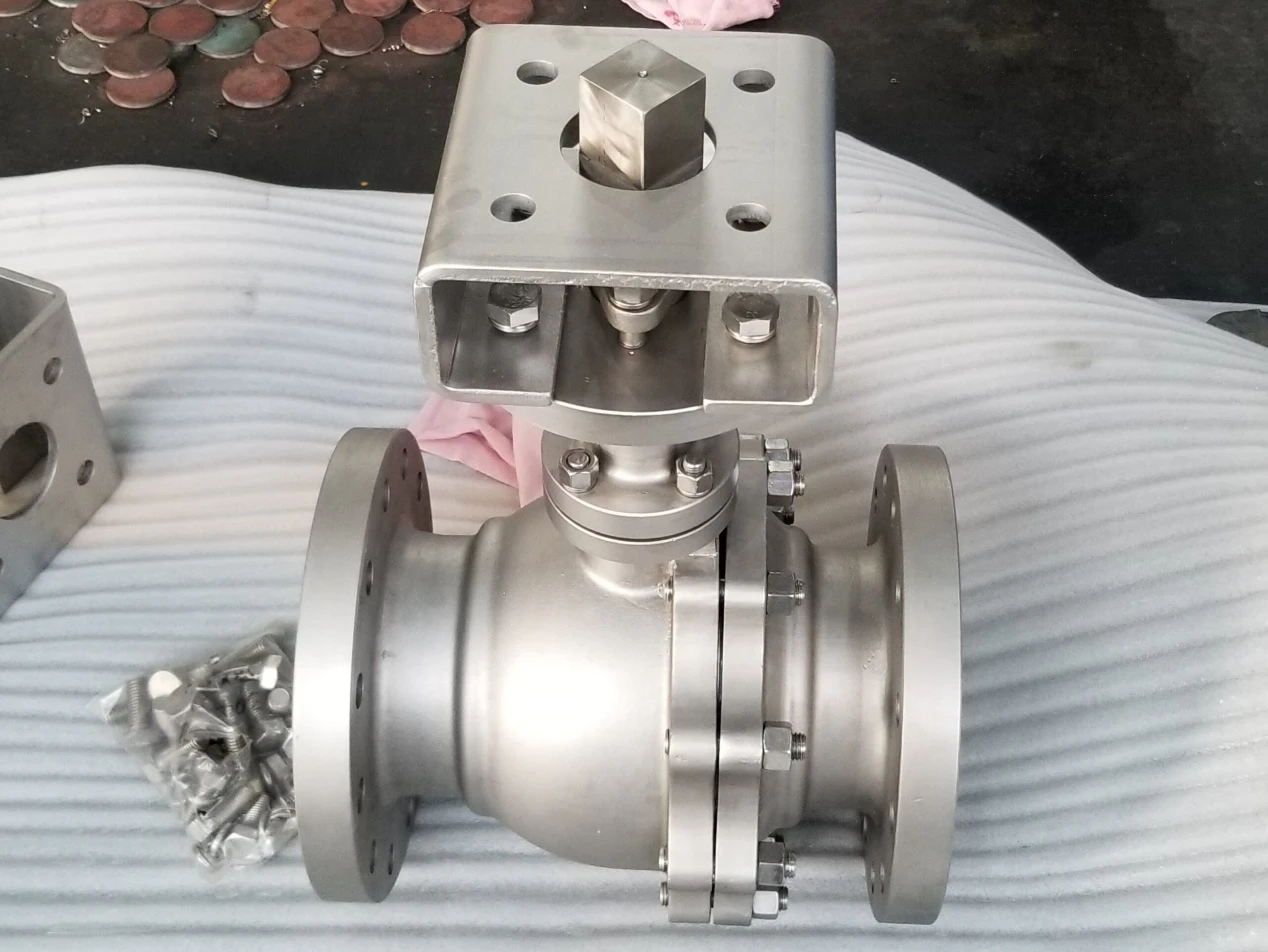

Forged steel lift check valves are engineered for rigorous environments. The key features revolve around:

- Forged Body: High-grain density, zero porosity, industry-leading mechanical strength

- CNC Machined Internal Components: Precision-fitted seat/disc assembly minimizes backflow and wear

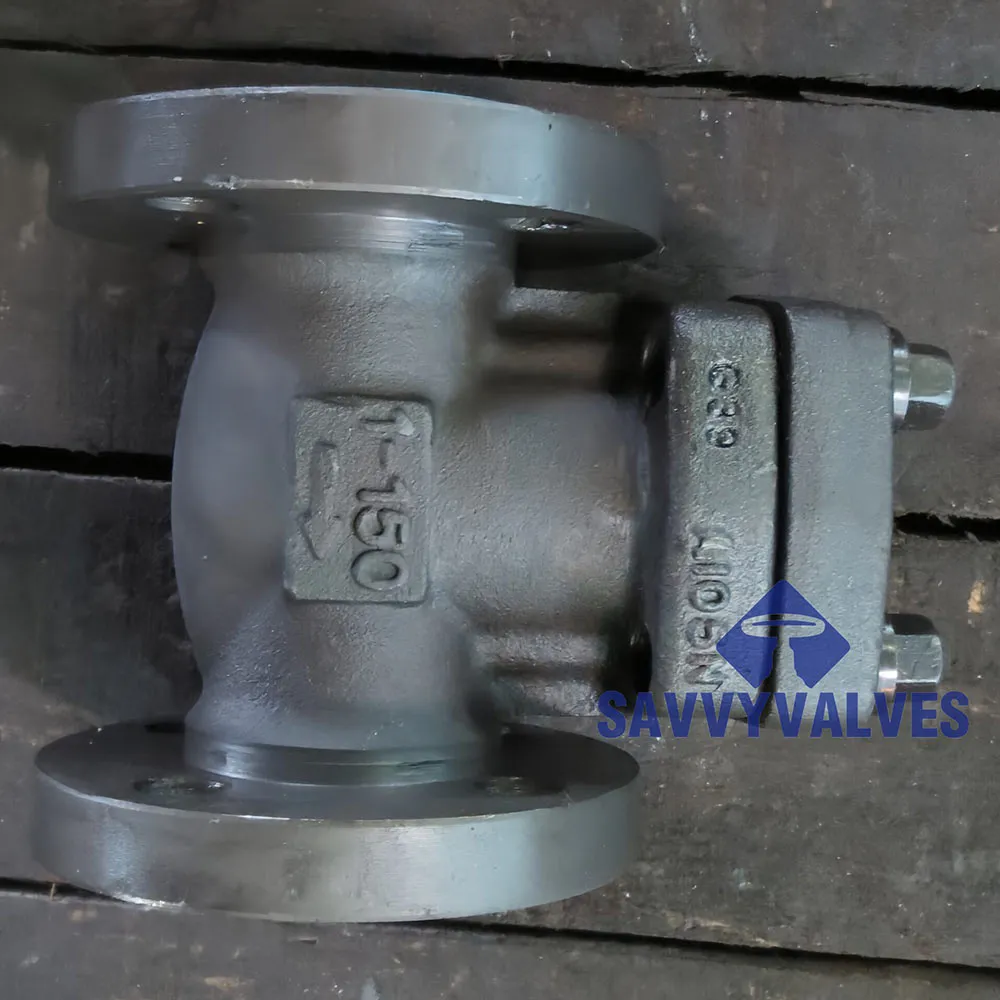

- Material Options: ASTM A105, F304(L), F316(L), F51, F53 & Alloy Steel (see chart below)

- End Connections: Socket Weld (SW), Threaded (NPT/BSP), Butt Weld (BW), Flanged

- Pressure Classes: ANSI Class 150 – 2500# (PN16–PN420)

- Temperature Range: -46°C to +550°C depending on seat and body material

| Parameter | Typical Range/Value | Standard/Spec |

|---|---|---|

| Body Material | A105, F304(F304L), F316(F316L), F51, F91 | ASTM/ASME B16.34 |

| Pressure Rating | Class 150 – 2500 / PN16 – PN420 | ANSI B16.34, API 602 |

| Seat Material | 13Cr, STL, F6a, PTFE, EPDM | N/A |

| Connection Type | SW, NPT, BSPT, BW, Flanged | ASME B16.11/B1.20.1 |

| Test Standard | API 598, EN12266-1 | API/ISO |

| Size Range | DN8–DN100 (1/4"–4") | API 602 |

| Operating Temp | -46°C to +550°C | Material Dependent |

| Medium | Steam, Oil, Gas, Water, Corrosive Fluids | Application Specific |

3. Manufacturing Process: Forged Steel Lift Check Valve Explained

The forged steel lift check valve undergoes rigorous manufacturing stages to ensure structural integrity and superior sealing. Key steps are illustrated in the process diagram below:

- All processes conform to API 602, ISO 9001:2015, API 598, ASME B16.34.

- Each forged steel lift check valve is serialized for traceable quality documentation.

- Final products undergo 100% seat leakage and shell pressure tests.

4. Technical Strength & Industry Certifications

- Forged Materials: Uniform grain orientation for maximum impact strength; mechanical performance 20-30% superior to cast valves.

- Product Longevity: Design life 15–25 years (statistical average in refineries/petrochemical pipelines).

- Anti-Corrosion: Stainless variants (F304, F316) pass over 5,000h salt-spray tests per ASTM B117.

- Leakage Resistance: API 602 lift check valves: seat leakage

| Standard | Description | Applies To |

|---|---|---|

| API 602 | Compact steel gate, globe, and check valves | Design, dimensions |

| ASME B16.34 | Valves – Flanged, threaded, welding end | Pressure–temp ratings, tests |

| API 598 | Valve inspection and test | Pressure test, leakage, shell integrity |

| ISO 9001:2015 | Quality management | Production, documentation, traceability |

5. Product Comparison: API 602 Pattern Forged Lift Check Valve vs. Main Rivals

| Product | Body Material | Design Standard | Pressure Rating | Operation Lifespan | API/ISO Certificate | End Connection |

|---|---|---|---|---|---|---|

| API 602 Pattern Forged Lifting Check Valve | A105, F304, F316, F51 | API 602 | Class 800, 1500, 2500 | 20+ yrs | API 602, ISO 9001 | SW/NPT/BW/Flanged |

| Cast Steel Swing Check Valve | WCB, CF8, CF8M | API 6D | Class 150–600 | 10–15 yrs | API 6D | Flanged/BW |

| Dual Plate Wafer Check Valve | CF8, CF8M, DI | API 594 | Class 150–900 | 10–12 yrs | API 594 | Wafer Type |

6. Product Data Visualization: Specs & Performance Charts

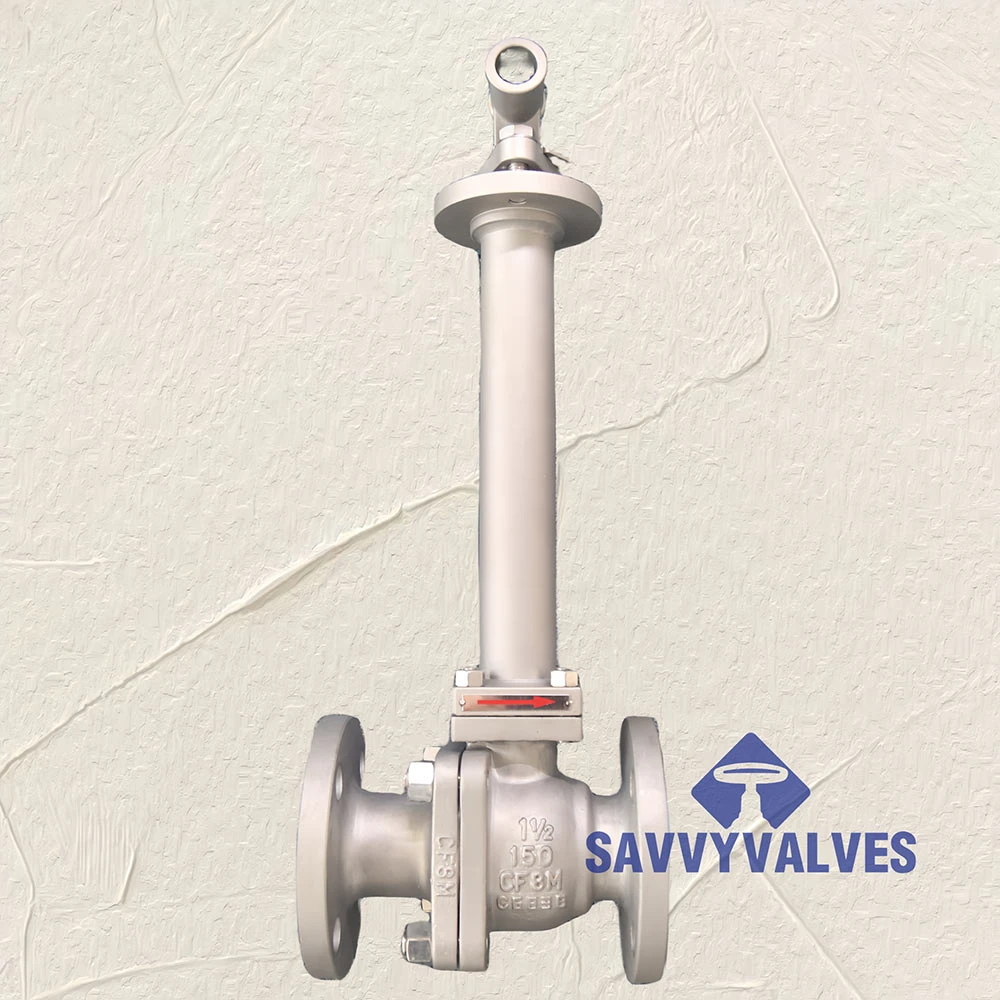

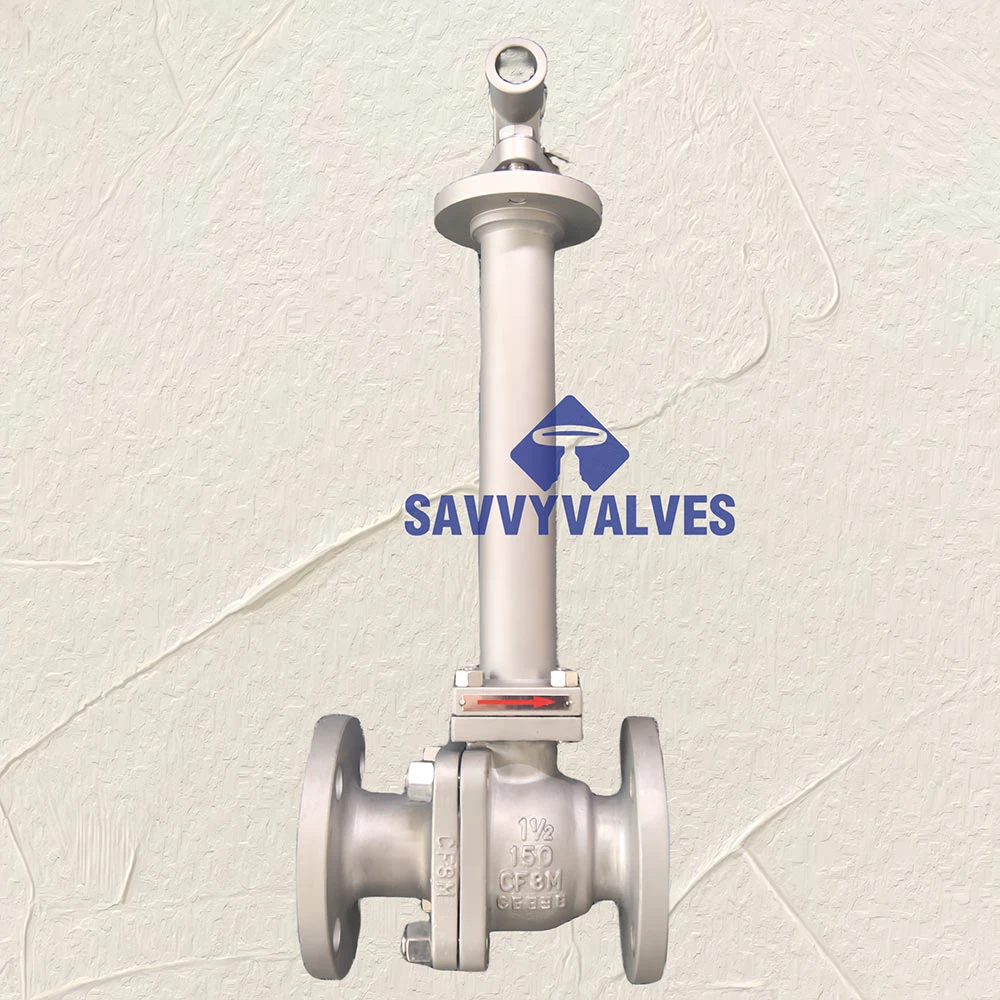

7. Customization & Engineering Solutions

Leading forged steel lift check valve suppliers provide tailored configurations for offshore, onshore, and specialty chemical plant projects:

- Exotic alloys for H₂S/CO₂ service (NACE MR0175 compliance)

- Soft seats (PTFE, EPDM) for ultra-low leakage isolation

- Extended bonnet & cryogenic service

- Special surface coatings (ENP, TCC, NiCr) for aggressive medias

- Reduced bore or full bore design per application

Warranty: Up to 36 months, manufacturer-backed certification & traceability.

8. Typical Applications & Case Studies

- Oil Refinery Mainline: Prevents backflow of process fluids at 110 bar, increased replacement interval by 65% over cast valves.

- Offshore Gas Platform: Stainless forged steel lift check valve with duplex trim reduced corrosion events by 90% (2019-2023).

- Power Plant Feedwater System: API 602 solution maintained zero failures across 8 years; verified by operator field logs.

- Desalination Facility (Saudi Arabia): Over 500 units in duplex and super duplex provide anti-scaling performance in brine pipelines.

9. Certifications, Partners & Service Commitments

- Full compliance: API 602, API 598, ISO 9001:2015, CE, SIL3 (where required)

- Serving 600+ global clients in 49 countries; top 10 petrochemical and oil/gas EPCs as direct customers

- 24/7 technical support, rapid field interventions, API-certified inspection/reporting

- After-sales stock of critical components; performance monitoring consultation

10. Professional FAQ on Forged Steel Lift Check Valves

11. Conclusion & References

Forged steel lift check valve technology underpins modern critical flow applications, delivering unmatched reliability, compactness, and durability with API/ISO quality credentials. Whether you require oil, gas, chemical, or utility service, the API 602 Pattern Forged Lifting Check Valve sets a global benchmark in safety, performance, and customization.

[1] Markets and Markets (2024): Check Valve Market Size & Trends

[2] Valve Magazine: Forged vs Cast Valves in Critical Services

[3] API – American Petroleum Institute: API Valve Standards

[4] ASME B16.34 Info: Valve Standards Technical Library

[5] API 602 Pattern Forged Lifting Check Valve Official Page