Globe Valves

-

SAMPLE SPECIFICATIONS

SIZE:24″

RATING:600LB

BODY AND BONNET : ASTM A216 WCC

PLUG: ASTM A182 F316 +STELLITE 6

STEM: ASTM A182 F6A

CAGE: ASTM A276 416

SEAT: ASTM A105+STELLITE 6

ACTUATION: ELECTRIC HYDRAULIC ACTUATOR

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:2″

RATING:150LB

STRUCTURER:BOLTED BONNET, OS&Y, RS

BODY AND BONNET : ASTM A105

DISC: ASTM A105+STELLITE 6

STEM: ASTM A182 F316

SEAT: ASTM A182 F316+STELLITE 6

ACTUATION: HAND WHEEL

-

Valve Type Bolted Bonnet Globe Valve Angle Pattern

Design Standard EN 13397 / ISO 15761 Lightweight Body

Size Range DN 15 to DN 100 (½" to 4")

Pressure Rating PN16 (16 bar @ 120°C) EN 1092-2

End Connection RF Flanges (EN 1092-2 PN16 Series A) Drilling: EN 1092-2

-

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE: 6″

RATING: 900LB

END: BW AS PER ASME B16.25

TEMPERATURE: -29 ℃~425℃

BODY AND BONNET : ASTM A216WCB

DISC: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

-

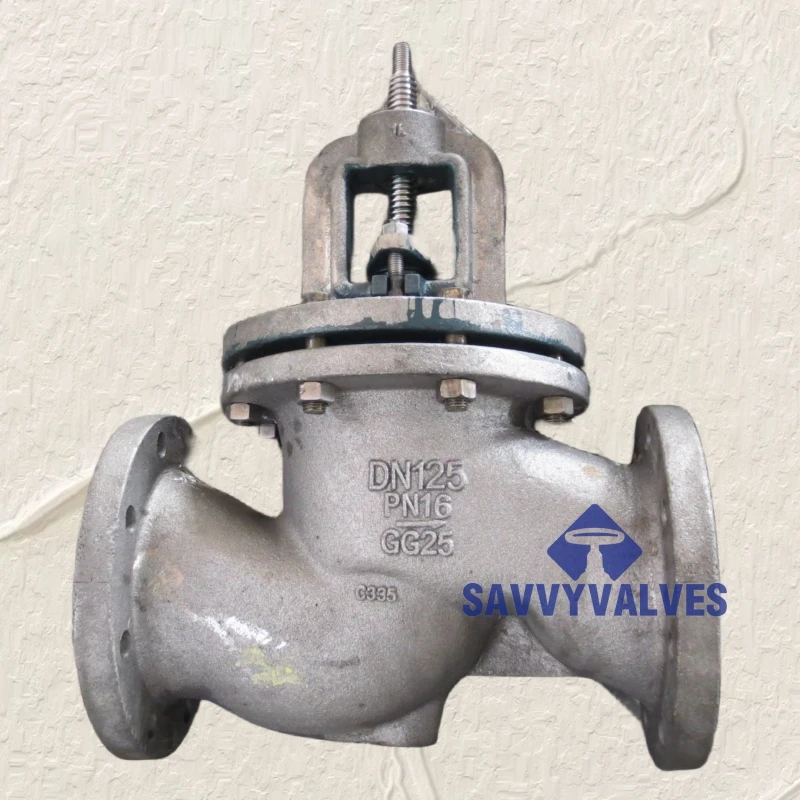

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:DN125

RATING:PN16

BODY AND BONNET : GG25

DISC: ASTM 536 65-45-12 + BRONZE B62/B148

SHAFT: STAINLESS STEEL 304

SEAT: STAINLESS STEEL 304

HAND WHEEL: DUCTILE IRON

-

Size: ¾"

Pressure Rating: 150 LB (ASME Class 150)

Key Materials (ASTM Standards):

Body/Bonnet/Disc/Stem/Seat: A182 F51 (Duplex Stainless Steel)

Operator: Handwheel Operated

Connection End: RF Flange (Raised Face)

Configuration: Straight Pattern

Surface Finish: Sandblasted & Degreased

Temperature Range: -29°C to 425°C

Service Compatibility: Seawater Applications

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:8″

RATING:125LB

BODY AND BONNET : ASTM 536 65-45-12

DISC: ASTM 536 65-45-12 + BRONZE B62/B148

SHAFT: BRONZE B62/B148

SEAT: BRONZE B62/B148

HAND WHEEL: DUCTILE IRON

-

Valve Type: Globe Valve (Stop-Check Design Optional)

Design Standard: ASME B16.34 / API 623 (Forged Steel Globe Valves)

Size (NPS): 3 Inch (3")

Pressure Class: ASME Class 1500 (1500 Lb)

Body & Bonnet Material: ASTM A217 WC6 (Cast Cr-Mo Alloy Steel for High-Temp Service)

Bonnet Type: Pressure Seal (Self-Sealing) Bonnet (Enhanced sealing under high pressure)

End Connection: Butt Weld (BW) per ASME B16.25

Flow Characteristic: Linear (Precise throttling capability)

Seat & Disc Contact Surfaces: Weld-Overlayed Stellite 6/21 (Cobalt-Chromium Alloy)

Provides extreme resistance to steam erosion, galling, and high-temperature corrosion.

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:3″

RATING:1500LB

STRUCTURE: BOLTED BONNET,OS&Y

BODY AND BONNET : ASTM A217 WC9

DISC: ASTM A217 WC9+STELLITE 6

STEM: ASTM A182 F316

SEAT: ASTM A182 F22+STELLITE 6

ACTUATION: ELECTRIC ACTUATOR

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:1″

RATING:800LB

BODY AND BONNET : ASTM A105

DISC: ASTM A105+STELLITE 6

STEM: ASTM A182 F316

SEAT: ASTM A182 F316+STELLITE 6

ACTUATION: HAND WHEEL

-

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE: DN50

RATING: PN250

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

-

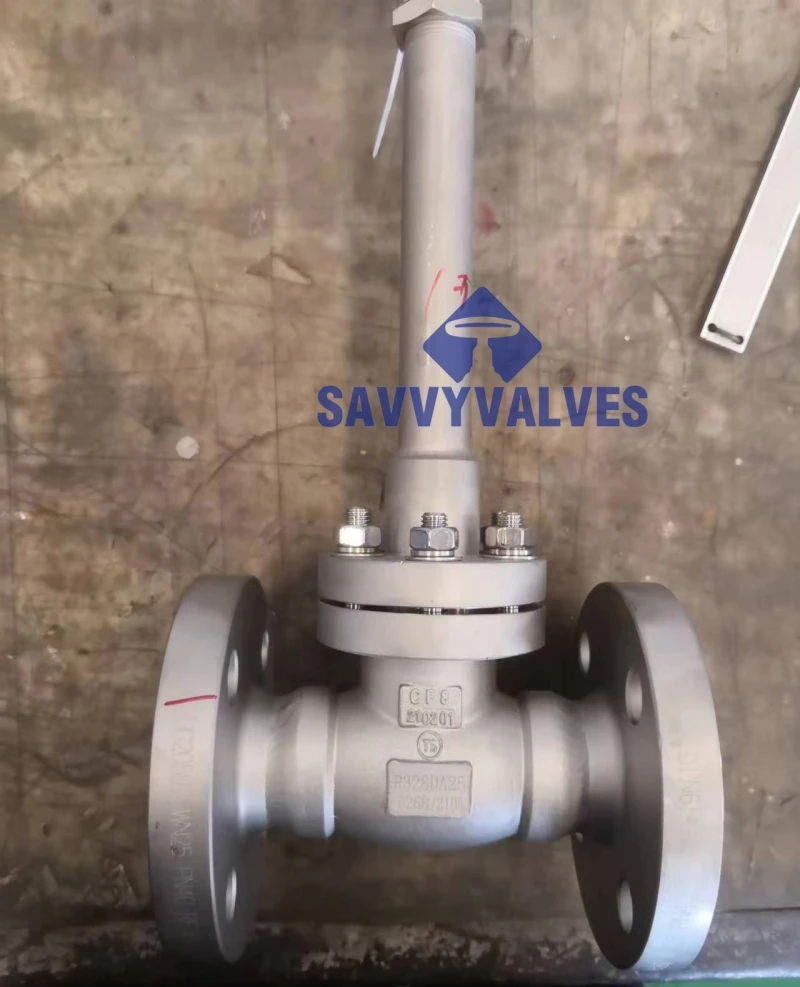

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE: 3″

RATING: 300LB

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

A globe valve is a linear motion valve primarily used to start, stop, and regulate fluid flow in a pipeline. Its internal structure includes a movable disk-type element and a stationary ring seat in a generally spherical body—hence the name "globe" valve. When the actuator or handwheel is turned, the stem moves the plug up or down, altering the flow path and providing throttling control. This design offers a good shutoff capability and is well-suited for applications where precise flow regulation is required. Due to the tortuous flow path, globe valves tend to have higher pressure drops than other types, but they compensate with excellent control accuracy. They are often used in chemical processing, power generation, and oil and gas systems where controlled flow and tight sealing are essential. Globe valves can handle various fluids including steam, water, oil, and gas, and are available in manual, pneumatic, or electric actuation versions. Their versatility and dependable operation make them a top choice for systems requiring modulation or frequent operation.

- 1

- 2