DIN Grilla Grills Wood Pellet Grill

SAMPLE SPECIFICATIONS

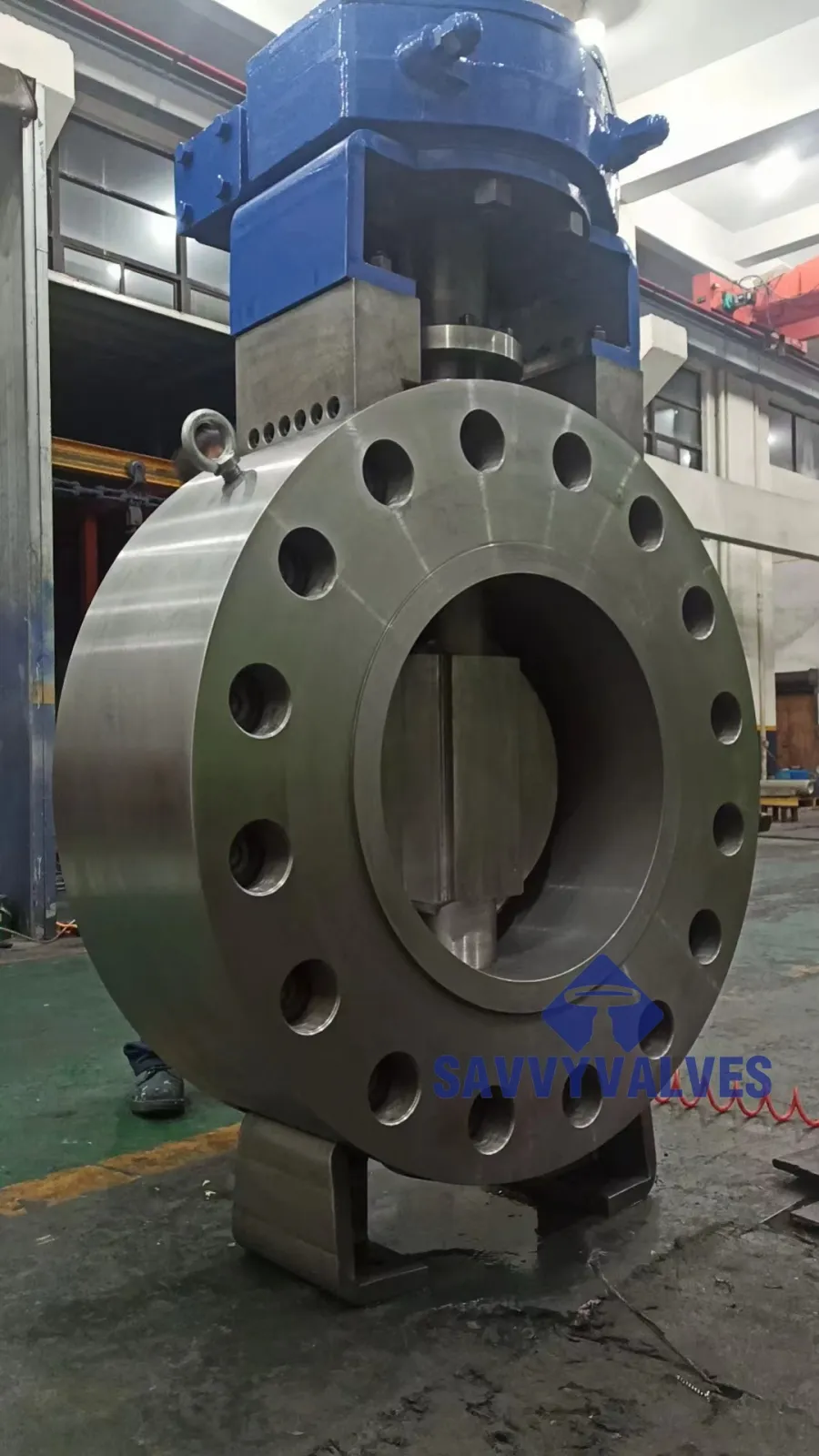

SIZE: 26″

RATING: 1500LB

BODY: ASTM A105N

DISC: ASTM A182 F316

EXTENDED YOKE: ASTM A182 F5

STEM: SS416

SEAT: ASTM A182 F316

SEAL: SS316+GRAPHITE LAMINATED

ACTUATION: GEAR UNIT

GENERAL DESIGNED SPECIFICATION

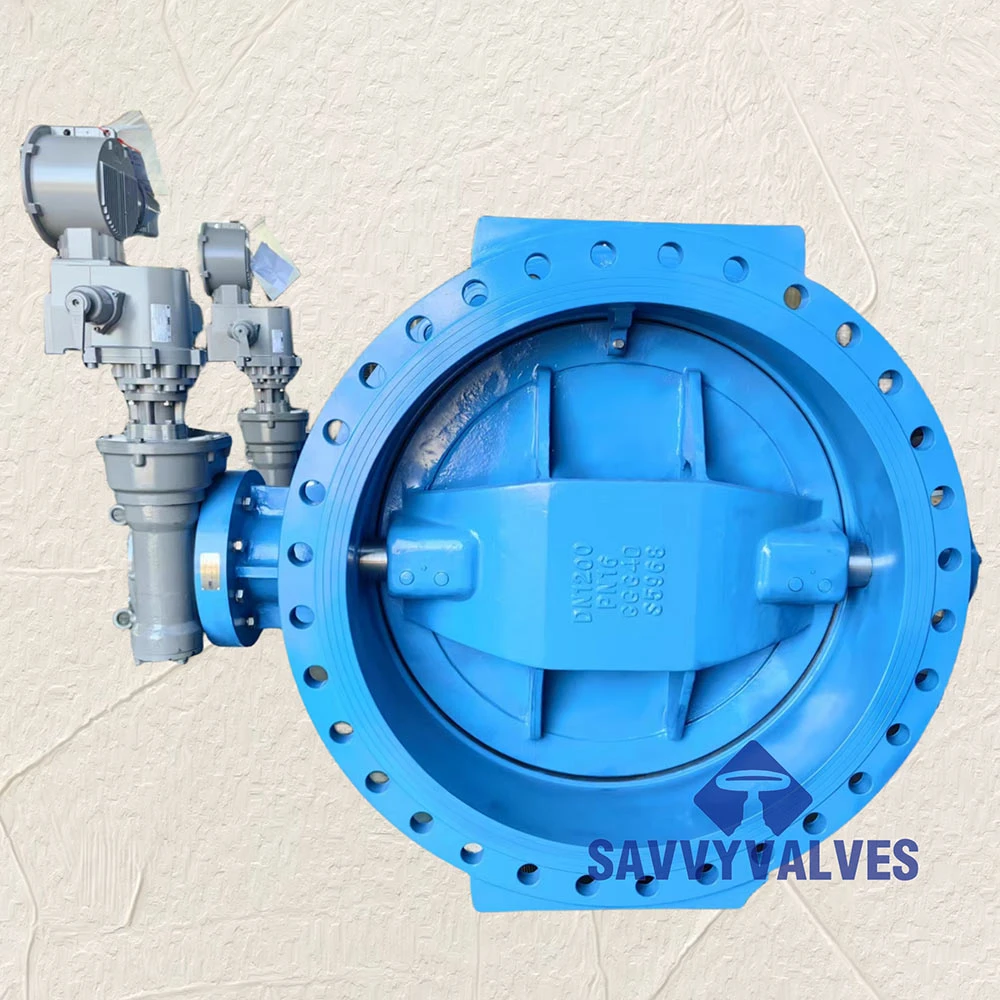

Size: 2″~144″.

Pressure Rating: 150LB~4500LB

Design Temperature: MAX. 800℃.

General applications: STEAM.

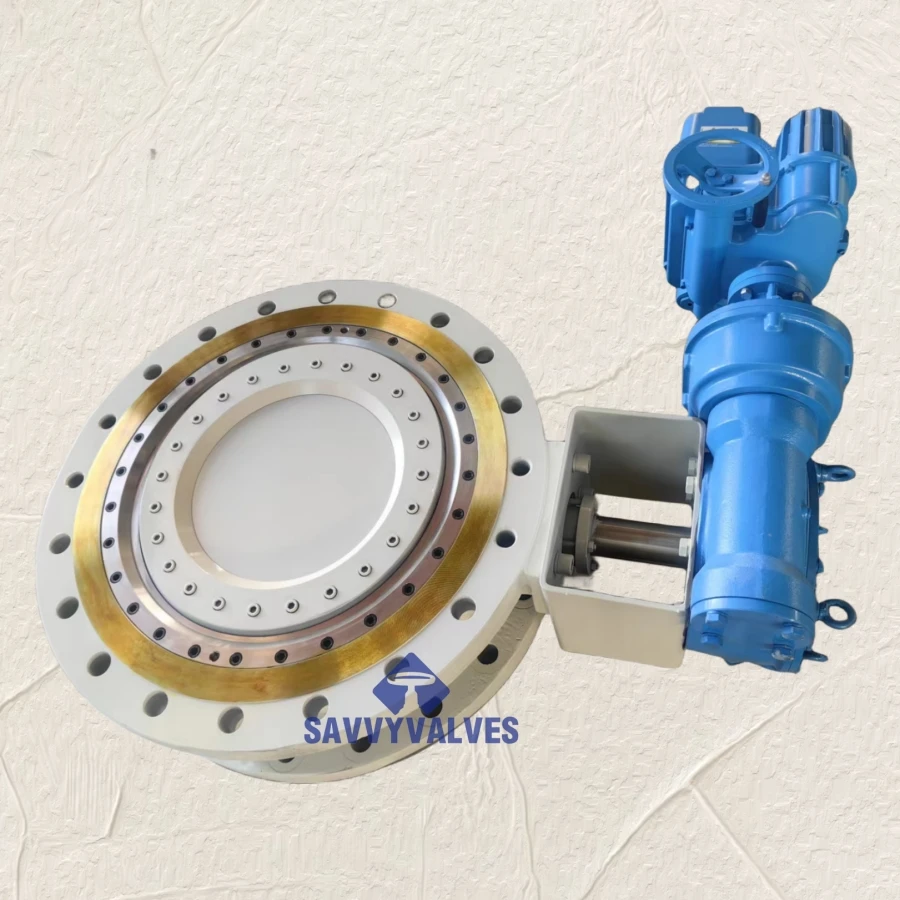

Design & Manufacture: API 609, EN 593 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.25, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: anti-blow out stem.thermal plate.

TYPICAL MATERIAL LIST

BODY: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

DISC: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

EXTENDED YOKE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

SEAT: STELLITE NO.6 HF

SEAL: SS316+GRAPHITE LAMINATED

OPERATOR: GEAR UNIT

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST AND INSPECTION

Inspection and approval norm: API598, API6D.

QUALITY CONTROL

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The thermal duty / high temperature triple offset butterfly valve in forged steel is specifically engineered for extreme temperature and pressure environments, making it a top choice for applications in power generation, oil refining, chemical processing, and steam systems. Its triple offset design ensures minimal friction between the disc and seat, enabling tight shut-off even after prolonged exposure to thermal stress. The forged steel body enhances mechanical strength and thermal resistance, allowing the valve to perform reliably in continuous high-temperature cycles. This valve is ideal for controlling superheated steam, hot gases, and aggressive fluids where standard valve materials would degrade. The metal-to-metal sealing design also prevents seat deformation and leakage under high differential pressure. With its robust construction, excellent sealing capability, and long service life, this valve offers superior performance in demanding industrial systems where temperature and safety are critical considerations.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.