DIN Grilla Grills Wood Pellet Grill

SAMPLE SPECIFICATIONS

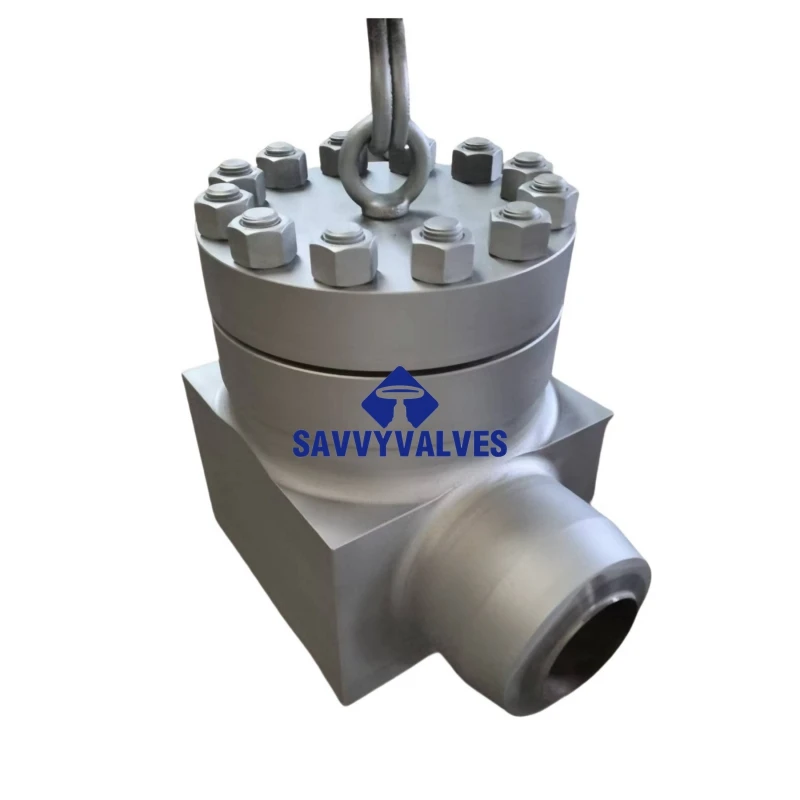

SIZE: DN20

RATING: PN420

END: BW AS PER B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

GENERAL

Size: 1/8″~24″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~800℃.

General applications: CNG, LNG,LPG, CO2, N2, other cryogenic duty.STEAM thermal duty.

DESIGN

Design & Manufacture: BS 6364, API 6D , ASME B16.34 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, ASME B16.10, BS EN 558

Connection: ASME B16.25, ASME B16.5, ASME B16.47, EN 1092, JIS 5K-20K. BW, RTJ are available.

Safety design: fire proof

GENERAL MATERIAL

BODY: ASTM A182 F304/F316/F304L/F316L/F51/F53, MONEL K400/K500, H276,INCONEL 625/718

PLUG: ASTM A182 F304, F316

SEAT: PCTFE, PEEK, HF METAL

OPERATOR: SPRING LOADED

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D, BS6364.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The CNG LNG cryogenic piston lifting check valve free forged is engineered to ensure backflow prevention in ultra-low temperature environments commonly found in liquefied gas systems such as CNG and LNG applications. Its piston-type lifting mechanism provides precise, responsive flow control and seals tightly upon flow reversal, which is critical for protecting downstream equipment in cryogenic conditions. The free forged body enhances the valve’s structural strength, pressure resistance, and resistance to thermal shock, which is vital for maintaining performance at temperatures as low as -196°C. Designed with an extended bonnet, it isolates the stem and packing from direct contact with cryogenic fluids, minimizing leakage risks. This valve is widely used in LNG terminals, gas liquefaction plants, and cryogenic storage tanks where safety, durability, and zero leakage are non-negotiable. Its compact size, low cracking pressure, and robust sealing performance make it ideal for high-integrity gas systems under extreme conditions.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.