DIN Grilla Grills Wood Pellet Grill

Brief:

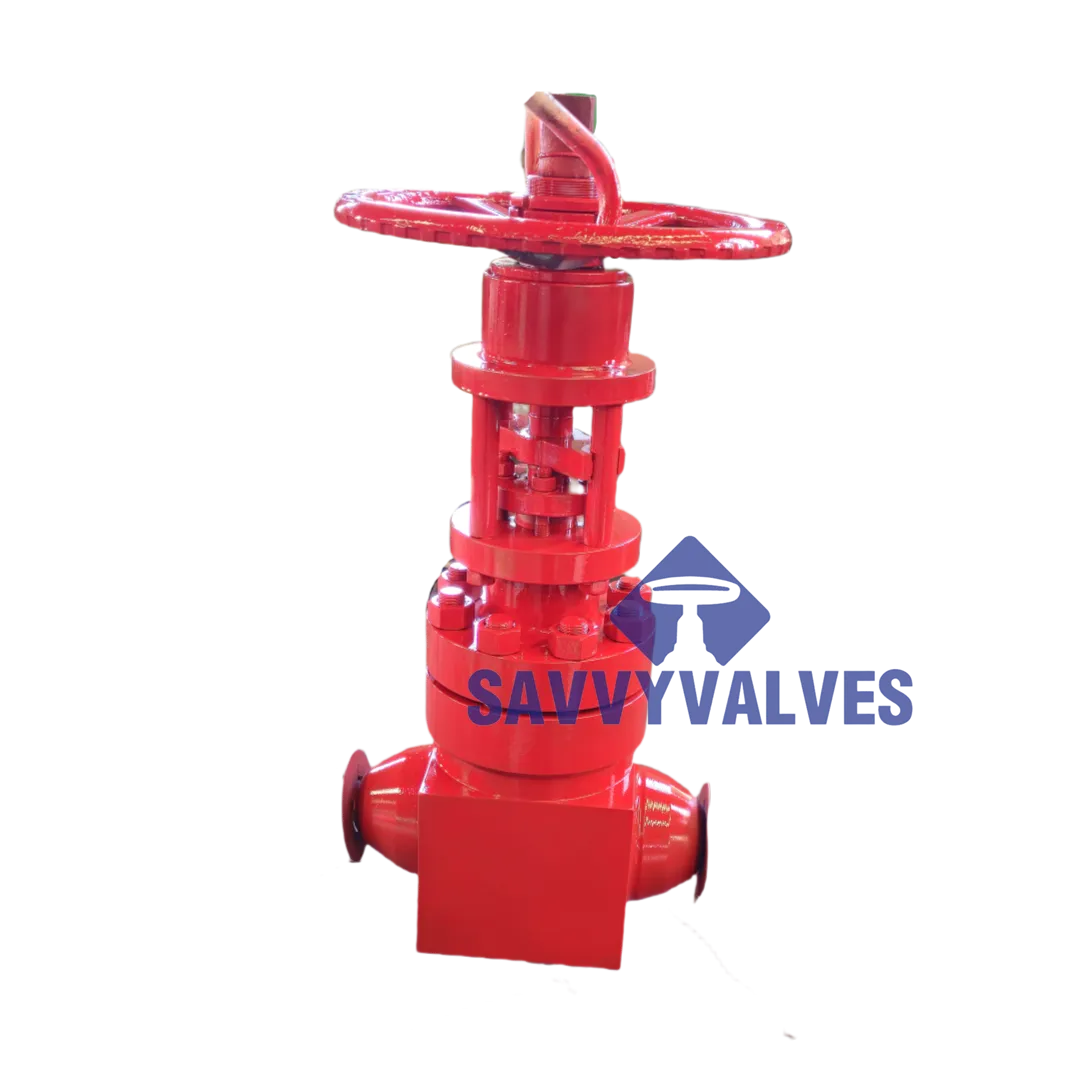

Size:3″

Rating:2500LB

Materials:

ASTM A182 F11 body and bonnet

ASTM A182 F11+stellite 6 Disc

ASTM A182 F6A stem

Stellite 6 overlay body seat

Operator: handwheel

Ends: BW as per ANSI B16.25

Materials:

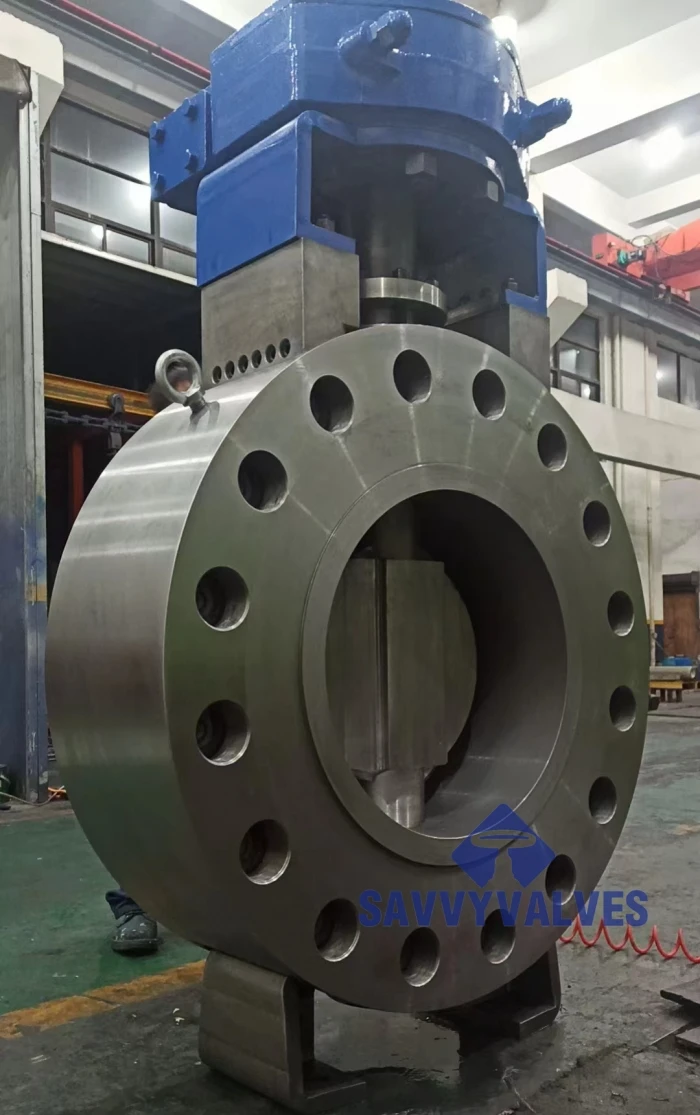

Body and bonnet: forged ASTM A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5, Casting A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2, Monel, Inconel, Hastelloy etc.

Design:BB, RS, OSY, integral body seat hard faced

Size: NPS 1/4” to NPS 6”

Rating: Class 2500

Ends: BW as per ANSI B16.25

GUATANTEE

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

The SAVVY 3″ 2500lb Globe Valve Thermal Duty/High Temperature is specifically engineered to perform reliably in extreme heat and high-pressure environments. With a 3-inch diameter and a pressure rating of 2500lb, this valve is ideal for thermal duty applications such as superheated steam, high-temperature water, and heat transfer fluids commonly found in power generation, refineries, and chemical processing plants. Its robust construction typically includes heat-resistant alloys and a precision-engineered globe body that maintains seal integrity and operational stability under thermal stress. The design also features tight shut-off capability and accurate flow control, making it suitable for both isolation and modulation in severe service conditions. SAVVY’s advanced manufacturing and material selection ensure the valve resists thermal expansion, oxidation, and warping, extending its service life and reducing maintenance needs. This makes it a dependable choice where consistent performance at elevated temperatures is essential.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.