DIN Grilla Grills Wood Pellet Grill

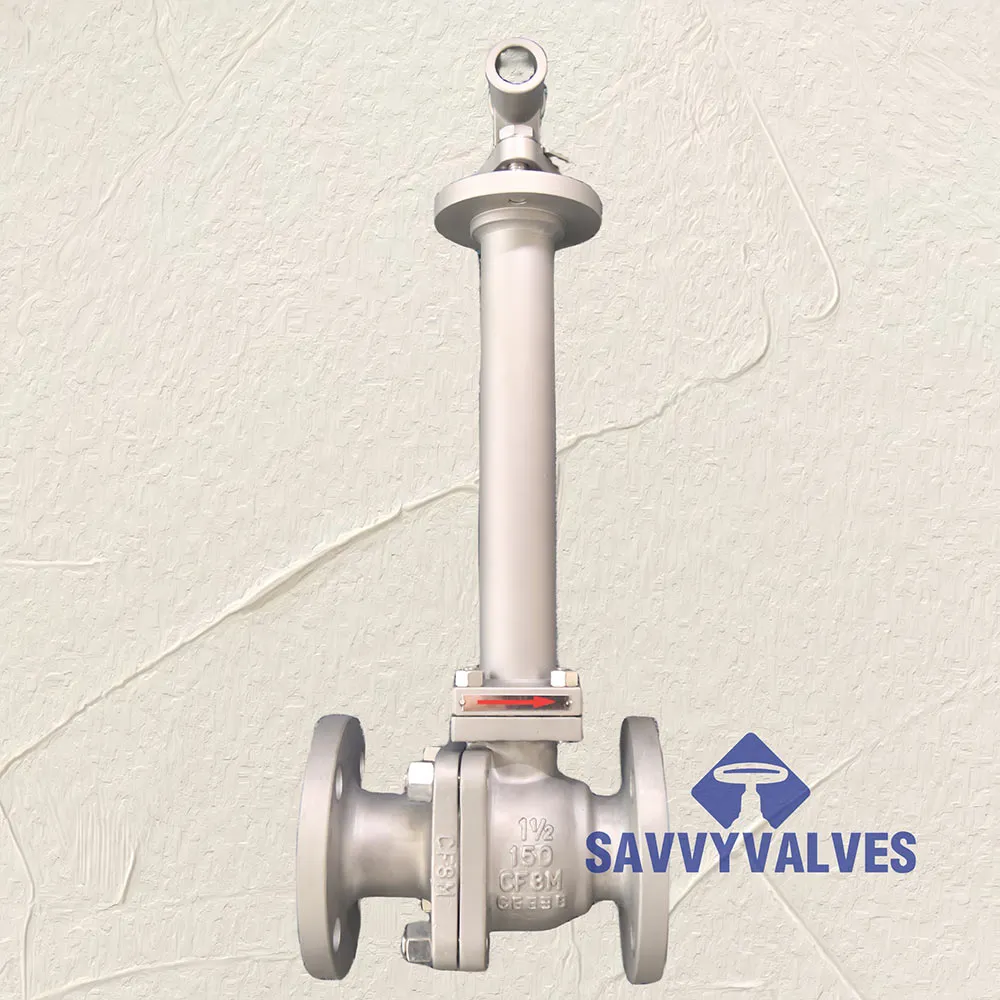

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE: 1-1/2″

RATING: 150LB

END: FLANGED AS PER ASME B16.5 300LB

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8M

BALL: ASTM A182 F316+HCR

STEM: ASTM A182 F316

SEAT: SPRING ENERGIZED PCTFE

ACTUATION: LEVER

Size: 1/8″~6″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~150℃.

General applications: LNG, LPG, CNG, CO2 etc.

Design & Manufacture: BS 6364, API 6D , ASME B16.34 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, ASME B16.10, BS EN 558

Connection: ASME B16.5, EN 1092, JIS 5K-20K. BW, RTJ are available.

Safety design: Fire proof, anti static, anti-blow out stem.

GENERAL MATERIAL

BODY: ASTM A351 CF8, CF8M,CF3, CF3M, 4A, 5A, MONEL K400, K500, H-276.

BALL: ASTM A182 F304/F304L/F316/F316L/F51/F53/MONEK K400 K500

EXTENDED BONNET: ASTM A351 CF8, CF8M A182 F304, F316

STEM: F304,F316,XM-19, 17-4PH, INCONEL 718, MONEL K-500

SEAT: SPRING ENERGIZED PCTFE/PEEK/HF METAL.

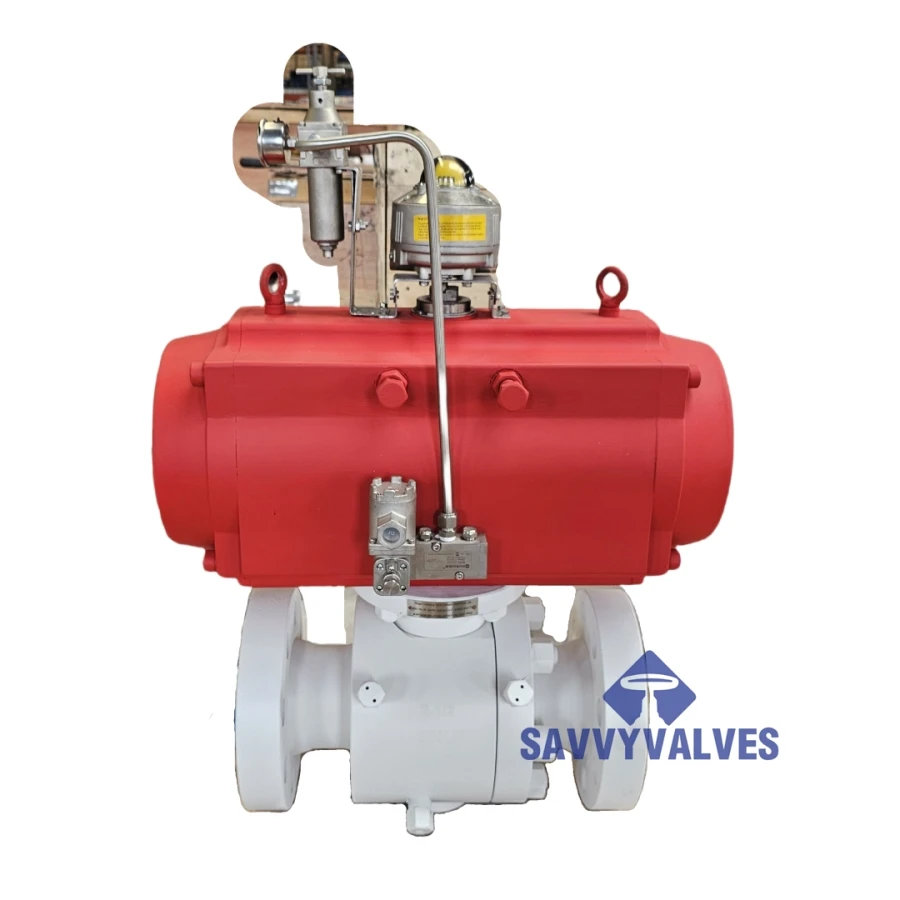

OPERATOR: LEVER OR GEAR

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D, BS6364.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The 2-piece cryogenic floating ball valve is specifically engineered for low-temperature environments like LNG, LPG, and other cryogenic applications, where reliable flow control and safety are critical. Its floating ball design enables tight shutoff by pressing against the downstream seat under pressure, ensuring leak-free operation even at extremely low temperatures. The 2-piece body construction offers easy maintenance and disassembly without disturbing the pipeline. It also features an extended bonnet to insulate the stem from cold media, reducing the risk of freezing at the packing area. Made with materials selected for cryogenic resilience, this valve performs consistently in conditions down to -196°C. It supports both manual and automated control, making it suitable for storage tanks, vaporization units, and transfer lines. With a compact footprint, high sealing integrity, and compliance with cryogenic standards, it is a dependable solution for demanding low-temperature flow control scenarios.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.