DIN Grilla Grills Wood Pellet Grill

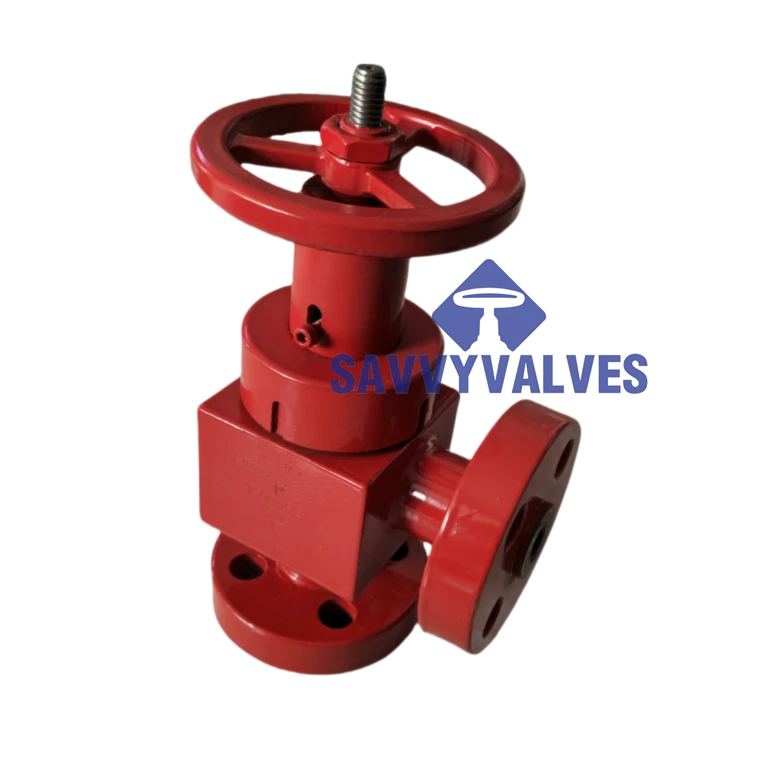

PHOTOS SHOW SPECIFICATIONS AS BELOW

SIZE:DN100

RATING: PN100

BODY AND BONNET : A216 WCB

PLUG: 410SS

STEM: 316SS

CAGE: 410SS

SEAT: 410SS

ACTUATION: PNEUMATIC ACTUATOR

DESIGN SPECIFICATIONS AS BELOW

Size: 2″~24″

Pressure Rating: 3000PSIG~30000PSIG

Design Temperature: API 6A

General applications: water, oil , gas

Design & Manufacture: API 6A, API 6D

F TO F dimensions: API 6D, API 6A

Connection: ASME B16.5, B16.47, API 6A TYPE 6BX, ANSI B36.10, ASME B16.25

Structure : TYPICAL PLUG TRIMS

CAGED BALANCED TRIMS

Performance: Linear, fast open, equal percentage

TYPICAL MATERIALS LIST

BODY AND BONNET: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

AISI 4130 4140

PLUG: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718 AISI 4130 4140

CAGE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, AISI 4130 4140

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

SEAT:A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276 +HARD FACED.

OPERATOR: ELECTRIC HYDRAULIC ACTUATOR / ELECTRIC ACTUATOR / PNEUMATIC ACTUATOR / HYDRAULIC ACTUATOR ,

ON OFF TYPE OR MODULATING TYPE

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST AND INSPECTION

Inspection and approval norm API598, API6D, API 6A

QUALITY CONTROL

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

FUGITIVE EMISSION TEST IS AVAILABLE.

GUATANTEE

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

The Pneumatic Choke Valve Through Conduit is designed for high-performance flow control in demanding oil and gas applications, especially in wellhead and production systems. One of its key advantages is its pneumatic actuation, which allows for fast, remote, and reliable operation in hazardous or hard-to-reach environments. The through conduit design ensures a full-bore flow path, minimizing pressure drop and turbulence, which is crucial for extending valve and pipeline life. This design also reduces the risk of solids accumulation, making it suitable for handling fluids with sand or other particulates. With fewer restrictions in the flow path, the valve improves flow efficiency and is easier to pig. Additionally, its robust construction supports high-pressure operation and ensures long-term reliability with minimal maintenance. The integration of precise control and rugged design makes this valve an excellent choice for automated systems in upstream oil and gas operations.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.