As a globally recognized leader in industrial valve manufacturing, Savvy Valves (formerly International Machinery Development Inc.) combines decades of engineering expertise with cutting-edge production capabilities to deliver high-performance, reliable valve solutions for the world's most demanding applications. Serving key sectors including oil & gas, petrochemicals, power generation, and water treatment, we specialize in OEM valve manufacturing, offering a comprehensive range of valves, actuators, and accessories that meet and exceed API, ASME, EN, ISO, and other critical international standards.

-

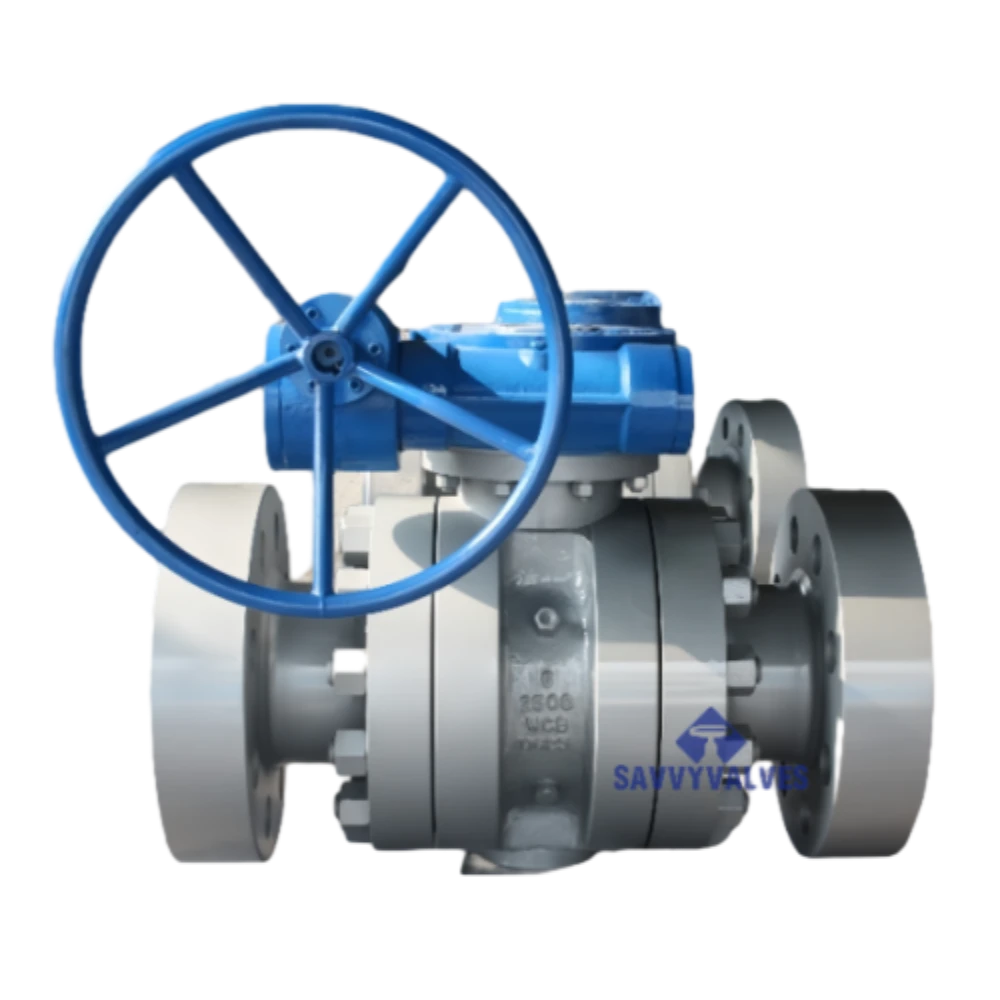

SIZE:6″,12″ RATING:2500LB BODY AND BONNET : ASTM A216 WCB

-

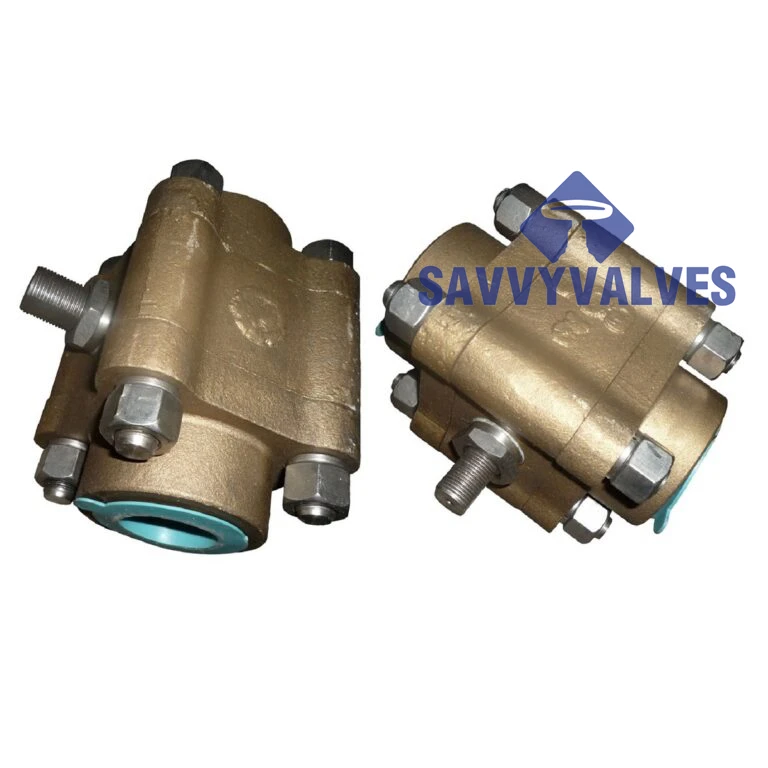

SAMPLE SPECIFICATIONS SIZE: 40″ RATING: 150LB

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Over the past decade, our company has actively participated in the bidding and valve supply for numerous major projects worldwide. These include the Municipal Water Supply System in the UK, the Irrigation System in Ecuador, the Pump Station in Venezuela, Crude Oil Transportation projects, the Seawater Desalination System in the UAE, and the Compressor System in Italy, among others. We have had the privilege of serving many renowned industry leaders such as ADNOC and PDVSA. Our valve products have consistently earned high praise from clients for their exceptional quality and reliable performance.