DIN Grilla Grills Wood Pellet Grill

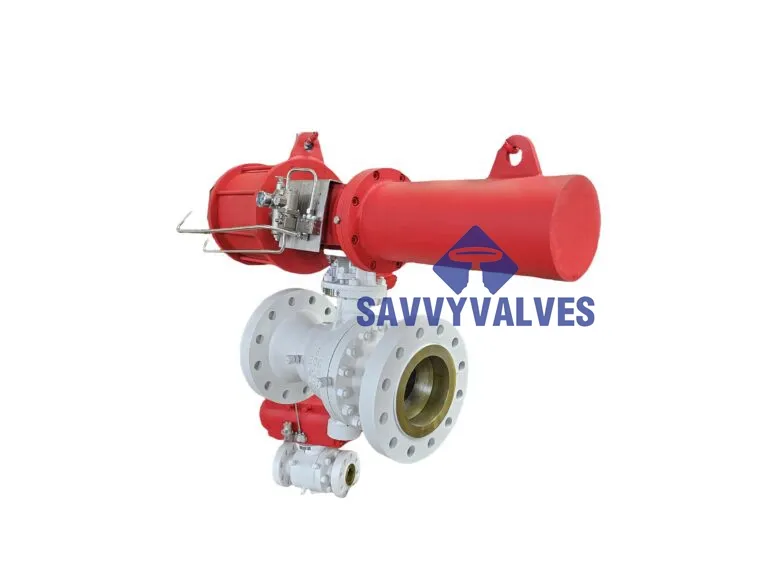

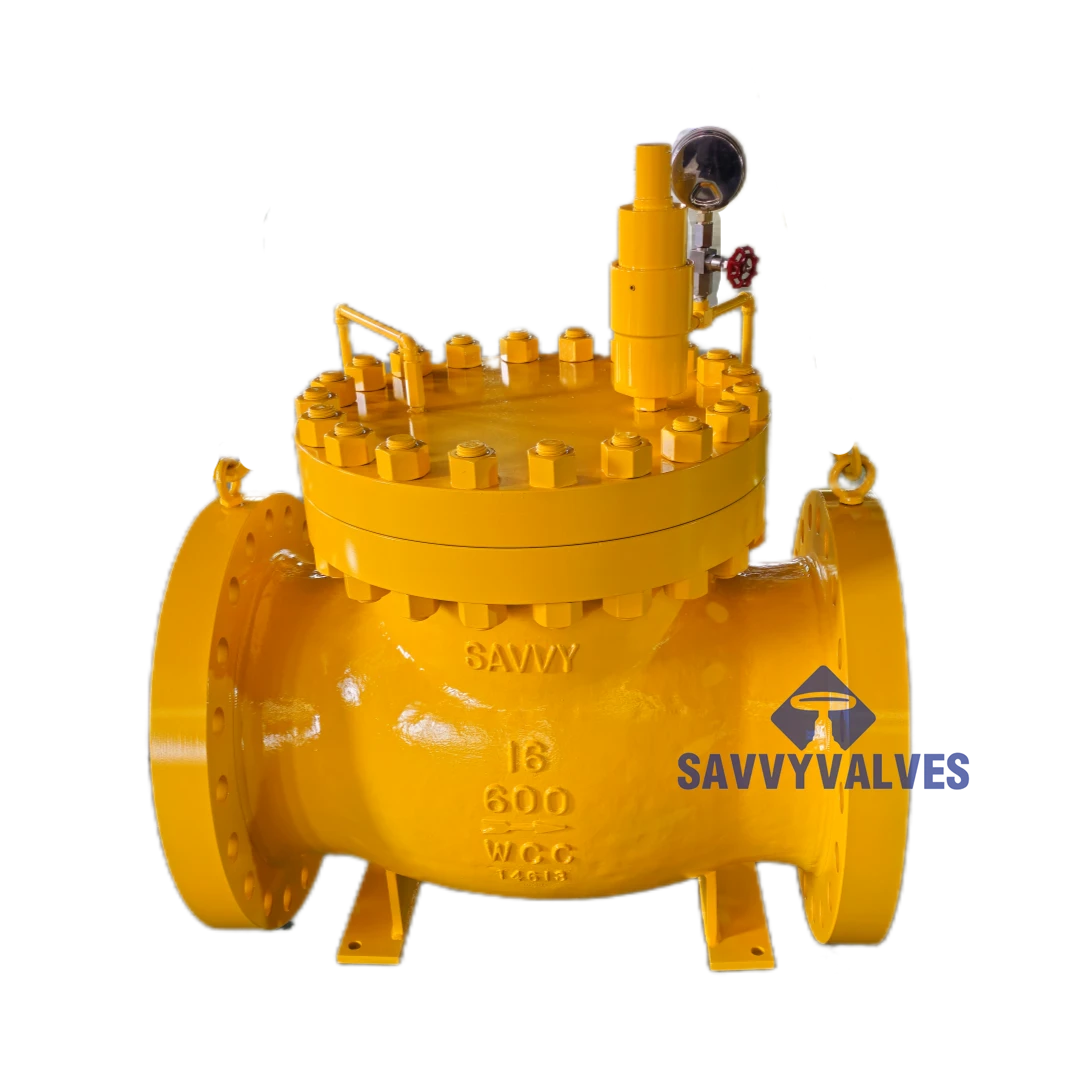

Size:8″ x 6″

Rating: 600LB

Materials: ASTM A216 WCB body and bonnet

ASTM A182 F316L trims

RPTFE seat

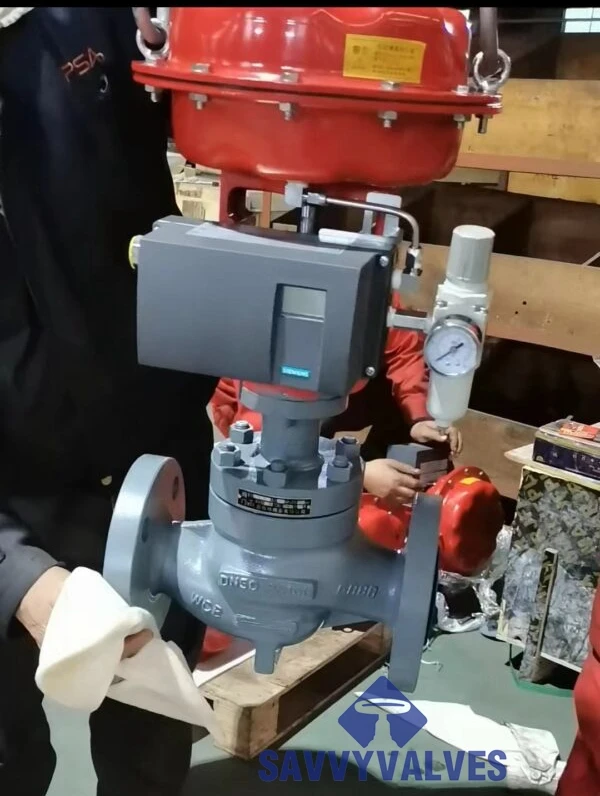

Operator: Single acting spring return pneumatic

ESD valve, type Trunnion Ball Valve

Savvy trunnion ball valves are offered in 2 PC side entry, 3 PC side entry, welded body and top entry design in a wide range of carbon, stainless steel, duplex stainless steel, alloy and other special materials.

Savvy trunnion ball valves are manufactured according to API 6D Design and fire safe tested per API 6FA and API 607 Standard.

PRODUCT RANGE

Sizes NPS 2 to NPS 60

API 6D Class 150 to Class 4500,

API 6A Class 3000 to Class 30000

DESIGN FEATURES

Full or Reduced Bore

RF, RTJ, BW or PE

Side entry, top entry, or welded body design

Double Block & Bleed (DBB),Double Isolation & Bleed (DIB)

Emergency seat and stem injection

Anti-Static Device

Anti-Blow out Stem

Cryogenic or High Temperature Extended Stem

MATERIALS

Available Forged (A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5,) Casting (A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2) Monel, Inconel, Hastelloy,Titanium alloy

DESIGN STANDARD

Design & manufacture according to API 6D, API 608, ISO 17292

Face-to-face according to API 6D, ASME B16.10

End Connection according to ASME B16.5, ASME B16.47, MSS SP-44 (NPS 22 Only)

Test & inspection according to API 6D, API 598

Fire safe design according to API 6FA, API 607

Also available per NACE MR-0175, NACE MR-0103, ISO 15848

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

The SAVVY 8″x6″ 600LB emergency shut-down ball valve is commonly used in critical safety systems across industries such as oil and gas, petrochemical, and offshore platforms. It is typically installed in key pipeline locations where immediate isolation of flow is essential during system failures, fire, or abnormal pressure spikes. When triggered—either manually or automatically through an emergency shutdown system—this valve rapidly cuts off fluid flow to protect personnel, equipment, and the environment. The 8"x6" size indicates a full-bore inlet with a reduced outlet, allowing controlled flow while ensuring shut-off capability under 600lb pressure conditions. Its fast-acting, quarter-turn ball design minimizes response time, making it ideal for emergency use. Operators benefit from its robust construction, minimal pressure drop, and low maintenance. For optimal reliability, it’s essential to test and maintain the valve regularly as part of the facility’s safety protocol.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.