DIN Grilla Grills Wood Pellet Grill

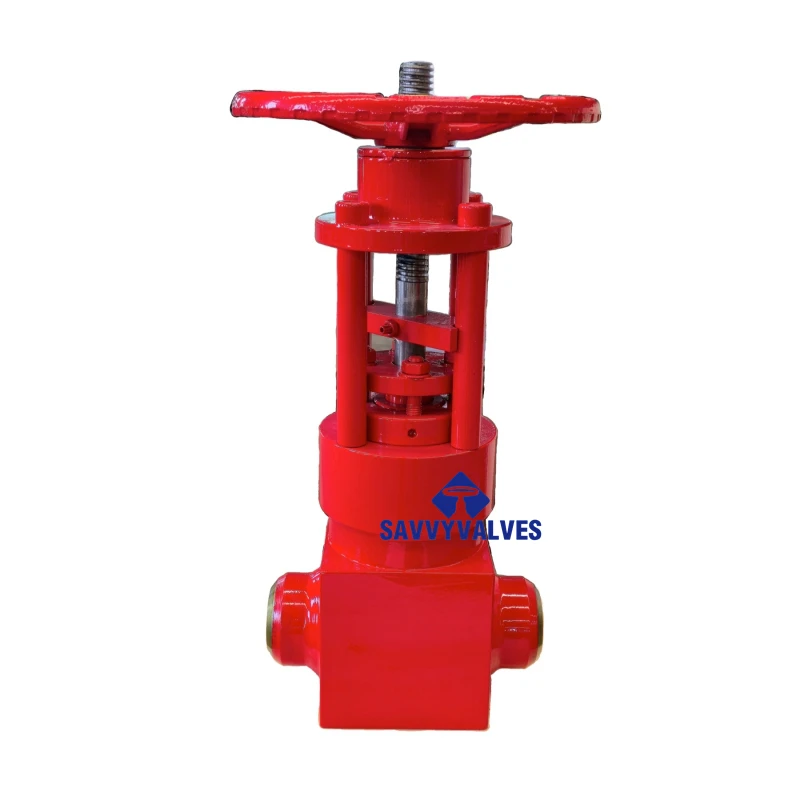

PHOTOS SHOWS SPECIFICATIONS AS BELOW

SIZE:DN200

RATING:PN420

BODY AND BONNET : ASTM A216 WCB

DISC: ASTM A182 F304+STELLITE 6, SOLID

STEM: ASTM A182 F6A

SEAT: ASTM A105+STELLITE 6

ACTUATION: WHEEL

GENERAL DESIGN SPECIFICATIONS

Size: 2″~60″

Pressure Rating: 150LB~4500LB, 6000PSI~30000 PSI

Design Temperature: API 6D, API 6A

General applications: water, oil , gas

Design & Manufacture: API 6A, API 6D are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, API 6A

Connection: API 6A, API 6D, API 6BX, ASME B16.5, B16.47

Structure : SLAB DISC, BB, FB.

TYPICAL MATERIAL LIST

BODY AND BONNET: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, AISI 4130 4140

DISC: ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718, AISI 4130 4140 +HARD FACED

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

SEAT:A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276+HARD FACED.

OPERATOR: WHEEL OR GEAR

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST AND INSPECTION

Inspection and approval norm: API598, API6D, API 6A

QUALITY CONTROL

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

A slab gate valve, also known as a flat gate valve, is designed with a single-piece gate that provides a solid barrier to fluid flow when closed. One of its main advantages is the full-bore, through-conduit design, which ensures minimal pressure drop and allows for pigging in pipeline applications. This makes it ideal for oil, gas, and petrochemical industries where maintaining flow efficiency and internal pipeline cleanliness is critical. The floating slab gate creates a tight seal against the seats, offering reliable shutoff even in high-pressure or high-temperature environments. Its simple structure and reduced number of internal moving parts contribute to long-term durability and low maintenance costs. Additionally, flat gate valves are less likely to be affected by debris buildup, ensuring smoother operation over time. These valves are particularly suitable for buried or remote installations where performance and longevity are essential.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.