DIN Grilla Grills Wood Pellet Grill

SAMPLE SPECIFICATIONS

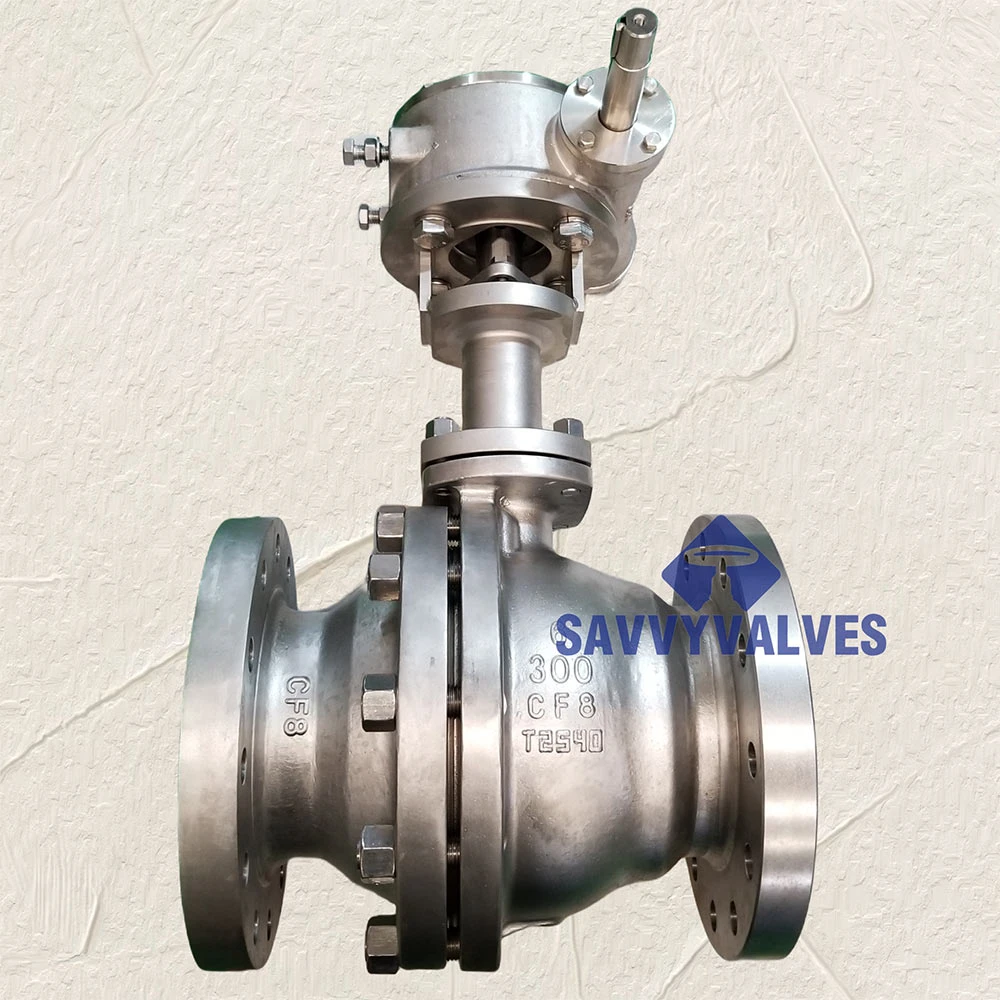

SIZE: DN20

RATING: PN420

END: BW AS PER B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

Size: 1/8″~24″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~800℃.

General applications: CNG, LNG,LPG, CO2, N2, other cryogenic duty.STEAM thermal duty.

DESIGN

Design & Manufacture: BS 6364, API 6D , ASME B16.34 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, ASME B16.10, BS EN 558

Connection: ASME B16.25, ASME B16.5, ASME B16.47, EN 1092, JIS 5K-20K. BW, RTJ are available.

Safety design: fire proof

GENERAL MATERIAL

BODY: ASTM A182 F304/F316/F304L/F316L/F51/F53, MONEL K400/K500, H276,INCONEL 625/718

PLUG: ASTM A182 F304, F316

SEAT: PCTFE, PEEK, HF METAL

OPERATOR: SPRING LOADED

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D, BS6364.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

The SAVVY CNG LNG Cryogenic Piston Lifting Check Valve Free Forged is specifically designed for ultra-low temperature applications involving cryogenic gases such as liquefied natural gas (LNG) and compressed natural gas (CNG). This valve uses a piston-type lifting mechanism to ensure reliable backflow prevention while maintaining smooth, controlled operation in cryogenic conditions. The free forged body enhances mechanical strength and integrity, reducing the risk of material failure under thermal stress. Engineered to perform at temperatures as low as -196°C, it features extended bonnets and cryogenic-compatible sealing materials to maintain leak-tight performance. The compact yet durable design minimizes pressure drop and ensures fast response to flow changes, which is critical in LNG and CNG processing, transport, and storage systems. SAVVY’s focus on precision and material quality makes this valve an ideal choice for industries requiring high safety, reliability, and efficiency under extreme cold.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.