DIN Grilla Grills Wood Pellet Grill

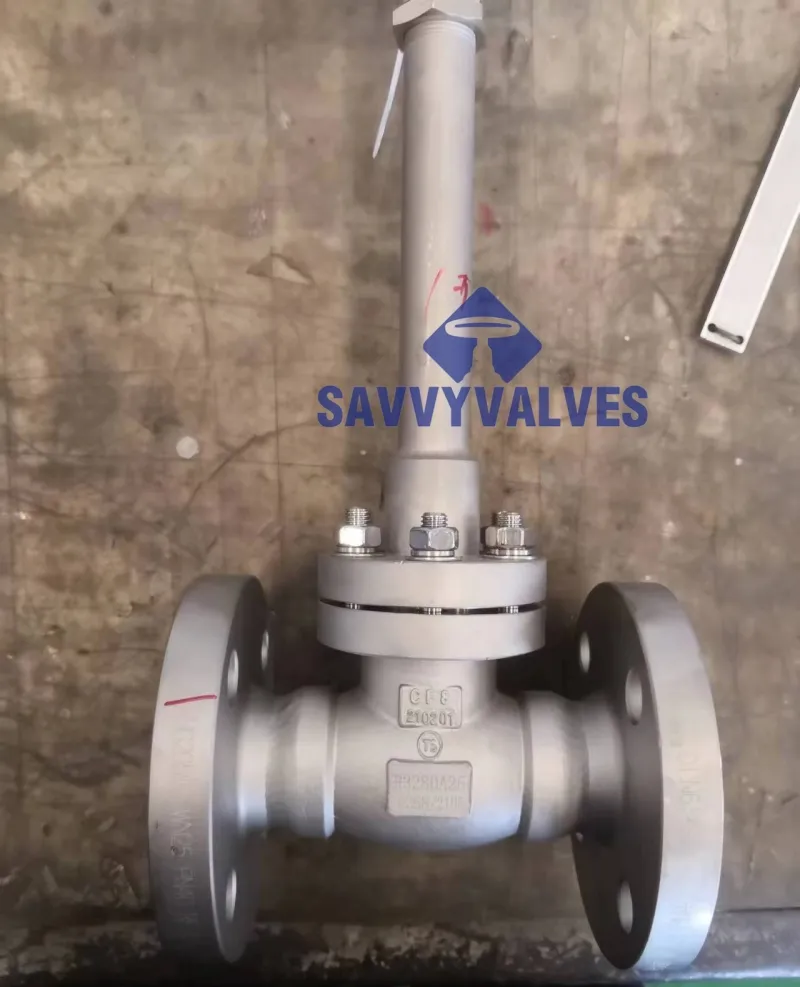

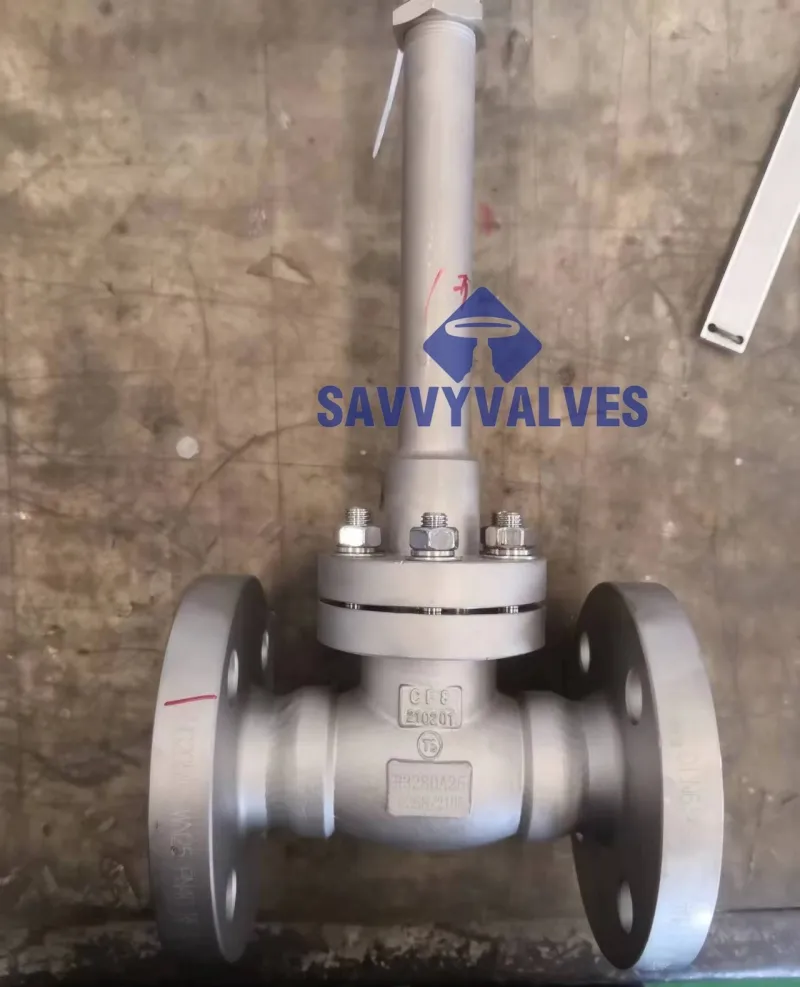

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE: 3″

RATING: 300LB

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

GENERAL

Size: 1/8″~36″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~800℃.

General applications: CNG, LNG,LPG, CO2, N2, other cryogenic duty.STEAM thermal duty.

Design & Manufacture: BS 6364, API 6D , ASME B16.34, API 602 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, ASME B16.10, BS EN 558

Connection: ASME B16.11, ASME B16.25, ASME B16.5, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: fire proof GENERAL MATERIAL

182 F304

BODY: ASTM A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, MONEL K400/K500, H276,INCONEL 625/718

PLUG: ASTM A182 F304, F316

SEAT: PCTFE, PEEK, HF METAL

OPERATOR: SPRING LOADED

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D, BS6364.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The CNG LNG LPG cryogenic globe valve is designed specifically for controlling the flow of liquefied gases at cryogenic temperatures, often reaching as low as -196°C. Its extended bonnet structure plays a vital role by distancing the stem packing from direct contact with cold media, effectively preventing frosting and seal degradation. The globe valve design offers excellent flow control and reliable shut-off, making it ideal for regulating sensitive cryogenic fluids in pipelines and storage systems. Built from materials selected for their low-temperature toughness, the valve maintains strength and sealing performance under extreme thermal stress. Commonly used in LNG terminals, CNG refueling stations, and LPG processing units, this valve ensures safety, accuracy, and operational reliability. Its compact and durable construction supports both manual and automated operation, making it an essential component in modern cryogenic gas handling systems.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.