DIN Grilla Grills Wood Pellet Grill

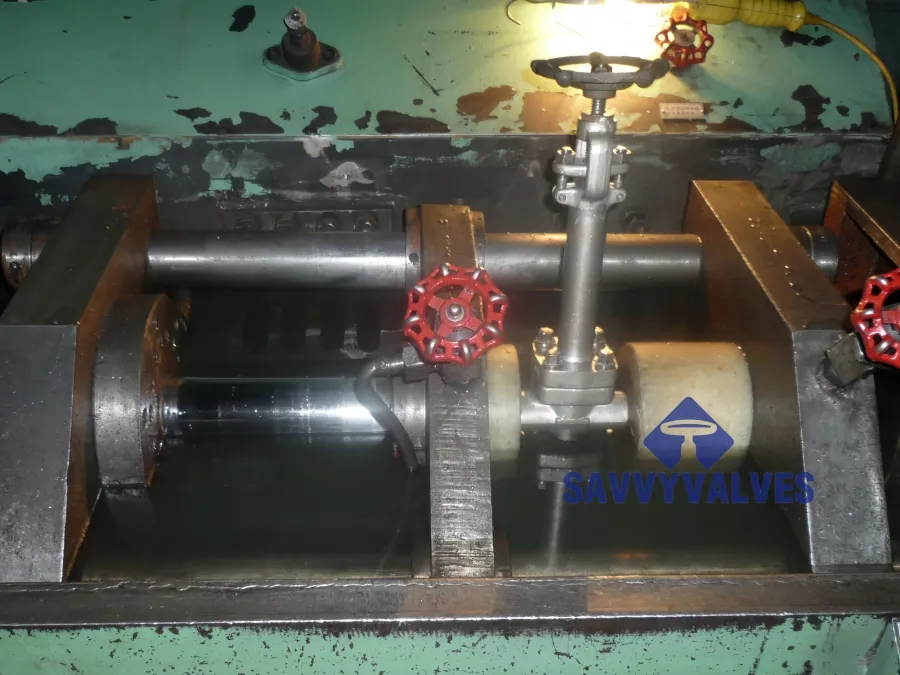

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE: 1″

RATING: 800LB

END: SW AS PER ASME B16.11

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

GENERAL

Size: 1/8″~4″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~800℃.

General applications: CNG, LNG,LPG, CO2, N2, other cryogenic duty.STEAM thermal duty.

Design & Manufacture: BS 6364, API 6D , ASME B16.34, API 602 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, ASME B16.10, BS EN 558

Connection: ASME B16.11, ASME B16.25, ASME B16.5, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: fire proof

GENERAL MATERIAL

BODY: ASTM A182 F304/F316/F304L/F316L/F51/F53, MONEL K400/K500, H276,INCONEL 625/718

PLUG: ASTM A182 F304, F316

SEAT: PCTFE, PEEK, HF METAL

OPERATOR: SPRING LOADED

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D, BS6364.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The CNG LNG LPG pattern forged cryogenic gate valve is specifically engineered for ultra-low temperature applications, where secure shut-off and reliable operation are critical. Designed for use in systems handling liquefied gases like CNG, LNG, and LPG, this valve features a forged body that ensures superior strength, uniform grain structure, and excellent resistance to thermal shock. The cryogenic extension bonnet keeps stem packing away from direct exposure to cold media, reducing the risk of frosting and leakage. Its full bore gate design offers minimal flow resistance and ensures unobstructed fluid passage, which is essential in high-capacity cryogenic transfer lines. The valve’s materials and design are compliant with international cryogenic standards to guarantee safety and durability under extreme conditions. With tight shut-off capability, long service life, and suitability for both manual and automated actuation, it’s an ideal choice for LNG terminals, gas processing plants, and cryogenic storage systems.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.