-

1.Material Production Monitoring

All raw materials are manufactured under strict ladle analysis supervision at certified foundries.

2.Incoming Material Verification

Upon arrival at our facility, all materials undergo precise compositional analysis using advanced spectroanalysis equipment.

-

Key quality controls:

Real-time molten metal monitoring during casting

Full chemical composition verification

Traceability maintained throughout production chain

Compliance with ASTM material specifications

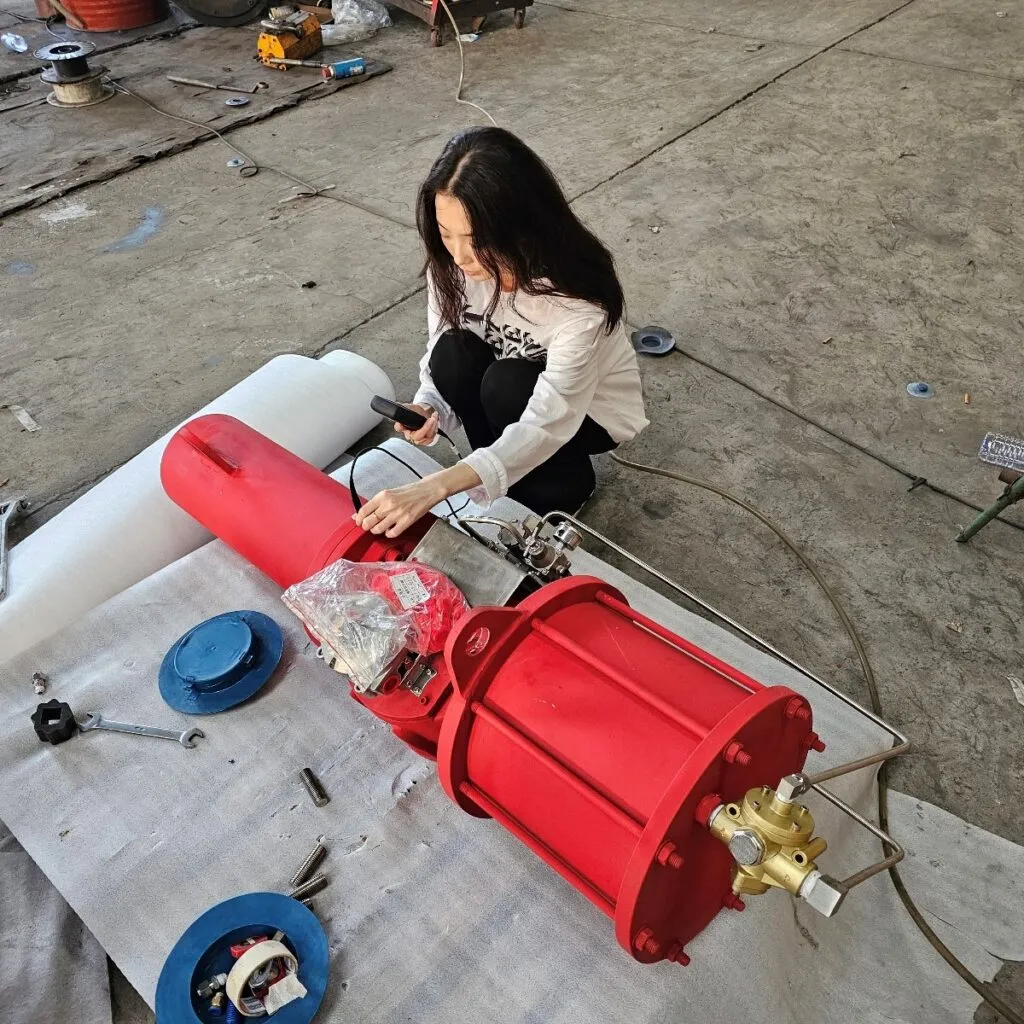

Cryogenic Treatment System (-196°C)

A standard conditioning process essential for LNG service valves and comparable cryogenic applications.

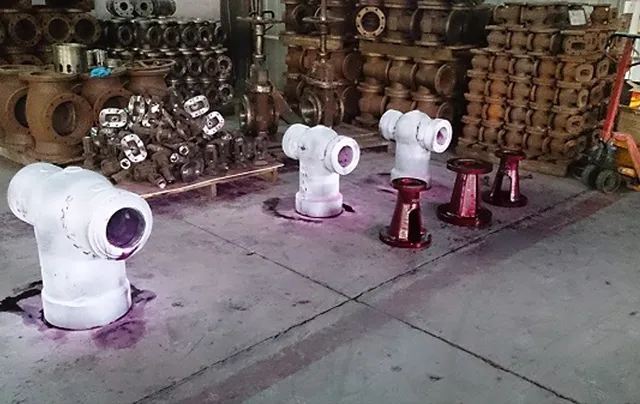

Film thickness inspection on each layer guarantees the good protection on the valves, a good paint provides longer service life of the valves.

Our 1200°C electric furnace facilitates multiple heat treatment cycles.

Hydraulic leakage test

All mechanical properties test will act before we use the materials to secure the performance and safety.

Quality Assurance through Non-Destructive Testing

-

1.Radiographic Inspection

Provides definitive verification of internal soundness in cast and forged components, ensuring complete freedom from subsurface discontinuities.

2.Ultrasonic Examination

Serves as a reliable alternative inspection methodology for comprehensive internal assessment.

3.Surface Inspection Methods

Liquid Penetrant Testing: Effectively reveals surface-breaking defects

Magnetic Particle Inspection: Specifically detects surface and near-surface flaws in ferromagnetic materials

-

All methods deliver:

Compliance with international quality standards

Comprehensive defect detection capabilities

Validated inspection reliability