DIN Grilla Grills Wood Pellet Grill

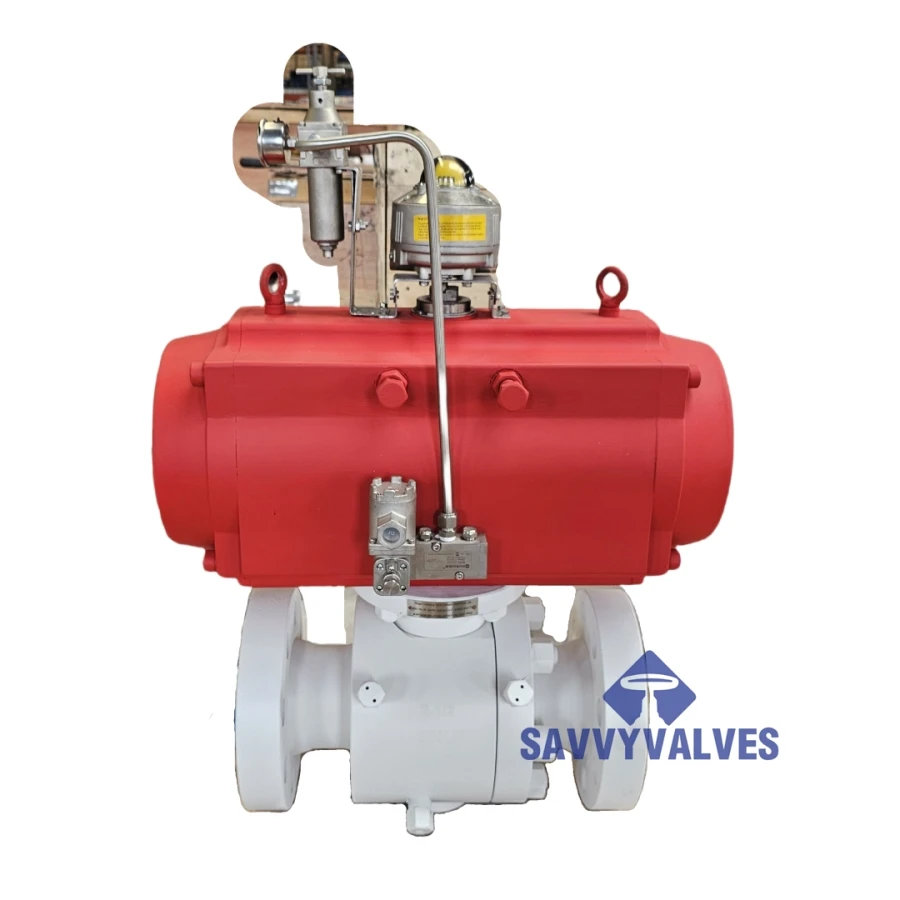

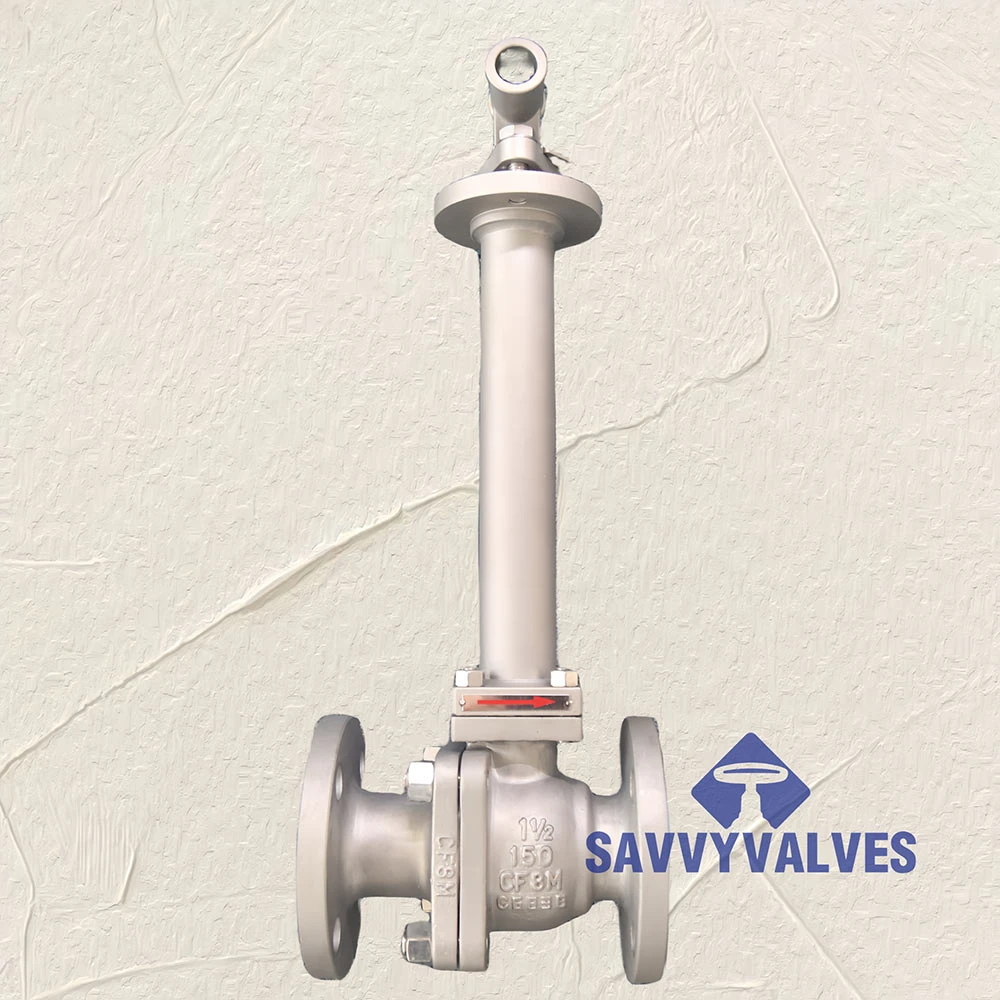

Valve Type Trunnion Mounted Ball Valve (API 6D Design)

Mechanical Anchor Dual Trunnion Support (Upper/Lower Fixed Shafts)

Body Construction 2-Piece Bolted Body (ASME B16.34), Side Entry

Bore Type Full Port (100% Pipe ID, Cv=3920 per ISA 75.01)

Pressure Rating ASME Class 150 (PN 25) @ 120°C Max

Pressure-Temp Rating Per ASME B16.34 Curve D

|

Category |

Parameter |

Specification |

|

Valve Design |

Valve Type |

Trunnion Mounted Ball Valve (API 6D Design) |

|

Mechanical Anchor |

Dual Trunnion Support (Upper/Lower Fixed Shafts) |

|

|

Body Construction |

2-Piece Bolted Body (ASME B16.34), Side Entry |

|

|

Flow Capacity |

Bore Type |

Full Port (100% Pipe ID, Cv=3920 per ISA 75.01) |

|

Size & Pressure |

Nominal Size |

8" (DN 200) |

|

Pressure Rating |

ASME Class 150 (PN 25) @ 120°C Max |

|

|

Pressure-Temp Rating |

Per ASME B16.34 Curve D |

|

|

Connection |

Flange |

ASME B16.5 Class 150 RF (Raised Face) |

|

Face-to-Face |

584 mm per ASME B16.10 |

|

|

Actuation |

Operation |

Manual Handwheel (ISO 5211 F05 Pad) |

|

Max Stem Torque |

650 Nm (Pre-lubricated Stem Bushing) |

|

|

Materials |

Body |

ASTM A216 WCB (Internally Epoxy Coated) |

|

Ball |

ASTM A351 CF8M (F316L SS), Mirror Polished (Ra≤0.4μm) |

|

|

Trunnion Shafts |

ASTM A182 F316 SS, Hardened to 35 HRC |

|

|

Stem |

ASTM A182 F316 SS w/ Integral Anti-Static Spring |

|

|

Seat |

F316 + Glass-Filled RPTFE (Fire-Safe Dual Seal) |

|

|

Sealing |

Seat Leakage |

ANSI/FCI 70-2 Class VI |

|

Stem Seal |

Graphite Packing (ISO 15848-1 Class B Compliant) |

|

|

Safety |

Fire Safe |

API 607 / ISO 10497 Certified (Metal-to-Metal Secondary Seal) |

|

Anti-Static |

EN 13480-3 (Resistance ≤5Ω) |

|

|

Stem Security |

Anti-Blowout Stem per API 6D Sec.6.1.5 |

|

|

Temperature |

Seat Limit |

-29°C to +120°C (RPTFE Primary Seal) |

|

Fire Safe Temp |

+425°C (Metal Secondary Seal) |

|

|

Testing |

Hydro Test |

Shell: 31.5 bar / Seat: 16.5 bar per API 598 |

|

Fire Test |

Post-fire Seat Leakage ≤ API 607 Limit (600 ml/min) |

GUATANTEE

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.