DIN Grilla Grills Wood Pellet Grill

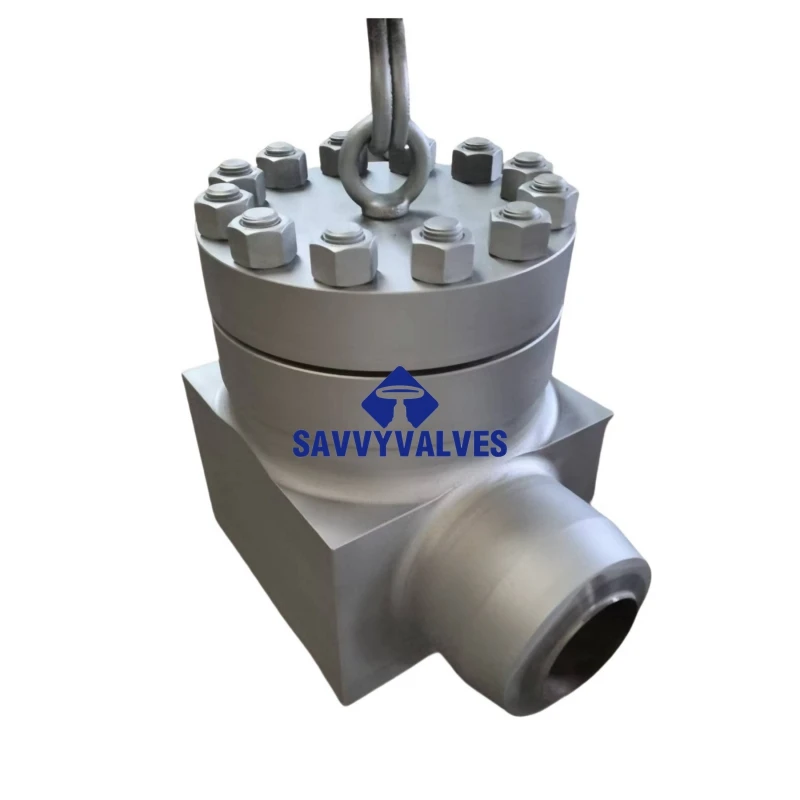

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:1″

RATING:150LB

BODY AND BONNET : ASTM A105

DISC: ASTM A105+STELLITE 6

SPRING: INCONEL X-750

SEAT: ASTM A105+STELLITE 6

LIFT/PISTON TYPE

Size: 1/8″~4″.

Pressure Rating: 150LB~4500LB

Design Temperature: -196℃~800℃.

General applications: water, oil , gas

Design & Manufacture: API 594, API 6D, ASME B16.34,API 602 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, API 594, ASME B16.10, BS EN 558

Connection: RF AS PER ASME B16.5,ASME B16.47, EN 1092, JIS 5K-20K. BW, RTJ are available.

Structure : PISTON DISC LIFT DISC, SPRING LOADED, BOLTED BONNET PRESSURE SEAL BONNET WELDED BONNET, FULL PORT OR REDUCE PORT

TYPICAL MATERIALS

BODY AND BONNET: ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718.

DISC: ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718 + HARD FACED

SPRING: INCONEL X-750

SEAT:ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718+HARD FACED.

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The API 602 Pattern Forged Lifting Check Valve is designed for high-pressure, high-temperature applications in compact piping systems, particularly in industries like oil and gas, power generation, and chemical processing. Built to conform with API 602 standards, this valve features a compact, forged body for enhanced strength and durability in critical service conditions. The lifting check mechanism allows the disc to rise with forward flow and automatically seat with reverse flow, preventing backflow and protecting pumps and equipment. Its forged construction ensures better grain structure and resistance to stress corrosion, while the tight sealing performance minimizes leakage and pressure drop. Typically available in a variety of materials and end connections, this valve is suited for use in small-bore piping with severe operating conditions. The API 602 pattern emphasizes reliability, space efficiency, and long-term performance, making it a trusted choice for engineers and plant operators requiring robust flow control in demanding environments.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.