-

What industries are your valve products mainly used in?

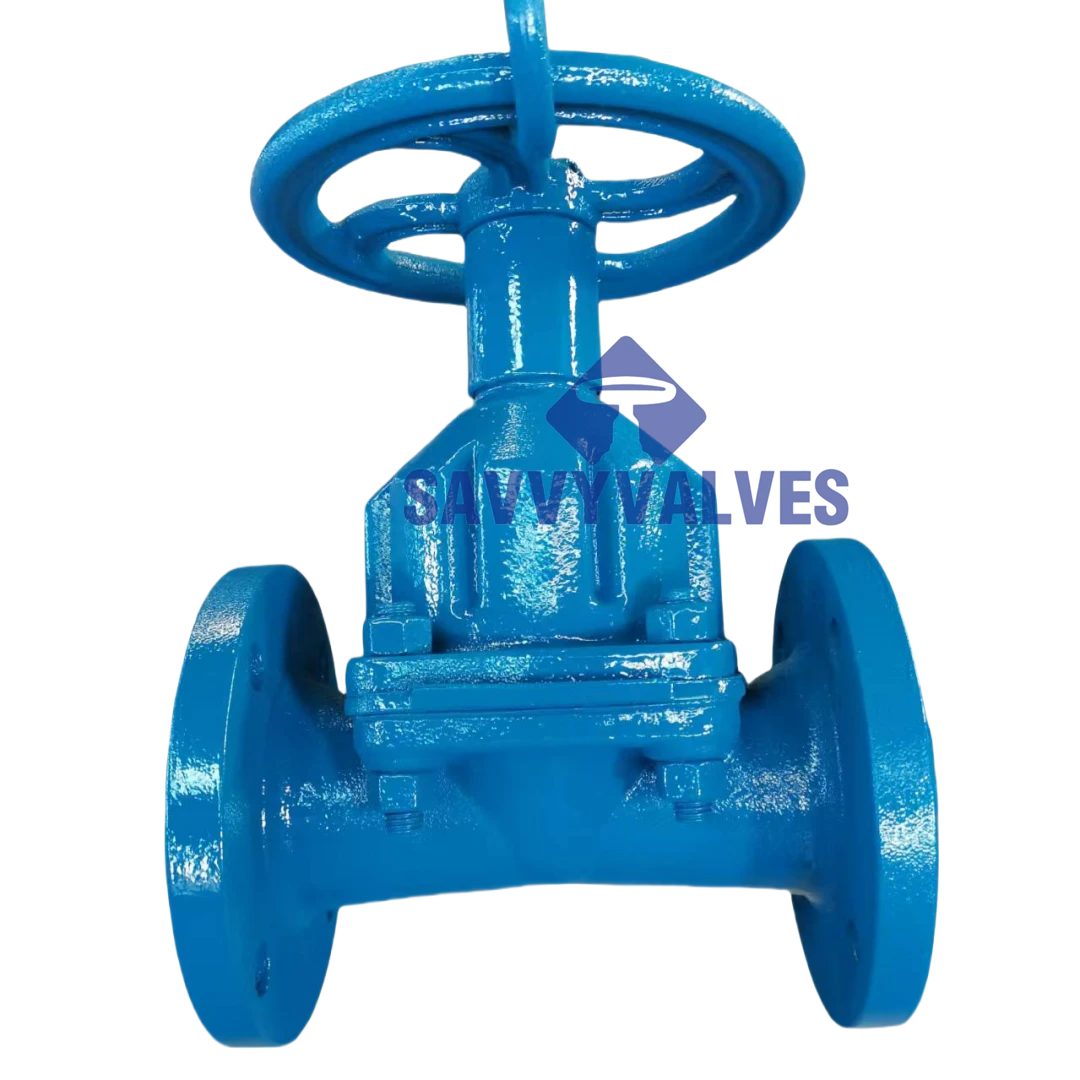

Our industrial valves are widely applied in:

- Oil & Gas: Crude oil and natural gas pipeline control

- Power Generation: Boiler systems, steam networks

- Water Treatment: Municipal water supply, wastewater plants

- Special Industries: Pharmaceuticals (GMP-standard), food & beverage (sanitary valves) -

Do you offer custom valves? What’s the lead time?

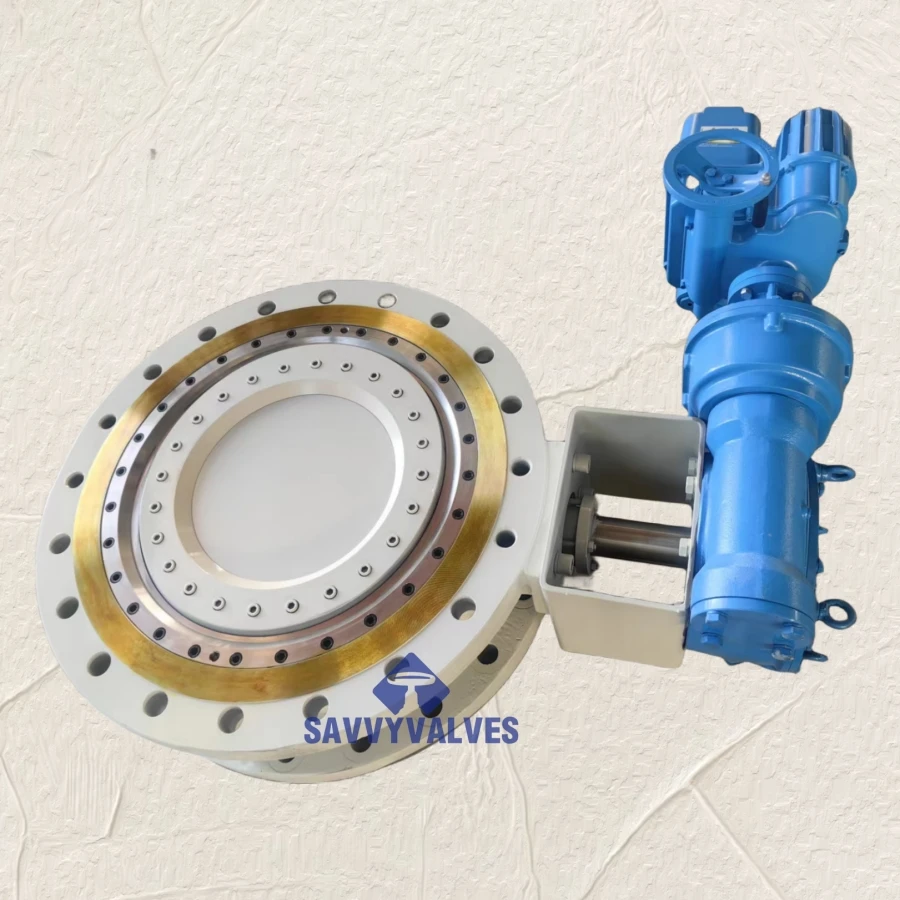

- Customization: Size (DN15-DN2000), pressure rating (PN10-PN420), actuation (manual/electric/pneumatic/hydraulic)

- Delivery Time:

- Standard valves: 15-30 days

- Custom valves: 4-8 weeks -

How do you ensure valve sealing performance and durability?

Triple quality assurance:

1. Testing: 100% API 598 seat/ shell tests

2. Sealing Tech: Soft seals (PTFE), metal hard seals (STL alloy overlay)

3. Warranty: Standard 12 months, extendable for special applications -

What if post-sale issues occur? Do you provide installation guidance?

Our service commitment:

- 48-hour response: Remote troubleshooting or on-site support

- Lifetime maintenance: Inventory of stems, seals, and wear parts(Free spare parts during warranty; fees apply after warranty.) -

Are your valves compliant with international standards (API, ANSI, ISO)?

Full certifications:

- API 6D: Petroleum gate valves

- ISO 15848: Low-emission certification

- CE/PED: EU market compliance -

Can valves operate in cryogenic (e.g., LNG) or ultra-high-temperature (>500°C) conditions?

Extreme-service solutions:

- Cryogenic Valves: -196°C deep-treated, explosion-proof design

- High-Temp Valves: Heat-dissipation fins, Cr-Mo steel body