Control Valves

-

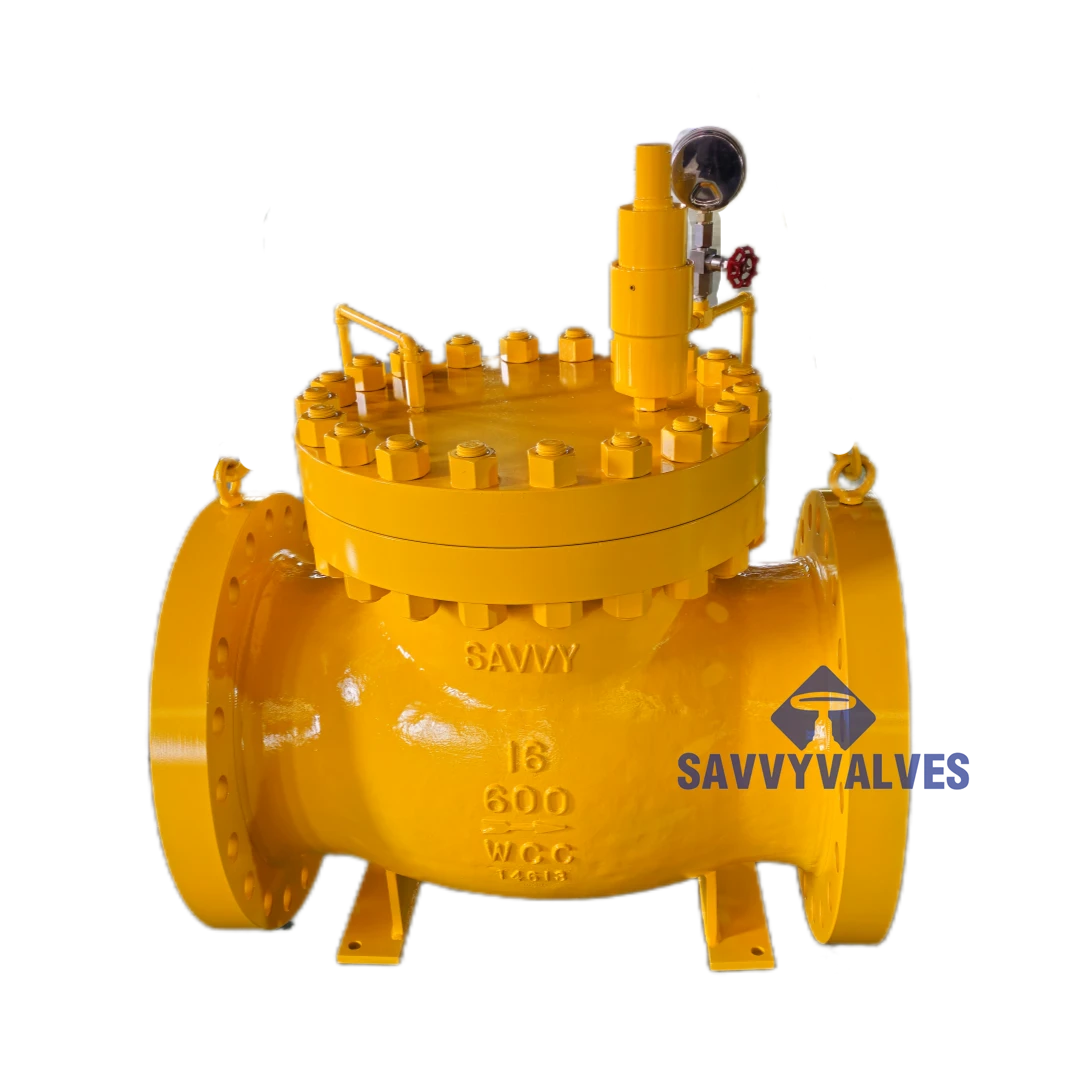

Brief: regulating downstream flow pressure to the set point pressure. Balanced piston trims design.

Size:16″

Rating: 600LB

Materials: ASTM A216 WCC body and cover

ASTM A182 F316 trims

RPTFE seat

Operator: Pilot Self-controlled

-

SAMPLE SPECIFICATIONS

SIZE:24″

RATING:600LB

BODY AND BONNET : ASTM A216 WCC

PLUG: ASTM A182 F316 +STELLITE 6

STEM: ASTM A182 F6A

CAGE: ASTM A276 416

SEAT: ASTM A105+STELLITE 6

ACTUATION: ELECTRIC HYDRAULIC ACTUATOR

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:42″br> RATING:600LBbr> BODY AND BONNET : ASTM A216 WCBbr> DISC: ASTM A216 WCB+STELLITE 6, FLEXIBLE WEDGE, FULL PORTbr> STEM: ASTM A182 F6Abr> SEAT: ASTM A105+STELLITE 6br> ACTUATION: LIMITORQUE SMC-5 480V AC, 3PH, 60HZ, WITH MANUAL OVERIDE.br> -

Size:8″ x 6″

Rating: 600LB

Materials: ASTM A216 WCB body and bonnet

ASTM A182 F316L trims

RPTFE seat

Operator: Single acting spring return pneumatic

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:20″*16″

RATING:300LB 600LB

BODY AND BONNET : ASTM A216 WCB

DISC: ASTM A216 WCB+STELLITE 6, FLEXIBLE WEDGE

STEM: ASTM A182 F6A

SEAT: ASTM A105+STELLITE 6

ACTUATION: LIMITORQUE INTELLIGENT MODULATING TYPE , 4-20mA signal,480V AC, 3PH, 60HZ, WITH MANUAL OVERIDE.

-

SAMPLE SPECIFICATIONS

SIZE:8″

RATING:300LB

BODY AND BONNET : ASTM A350 LF2

V-NOTCH BALL: ASTM A182 F316+TCC 90℃ NOTCH.

STEM: ASTM A564 17-4PH

SEAT: ASTM A182 F316+TCC

SPRING: INCONEL X-750

ACTUATION: ELECTRIC HYDRAULIC ACTUATOR

-

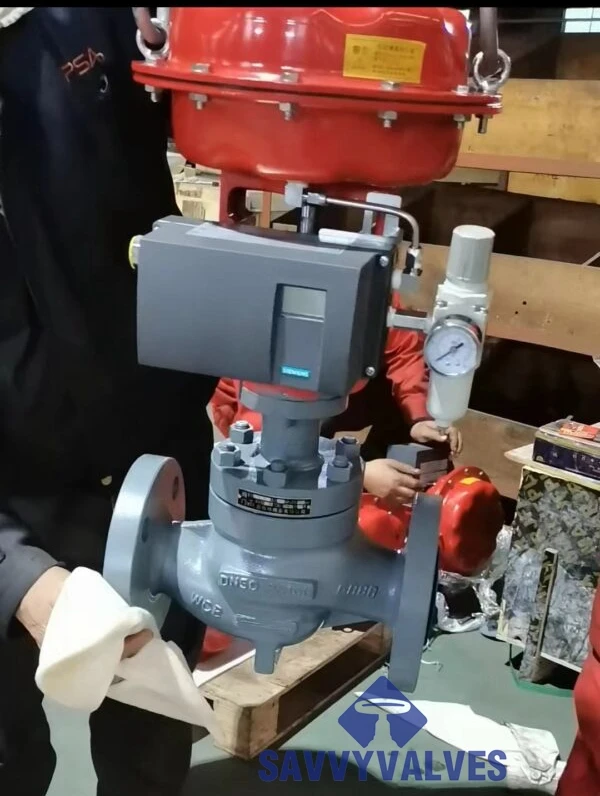

SAMPLE SPECIFICATIONS

SIZE:2″

RATING:600LB

BODY AND BONNET : ASTM A216 WCC

PLUG: ASTM A182 F316 +STELLITE 6

STEM: ASTM A182 F6A

CAGE: ASTM A276 416

SEAT: ASTM A105+STELLITE 6

ACTUATION: DIAPHRAGM PNEUMATIC ACTUATED

-

PHOTOS SHOW SPECIFICATIONS AS BELOW

SIZE:3″

RATING: 10000PSIG

BODY AND BONNET : TC YG6

PLUG: TC YG20

STEM: INCONEL 625

CAGE: INCONEL 625

SEAT: YG 6

ACTUATION: ELECTRIC ACTUATOR

-

Brief:

Size:3″

Rating:2500LB

Materials:

ASTM A182 F11 body and bonnet

ASTM A182 F11+stellite 6 Disc

ASTM A182 F6A stem

Stellite 6 overlay body seat

Operator: handwheel

Ends: BW as per ANSI B16.25

A control valve is a critical component in fluid handling systems, used to regulate the flow rate, pressure, temperature, or level of a fluid by varying the size of the flow passage. It operates by receiving signals from a controller, which determines how much the valve should open or close based on input from process sensors. The valve includes an actuator (pneumatic, electric, or hydraulic) that moves the valve stem or plug in response to control signals. This modulation of valve position allows for precise adjustments of fluid parameters within a system. Control valves are essential in automated process control, helping maintain desired operating conditions in industries such as oil and gas, power generation, water treatment, and chemical manufacturing. Depending on the design, they may operate linearly or rotationally and can be equipped with positioners to ensure accurate alignment with control signals. Their flexibility and precision make them indispensable for safe, efficient, and responsive control of complex processes.