DIN Grilla Grills Wood Pellet Grill

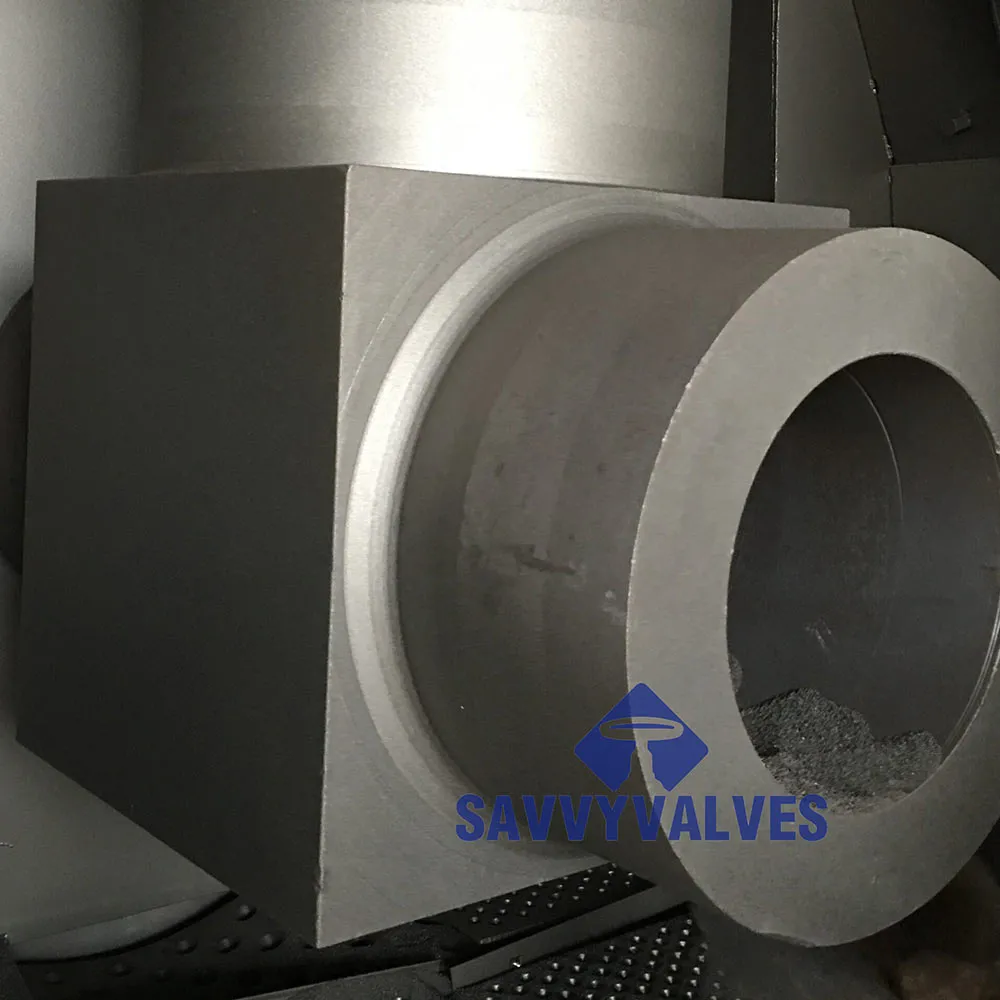

PHOTOS SHOWS SPECIFICATIONS AS BELOW

SIZE: 16″

RATING: 1500LB

BODY: ASTM A182 F91

DISC: ASTM A182 F91

SPRING: INCONEL X-750

STEM: ASTM A182 F91

SEAT: ASTM A182 F91 REPLACEABLE.

ACTUATION: GEAR UNIT

Size: 2″~60″

Pressure Rating: 150LB~4500LB, 6000PSI~30000PSI

Design Temperature: 425℃~1100℃

General applications: STEAM THERMAL DUTY

Design & Manufacture: API 600, ASME B16.34 are basic, other norms could be used according to orders.

F TO F dimensions: API 600, ASME B16.10,BS EN 558

Connection: ASME B16.25,ASME B16.5 B16.47, EN 1092, JIS 5K-20K. RF, RTJ are available.

Structure: Parallel dual discs.

TYPICAL MATERIALS LIST

BODY: ASTM A217 WC6, ASTM A217 WC9 , ASTM A217 C5, ASTM A182 F91

DISC: ASTM A217 WC6, ASTM A217 WC9 , ASTM A217 C5, ASTM A182 F91

EXTENDED YOKE: ASTM A217 WC6, ASTM A217 WC9 , ASTM A217 C5, ASTM A182 F91

STEM: 13CR,XM-19, 17-4PH, INCONEL 718, MONEL K-500

SEAT: STELLITE NO.6 HF

OPERATOR: GEAR UNIT

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST AND INSPECTION

Inspection and approval norm: API598, API6D.

QUALITY CONTROL

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The 16″ 1500LB F91 parallel disc gate valve is specifically engineered for thermal duty applications where high temperature and pressure demand superior material strength and sealing performance. Constructed from F91 alloy steel, the valve offers excellent creep resistance and thermal stability, making it suitable for power plants, refineries, and high-temperature steam systems. Its parallel disc design ensures a reliable seal through line pressure, reducing seat wear and enhancing longevity under cyclic thermal stress. This design also minimizes the risk of thermal binding, which is critical during frequent temperature fluctuations. The full-bore passage reduces flow resistance, while manual operation ensures precise control even in demanding conditions. Thanks to its robust construction and heat-resistant capabilities, this valve delivers safe, efficient, and long-lasting performance in challenging thermal service environments.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.