DIN Grilla Grills Wood Pellet Grill

SAMPLE SPECIFICATIONS

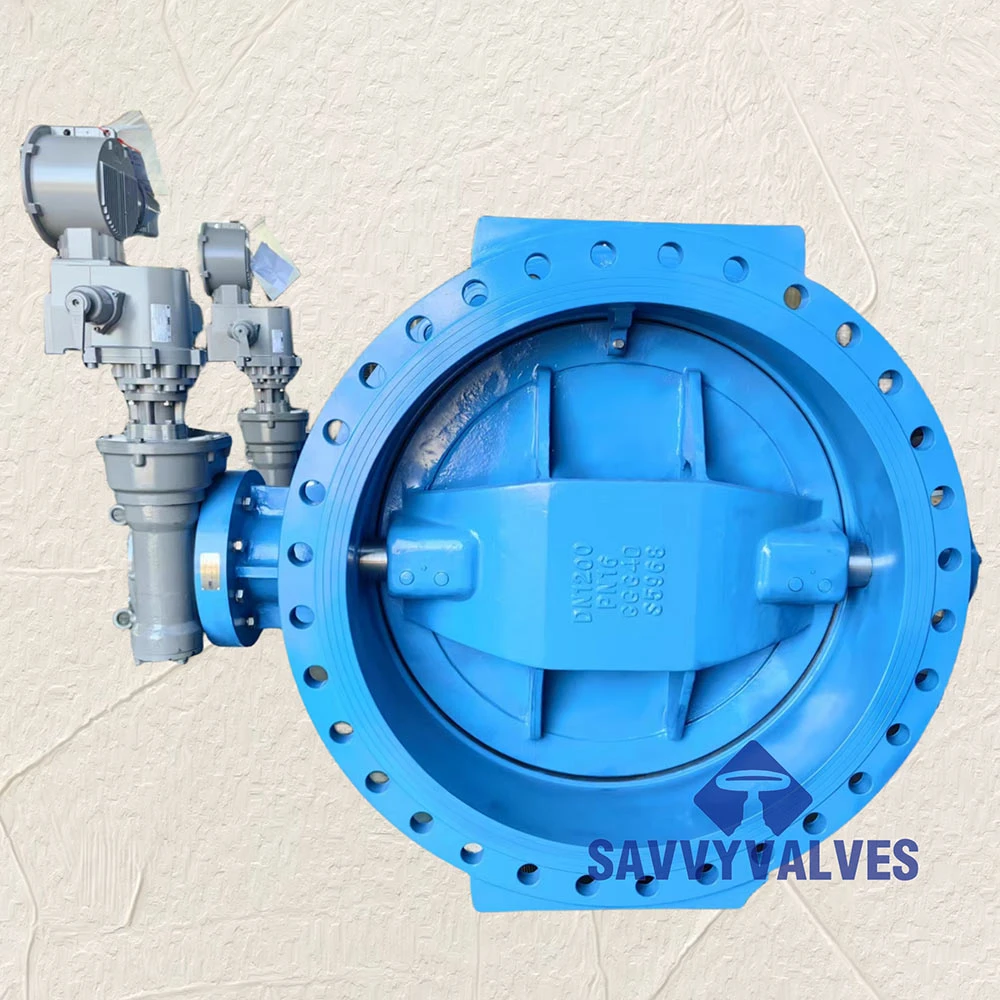

SIZE: 48″

RATING: PN16

BODY: ASTM A536 DUCTILE IRON WITH NYLON SPRAY INTERNAL

DISC: ASTM A536 DUCTILE IRON WITH NYLON SPRAY EXTERNAL

STEM: SS416

SEAT: SS HARD FACED

SEAL: EPDM

ACTUATION: GEAR UNIT

Size: 4″ and above.

Pressure Rating: 150LB,PN6,PN10,PN16,PN20,JIS 5K, 10K, 20K.

General applications: Water. Oil. Gas.

DESIGN

Design & Manufacture: API 609 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.5, EN 1092, JIS 5K-20K. BW, RTJ are available.

Safety design: anti-blow out stem.

GENERAL MATERIAL

BODY: ASTM A536 DUCTILE IRON NYLON SPRAY INTERNAL

DISC: ASTM A536 DUCTILE IRON NYLON SPRAY EXTERNAL

STEM: 13CR,SS304, SS316, DSS F51, F53,F55, XM-19, 17-4PH, INCONEL 718, MONEL K-500

SEAT: SS HARD FACED

SEAL: EPDM, NBR, VITON

OPERATOR: GEAR UNIT

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The nylon sprayed double offset butterfly valve is specifically designed to deliver enhanced performance in corrosive or abrasive environments. The double offset structure ensures that the disc moves away from the seat during operation, minimizing friction and wear, which extends the valve’s lifespan and ensures a tight seal. The nylon spray coating adds an additional layer of protection against corrosion, chemical attack, and mechanical damage, making the valve suitable for industries such as water treatment, chemical processing, and marine applications. This coating also provides a smoother surface finish, which reduces fluid resistance and helps maintain flow efficiency. The combination of durable construction, improved sealing performance, and protective coating makes this valve a low-maintenance, high-reliability solution for demanding fluid control tasks.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.