DIN Grilla Grills Wood Pellet Grill

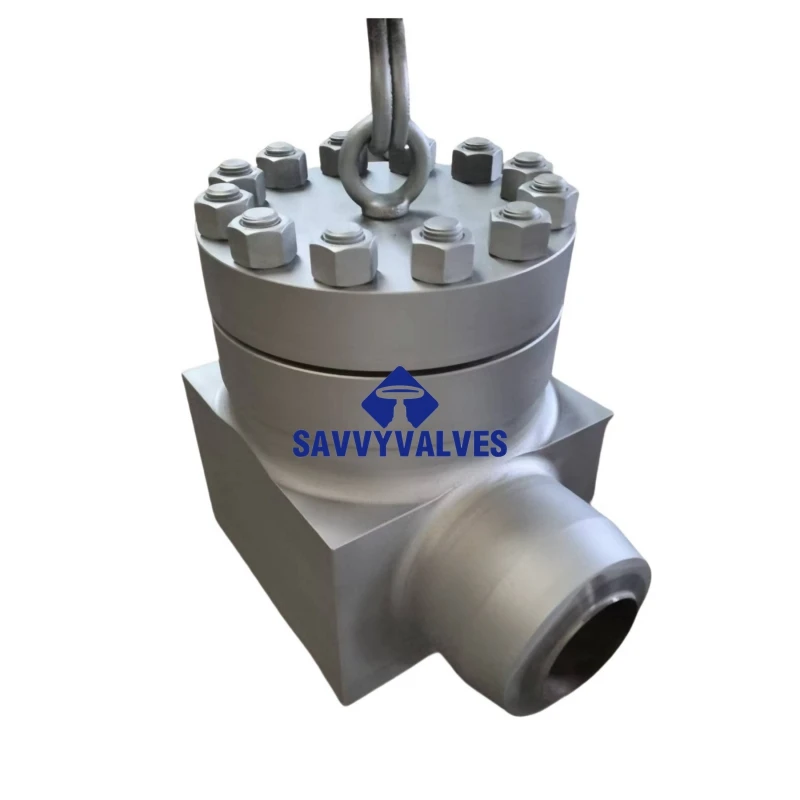

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE:30″

RATING:600LB

BODY AND BONNET : ASTM A216 WCB

DISC: ASTM A216 WCB+STELLITE 6

SHAFT: ASTM A182 F6A

SEAT: ASTM A105+STELLITE 6

Size: 2″~48″.

Pressure Rating: 150LB~4500LB

Design Temperature: -196℃~800℃.

General applications: water, oil , gas

Design & Manufacture: API 594, API 6D, ASME B16.34 are basic,other norms could be used according to orders.

F TO F dimensions: API 6D, API 594, ASME B16.10, BS EN 558

Connection: RF AS PER ASME B16.5,ASME B16.47, EN 1092, JIS 5K-20K. BW, RTJ are available.

Structure : SWING DISC, BOLTED BONNET / PRESSURE SEAL BONNET / WELDED BONNET, STELLITED 21 HARD FACED SEAT

GENERAL MATERIAL

BODY AND BONNET: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718.

DISC: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718+HARD FACED

SHAFT: ASTM A 182 F6A, F304,F316,XM-19, 17-4PH, INCONEL 625/718, MONEL K-400/500

SEAT: ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718+HARD FACED.

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The 30″ 600LB metal seated swing check valve is designed for large-diameter, high-pressure pipelines where flow protection and durability are essential. Its metal-to-metal seating provides excellent resistance to wear, high temperatures, and aggressive media, making it ideal for use in power plants, petrochemical systems, and high-temperature steam lines. The swing-type mechanism allows smooth forward flow while effectively preventing backflow when the flow reverses, helping to protect pumps and other critical downstream equipment. With a 600LB pressure rating, it can withstand demanding operating conditions while maintaining reliable sealing performance. The large 30-inch size accommodates high flow volumes, and the heavy-duty construction ensures long service life with minimal maintenance. This valve is particularly well-suited for applications where soft seats might fail due to temperature, pressure, or media characteristics, offering a robust and dependable solution for mission-critical operations.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.