DIN Grilla Grills Wood Pellet Grill

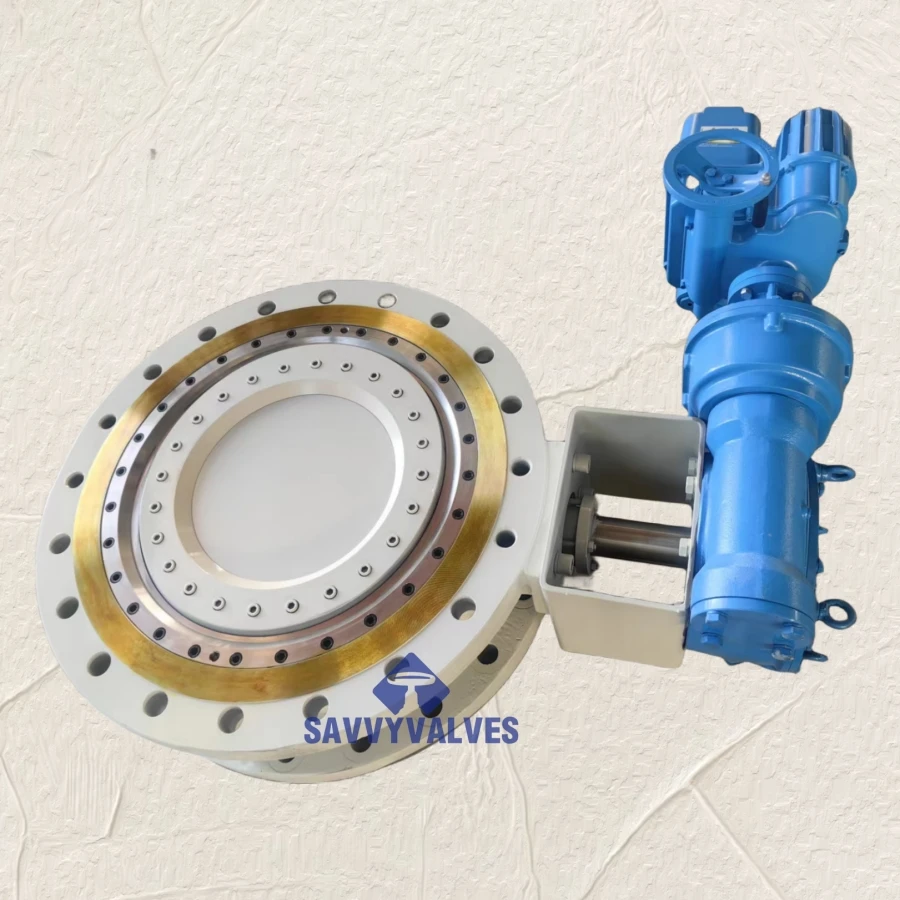

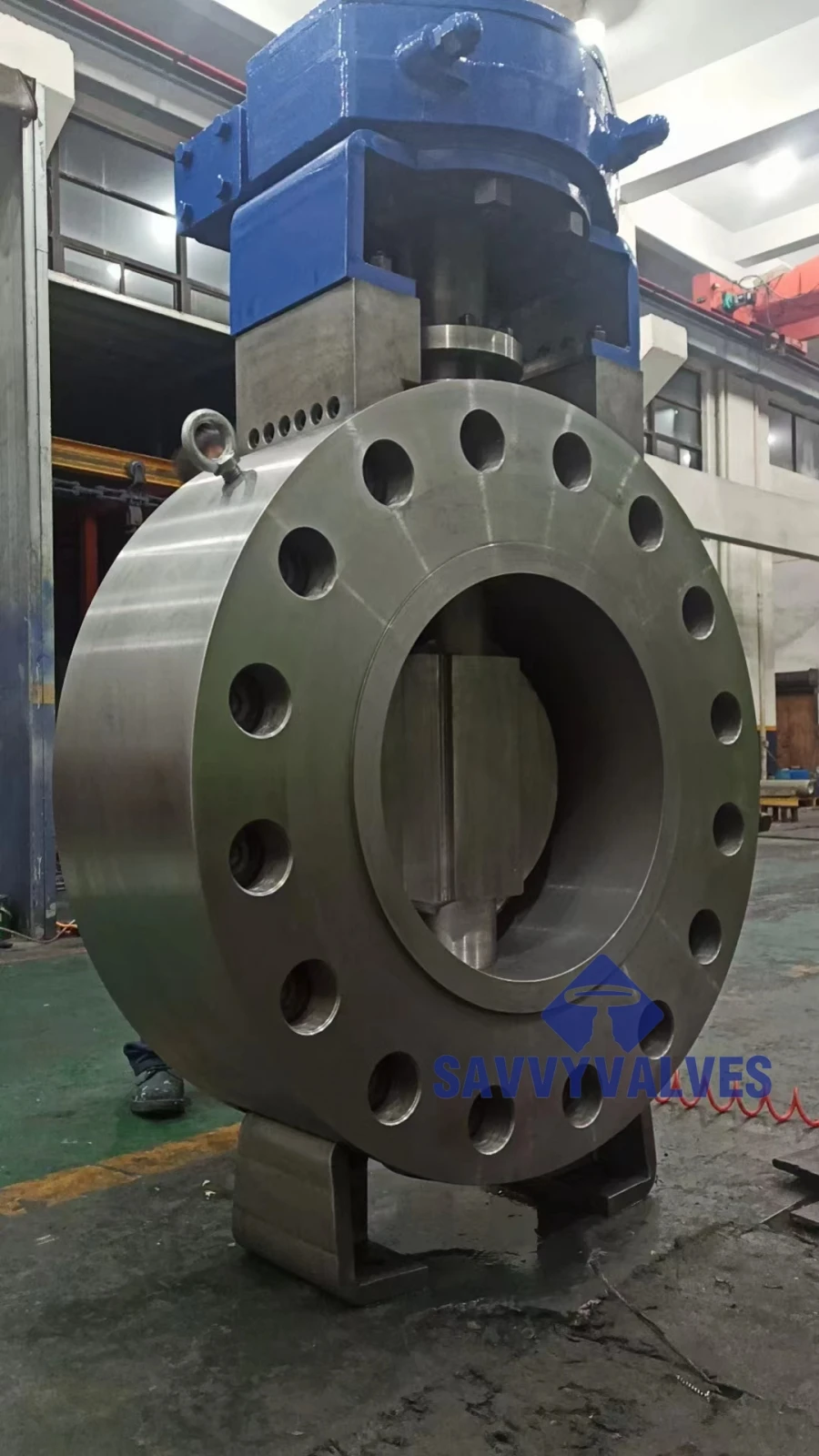

Valve Type: Triple Eccentric Butterfly Valve (Metal-Seated, Zero Friction Design)

Design Standard: API 609 / ISO 17292

Size: 14" (DN 350)

Pressure Class: ASME Class 150 (150 LB)

End Connection: RF Flange per ASME B16.5 (Raised Face: 1/16")

Body & Disc Material: ASTM A217 C5 (5% Cr-0.5% Mo Cast Steel for ≤593°C)

Seat System:

Laterally Replaceable Seat Ring

Valve Type: Triple Eccentric Butterfly Valve (Metal-Seated, Zero Friction Design)

Design Standard: API 609 / ISO 17292

Size: 14" (DN 350)

Pressure Class: ASME Class 150 (150 LB)

End Connection: RF Flange per ASME B16.5 (Raised Face: 1/16")

Body & Disc Material: ASTM A217 C5 (5% Cr-0.5% Mo Cast Steel for ≤593°C)

Seat System:

Laterally Replaceable Seat Ring

Sealing Face: Stellite 6 Overlay (3mm Min, HRC 46-52)

Graphite Pressure-Activated Backup Gasket

Disc Seal: Laminated Structure:

Inconel 625 Carrier + Flexible Graphite Layer (API 607 Fire-Safe)

Stem: Extended High-Temp Stem (17-4PH H1150, Plasma Nitrided ≥0.1mm)

Sealing Performance: ISO 5208 Rate A (Bubble-Tight) @ 593°C

Temperature Range: -29°C to 593°C (Continuous Operation)

Critical Features:

Side-Loaded Seat Replacement (2-Bolt Removal, ≤1.5 Hours)

Live-Loaded Stem Packing (ISO 15848-1 Class BH)

Conical Disc Offset: 8° Angle (Guarantees Zero Wear)

Power Plant Applications:

Boiler Bypass Ducts: 565°C Flue Gas Isolation

Hot Reheat Lines: 540°C @ 4.2MPa Steam

SCR/SNCR Systems: Abrasion-Resistant Sealing for Ash-Laden Gas

GUATANTEE

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.