Check Valves

-

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE:30″

RATING:600LB

BODY AND BONNET : ASTM A216 WCB

DISC: ASTM A216 WCB+STELLITE 6

SHAFT: ASTM A182 F6A

SEAT: ASTM A105+STELLITE 6

-

PHOTO SHOWS SPECIFICATION AS BELOW

SIZE:12″

RATING:600LB

BODY AND BONNET : ASTM A216 WCB

DISC: ASTM A216 WCB+STELLITE 6

SHAFT: ASTM A182 F6A

SEAT: ASTM A105+STELLITE 6

-

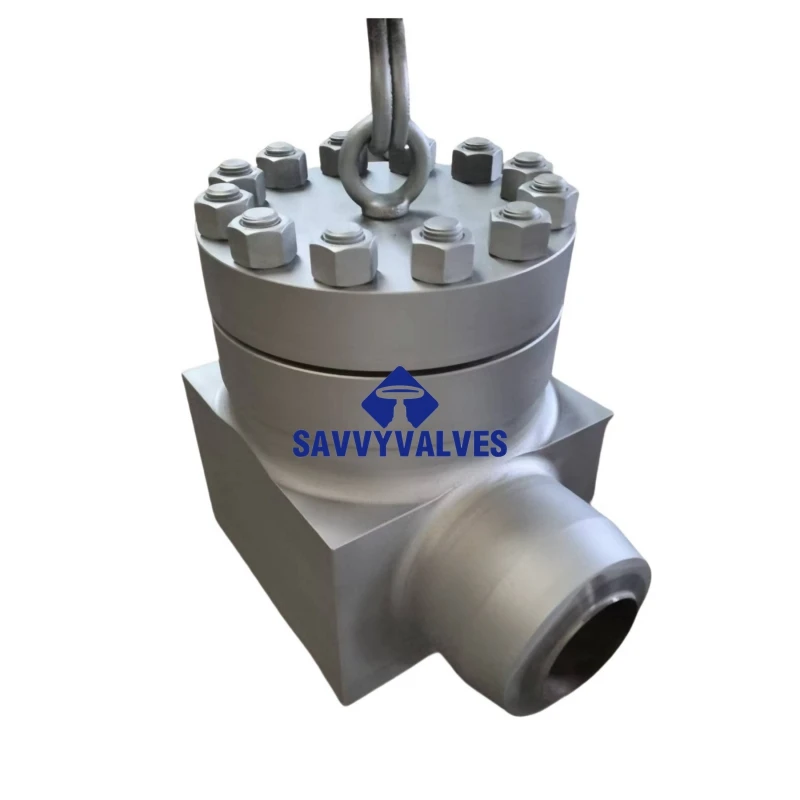

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:1″

RATING:150LB

BODY AND BONNET : ASTM A105

DISC: ASTM A105+STELLITE 6

SPRING: INCONEL X-750

SEAT: ASTM A105+STELLITE 6

LIFT/PISTON TYPE

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:4″

RATING:125LB

BODY AND BONNET : ASTM 536 65-45-12

DISC: ASTM 536 65-45-12 + BRONZE B62/B148

SHAFT: BRONZE B62/B148

SEAT: BRONZE B62/B148

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:24″

RATING:600LB

BODY AND BONNET : ASTM A216 WCB+STELLITE 6 HF

DISC: ASTM A351 CF8M + STELLITE 6 HF

SHAFT: ASTM A182 F6A

SEAT: STELLITE 6 HF

SPRING: INCONEL X-750

-

SAMPLE SPECIFICATIONS

SIZE: DN25 DN40

RATING: PN16

END: BW AS PER B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

-

SAMPLE SPECIFICATIONS

SIZE: DN20

RATING: PN420

END: BW AS PER B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

-

Size: 8" (DN 200)

Pressure Rating: 2500LB (ASME B16.34)

Key Materials:

Body: ASTM A350 LF2

Bonnet: ASTM A350 LF2

Disc: ASTM A350 LF2 + STL.6 HF

Stem: AISI 410

Seat: ASTM A350 LF2 + STL.6 HF

Actuation: Self-operated

Connection End: Butt Weld (BW)

Design Configuration: Single disc, swing type

Surface Treatment: Sandblasted + epoxy coating

Temperature Range: -46°C to +425°C (-50°F to +800°F)

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:8″

RATING:150LB

BODY AND BONNET : ASTM A351 CF8+STELLITE 6 HF

DISC: ASTM A351 CF8 + STELLITE 6 HF

SHAFT: ASTM A182 F316

SEAT: STELLITE 6 HF

SPRING: INCONEL X-750

-

1. Sealing System

o Pure FKM (Viton®) seats bonded directly to C95800 discs

o Zero metal sealing components – eliminates galling risk

o Leakage rate: ≤ 0.01 ml/min per inch seat dia. (Class VI)

2. Simplified Disc Design

o No Stellite hardfacing – cost-optimized for non-abrasive services

o Disc surface: Machined to Ra 3.2 μm for optimal rubber adhesion

3. Standard Hinge Mechanism

o No torsion springs (non-slam feature removed)

o Gravity-assisted closing (vertical installation required for optimal performance)

-

SAMPLE SPECIFICATIONS

SIZE: 2″

RATING: 900LB

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

-

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE:DN100

RATING:PN16

BODY AND BONNET : ASTM A536 65-45-12

DISC: ASTM A536 65-45-12

SHAFT: 416SS

SEAT: EPDM

A check valve, also known as a non-return valve, is a type of valve that allows fluid or gas to flow in one direction only, preventing backflow that could damage equipment or disrupt system performance. It operates automatically and doesn’t require manual or external control. Inside the valve, a disc or similar mechanism opens when fluid flows in the intended direction and closes if the flow reverses. There are several types of check valves, such as swing, lift, ball, and diaphragm types, each designed for specific applications or media. For instance, swing check valves are commonly used in water and wastewater systems, while lift check valves are more suitable for high-pressure lines. Check valves are critical in protecting pumps, compressors, and pipelines from backflow damage, maintaining pressure, and preventing contamination. Their simple, self-operating design makes them ideal for both industrial and domestic use, especially in systems where reliability and safety are essential.

- 1

- 2