DIN Grilla Grills Wood Pellet Grill

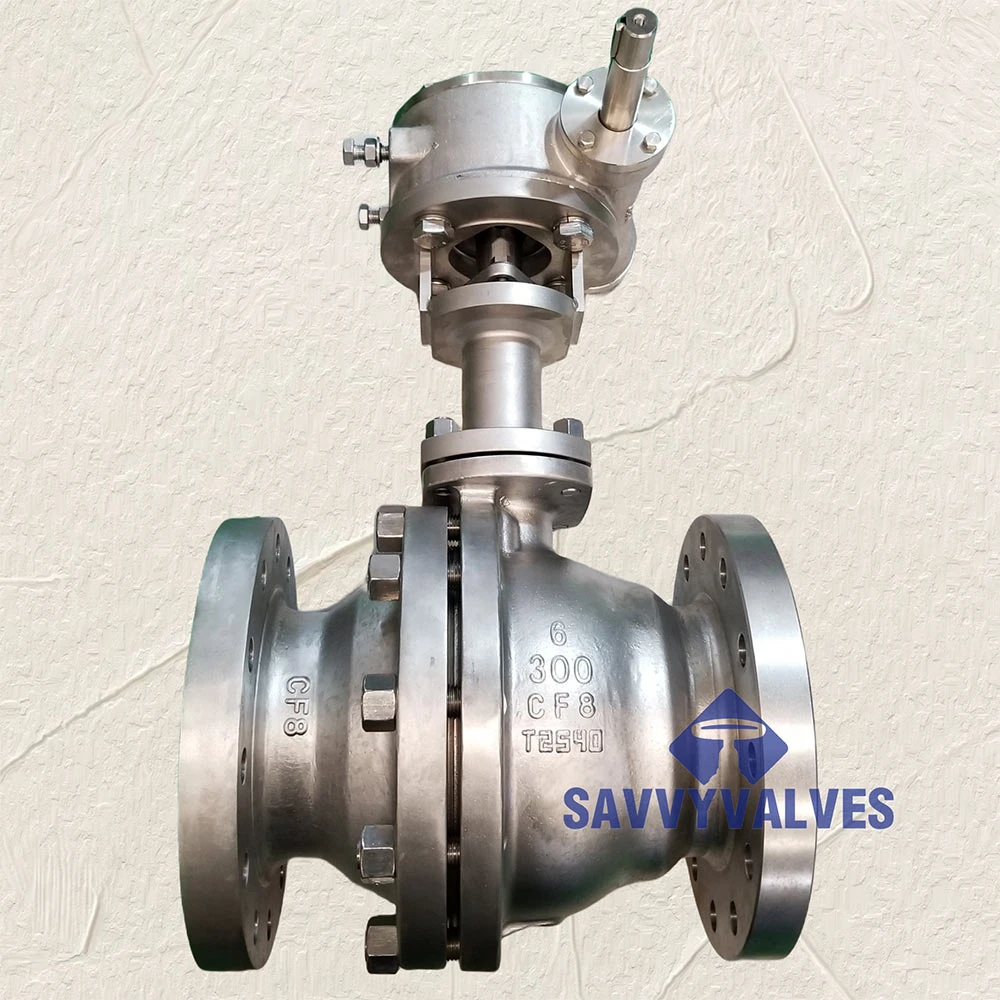

PHOTOS SHOW SPECIFICATIONS AS BELOW:

SIZE: 1″

RATING: 150LB

END: BW AS PER ASME B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : A182 F316

BALL: ASTM A182 F316+HF

STEM: ASTM A182 F316

SEAT: PEEK OR HF METAL

ACTUATION: MANUAL AND GEAR

GENERAL

Size: 1/8″~36″.

Pressure Rating: 150LB~4500LB, PN6~PN750

Design Temperature: -196℃~120℃

Design Manufacture Code: ASME B16.34, BS6364, API 608, API 6D,SHELL SPE77/200

Face to Face: ASME B16.10, EN558

Connection: ASME B16.5, B16.47, EN1092, RF/RTJ. ASME B16.25 BW ASME B16.11 SW/NPT ETC.

Trims Design: Floating ball / Trunnion ball

General Applications: CNG,LNG,LPG, CO2,N2 ETC.

Safety Design: anti-blow out stem, fire proof, anti-static

Special Test if Required: Low Emission, DNV/BV/SGS TPI service is available.

MAIN TYPICAL MATERIALS LIST

BODY: ASTM A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, MONEL K400/K500, H-276

BALL: ASTM A182 F304/F316/F51/F53/F55,MONEL K400/K500, H-276 hardened

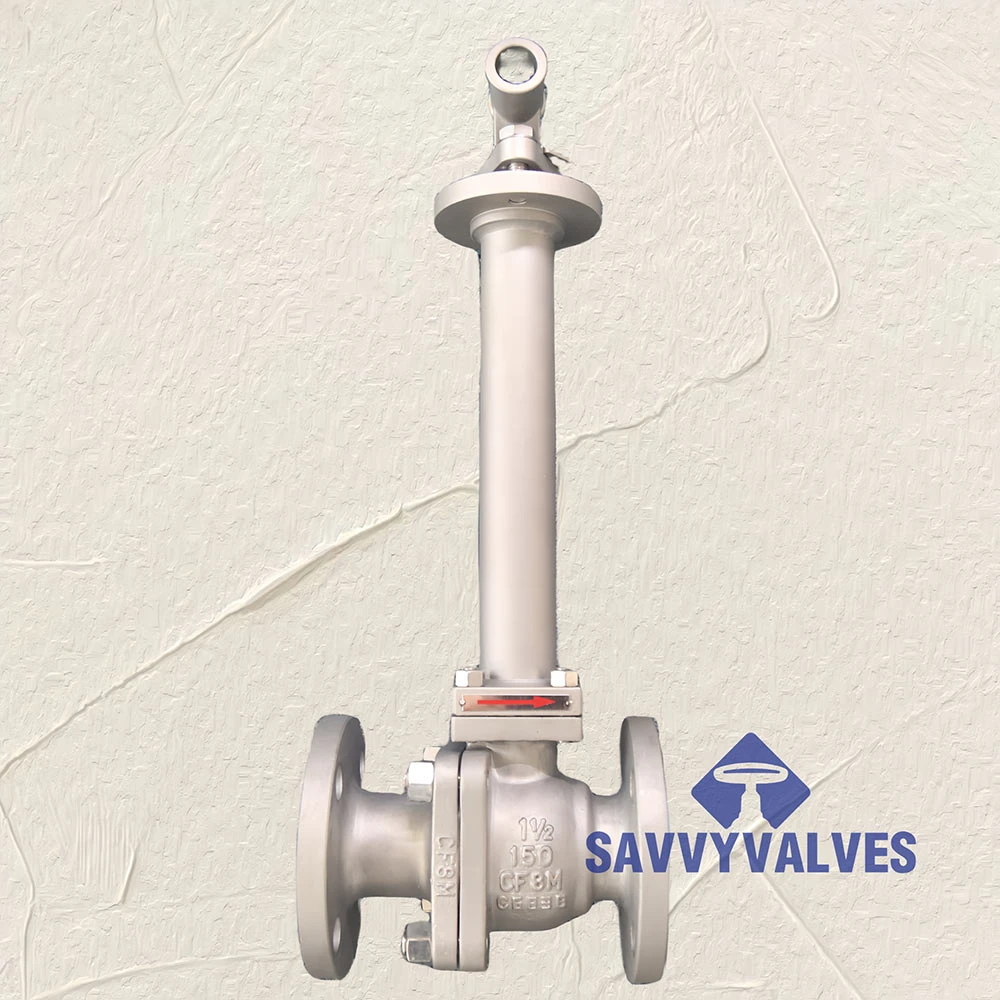

EXTENDED BONNET: ASTM A351 CF8/CF8M, ASTM A182 F304/F316

STEM: F304,F316,XM-19, 17-4PH, INCONEL 718, MONEL K-500

SEAT: SPRING ENERGIZED PCTFE, PEEK OR HF METAL

OPERATOR: LEVER OR GEAR OR ACTUATOR

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST

Inspection and approval norm: API598, API6D.BS6364

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The CNG LNG LPG top entry cryogenic floating ball valve is engineered for reliable performance in cryogenic environments, where safe and efficient flow control of liquefied gases is crucial. Its floating ball design ensures tight shutoff by allowing the ball to move slightly under pressure, pressing against the downstream seat for a leak-proof seal. The top entry configuration enables quick and convenient maintenance from above, ideal for large-scale installations where removing the valve from the pipeline would be costly or impractical. Built with extended bonnets and low-temperature-resistant materials, this valve prevents frost damage and maintains packing integrity down to -196°C. It is widely used in LNG terminals, CNG fueling stations, and LPG distribution networks. With its compact structure, precise sealing, and cryogenic certification, this valve ensures long-term safety and performance in demanding cold gas service applications.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.