Description

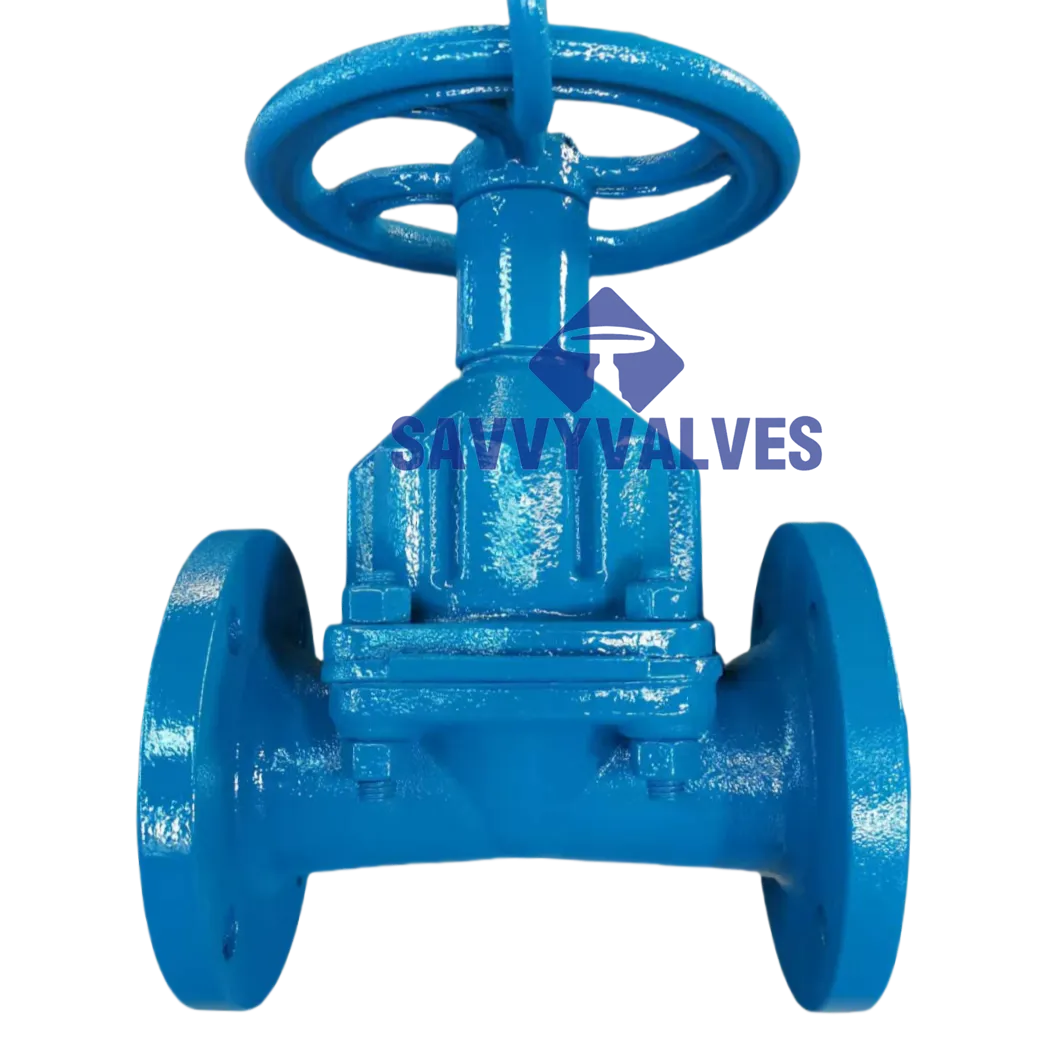

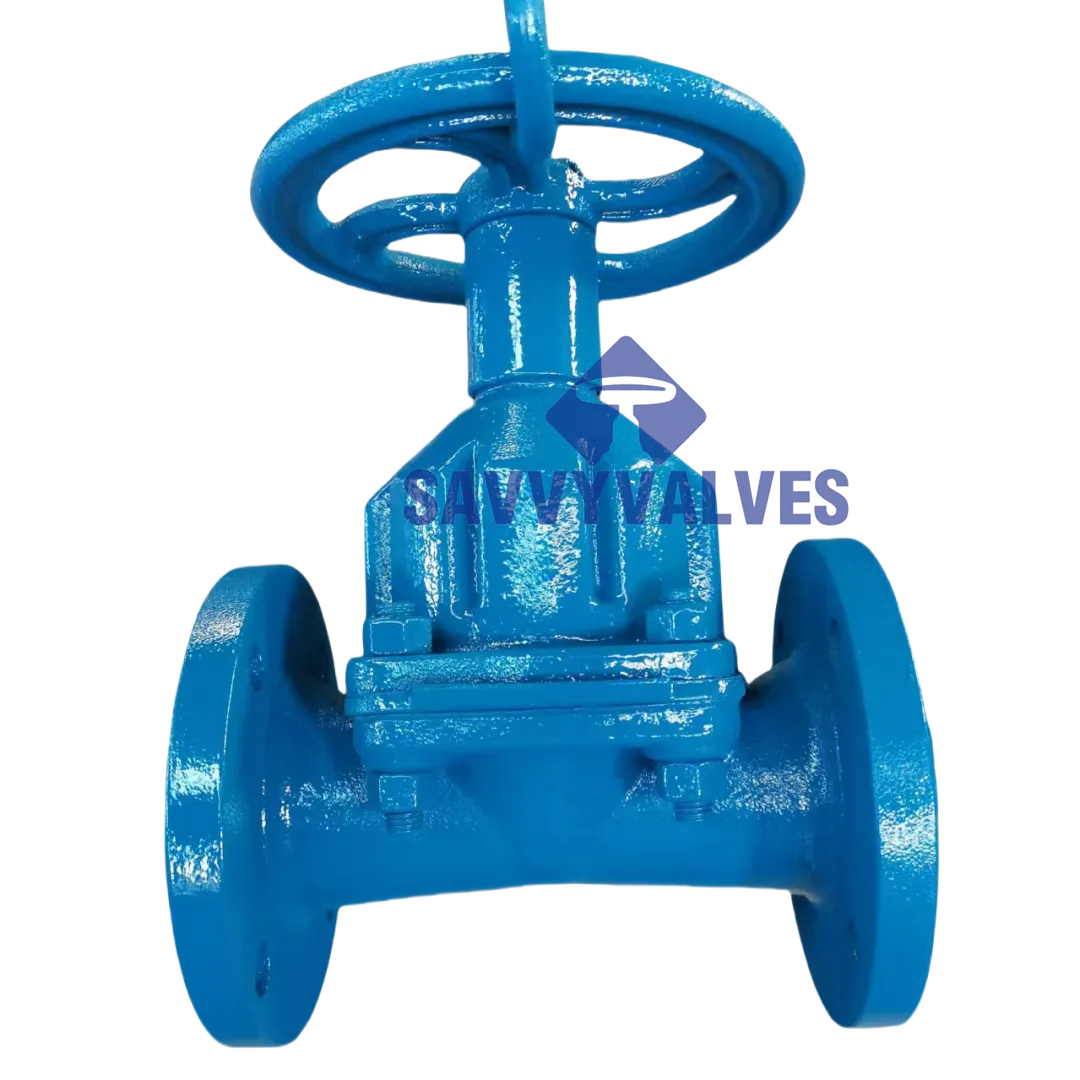

Rubber lined diaphragm valve

Savvy rubber lined diaphragm valves are offered in fully lined design in a wide range of carbon, stainless steel, duplex stainless steel, alloy and other special materials. The liner could be EPDM, HYPALON, VITON, PTFE, PFA etc.

-

PRODUCT RANGE

Sizes NPS 2 to NPS 6

Class 150

-

MATERIALS

Body and bonnet: ASTM A126B, ASTM A536, ASTM A395, ASTM A216 WCB, ASTM A351 CF8 CF8M CF3 CF3M etc.

Liner: EPDM, HYPALON, VITON, PTFE, PFA

Stem: CS, SS