DIN Grilla Grills Wood Pellet Grill

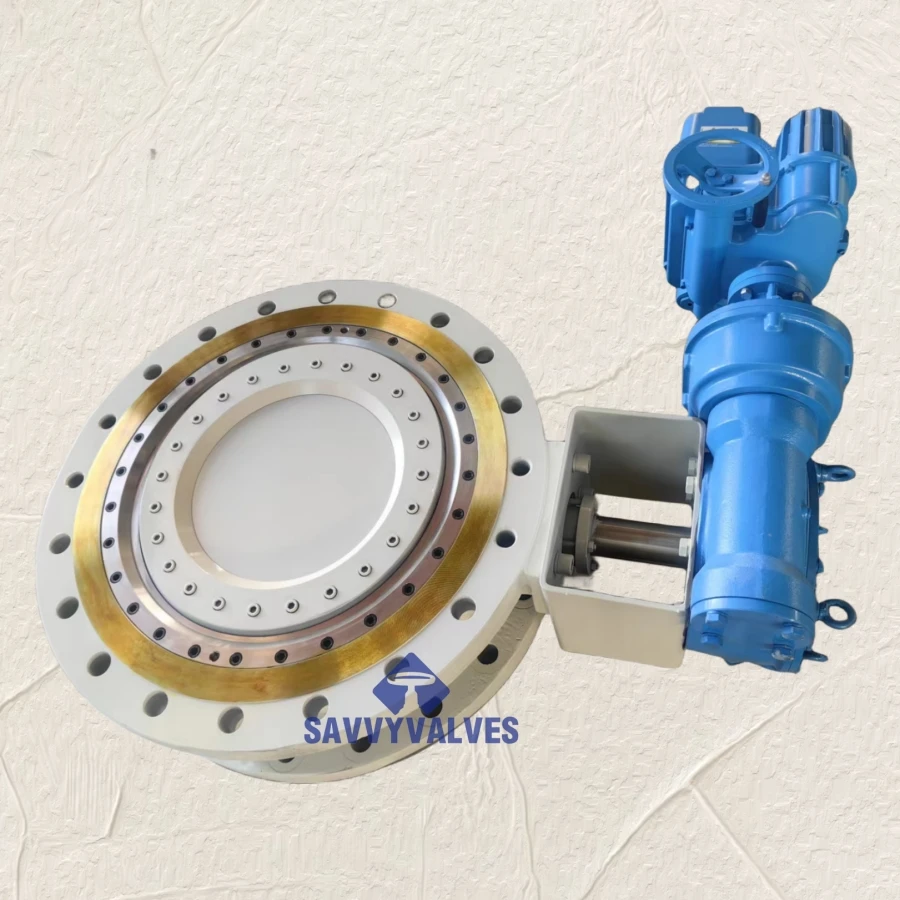

SIZE: DN700

RATING: PN6

BODY: ASTM A536 65-45-12

DISC: ASTM A351 CF8M

STEM: SS416 PINLESS

SEAT: NBR

PAINTING: FLUORINE CARBON, C5-I

ACTUATION: GEAR UNIT

GENERAL DESIGN SPECIFICATION

Size: 2″~48″.

Pressure Rating: PN6, PN10, PN16,PN20, 200WOG, 125LB, 150LB, JIS 5K 10K 16K 20K

General applications: Water. Oil. Gas.

Suitable temperature: -29℃~150℃

Design & Manufacture: API 609 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: Drilled as per ASME B16.5, EN 1092, JIS 5K-20K. BW, RTJ are available.

Safety design: anti-blow out stem.

TYPICAL MATERIAL LIST

BODY: ASTM A126 , ASTM A536, ASTM A216 WCB ASTM A395

DISC: ASTM A536, ASTM A395, ASTM A351 CF8, ASTM A351 CF8M, ALUMINIUM BRONZE (C95400, C95500), DSS F51, F53, F55

STEM: 13CR,SS304,SS316, DSS F51, F53, F55, XM-19, 17-4PH, INCONEL 718, MONEL K-500

SEAT: EPDM, NPR, VITON

OPERATOR: LEVER AND GEAR UNIT

OTHER SPECIAL MATERIALS ARE AVAILABLE TO CUSTOMIZE.

TEST AND INSPECTION

Inspection and approval norm: API598, API6D.

QUALITY CONTROL

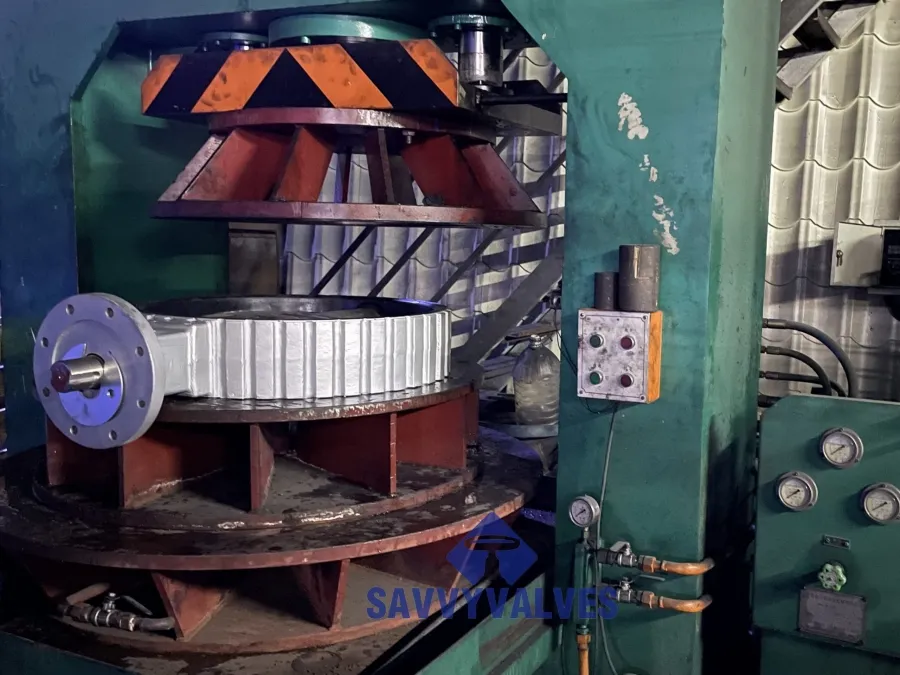

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE

SAVVY VALVES provide 12 months service life at least, free spares and maintenance instruction will be provided when required.

The ASME B16.47 B series vulcanized rubber seated butterfly valve is ideal for large-diameter pipeline applications in industries such as water treatment, HVAC, and industrial fluid control. Designed to meet the dimensional standards of ASME B16.47 B, it ensures compatibility with standard flanges in high-volume flow systems. The vulcanized rubber seat, which is permanently bonded to the valve body, provides excellent sealing performance and durability under varying pressures and temperatures. This eliminates seat displacement or leakage over time, even with frequent operation. The valve allows for bi-directional flow control and is easy to install, operate, and maintain, making it well-suited for critical isolation or throttling functions in systems up to 48 inches or more. Its robust sealing and corrosion resistance make it a dependable choice for cost-effective, leak-tight service in demanding environments.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.