Cryogenic Valves

-

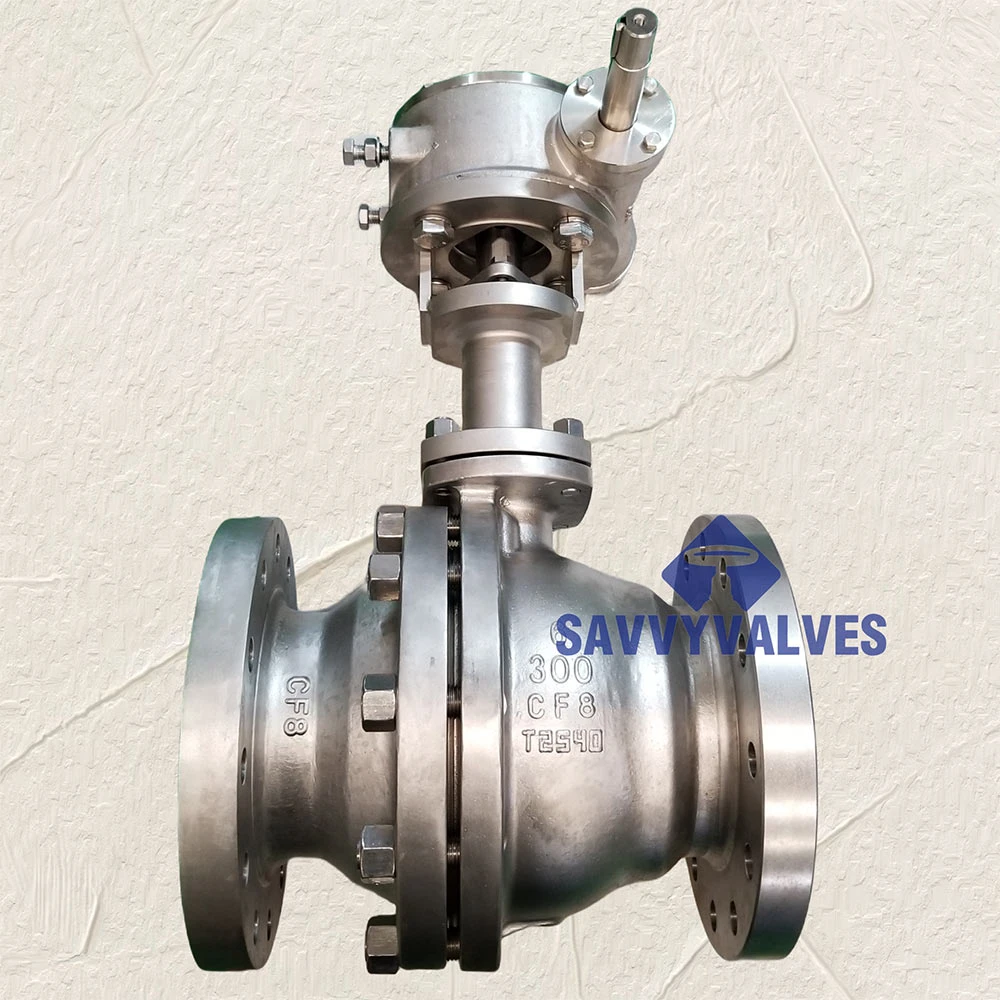

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE: 6″

RATING: 300LB

END: FLANGED AS PER ASME B16.5 300LB

TEMPERATURE: -70 ℃

BODY AND BONNET : ASTM A351 CF8

BALL: ASTM A182 F304

STEM: ASTM A182 F304

SEAT: SPRING ENERGIZED PCTFE

ACTUATION: PNEUMATIC ACTUATOR

-

SAMPLE SPECIFICATIONS

SIZE: DN25 DN40

RATING: PN16

END: BW AS PER B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

-

SIZE: 3″

RATING: 300LB

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

-

SIZE: 6″

RATING: 300LB

END: FLANGE AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

BALL: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: MANUAL AND GEAR

-

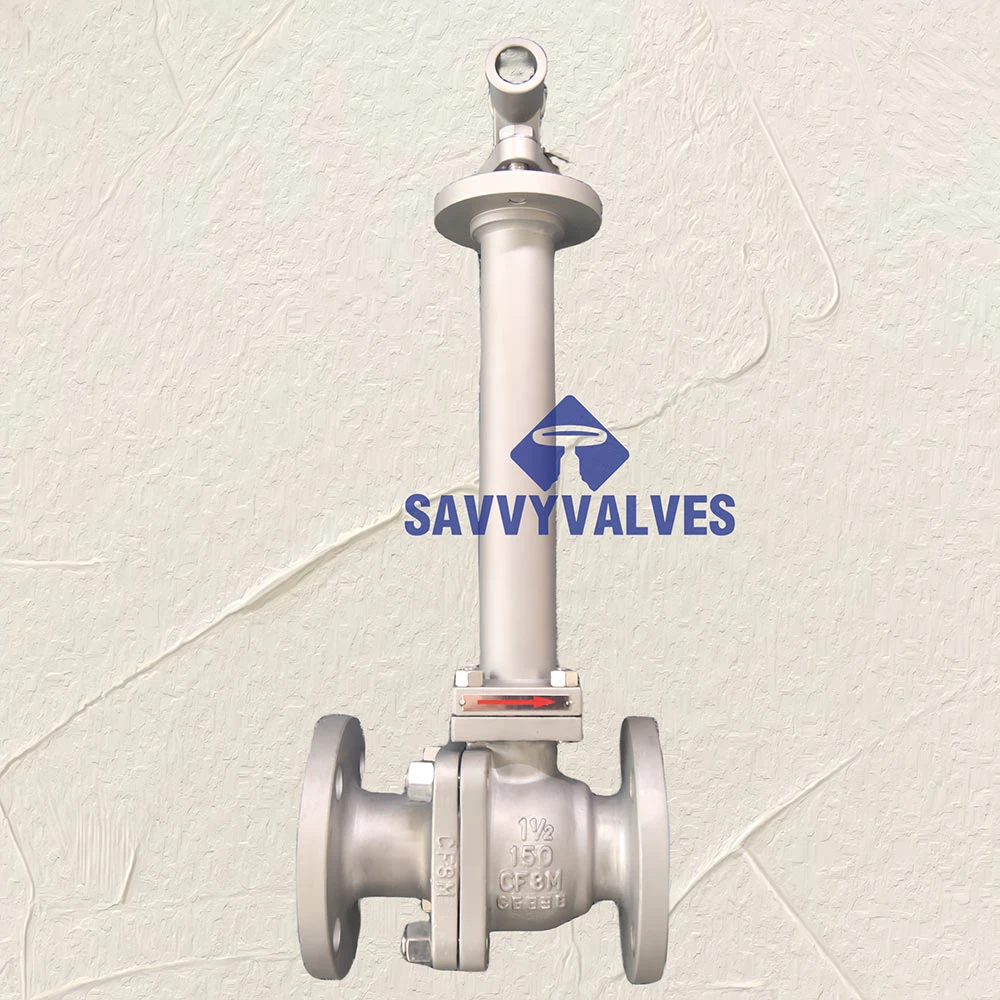

PHOTO SHOWS SPECIFICATIONS AS BELOW

SIZE: 1-1/2″

RATING: 150LB

END: FLANGED AS PER ASME B16.5 300LB

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A351 CF8M

BALL: ASTM A182 F316+HCR

STEM: ASTM A182 F316

SEAT: SPRING ENERGIZED PCTFE

ACTUATION: LEVER

-

SIZE: 3/4″ 6″

RATING: 150LB 300LB

END: FLANGE AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

BALL: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: MANUAL AND GEAR

-

SIZE: 1/8″~4″

RATING: 800LB

END: SW AS PER ASME B16.11

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

-

SIZE: 8″

RATING: 150LB

END: FLANGE AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : A351 CF8M

BALL: ASTM A182 F316+HF

STEM: ASTM A182 F316

SEAT: PCTFE OR HF METAL

ACTUATION: MANUAL AND GEAR

-

SIZE: 1″

RATING: 150LB

END: BW AS PER ASME B16.25

TEMPERATURE: -196 ℃

BODY AND BONNET : A182 F316

BALL: ASTM A182 F316+HF

STEM: ASTM A182 F316

SEAT: PEEK OR HF METAL

ACTUATION: MANUAL AND GEAR

-

SIZE: 1″

RATING: 800LB

END: SW AS PER ASME B16.11

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

-

SIZE: 1/8″~36″

RATING: PN250

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

WEDGE: SOLID ASTM A182 F304+HF

STEM: ASTM A182 F304

SEAT: HF METAL

ACTUATION: HAND WHEEL

-

SIZE: 1/8″~24″

RATING: 900LB

END: RF AS PER ASME B16.5

TEMPERATURE: -196 ℃

BODY AND BONNET : ASTM A182 F304

PLUG: ASTM A182 F304+HF

SEAT: PCTFE OR HF METAL

ACTUATION: SPRING LOADED

Cryogenic valves are specially engineered valves designed to operate in extremely low temperatures, typically below -150°C (-238°F), often used in the storage and transport of liquefied gases like LNG, liquid nitrogen, oxygen, or helium. These valves are built with extended bonnets to isolate the stem and packing from the cold media, preventing frost build-up and maintaining seal integrity. The materials used in cryogenic valves are carefully selected to withstand thermal shock and maintain flexibility and durability at cryogenic temperatures—common materials include stainless steel and Monel. These valves are usually top-entry or bolted-bonnet types for easy maintenance and are often fire-tested and certified for leak-tight performance under cryogenic conditions. Their seats and seals are typically soft-seated (PTFE or similar) for bubble-tight shut-off, although some use metal-seated designs for severe applications. The primary function of cryogenic valves is to provide precise control and reliable shutoff of cryogenic liquids and gases, which are stored under high pressure at low temperatures. Their design must also accommodate pressure buildup during rapid vaporization, ensuring safe venting and flow control.

- 1

- 2