DIN Grilla Grills Wood Pellet Grill

SAMPLE SPECIFICATIONS

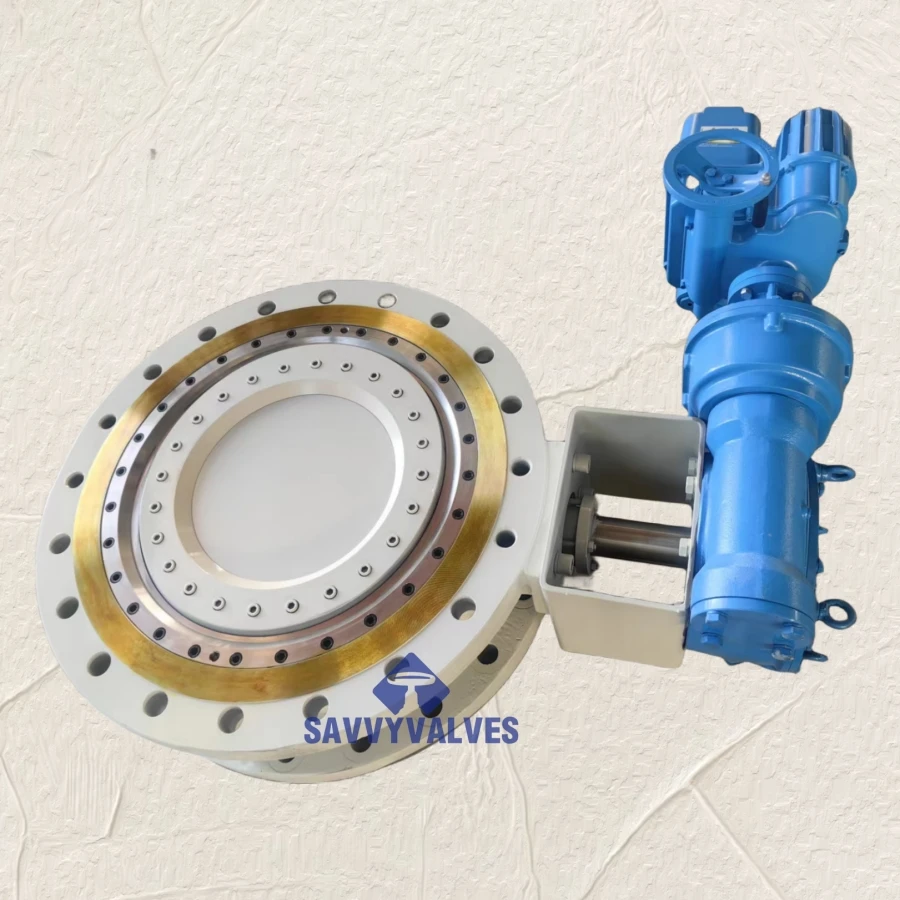

SIZE: 40″

RATING: 150LB

BODY: ASTM A536 DUCTILE IRON

DISC: C95400 ALUMINIUM BRONZE

STEM: MONEL K-500

SEAT: EPDM

TAPER PIN: MONEK K-500

ACTUATION: ELECTRIC ACTUATOR

GENERAL

Size: 28″ and above.

Pressure Rating: PN6~PN25

General applications: Water. Oil. Gas.

DESIGN

Design & Manufacture: API 609 are basic, other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.5, EN 1092, JIS 5K-20K. BW, RTJ are available.

Safety design: anti-blow out stem.

GENERAL MATERIAL

BODY: CAST IRON, DUCTILE IRON

DISC: ALUMINIUM BRONZE (C95400, C95500, C95800), STAINLESS STEEL(CF8,CF8M,CF3,CF3M,2205,2507),MONEL(K-400,K-500)

STEM: 13CR, SS304, SS316, F51, F53, F55, 17-4PH, INCONEL 718, MONEL K-500

SEAT: EPDM, NBR, BUNA-N, VITON

TEST

Inspection and approval norm: API598, API6D.

QUALITY CONTROL:

100% Chemical analysis and mechanical test with raw materials of each heat numbers.

100% DPT test with the castings, partly MT or UT test, RT is always available if required.

100% hydraulic test with the shell and seal and low pressure air test.

GUATANTEE:

SAVVY VALVES is committed to delivering exceptional product quality and worry-free after-sales service. Our valves are guaranteed to provide a minimum service life of 12 months, during which we will supply all necessary spare parts and detailed maintenance instructions free of charge. Within the warranty period, if any non-human-induced damage occurs, we will replace components at no cost and provide professional technical support. After the warranty expires, customers only need to pay for the cost of spare parts, while still benefiting from discounted maintenance services. Our goal is to help clients reduce operational costs and enhance production efficiency through reliable quality and comprehensive after-sales support. Whether for technical inquiries or maintenance needs, our expert team will respond promptly to ensure your valve system maintains optimal performance at all times.

The Marine U section double flange butterfly valve is specifically engineered for maritime applications where space-saving, durability, and corrosion resistance are critical. Its U-section body ensures structural reinforcement, making it ideal for installation in ship pipelines subject to vibration and pressure fluctuations. The double flange design allows for secure, leak-proof connections between pipe sections, enhancing operational safety in marine environments. This type of valve is commonly used for seawater, ballast systems, fuel handling, and bilge piping due to its reliable shutoff performance and resistance to saltwater corrosion. The butterfly disc ensures fast opening and closing, while the seat material—often rubber-lined—provides tight sealing even after repeated use. With its compact size, robust construction, and easy maintenance, this valve is a trusted solution for shipbuilders and marine operators looking for efficiency and safety in fluid control.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.