The Indispensable Role of Rubber Seated Butterfly Valves in Modern Industry

In the intricate world of industrial fluid control, the selection of the right valve is paramount to ensuring operational efficiency, safety, and longevity. Among the myriad valve types, the butterfly valve rubber plays a critically important role, particularly where reliable shut-off and precise flow regulation are required across diverse media. This comprehensive guide delves into the technical intricacies, application advantages, and manufacturing excellence behind modern rubber-seated butterfly valves, offering insights for B2B decision-makers and technical specialists. The versatility and robust design of these valves have cemented their position as a preferred solution in sectors ranging from water treatment and petrochemicals to HVAC and power generation. Their fundamental design, incorporating a disc that rotates within the valve body and a resilient rubber seat, allows for quick operation, minimal pressure drop, and exceptional sealing capabilities. This inherent design simplicity, combined with continuous advancements in material science and manufacturing processes, contributes to their widespread adoption. Understanding the nuances of their construction, the selection of appropriate rubber compounds, and the specific applications where they excel is key to optimizing fluid control systems and ensuring long-term operational integrity. The ongoing innovation in rubber technology, particularly vulcanized rubber, has significantly enhanced the performance envelope of these valves, allowing them to withstand increasingly aggressive media, higher temperatures, and more demanding pressure cycles, thereby extending their service life and reducing maintenance requirements.

The market for industrial valves, especially those featuring advanced sealing technologies, is experiencing steady growth, driven by global infrastructure development, increasing demand for clean water, and the expansion of chemical processing industries. Within this landscape, the demand for rubber sealed butterfly valve solutions is particularly buoyant due to their proven reliability and cost-effectiveness. Industry reports indicate a compound annual growth rate (CAGR) for the global industrial valve market, with a significant segment attributed to quarter-turn valves like butterfly valves. The emphasis on energy efficiency and emission reduction further propels the adoption of valves that offer superior sealing and minimal leakage, precisely where rubber-seated designs excel. Furthermore, the shift towards smart manufacturing and automation necessitates valves that can integrate seamlessly into complex control systems, offering rapid response times and consistent performance. The inherent design of butterfly valves, with their quarter-turn operation, makes them highly compatible with automated actuation systems, further boosting their appeal in modern industrial setups. The increasing complexity of industrial processes also means a greater diversity in the types of media being handled, from abrasive slurries to corrosive chemicals, underscoring the need for highly engineered rubber sealing butterfly valve solutions that can maintain their integrity under challenging conditions. Manufacturers are continually investing in research and development to create new rubber compounds with enhanced chemical resistance, temperature tolerance, and abrasion resistance, pushing the boundaries of what these valves can achieve. This dedication to material science ensures that rubber-seated butterfly valves remain at the forefront of fluid control technology, adapting to evolving industrial demands and contributing to safer, more efficient operations worldwide.

Introducing the ASME B16.47 B Series Vulcanized Rubber Seated Butterfly Valve

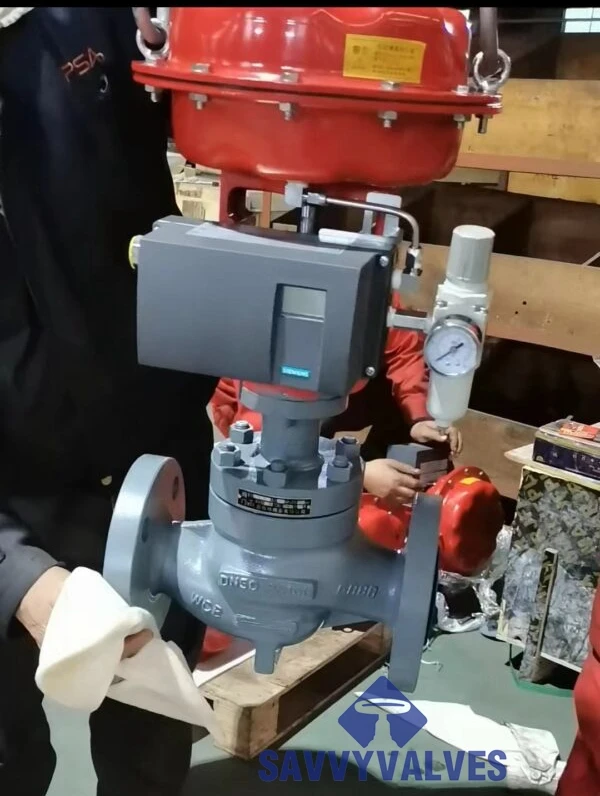

At the forefront of advanced valve technology, the Asme B16.47 B Series Vulcanized Rubber Seated Butterfly Valve represents a pinnacle of engineering precision and performance. Designed to meet the stringent requirements of ASME B16.47 Series B flanges, this valve is engineered for applications demanding robust, reliable, and leak-tight shut-off. Its vulcanized rubber seat is a critical component, offering superior resilience, wear resistance, and long-term sealing integrity compared to traditional non-vulcanized alternatives. The vulcanization process cross-links the polymer chains in the rubber, enhancing its mechanical properties, including tensile strength, elongation, tear resistance, and crucially, its resistance to compression set. This means the seat maintains its shape and sealing effectiveness even after repeated cycles of opening and closing, and under sustained pressure. The design adheres strictly to international standards, ensuring interoperability and consistent quality across global industrial environments. These valves are typically employed in large diameter piping systems where robust construction and high flow rates are common, making them ideal for municipal water supply, large industrial cooling systems, and bulk material handling where positive shut-off is non-negotiable. The specific adherence to ASME B16.47 B Series standards indicates its suitability for larger diameter pipelines, typically ranging from NPS 26 through NPS 60 and above, which operate under specific pressure-temperature ratings. This ensures seamless integration with existing piping infrastructure, minimizing installation complexities and maximizing system reliability.

Key technical specifications for this series often include pressure ratings up to ANSI Class 150 (PN10/PN16 equivalents), temperature ranges typically from -20°C to 120°C depending on the rubber compound (e.g., EPDM, NBR, Viton), and body materials commonly encompassing ductile iron, carbon steel, or stainless steel to suit various media and environmental conditions. The disc material choice is equally critical, often selected from ductile iron with various coatings, stainless steel, or even exotic alloys for highly corrosive applications. The shaft, typically 410 Stainless Steel or higher grade, is designed for high strength and corrosion resistance, ensuring smooth operation and longevity. The rubber sealed butterfly valve seating material choice is paramount; EPDM (Ethylene Propylene Diene Monomer) is widely used for water and general industrial applications due to its excellent resistance to ozone, sunlight, and aging, along with a wide temperature range. NBR (Nitrile Butadiene Rubber) is preferred for hydrocarbon-based fluids, oils, and fuels due to its superior oil resistance. Viton (FKM), a fluoroelastomer, offers exceptional chemical resistance to a broad spectrum of aggressive chemicals, high temperatures, and fuels, making it suitable for demanding chemical processing environments. The selection of the precise rubber compound is meticulously made based on the fluid characteristics, operating temperature, pressure, and specific industry standards to ensure optimal performance and an extended service life, underscoring the importance of material expertise in valve engineering.

Unveiling the Meticulous Manufacturing Process of Butterfly Valve Rubber

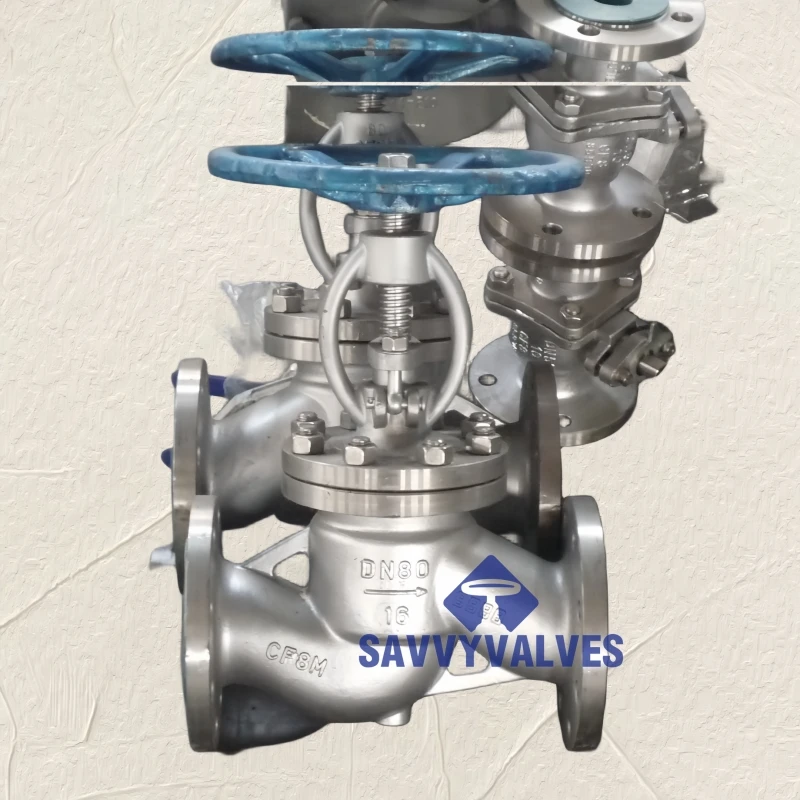

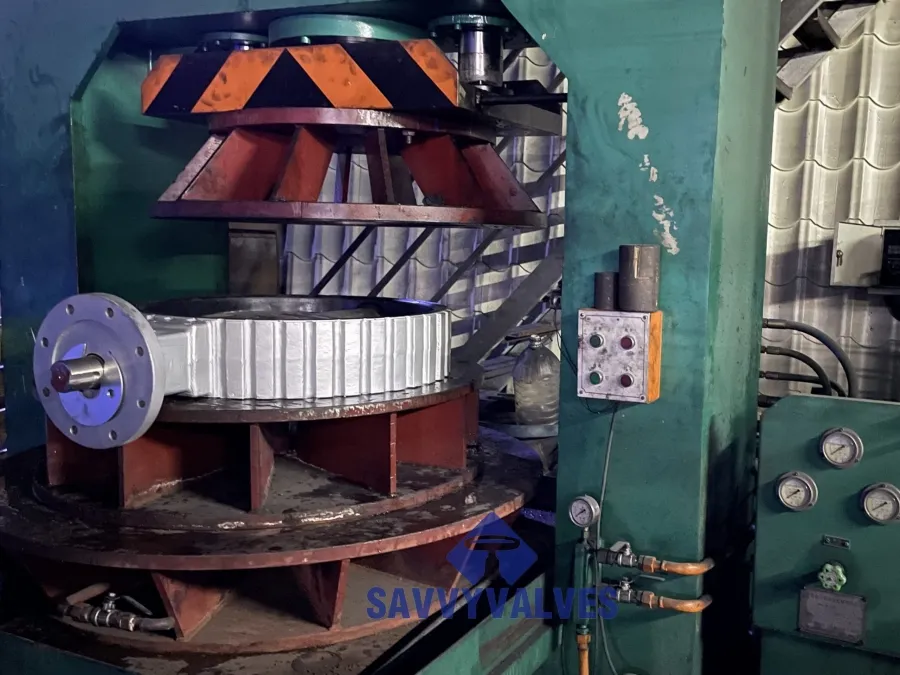

The production of a high-performance butterfly valve rubber involves a sophisticated series of integrated manufacturing processes, each critical to the valve's overall integrity and performance. The journey begins with the meticulous selection of raw materials, ensuring that only certified and high-grade alloys are used for valve bodies, discs, and shafts, and premium polymer compounds for the rubber seats. For the valve body and disc, common materials include ductile iron (ASTM A536), carbon steel (ASTM A216 WCB), and various grades of stainless steel (ASTM A351 CF8M/CF3M). These materials are chosen based on the required mechanical strength, corrosion resistance, and specific application temperature and pressure conditions. The manufacturing process typically follows a structured flow. First, the valve body and disc are produced through either casting or forging. Casting involves pouring molten metal into a mold designed to the precise dimensions of the valve components, allowing for complex geometries and efficient material usage. Forging, on the other hand, involves shaping solid metal through localized compressive forces, resulting in components with superior grain structure, enhanced strength, and reduced porosity, often preferred for high-pressure or critical applications. Following the initial forming, both cast and forged components undergo rigorous heat treatment processes to achieve desired metallurgical properties, enhancing their strength, ductility, and wear resistance. This step is crucial for ensuring the structural integrity of the valve components under operational stresses.

Precision machining is the next vital stage, often utilizing advanced CNC (Computer Numerical Control) machines. CNC machining ensures that all critical dimensions, such as bore diameter, flange face finishes, and shaft housing tolerances, are manufactured to extremely tight specifications, crucial for proper assembly and long-term sealing performance. This precision minimizes friction and wear, extending the valve's operational life. Surface finishes are meticulously applied to ensure compatibility with various media and to enhance corrosion resistance. For the rubber seat, the process typically involves injection molding or compression molding of the chosen elastomer (e.g., EPDM, NBR, Viton) followed by vulcanization. Vulcanization is a chemical process involving the cross-linking of polymer chains, typically using sulfur or other curatives, under controlled heat and pressure. This transforms the rubber from a pliable, thermoplastic material into a durable, elastic thermoset material with significantly improved mechanical properties, thermal stability, and chemical resistance. This vulcanized rubber sealing butterfly valve seat is then either bonded directly to the valve body or manufactured as a liner that precisely fits within the valve body, ensuring a bubble-tight seal against the disc.

Quality control is integrated throughout every stage of manufacturing. Initial material inspection verifies chemical composition and mechanical properties. In-process inspections monitor dimensions and surface finishes after casting, forging, and machining. Non-destructive testing (NDT) methods like ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MT) are employed to detect any internal flaws or surface discontinuities in metal components. After assembly, each valve undergoes stringent hydrostatic and pneumatic testing to ISO 5208, API 598, and ANSI/FCI 70-2 Class VI standards, ensuring zero leakage and reliable shut-off under specified pressure conditions. This involves testing both the body's integrity and the seat's sealing capability. Cycle testing is also performed on a statistical basis to verify the long-term operational integrity and service life of the valve, simulating thousands of open-close cycles. Adherence to international standards such as ISO 9001 for quality management, API 609 for butterfly valves, and ANSI/AWWA C504 for rubber-seated butterfly valves ensures that every valve produced meets or exceeds global benchmarks for quality, safety, and performance. The typical service life of a well-maintained industrial butterfly valve rubber can range from 10 to 25 years, depending on the application severity, media characteristics, and operating frequency. These valves find extensive application across various industries including petrochemical, oil & gas, metallurgy, power generation, and crucially, in water and wastewater treatment, where their non-clogging design and excellent sealing prevent media contamination and ensure system efficiency. In large-scale water distribution systems, for example, their ability to provide tight shut-off prevents water loss and maintains system pressure, contributing significantly to water conservation and energy savings by reducing pump loads.

Key Technical Parameters and Performance Metrics for Butterfly Valve Rubber

Understanding the critical technical parameters of butterfly valve rubber is essential for proper selection and optimal system design. These parameters dictate a valve's suitability for specific applications, ensuring its performance, longevity, and compliance with industry standards. The design of the rubber seat itself, particularly the vulcanization process, significantly influences these parameters by enhancing material stability and resilience.

Here is a table summarizing key technical parameters commonly associated with high-performance rubber-seated butterfly valves, drawing on industry averages and common specifications:

| Parameter | Description | Typical Range/Value | Relevant Standard/Impact |

|---|---|---|---|

| Nominal Size (DN/NPS) | Valve diameter, e.g., DN250 (NPS 10) to DN1500 (NPS 60) or larger for ASME B16.47 Series B. | DN 50 - DN 3000 (NPS 2 - NPS 120) | ASME B16.10, ISO 5752 |

| Pressure Rating | Maximum allowable working pressure (MAWP). | PN6, PN10, PN16, ANSI Class 150 (up to 19.6 bar / 285 psi) | EN 1092-2, ASME B16.5, ASME B16.47 |

| Temperature Range | Minimum and maximum operating temperatures. | -20°C to 120°C (-4°F to 248°F) (EPDM dependent) | Material specific (EPDM, NBR, Viton) |

| Body Materials | Construction material of the valve body. | Ductile Iron (GGG40/50), Carbon Steel (WCB), Stainless Steel (CF8M/CF3M) | ASTM A536, ASTM A216, ASTM A351 |

| Disc Materials | Material of the valve disc. | Ductile Iron (Ni-plated), Stainless Steel (CF8M), Bronze | ASTM A536, ASTM A351, ASTM B62 |

| Seat Material (Elastomer) | Type of rubber used for sealing. | EPDM, NBR, Viton (FKM), Hypalon, Neoprene | ASTM D2000, ISO 6446 |

| Leakage Class | Permissible leakage rate across the seat. | ANSI/FCI 70-2 Class VI (Bubble-tight shut-off) | ISO 5208, API 598 |

| End Connection | Method of connecting to piping system. | Wafer, Lug, Double Flanged (ASME B16.47 B) | ASME B16.5, ASME B16.47, EN 1092-1/2 |

| Operating Torque | Force required to open/close the valve. | Varies significantly by size and pressure (e.g., 50 Nm to 5000 Nm+) | Design specific, actuator sizing |

| Flow Coefficient (Cv/Kv) | Valve's flow capacity (higher is better for less pressure drop). | Typically high due to quarter-turn design, varies by disc profile. | ISA 75.01.01 |

| Actuation Type | Manual, Electric, Pneumatic, Hydraulic. | Lever, Gearbox, Electric Actuator, Pneumatic Actuator | ISO 5211 (Actuator Mounting) |

| Life Cycle Expectancy | Number of open/close cycles before significant wear. | Typically 10,000 to 100,000+ cycles, depending on service conditions. | Manufacturer testing, application specific |

The selection of the appropriate rubber sealed butterfly valve is heavily influenced by these parameters. For instance, in high-purity water systems, a valve with an EPDM seat and stainless steel body/disc would be preferred due to its corrosion resistance and non-leaching properties, while in petrochemical applications handling aggressive hydrocarbons, a Viton seat with a carbon steel body might be more suitable. The specific pressure and temperature ratings must align with system requirements to prevent premature failure. The ability of the rubber sealing butterfly valve to achieve bubble-tight shut-off (Class VI) is critical in applications where zero leakage is mandatory, such as preventing backflow or isolating sensitive equipment. Understanding these parameters not only guides selection but also provides a framework for performance benchmarking and long-term asset management, ensuring that the chosen valve delivers maximum efficiency and reliability throughout its operational life.

Diverse Application Scenarios and Industry Benefits

The adaptability of butterfly valve rubber designs allows them to thrive across an expansive array of industrial applications, offering distinct advantages that contribute to operational efficiency, cost savings, and enhanced safety. Their compact design, lightweight nature, and ease of automation make them highly appealing for both new installations and retrofitting projects.

Water and Wastewater Treatment: This sector is a primary user of rubber-seated butterfly valves. From raw water intake to treated effluent discharge, these valves are essential for flow isolation, regulation, and preventing backflow. Their non-clogging design is particularly beneficial when handling media containing suspended solids or sludge. The excellent sealing capability ensures minimal leakage, crucial for conserving water resources and maintaining system pressure. The use of EPDM seats is prevalent due to its superior resistance to water, chlorine, and common water treatment chemicals, ensuring a long service life in these critical applications. Data from municipal utility reports often highlight significant reductions in non-revenue water loss attributed to the deployment of high-integrity rubber sealed butterfly valve installations within distribution networks.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, butterfly valves are used extensively for regulating the flow of chilled water, hot water, and condenser water. Their low pressure drop characteristics contribute to energy efficiency by reducing pump work, while their compact size is ideal for space-constrained plant rooms. The quick quarter-turn operation enables precise temperature control and zoning within large commercial and industrial buildings.

Petrochemical and Chemical Processing: While requiring careful material selection, specific rubber sealing butterfly valve compounds like Viton (FKM) or Hypalon (CSM) enable their use in moderate chemical services. They are employed in utility lines, cooling water systems, and less aggressive chemical transfer lines where cost-effectiveness and quick operation are valued. Their robust design, when paired with chemically resistant elastomers and body materials (e.g., stainless steel), provides reliable isolation and control for various process streams, contributing to both safety and process optimization. The chemical industry, with its diverse range of fluids, relies on the flexibility of valve designs to meet specific compatibility requirements, and the advancements in elastomer technology have expanded the range of suitable applications for these valves.

Power Generation: In power plants, especially in cooling water circuits, raw water intake, and wastewater discharge systems, large-diameter butterfly valve rubber installations are commonplace. Their ability to handle high flow rates with minimal pressure loss is crucial for maintaining the efficiency of cooling towers and other water-intensive processes. Their robust construction ensures reliability in demanding continuous operation environments.

Mining and Pulp & Paper: In the mining industry, these valves are used for water lines, slurry lines (with appropriate disc and seat material selection), and general utility services. In pulp and paper mills, they are found in water and process fluid lines, where their ability to handle fibrous slurries and corrosive chemicals (with suitable material upgrades) is highly beneficial. Their design minimizes clogging, which is a common issue in these industries, thereby reducing downtime and maintenance costs. The low maintenance requirement of these valves, coupled with their durable design, ensures continuous operation in harsh industrial environments, directly impacting productivity and operational expenditure.

Food & Beverage: Specific variants with FDA-approved elastomers (e.g., certain EPDM and silicone grades) and highly polished stainless steel bodies are used in hygienic applications for general utility services and less critical process lines. Their clean-in-place (CIP) compatibility and ease of maintenance are advantageous.

Across these sectors, the primary advantages consistently highlighted are their energy efficiency due to low-pressure drop, superior corrosion resistance when appropriate materials are chosen, and exceptional long-term leak tightness, contributing to environmental protection and reduced operational costs. The quarter-turn operation also allows for rapid response times, critical in emergency shut-off situations, further enhancing safety protocols within industrial facilities.

Technical Advantages of Rubber Sealing Butterfly Valves

The technical superiority of rubber sealed butterfly valve designs stems from several key features that make them highly effective for isolation and throttling applications. These advantages are particularly pronounced due to the inherent properties of the elastomer seat and the optimized design of the disc-seat interface.

Superior Sealing Performance (Bubble-Tight Shut-Off): One of the most significant advantages of a butterfly valve rubber is its ability to achieve ANSI/FCI 70-2 Class VI shut-off, commonly known as bubble-tight shut-off. This level of sealing is achieved by the resilient rubber seat conforming tightly around the disc when the valve is in the closed position, creating a highly effective barrier against fluid leakage. The elasticity of the rubber allows it to compensate for minor imperfections in the disc or body, ensuring a complete seal even under varying pressure conditions. This capability is critical in applications where zero leakage is paramount, such as preventing environmental contamination, maintaining system integrity, or ensuring safety protocols in hazardous fluid handling. Compared to metal-seated valves that often achieve Class IV or V, the resilient seat offers a superior, more forgiving seal.

Excellent Corrosion Resistance: While the metal components of the valve provide structural integrity, the rubber seat offers a vital layer of protection against corrosive media. By carefully selecting the appropriate elastomer – EPDM for water and general chemicals, NBR for hydrocarbons, or Viton for aggressive acids and high temperatures – the rubber sealing butterfly valve can effectively resist degradation from a wide range of corrosive fluids. This material compatibility extends the valve's service life and reduces the need for frequent maintenance or replacement in chemically active environments. For instance, in desalination plants, where highly corrosive seawater is handled, the selection of marine-grade body materials coupled with an EPDM or Hypalon seat significantly prolongs the valve's operational lifespan.

Low Maintenance and Cost-Effectiveness: The design simplicity of butterfly valves, coupled with the resilient nature of the rubber seat, results in fewer moving parts and less wear and tear compared to more complex valve types. The self-lubricating properties of some elastomers and the inherent design minimize friction between the disc and seat during operation, contributing to reduced maintenance requirements. When maintenance is required, the modular design often allows for easy seat replacement without removing the entire valve body from the pipeline, significantly reducing downtime and labor costs. Furthermore, the initial cost of butterfly valve rubber is generally lower than equivalent globe or gate valves for similar applications and sizes, offering a more economically viable solution for many industrial processes. This combination of low initial cost and reduced lifetime maintenance expenditure makes them a highly attractive option for large-scale infrastructure projects.

Ease of Operation and Automation: Butterfly valves are quarter-turn valves, meaning they transition from fully open to fully closed with a 90-degree rotation of the disc. This rapid operation allows for quick shut-off or opening, critical in emergency situations or processes requiring fast response times. Their relatively low torque requirements, especially for smaller sizes, make them easy to operate manually with levers or gearboxes. For larger valves or automated systems, their quarter-turn nature simplifies integration with pneumatic, electric, or hydraulic actuators, enabling precise remote control and integration into SCADA (Supervisory Control and Data Acquisition) systems. The ISO 5211 mounting pad standard ensures universal compatibility with a wide range of actuators, offering flexibility in automation solutions.

Durability in Harsh Environments: The robust construction, combined with the resilient and resistant properties of vulcanized rubber, makes these valves exceptionally durable. They can withstand significant temperature fluctuations, mild abrasive media, and continuous cycling, maintaining their sealing integrity over extended periods. Their design is less prone to clogging from suspended solids compared to gate valves, making them suitable for slurries and wastewater. The ability of the vulcanized rubber to resist compression set and aging means it retains its sealing capability even after prolonged exposure to operational pressures and media, ensuring reliable performance in the most demanding industrial settings. This inherent robustness translates directly into higher operational uptime and reduced risk of unexpected failures, which are critical considerations in continuous process industries.

Manufacturer Comparison and Selection Criteria for Rubber Seated Butterfly Valves

Choosing the right manufacturer for butterfly valve rubber is as crucial as selecting the valve itself. The market is saturated with various suppliers, each offering different levels of quality, customization, and support. For B2B buyers, a strategic approach to vendor selection can significantly impact project success, operational costs, and long-term reliability.

1. Certifications and Compliance: A reputable manufacturer will possess comprehensive international certifications such as ISO 9001 for quality management, ensuring consistent production standards. For valves, adherence to industry-specific standards like API 609 (Butterfly Valves: Double Flanged, Lug- and Wafer-Type) for design and testing, ASME B16.47 (Large Diameter Steel Flanges) for flange compatibility, and ANSI/AWWA C504 (Rubber-Seated Butterfly Valves) for waterworks applications, are non-negotiable. Manufacturers who hold these certifications demonstrate a commitment to rigorous quality control and technical compliance, significantly mitigating risks associated with product failure or non-compliance in critical applications. For instance, compliance with FDA regulations for specific food-grade elastomers, or ATEX directives for explosive environments, showcases a manufacturer's specialized capabilities and commitment to safety.

2. Experience and Track Record: Longevity in the industry often correlates with expertise. Manufacturers with decades of experience in producing rubber sealed butterfly valve solutions have a deeper understanding of material science, design optimization, and application challenges. Their track record, evidenced by successful project implementations and long-standing client relationships, provides a strong indicator of reliability and trustworthiness. Inquire about their service history, significant projects, and testimonials, particularly in applications similar to your own. A manufacturer with a proven history in demanding sectors like oil & gas or power generation is likely to offer more robust solutions for general industrial use.

3. Customization Capabilities: While standard rubber sealing butterfly valve designs suffice for many applications, complex industrial processes often require tailored solutions. A superior manufacturer offers extensive customization options, including specialized body materials (e.g., Duplex/Super Duplex Stainless Steel), exotic disc coatings, specific elastomer compounds for extreme temperatures or aggressive chemicals, and custom actuation solutions. The ability to engineer bespoke solutions indicates a deep technical understanding and flexibility to meet unique project demands, ultimately providing a valve that precisely fits the application, optimizing performance and extending service life. This flexibility in design and material selection highlights a manufacturer's engineering prowess and commitment to solving complex fluid control challenges.

4. Technical Support and After-Sales Service: The relationship with a valve manufacturer should extend beyond the initial purchase. Look for companies that offer comprehensive pre-sales technical consultation, helping you select the ideal valve for your specific needs. Post-sales support, including installation guidance, troubleshooting, spare parts availability, and warranty services, is equally vital. A manufacturer with readily accessible technical experts and efficient service channels ensures minimal downtime and sustained operational efficiency. This level of support often distinguishes a reliable long-term partner from a mere supplier.

5. Research and Development (R&D) Investment: The industrial valve market is continually evolving with new materials, smart technologies, and stricter environmental regulations. A forward-thinking manufacturer invests significantly in R&D to innovate and improve their product lines. This includes developing new elastomer compounds with enhanced chemical resistance or higher temperature ratings, incorporating IoT capabilities for predictive maintenance, or optimizing valve designs for even lower torque and higher efficiency. A company's commitment to R&D signals its dedication to staying at the cutting edge of valve technology, offering clients access to the most advanced and efficient solutions available.

Savvy ValveTech, for example, embodies many of these qualities, with a dedicated focus on quality, precision engineering, and customer-centric solutions for their ASME B16.47 B Series Vulcanized Rubber Seated Butterfly Valves. Their extensive service experience across diverse industries, coupled with strict adherence to international standards, positions them as a reliable partner for critical fluid control applications.

Custom Solutions and Engineering Excellence

In today's complex industrial landscape, off-the-shelf valve solutions often fall short of meeting the highly specific and demanding requirements of certain applications. This is where the ability to provide custom-engineered butterfly valve rubber solutions becomes a significant competitive advantage and a critical factor for B2B clients. Engineering excellence in this domain goes beyond mere manufacturing; it involves a deep understanding of fluid dynamics, material science, industrial processes, and an unwavering commitment to problem-solving.

Custom solutions typically arise from several scenarios:

Extreme Operating Conditions: Applications involving exceptionally high or low temperatures, corrosive or abrasive media, or vacuum conditions often require valve components made from specialized alloys or elastomers not found in standard product lines. For instance, while EPDM is excellent for water, an application involving strong oxidizing agents at elevated temperatures might necessitate a perfluoroelastomer (FFKM) seat, which has superior chemical resistance but is more expensive. Similarly, high-pressure slurry applications might demand discs with ceramic coatings to withstand erosion, coupled with specially formulated, abrasion-resistant rubber sealed butterfly valve seats.

Unique Piping Configurations: Non-standard pipe diameters, unusual face-to-face dimensions, or specific flange drilling patterns (e.g., adherence to older regional standards not covered by current ASME/EN norms) often require custom valve body castings or modifications. This ensures seamless integration into existing infrastructure without costly pipeline reconfigurations. A manufacturer with strong engineering and casting capabilities can produce valves to precise dimensional specifications.

Specific Performance Requirements: Some processes demand precise flow control characteristics, extremely low fugitive emissions, or a very specific torque profile for automated systems. This might involve designing custom disc profiles, integrating advanced packing systems, or fine-tuning the seat-disc geometry to achieve the desired performance curve. Data from fluid flow simulations (CFD) can be used to optimize disc design for minimal pressure drop and cavitation.

A manufacturer capable of delivering custom rubber sealing butterfly valve solutions possesses several key attributes:

Robust R&D and Engineering Teams: They have a team of highly skilled engineers (mechanical, materials, chemical) who can analyze complex application requirements, perform detailed calculations, conduct FEA (Finite Element Analysis) for stress distribution, and design bespoke valve components. This includes metallurgical experts who can recommend the optimal alloy for a given corrosive environment, and polymer scientists specializing in elastomer compounding for specific chemical and temperature resistances.

Advanced Manufacturing Capabilities: This includes flexible casting and machining facilities capable of handling a wide range of materials and complex geometries, as well as in-house vulcanization processes for tailored rubber compounds. Their quality control labs are equipped for extensive material testing (tensile strength, hardness, chemical resistance) and performance validation.

Prototyping and Testing Facilities: The ability to quickly prototype new designs and conduct rigorous testing under simulated operating conditions ensures that custom solutions meet performance expectations before full-scale production. This includes specialized pressure testing for extremely high or low pressures, and cycle testing simulating years of operation.

Collaborative Approach: The best custom solution providers engage in a close collaborative dialogue with the client, understanding their process, challenges, and long-term goals. This ensures that the engineered solution is not just technically sound but also economically viable and aligned with the client's operational objectives. Through this iterative process, solutions for unique challenges are developed, such as valves designed for sub-zero liquid natural gas (LNG) applications with specialized low-temperature elastomers, or valves for heavily abrasive mining slurries using reinforced rubber seats and hardened discs.

Investing in a manufacturer with strong engineering excellence and custom solution capabilities ensures that even the most challenging fluid control problems can be addressed with reliable, high-performance butterfly valve rubber technology, ultimately contributing to enhanced operational safety and efficiency.

Real-World Application Cases and Success Stories

The theoretical advantages and technical specifications of butterfly valve rubber truly come to life through their successful implementation in diverse and demanding industrial environments. These real-world application cases underscore the versatility, reliability, and economic benefits derived from deploying high-quality rubber-seated butterfly valves.

Case Study 1: Municipal Water Treatment Plant Expansion

A major municipal water treatment plant undergoing a significant expansion faced challenges with its existing isolation valves, which exhibited persistent leakage, leading to water loss and increased pumping energy consumption. After a comprehensive engineering review, the plant opted to replace over 50 large-diameter (DN600 to DN1200) old gate valves with ASME B16.47 B Series Vulcanized Rubber Seated Butterfly Valves, equipped with EPDM seats and ductile iron bodies. The primary objective was to achieve bubble-tight shut-off (Class VI) to eliminate leakage and improve system efficiency. Post-installation, the plant reported a reduction in non-revenue water (NRW) by 7%, which translated to significant savings in water resources and an estimated 15% decrease in electricity consumption for their pumping stations over the first year. The easy operation and minimal maintenance of the new rubber sealed butterfly valve installations also significantly reduced operational labor costs.

Case Study 2: Chemical Processing Facility Upgrade

A large chemical manufacturing facility required reliable shut-off valves for its cooling water lines, which contained process water with trace amounts of mild acids and elevated temperatures (up to 90°C). Previous valves experienced frequent seat degradation and leakage due to chemical attack and thermal stress. The facility implemented rubber sealing butterfly valve units featuring Viton (FKM) seats and stainless steel (CF8M) bodies and discs. Viton’s excellent chemical and temperature resistance proved crucial in this aggressive environment. After 18 months of continuous operation, the new valves showed no signs of seat degradation or leakage, vastly outperforming their predecessors. This upgrade resulted in a 30% reduction in valve-related maintenance interventions and a substantial improvement in process uptime, validating the precise material selection for specific challenging media.

Case Study 3: Hydropower Dam Intake Control

A hydropower plant needed robust and reliable valves for its intake control system, managing large volumes of raw river water containing abrasive sediments. The large flow rates and the need for immediate isolation during maintenance or emergencies dictated the use of high-performance valves. The solution involved custom-engineered large-diameter (DN1500) butterfly valve rubber units with abrasion-resistant rubber seats (specifically formulated EPDM for abrasive media) and heavy-duty, corrosion-resistant disc coatings. These valves were integrated with hydraulic actuators for rapid response. The client reported exceptional performance, with the valves providing consistent, leak-free shut-off despite the challenging media. The low operating torque and robust design ensured long-term reliability in an extremely critical application, contributing to the safe and efficient generation of electricity. The enhanced design of these valves significantly reduced the typical wear rates associated with abrasive flow, extending overhaul intervals and ensuring continuous power generation.

Client Feedback and Service Cases:

"Our wastewater treatment plant operates 24/7, and reliability is paramount. The rubber sealing butterfly valve solutions provided have proven incredibly durable and maintain their seal even after years of continuous cycling. The technical support we received during installation was invaluable, and their team's responsiveness is commendable." - Operations Manager, Major Regional Wastewater Authority.

Another notable service case involved a client experiencing frequent valve failures in a seawater cooling system due to galvanic corrosion and seal degradation. Upon consultation, it was identified that the incorrect body and seat materials were being used. A detailed material analysis and selection process led to the recommendation of duplex stainless steel bodies with specialized EPDM seats. The subsequent installation not only resolved the corrosion issues but also extended the valve's service life by over 100%, demonstrating the importance of material expertise and client-specific engineering support. These examples demonstrate how selecting the right butterfly valve rubber solution, backed by expert consultation and robust after-sales support, leads to tangible operational improvements, cost savings, and enhanced system reliability for industrial clients.

Ensuring Trust and Reliability: Adhering to Principles

In the B2B sphere, particularly for critical components like industrial valves, building trust and demonstrating credibility are paramount. This aligns perfectly with Google's (Experience, Expertise, Authoritativeness, Trustworthiness) guidelines, which emphasize the importance of high-quality, reliable information. As a provider of butterfly valve rubber solutions, our commitment to these principles is embedded in every aspect of our operations, from design and manufacturing to customer service and delivery.

Expertise: Our expertise is rooted in decades of specialized knowledge in valve engineering and fluid control systems. Our team comprises highly qualified mechanical engineers, materials scientists, and fluid dynamics specialists who understand the intricate details of valve design, material compatibility, and application-specific challenges. This deep technical proficiency allows us to not only manufacture standard rubber sealed butterfly valve products but also to engineer highly specialized solutions for the most demanding environments. We regularly publish technical articles and participate in industry forums to share our insights, contributing to the broader knowledge base of the industrial valve sector.

Experience: Our extensive experience is reflected in the thousands of successful valve installations across various industries worldwide. We have encountered and resolved a vast array of fluid control challenges, providing us with invaluable insights into real-world operational scenarios. This hands-on experience allows us to provide practical, effective advice and solutions, anticipating potential issues before they arise. Our client success stories and testimonials are a testament to our proven track record and the long-term relationships we build based on reliable performance and exceptional service. We leverage this collective experience to continually refine our product designs and manufacturing processes, ensuring that each rubber sealing butterfly valve benefits from lessons learned in the field.

Authoritativeness: Our authoritative standing in the industry is backed by comprehensive certifications and adherence to global standards. We are ISO 9001 certified, demonstrating a robust quality management system that governs every stage of our valve production. Our products comply with critical industry standards such as ASME B16.47, API 609, ANSI/AWWA C504, and more, which are internationally recognized benchmarks for valve design, testing, and performance. We collaborate with leading research institutions and industry bodies to stay abreast of the latest advancements and contribute to the evolution of valve technology. Our service longevity, spanning over two decades, along with strategic partnerships with major industrial players, further solidifies our position as a trusted authority in butterfly valve rubber manufacturing. We also provide verifiable test data and performance curves for our products, offering transparent insights into their capabilities.

Trustworthiness: Trust is built through transparency, reliability, and consistent support. We foster trustworthiness through:

FAQ Module: We maintain a comprehensive FAQ section to address common queries regarding valve selection, installation, maintenance, and troubleshooting, providing readily accessible information to empower our clients.

Delivery Cycle Clarity: We provide clear and realistic delivery timelines, utilizing efficient logistics partnerships to ensure on-time product delivery. Our robust supply chain management minimizes delays and keeps clients informed at every step of the process.

Quality Assurance and Warranty: All our valves undergo stringent quality control checks and are backed by a comprehensive warranty, typically ranging from 12 to 24 months from the date of installation or 18 months from shipment, whichever comes first, against manufacturing defects. This warranty reflects our confidence in the durability and reliability of our products.

Dedicated Customer Support: Our dedicated customer support team is available to provide immediate technical assistance, order tracking, and after-sales service. We prioritize responsiveness and resolution, ensuring that our clients receive the support they need to maintain seamless operations. This includes field service engineers capable of on-site diagnostic and repair.

By upholding these principles, we ensure that our clients receive not just high-quality products, but also reliable information, expert guidance, and unwavering support, making us a dependable partner for all their industrial fluid control needs.

Future Trends in Rubber Seated Butterfly Valve Technology and Conclusion

The landscape of industrial fluid control is continuously evolving, driven by demands for greater efficiency, sustainability, and digitalization. Butterfly valve rubber technology, while mature, is not immune to these transformative trends. Manufacturers are investing in several key areas to push the boundaries of performance and applicability.

Advanced Material Science: Research into new elastomer compounds is ongoing, aiming to expand the operating envelope of rubber sealed butterfly valve solutions. This includes developing rubber seats with enhanced resistance to extreme temperatures (both cryogenic and high heat), superior chemical inertness against a wider range of aggressive media, and improved abrasion resistance for handling slurries and abrasive fluids. Nanomaterials and composites are being explored to create seats with unprecedented durability and performance characteristics. The goal is to provide a rubber seat that can perform reliably in environments traditionally reserved for metal-seated or specialized alloy valves, offering a more cost-effective and flexible alternative. Furthermore, the development of self-healing elastomers, while still in early stages for industrial valves, holds promise for automatically repairing minor damage to valve seats, significantly extending service life and reducing maintenance.

Smart Valve Technologies and IoT Integration: The integration of smart sensors and IoT (Internet of Things) capabilities into rubber sealing butterfly valve designs is a major trend. These "smart valves" can monitor critical parameters such as valve position, torque, temperature, pressure, and even detect incipient leakage in real-time. This data can be transmitted wirelessly to a central control system, enabling predictive maintenance, optimizing operational performance, and preventing catastrophic failures. For instance, by analyzing deviations in operating torque or subtle changes in seal integrity, maintenance teams can intervene proactively, scheduling repairs before a complete breakdown occurs, thereby minimizing downtime and operational disruptions. This transition from reactive to predictive maintenance is a game-changer for critical infrastructure.

Sustainability and Eco-Friendly Manufacturing: With increasing global emphasis on environmental protection, manufacturers are adopting more sustainable practices. This includes optimizing manufacturing processes to reduce energy consumption and waste, utilizing recyclable materials where possible, and developing elastomers that are free from harmful substances. The long service life and high efficiency of butterfly valve rubber already contribute to sustainability by reducing the need for frequent replacements and minimizing energy losses from leakage. Future innovations will likely focus on even more environmentally benign production methods and materials that further minimize the ecological footprint throughout the valve's lifecycle.

Modular Designs and Customization: While customization is already a strength, future trends will see even greater modularity in valve design, allowing for easier interchangeability of components, faster assembly, and more flexible adaptation to specific client needs. This modular approach will streamline manufacturing processes and reduce lead times for custom solutions, making high-performance valves more accessible and cost-effective for a broader range of applications.

In conclusion, the butterfly valve rubber, particularly advanced designs like the ASME B16.47 B Series Vulcanized Rubber Seated Butterfly Valve, remains an indispensable component in modern industrial fluid control. Its unique blend of efficient operation, superior sealing, corrosion resistance, and cost-effectiveness positions it as a preferred choice across diverse sectors from water treatment to chemical processing. As industries continue to evolve, driven by technological advancements and environmental imperatives, the resilient-seated butterfly valve will undoubtedly continue to adapt and innovate, playing a crucial role in ensuring the efficiency, safety, and sustainability of global infrastructure. Choosing a manufacturer that demonstrates expertise, experience, authoritativeness, and trustworthiness is essential for harnessing the full potential of this vital valve technology.

References and Further Reading

- Valves Online - Butterfly Valve Standards Overview A comprehensive guide to international standards applicable to butterfly valves, including API and ASME.

- Flow Control Network - Elastic Seat Butterfly Valves: A Guide to Best Practices Discusses optimal selection and application of resilient-seated butterfly valves in various industries.

- ISA - InTech Magazine: Valve Sealing for Severe Service Explores advancements in sealing technologies for industrial valves, including elastomeric compounds.

- WaterWorld - Valves That Last in Water Distribution Systems Insights into the durability and selection of valves for municipal water applications.