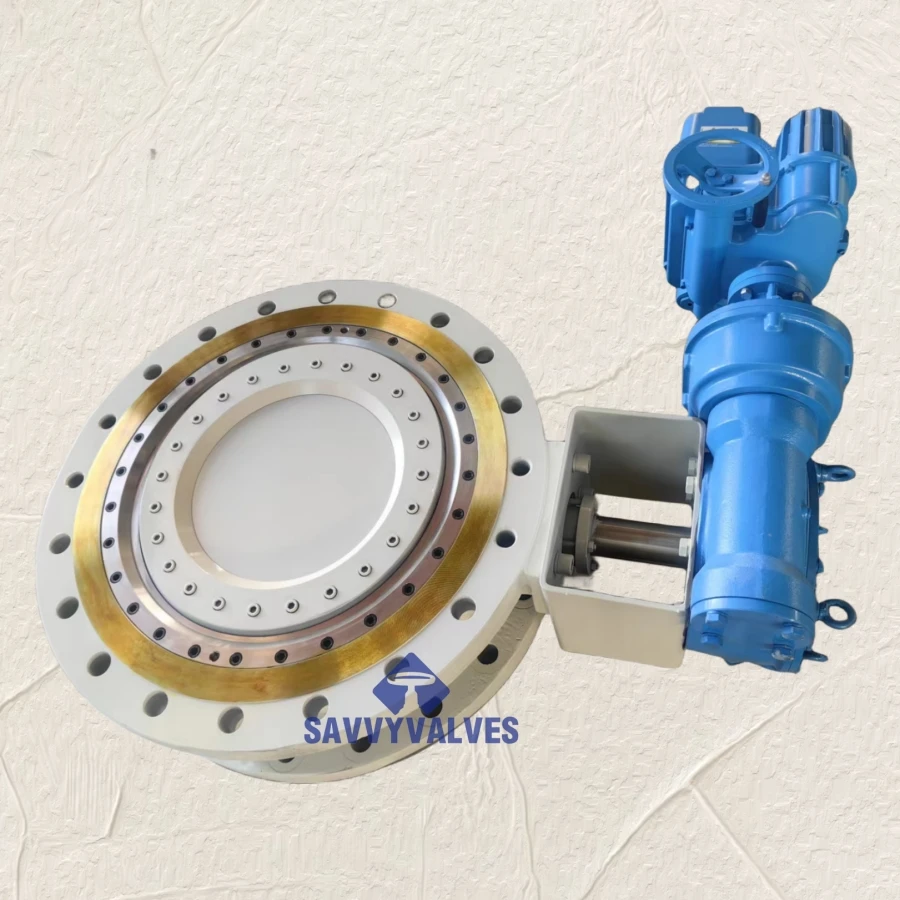

In industrial piping systems, the ball valve flange plays a crucial role in controlling fluid flow with ease and reliability. Whether in oil and gas, water treatment, chemical processing, or power generation, choosing a robust and durable ball valve flange ensures smooth operation and minimal downtime.

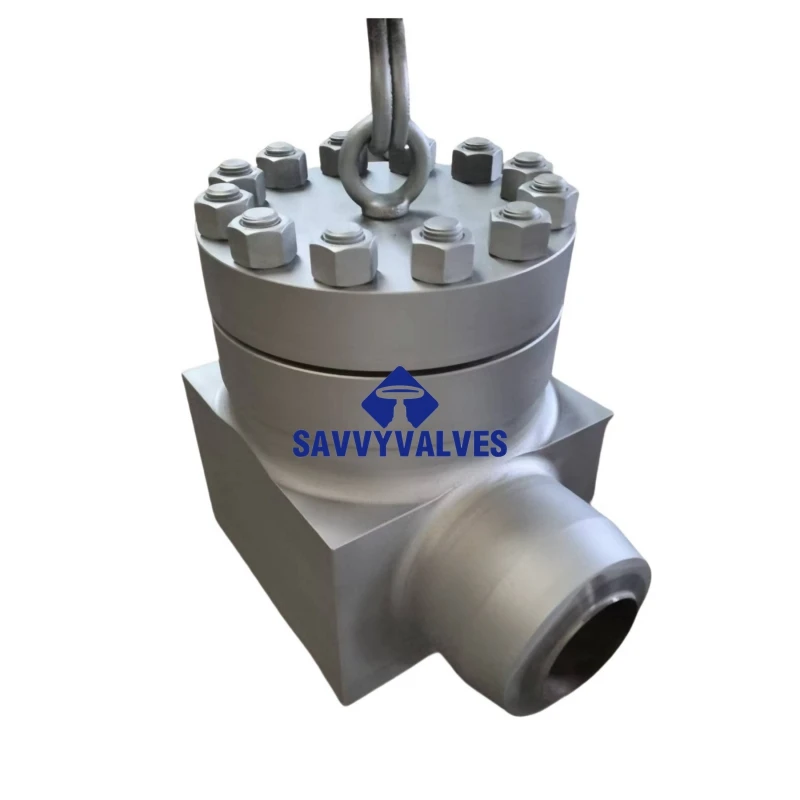

A well-designed flange ball valve offers excellent sealing performance, easy installation, and maintenance advantages. Materials such as stainless steel, carbon steel, and alloy steels are commonly used to manufacture these valves to withstand harsh environments, corrosion, and high pressure.

When selecting a ball valve flange, it's essential to consider the flange connection standards to ensure compatibility with existing pipeline components. Investing in superior quality valves not only improves system efficiency but also helps prevent costly leaks and operational failures.

Factors Affecting the Flange Type Ball Valve Price You Should Know

When evaluating the flange type ball valve price, several important factors come into play. Price variations are often influenced by valve size, material selection, manufacturing standards, and additional features.

Larger valve sizes generally demand more raw material and more complex manufacturing processes, which increases the flange type ball valve price. The choice of material—such as stainless steel 304, 316, or specialized alloys—also significantly affects cost due to their different corrosion resistance and durability levels.

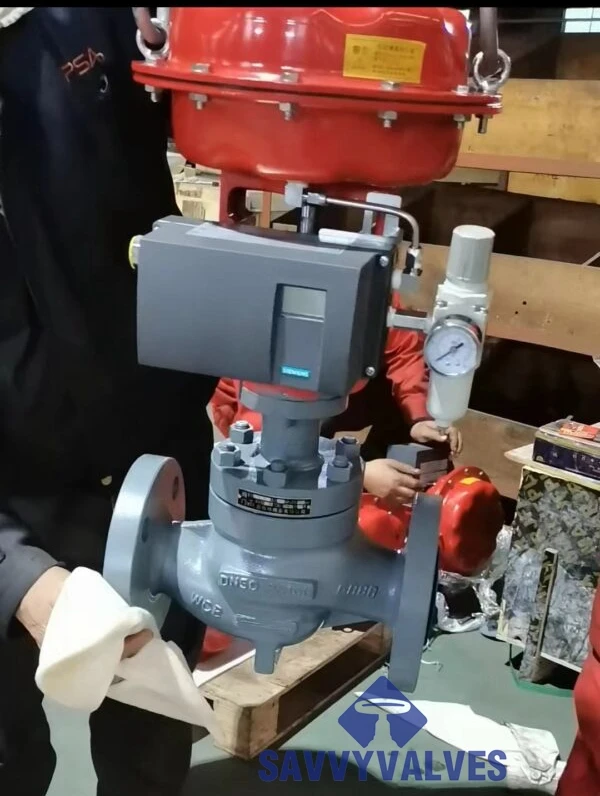

Moreover, valves that comply with international standards like API, ANSI, or DIN typically command higher prices because of their tested quality and reliability. Customizations such as special coatings, actuators, or enhanced sealing technologies also impact the final flange type ball valve price.

Understanding these factors helps buyers make informed decisions balancing cost with performance and longevity.

Why Choose a China Flange Ball Valve for Your Industrial Needs

China has become a global hub for manufacturing high-quality industrial valves, including the china flange ball valve. Chinese manufacturers offer a wide range of flange ball valves that combine competitive pricing with adherence to international quality standards.

The china flange ball valve market features products that meet API, ISO, and CE certifications, ensuring reliability in various demanding applications. These valves are made with advanced precision manufacturing technologies and rigorous quality control processes.

Buying a china flange ball valve can provide excellent value, especially when sourcing large quantities or customized solutions. Additionally, many Chinese suppliers offer flexible MOQ, customization options, and efficient logistics, making them a trusted partner for global industries.

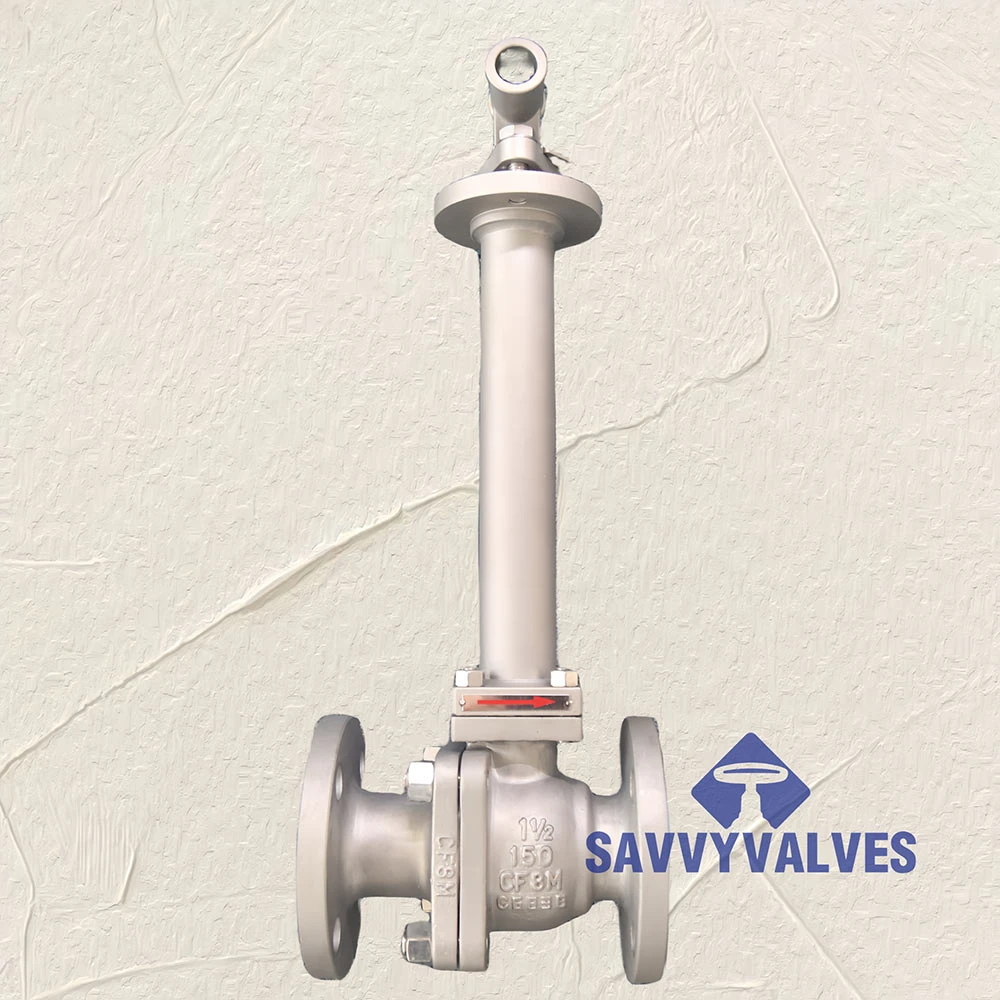

Understanding the Importance of Accurate 1 Flanged Ball Valve Dimensions

Accurate 1 flanged ball valve dimensions are critical for ensuring proper fit and function within a piping system. Even minor deviations can lead to installation difficulties, leakage, or system inefficiencies.

The term “1 flanged ball valve dimensions” typically refers to the dimensional specifications of a 1-inch ball valve with flanged ends, including face-to-face length, flange diameter, bolt circle, number of bolts, and flange thickness.

Ensuring these dimensions conform to recognized standards such as ANSI B16.5 or DIN is vital for interchangeability and smooth integration with existing pipeline components. When ordering or designing a system, requesting detailed 1 flanged ball valve dimensions from suppliers helps avoid costly modifications or delays.

Tips for Finding Reliable Suppliers of Ball Valve Flange Products

Finding a trustworthy supplier for your ball valve flange needs is essential for securing quality products and responsive service. A reputable supplier offers transparent product information, certifications, and technical support.

Look for suppliers who provide detailed datasheets covering material composition, pressure ratings, temperature limits, and compliance with relevant standards. Additionally, verified manufacturing capabilities and after-sales services such as installation guidance or warranty policies enhance supplier reliability.

Many suppliers also offer customization services tailored to your specific application requirements, including special materials, coatings, or actuator options. Developing a strong partnership with your ball valve flange supplier ensures smoother procurement cycles and long-term operational success.

ball valve flange FAQs

What materials are commonly used for ball valve flange bodies?

Common materials include stainless steel (304, 316), carbon steel, cast steel, and various alloys. The choice depends on the media, temperature, pressure, and corrosion resistance requirements.

How does the flange type ball valve price change with valve size?

As valve size increases, more material and larger components are needed, which raises manufacturing complexity and cost, leading to a higher price.

Are china flange ball valve products reliable for critical applications?

Yes, many Chinese manufacturers produce valves that meet international certifications like API, ISO, and CE, ensuring quality and reliability for critical industrial uses.

Why are precise 1 flanged ball valve dimensions important?

Accurate dimensions ensure compatibility with pipeline flanges, prevent leaks, and avoid installation issues, which is critical for safety and efficiency.

What certifications should I look for when buying a ball valve flange?

Look for certifications such as API 6D, ISO 9001, ANSI, CE, and any industry-specific approvals to ensure product quality and compliance with safety standards.