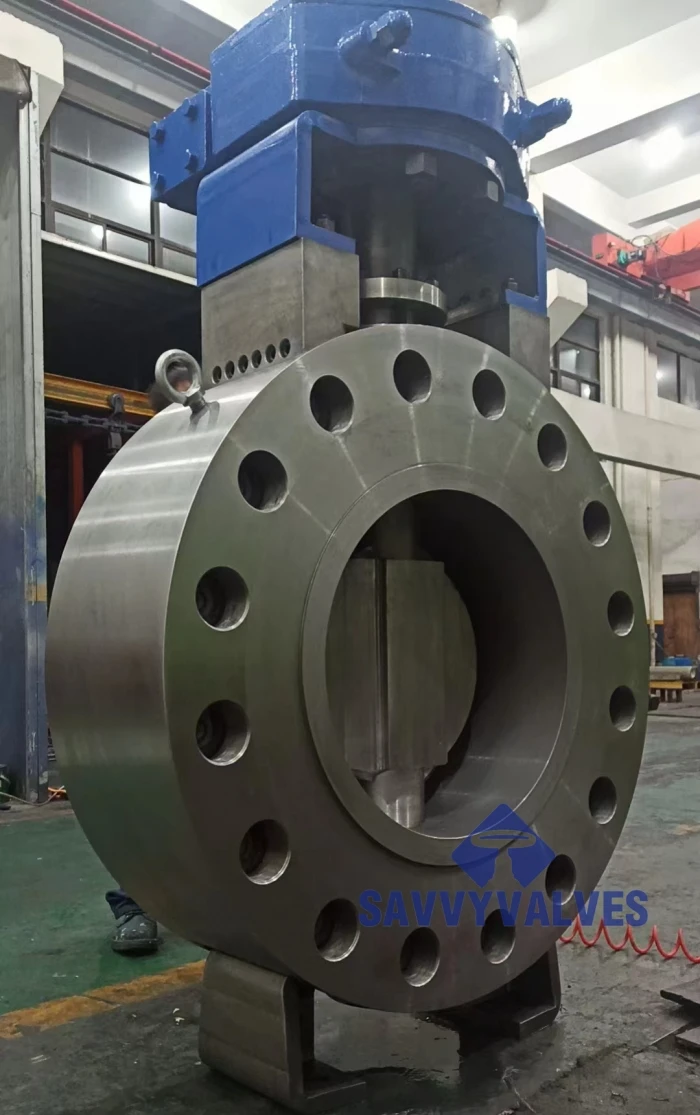

When it comes to efficient and reliable flow control in various industries, the butterfly valve stands out as a versatile and cost-effective solution. Known for their compact design, quick operation, and excellent sealing capabilities, butterfly valves are integral components in countless fluid handling systems. Whether you're looking for information on what a butterfly valve used for, seeking butterfly valves for sale, or curious about butterfly valves price, you’ve come to the right place. Discover how our high-quality butterfly valves can optimize your operations.

Butterfly Valve Used For: Versatility Across Industries

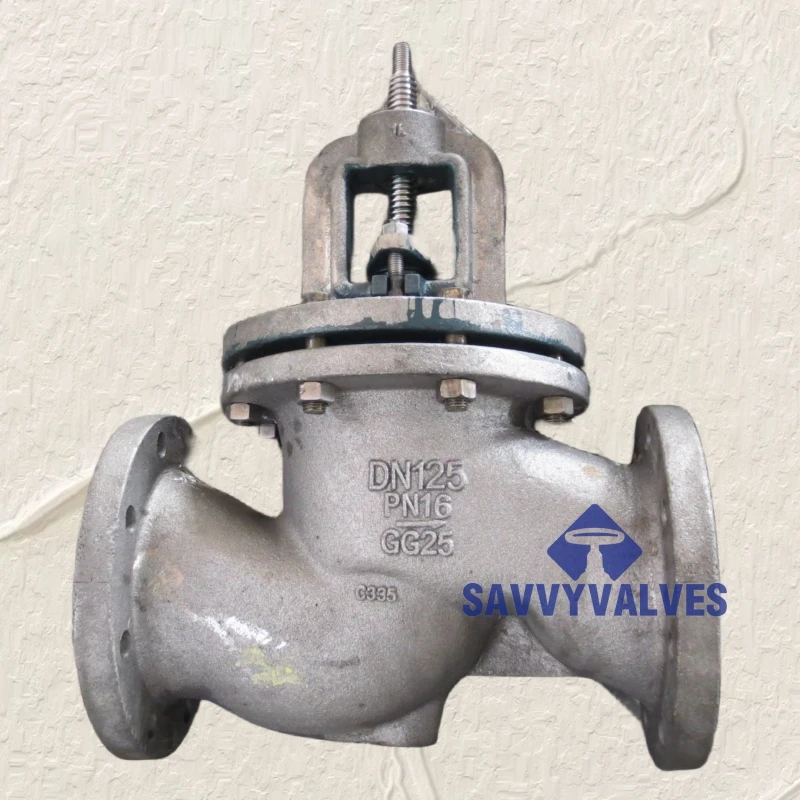

Understanding what a butterfly valve used for is crucial to appreciating its widespread applicability. These valves are incredibly versatile, finding use in a vast array of sectors including water treatment, chemical processing, HVAC systems, power generation, and food and beverage industries. Their primary function is to regulate or isolate the flow of liquids, gases, and slurries. The simple yet effective design, featuring a disc that rotates on a central axis, allows for quick opening and closing, making them ideal for applications requiring frequent operation.

From controlling cooling water in power plants to managing airflow in ventilation systems, the butterfly valve excels in applications where minimal pressure drop and a tight shut-off are essential. Their compact size compared to other valve types means they require less installation space and are easier to maintain, making them a preferred choice for many engineers and operators.

Butterfly Valves for Sale: Quality and Variety at Your Fingertips

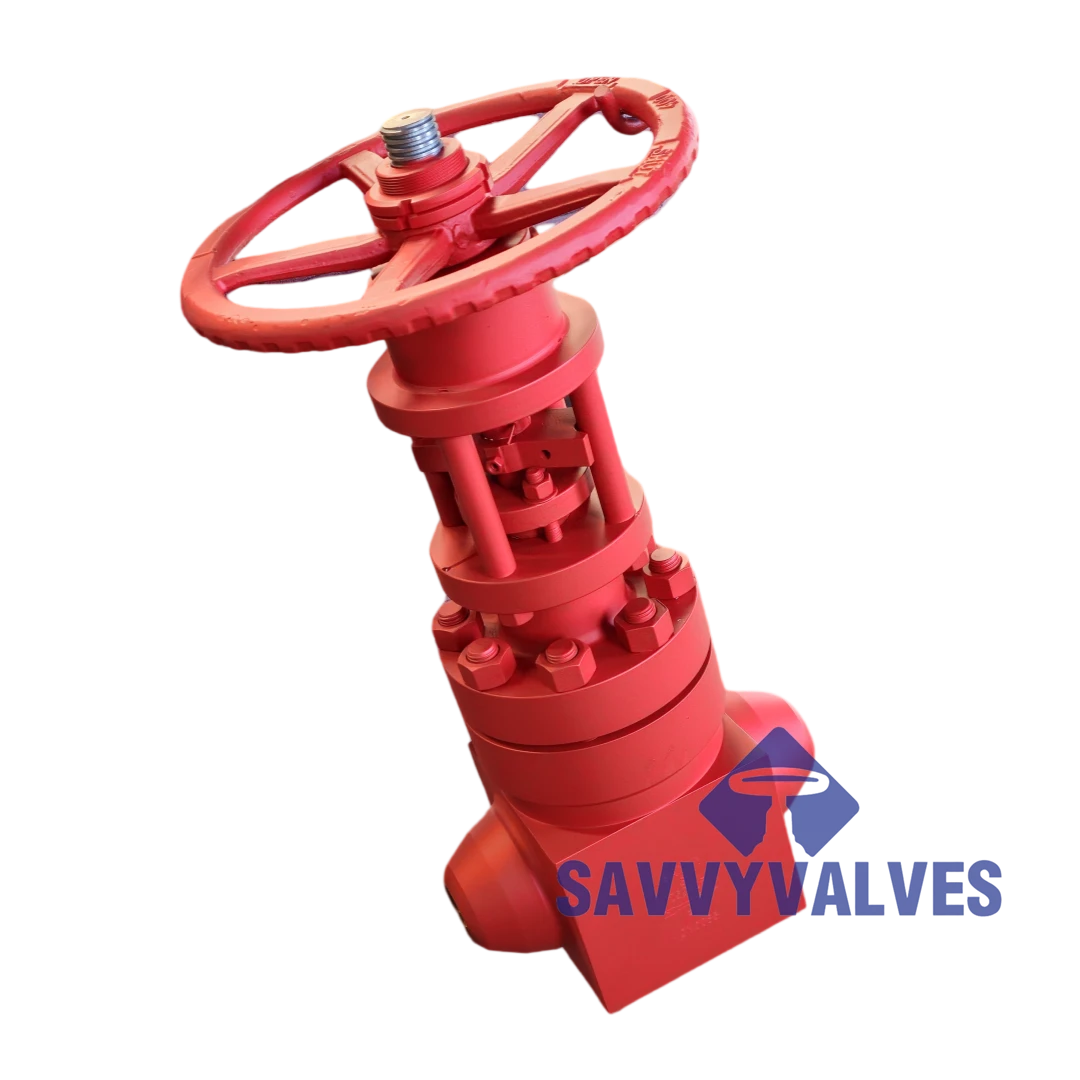

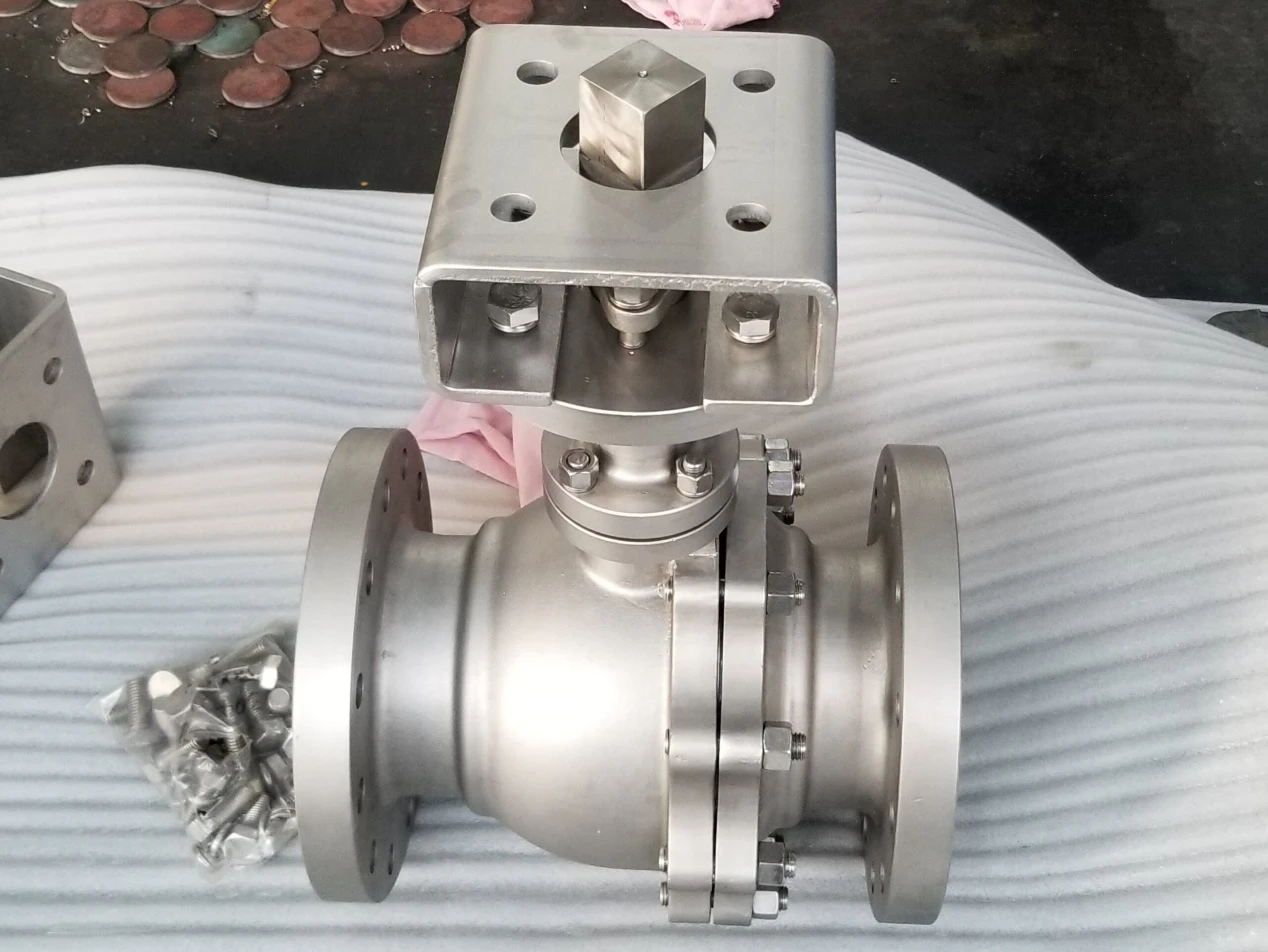

If you're in the market for butterfly valves for sale, our extensive inventory offers a wide range of options to meet your specific needs. We pride ourselves on providing high-quality butterfly valves constructed from durable materials such as ductile iron, stainless steel, and various alloys, ensuring long-lasting performance even in demanding environments. Our selection includes different types, such as concentric, eccentric, and high-performance butterfly valves, each designed to excel in particular applications.

Whether you require a valve for general utility, corrosive media, or high-temperature service, you’ll find the perfect solution among our butterfly valves for sale. We also offer various actuation options, including manual levers, gearboxes, pneumatic actuators, and electric actuators, allowing for precise control and integration into automated systems. Our commitment to quality ensures that every valve meets rigorous industry standards, providing you with reliability and peace of mind.

Butterfly Valves Price: Cost-Effective Solutions for Every Project

Understanding the butterfly valves price is a key factor in any purchasing decision. We offer competitive pricing across our entire range of butterfly valves, ensuring you get the best value without compromising on quality or performance. The cost of a butterfly valve can vary based on factors such as size, material, pressure rating, and actuation type. However, their generally lower manufacturing cost compared to other valve types, combined with their efficiency and longevity, makes them a very cost-effective choice in the long run.

We strive to provide transparent pricing and flexible options to accommodate projects of all scales. Whether you need a single valve for a small repair or a bulk order for a large industrial installation, our butterfly valves price structure is designed to offer affordability. Investing in our butterfly valves means investing in reliable flow control that minimizes maintenance costs and maximizes operational efficiency over their lifespan.

Why Choose Our Butterfly Valves? Efficiency, Durability, and Precision

Choosing the right butterfly valve can significantly impact the efficiency and reliability of your fluid control systems. Our butterfly valves are engineered for optimal performance, featuring a simple quarter-turn operation that allows for quick opening and closing. This rapid response time is critical in applications where immediate shut-off or flow regulation is necessary.

The robust design and choice of high-grade materials ensure exceptional durability and resistance to wear and tear, even in harsh operating conditions. Furthermore, our butterfly valves are designed for tight shut-off, preventing leakage and ensuring system integrity. Their lightweight and compact nature also simplify installation and reduce overall piping system stress. With superior flow characteristics and a wide range of configurations, our butterfly valves deliver precision control, making them an indispensable component for efficient fluid management.

Butterfly Valves FAQs

-

What is a butterfly valve and how does it work?

A butterfly valve is a type of quarter-turn valve that uses a rotating disc to control the flow of fluid in a pipeline. When the valve is fully open, the disc is rotated a quarter turn (90 degrees) parallel to the flow, allowing for full fluid passage. When closed, the disc rotates to be perpendicular to the flow, effectively blocking it. This simple mechanism allows for quick and efficient operation, making it ideal for applications requiring rapid on/off functionality or flow modulation.

-

What industries commonly use butterfly valves?

Butterfly valveile and are commonly used in a wide range of industries due tos are incredibly versat their efficient flow control and compact design. You'll find them extensively in water and wastewater treatment plants, chemical and petrochemical industries, HVAC systems for air handling, power generation facilities, food and beverage processing, and shipbuilding. Their ability to handle various media, including liquids, gases, and slurries, makes them a popular choice across diverse industrial applications.

-

Are there different types of butterfly valves for sale?

Yes, when looking for butterfly valves for sale, you'll encounter several types, each designed for specific applications and performance requirements. The main types include concentric (resilient seated), eccentric (double offset), and triple offset butterfly valves. Concentric valves are generally used for lower pressure and temperature applications, while eccentric and triple offset valves are designed for higher pressures, temperatures, and more demanding services, offering improved sealing and reduced wear. Additionally, they come with various actuation options like manual, pneumatic, and electric.

-

How does the butterfly valves price compare to other valve types?

Generally, the butterfly valves price is quite competitive, often being more affordable than other valve types like gate or globe valves, especially for larger line sizes. This is due to their simpler design, lighter weight, and smaller footprint, which reduces material and manufacturing costs. While prices vary depending on material, size, pressure rating, and automation features, butterfly valves typically offer an excellent balance of performance and cost-effectiveness, making them a popular choice for many budget-conscious projects.

-

How do I choose the right butterfly valve for my application?

Choosing the right butterfly valve requires considering several factors. First, identify the type of fluid (liquid, gas, slurry), its temperature, pressure, and chemical compatibility. Next, consider the required flow control (on/off or throttling) and the desired actuation method (manual, pneumatic, electric). The valve size, connection type (wafer, lug, flanged), and specific industry standards or certifications also play a crucial role. Consulting with a valve expert or supplier can help you select the most suitable butterfly valve for your specific application, ensuring optimal performance and longevity.