Double flanged butterfly valves and their derivatives (including butterfly valve double flange, double flange butterfly valve, butterfly valve double flange type, and double flanged short pattern butterfly valve) are recognized as an industry standard for critical flow control in marine, petrochemical, water supply and metallurgy sectors. This comprehensive guide explores their technological evolution, application landscapes, advanced manufacturing, and competitive vendor strategy – with specific focus on Marine U Section Double Flange Butterfly Valve.

2024 Industry Trends & Market Overview

According to recent market reports (Source: MarketsandMarkets 2024), the global market for double flanged butterfly valves is projected to exceed USD 12.4 billion by 2028, with year-on-year growth driven by smart infrastructure, industrial automation and demand for corrosion-resistant materials in harsh environments.

| Key Parameter | Value/Trend (2024) | Remarks |

|---|---|---|

| Material Base | Ductile Iron (DI), Cast Steel, Stainless Steel (304/316), Bronze | DI accounts for approx. 49% share |

| Size Range | DN50–DN3000 (2"–120") | Most common: DN100–DN600 |

| Pressure Ratings | PN6/PN10/PN16/PN25/PN40/150LB | Suitable for a variety of high-stress systems |

| Industry Usage | Water/Wastewater (32%), Marine (18%), Oil & Gas (14%), Power & Industrial (36%) | Expanding in desalination, offshore platforms |

| Life Cycle (ISO/EN compliant) | Up to 50,000 cycles | Tested per EN 12266-1, ISO 5208 |

| Smart Integration | Actuator ready (electric/pneumatic/hydraulic) | Rising in industrial 4.0 applications |

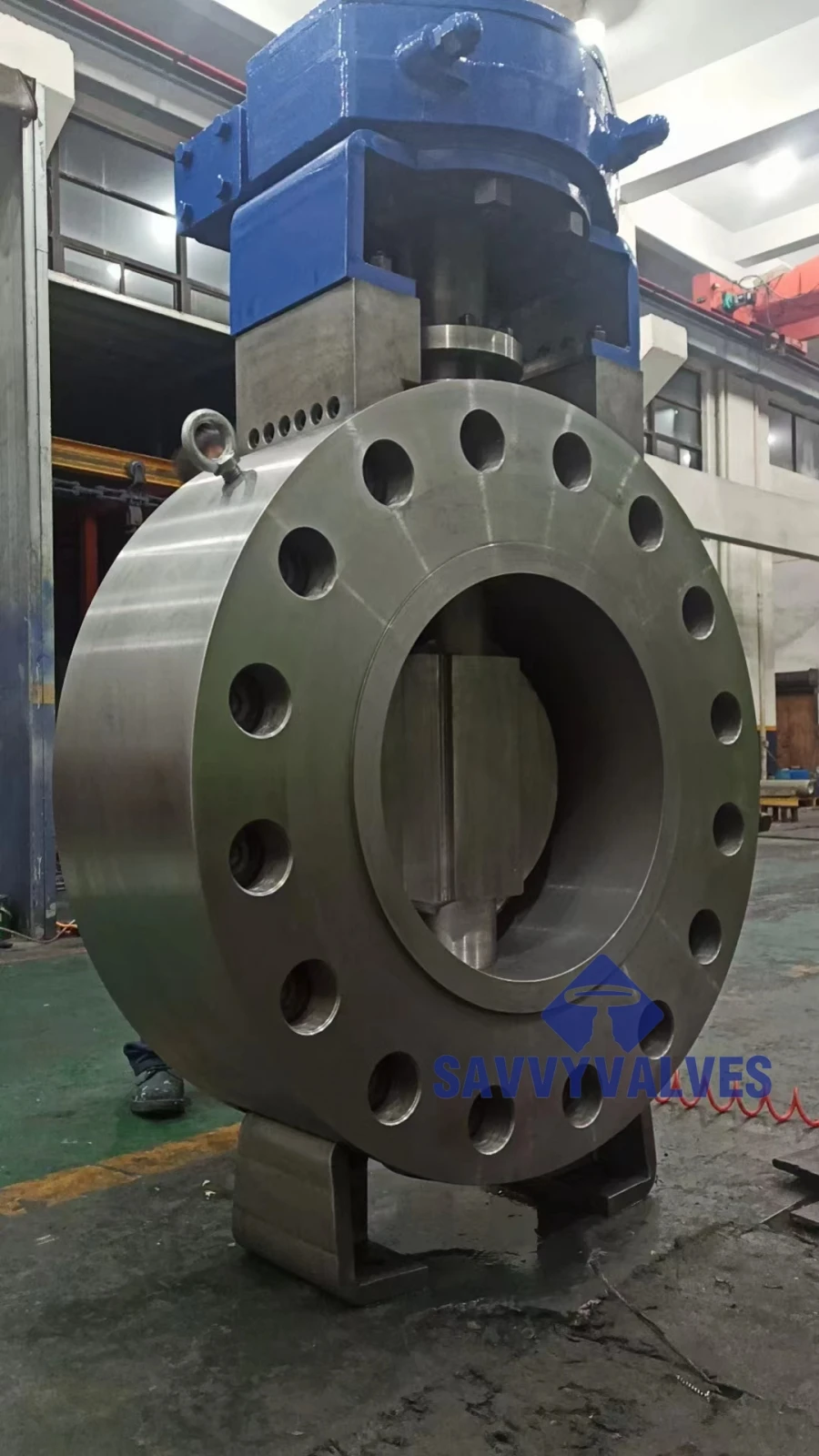

Marine-grade double flanged butterfly valves installed onboard for seawater control (Image © Savvy Valve Tech)

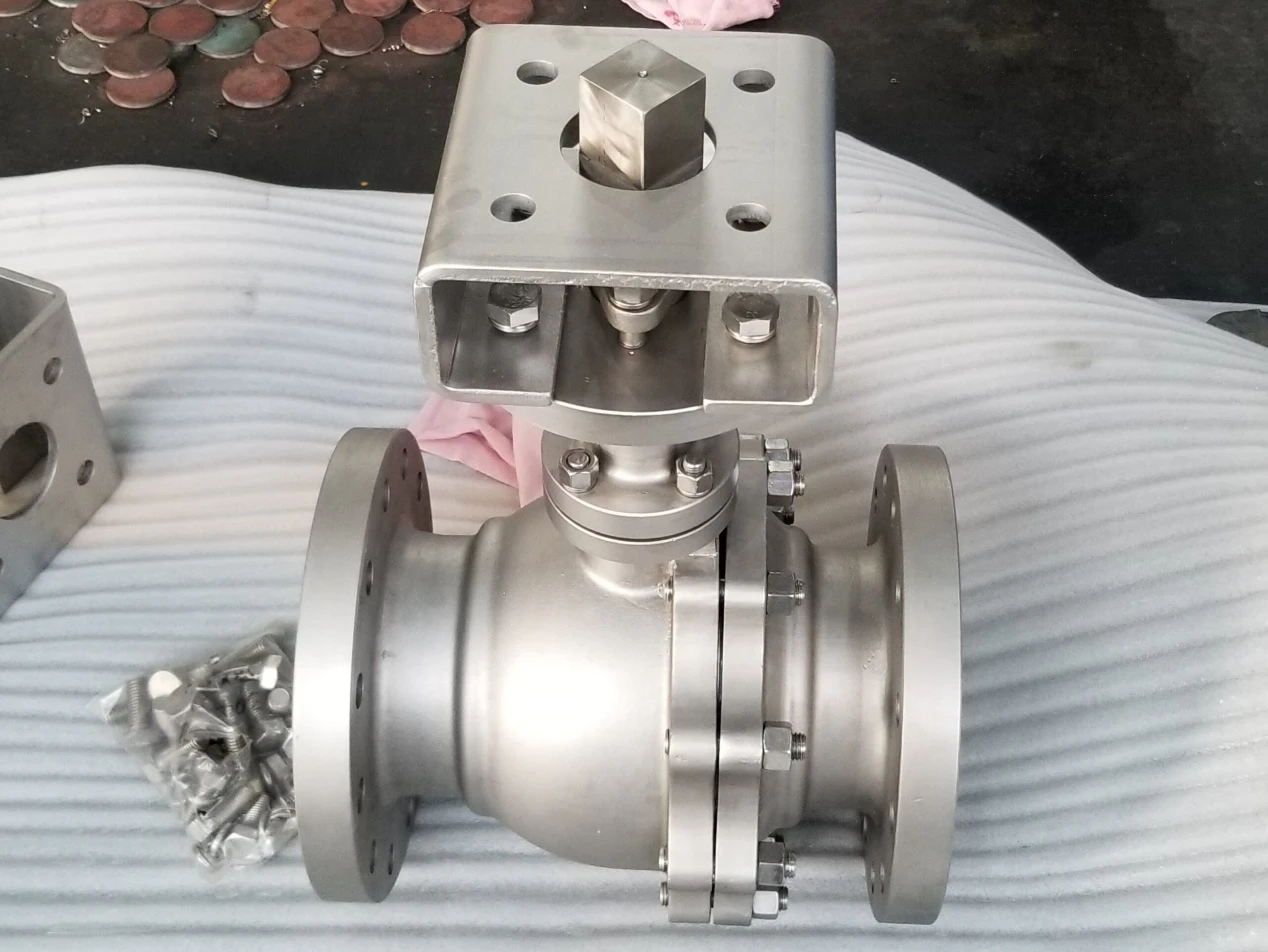

From Design to Manufacturing: The Complete Crafting Journey

The performance, durability, and reliability of double flanged butterfly valves are determined by their precise manufacturing steps. The Marine U Section Double Flange Butterfly Valve exemplifies this process, using state-of-the-art technology, world-class materials, and rigorous international standards.

Manufacturing Process Flowchart

- Material Selection (e.g. ASTM A536, EN GJS-400-15 ductile iron or stainless steel) → Defines core corrosion, pressure, and fatigue performance

- Casting & Forging: High-integrity body and disc prepared via lost-foam casting or die forging (ISO 9001:2015/EN 593)

- CNC Machining: Body, flanges, and disc machined to μm tolerances; bi-directional sealing ensured

- Surface Protection: Multilayer epoxy or polyester coatings for marine/industrial corrosive environments; thickness ≥250μm (EN ISO 12944)

- Seat/Seal Installation: Vulcanized elastomer (EPDM, NBR, Viton) or PTFE seats; tested for vacuum & high-pressure

- Flange Facing: ISO/ANSI-compliant double flanges ensure perfect pipeline alignment and bolt integrity

- Quality Control: Each unit undergoes hydrostatic, shell, and seat tests per ISO 5208 Class A/EN 12266-1 standards

- Packing & Traceability: Unique laser-engraved batch marking for QA/QC and marine compliance

Marine U Section Double Flange Butterfly Valve: Technical Excellence

The Marine U Section Double Flange Butterfly Valve is specifically engineered for robust marine, offshore, and corrosive applications. Compared with standard double flanged butterfly valves, it boasts unique geometry, materials, and test credentials.

Key Specifications Snapshot

- Size: DN50–DN1600 (2"–64")

- Body Material: Ductile Iron (EN GJS-400-15), Stainless Steel 316 (A4)

- Disc Material: Stainless Steel, Nickel-plated Ductile Iron

- Pressure Rating: PN10/PN16/PN25, ANSI 150LB

- Seat: EPDM, NBR, PTFE, or Viton (accommodates seawater/chemicals)

- Operation: Manual (handwheel), Gear, Electric, Pneumatic

- Flange Standard: ISO 7005/EN 1092-2/ANSI B16.5/DIN

- Coating: Fusion Bonded Epoxy, min. 250μm (marine grade)

- Certifications: ISO 9001, DNV-GL, LR, ABS, RINA, EN 593

Industry Test Data (Sample)

- Shell Test Pressure: 1.5 x PN (e.g. 24 bar for PN16 valves)

- Seal Test Pressure: 1.1 x PN

- Cycle Life: ≥ 40,000 open/close cycles (ISO 5208)

- Torque Range: 29–28000 Nm (size/pressure dependent)

- Leakage Rate: Class A (zero-leakage, per EN 12266-1)

- Salt Fog Resistance: >2000 hours (ASTM B117)

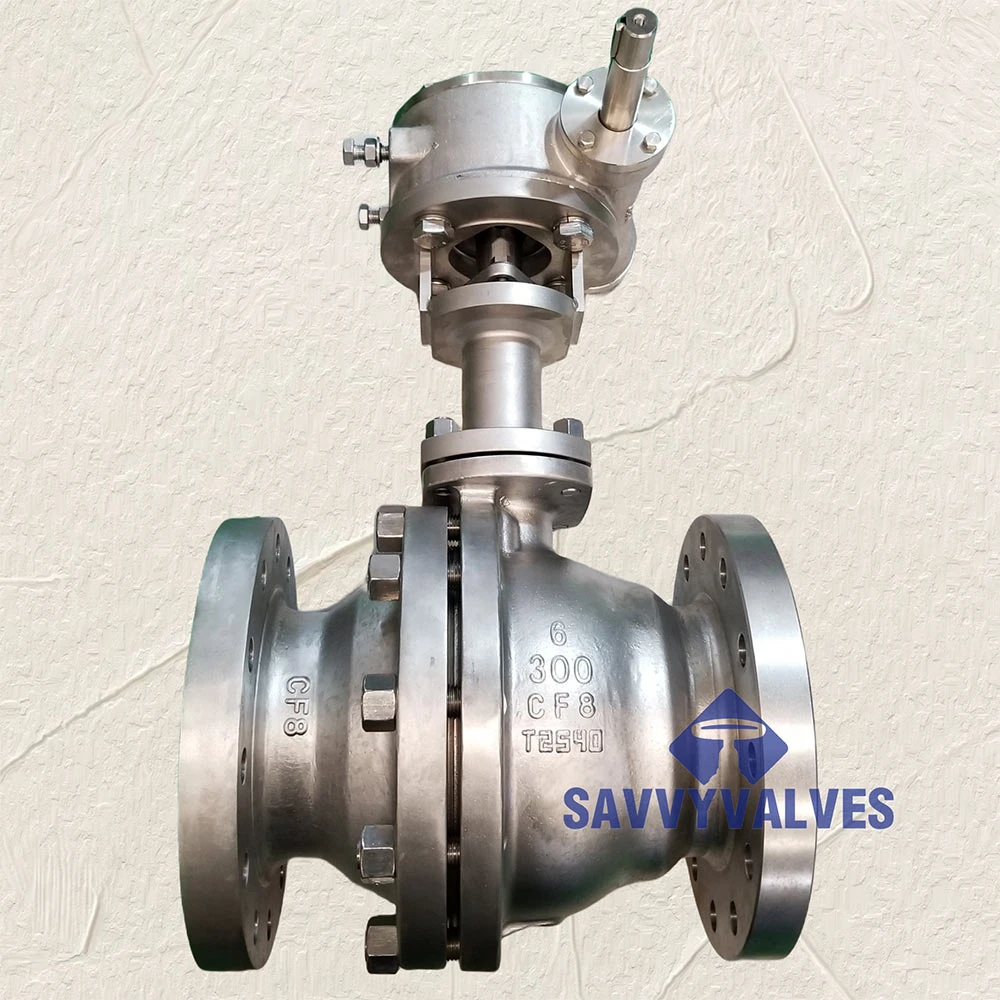

Sample of butterfly valve double flange type with advanced epoxy protection (Image © Savvy Valve Tech)

Technical Data Visualization

Product Comparison: Marine U Section vs. Standard Double Flanged Butterfly Valve

Industry Usage (%) – Double Flanged Butterfly Valves

Service Life Comparison by Valve Type

Key Technical Advantages Explained

- Bi-directional Sealing: Ensures reliable shut-off regardless of flow direction (critical for marine & safety systems).

- High Corrosion Resistance: Epoxy coatings, stainless steel options, and precision sealing for aggressive media.

- Rigid Flange Connection: The double flange design provides pipeline structural integrity, especially for large-diameter/critical lines.

- Low Maintenance: Self-lubricating bushings and seat materials, reduced torque and wear over decades.

- Smart-Ready: Easily integrates electric/pneumatic or IoT sensors for automated or remote-controlled systems (Industry 4.0).

Vendor Comparison Matrix

| Brand | Main Material | Max. Size | Certification | Coating | Typical Lead Time | Warranty |

|---|---|---|---|---|---|---|

| Savvy Valve Tech (Marine U Section) |

DI, SS316 | DN1600 | ISO, DNV, LR | Epoxy ≥250μm | 15–30 days | 36 months |

| Tyco Flow Control | DI, Steel | DN1200 | ISO, CE | Epoxy 180μm | 25–40 days | 24 months |

| AVK Group | DI, Bronze | DN1000 | ISO, FM, WRAS | PES/EP Coating | 30–45 days | 24 months |

| Wouter Witzel | SS304, DI | DN1400 | CE, ISO | FBE, NBR | 20–45 days | 24 months |

Custom Engineering & Project Solutions

Custom double flanged butterfly valves are often tailored for application-specific challenges – including seawater intakes, fire-fighting ring mains, chemical dosing, or district cooling tunnels. Savvy Valve Tech offers full-cycle engineering:

- FEA-based design per ISO 5752, API 609

- ATEX/IECEx (explosive zone) actuator options

- Flushing connections/custom drain ports

- Exotic alloys for special fluids (duplex, super-duplex, bronze)

- Retrofit flanged adaptors for legacy lines

Typical Applications & Case Studies

Supply: 300+ sets of double flanged butterfly valves ranging DN100–DN1200 for seawater, firewater, and vent applications. Valve internals in SS316/duplex for extended lifetime; all marine certified (ABS/DNV-GL).

Case 2: Urban Waterworks, Middle East

Replaced 15-year-old carbon steel units with Marine U Section Design. Result: 60% longer service intervals, leak rate reduced to zero, actuator retrofit completed in 7 days per line.

Major Certifications & Endorsements

Professional FAQs: Double Flanged Butterfly Valve Technology

Delivery Time, Warranty, & Customer Support

- Standard lead time: 15–30 working days (project/volume dependent)

- Warranty: 36 months from shipment (extended options available)

- Spare parts: 48h express dispatch for critical service lines

- 24/5 Technical Hotline, TeamViewer/AR guidance & on-site troubleshooting

- Full QA traceability and digital valve documentation provided

Conclusion & Authoritative Resources

In summary, double flanged butterfly valves remain the gold standard for modern flow control in infrastructure, industry and marine domains, with continuous improvements in reliability, materials and global compatibility. For in-depth technical bulletins, third-party test reports, and operator discussions, consult:

—ValveForum.com Community, 2024