When it comes to managing fluid flow efficiently and cost-effectively, butterfly valves for sale are a popular choice across many industries. Their simple design, compact size, and versatile applications make them indispensable in water treatment plants, chemical processing, HVAC systems, and food production.

Finding reliable butterfly valves for sale ensures you get products that meet stringent quality standards, deliver durability, and provide smooth operation. High-performance butterfly valves offer quick quarter-turn operation, low-pressure drop, and tight sealing capabilities, reducing energy consumption and improving system reliability.

Trusted suppliers often provide a broad range of butterfly valves for sale in various materials such as stainless steel, cast iron, and ductile iron, tailored to resist corrosion, pressure, and temperature fluctuations. Whether you need manual, electric, or pneumatic actuated valves, choosing the right valve from a reputable source guarantees long-term value.

What is a Butterfly Valve and Why is it Essential in Fluid Control?

A butterfly valve is a quarter-turn valve that uses a rotating disc to regulate or isolate fluid flow. When the disc is turned parallel to the flow, the valve is fully open, and when perpendicular, it closes the flow completely. This design offers a compact solution for large pipe diameters where space and weight savings are crucial.

The butterfly valve is prized for its versatility in handling liquids, gases, and slurries with minimal maintenance requirements. It provides efficient throttling capabilities and fast operation, which is ideal for process control systems requiring rapid response times.

Due to their lightweight design and relatively low cost compared to gate or globe valves, butterfly valves are widely used in municipal water supplies, wastewater treatment, HVAC systems, and chemical plants. They also accommodate automation through various actuators, enabling integration into smart control systems.

Different Type Butterfly Valve Designs and Their Applications

Understanding the type butterfly valve available helps in selecting the best fit for your application. The primary type butterfly valve designs include:

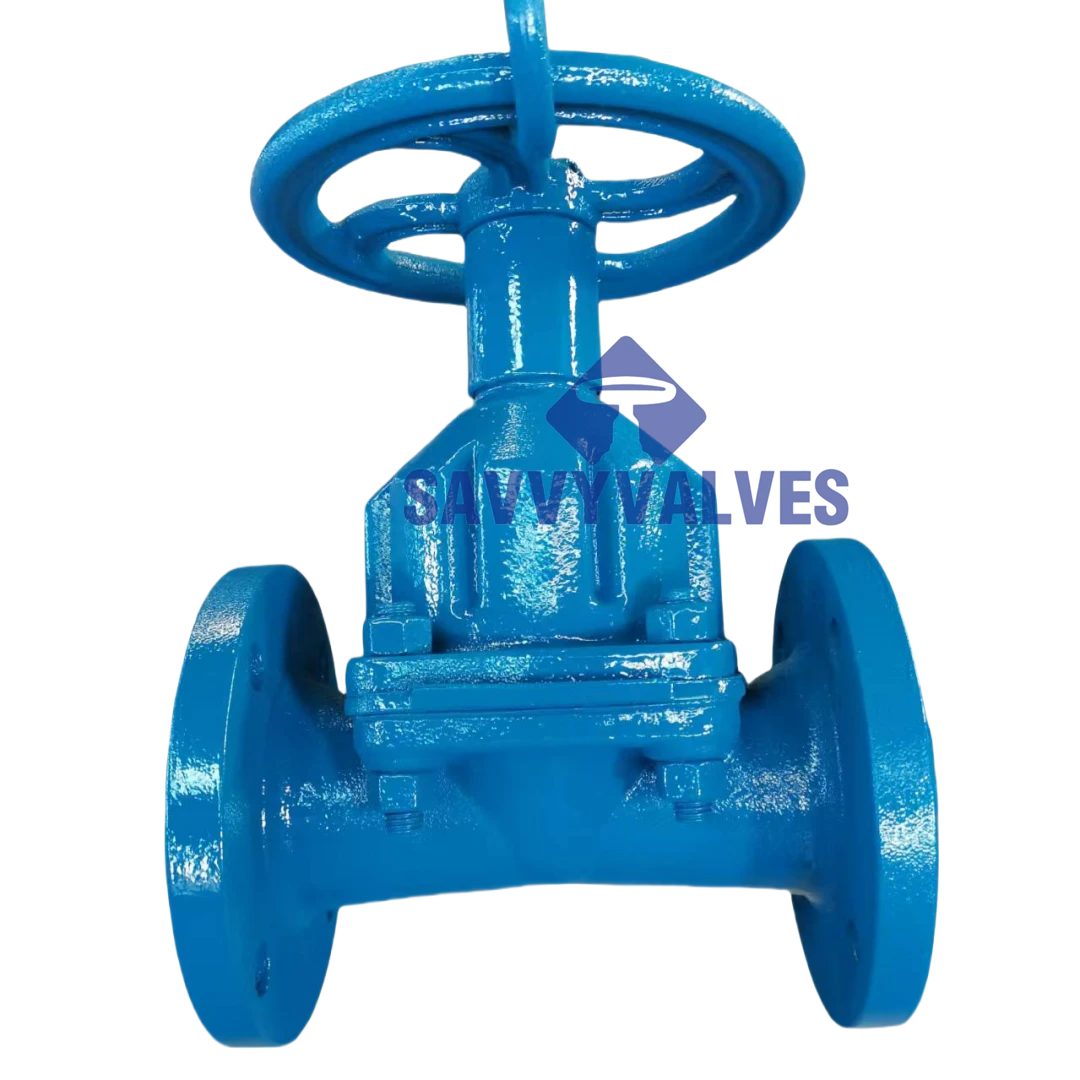

Wafer Butterfly Valve: This popular type fits between two pipe flanges and is held in place by bolts. It’s space-saving and suitable for low-pressure systems.

Lug Butterfly Valve: Equipped with threaded inserts (lugs) around the valve body, this valve allows for one-side pipe removal without disturbing the other side, ideal for maintenance and repair tasks.

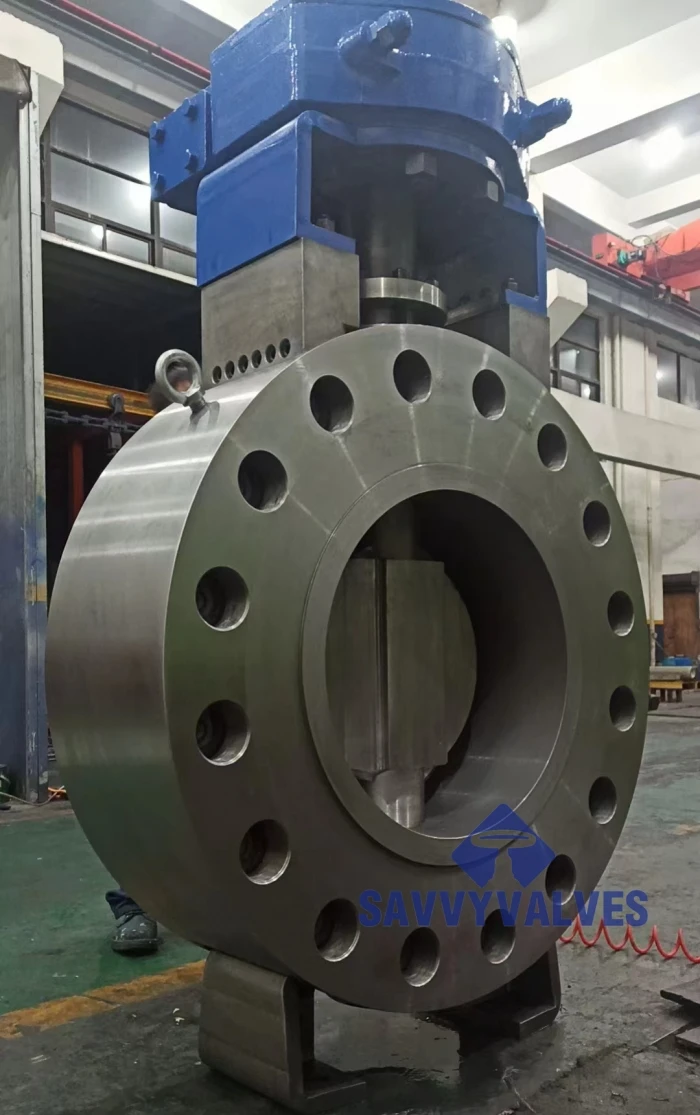

Flanged Butterfly Valve: Featuring flanges on both ends, this type offers strong connections for high-pressure and critical applications.

Triple-Eccentric Butterfly Valve: Designed with an offset shaft and seat to eliminate friction during operation, this type is used for high-performance sealing, especially in demanding industries like oil and gas.

Each type butterfly valve offers unique advantages in terms of pressure handling, sealing performance, and installation ease. Choosing the right design based on your system's pressure, temperature, and media characteristics optimizes efficiency and longevity.

Key Features to Look for When Buying Butterfly Valves for Sale

When exploring butterfly valves for sale, it’s essential to consider features that affect performance and durability:

Material Quality: The valve body and disc materials should match your application’s media and environmental conditions. Stainless steel, ductile iron, and carbon steel are common choices.

Sealing Mechanism: Look for resilient seat materials such as EPDM, PTFE, or NBR that provide leak-tight sealing while withstanding chemical exposure and temperature extremes.

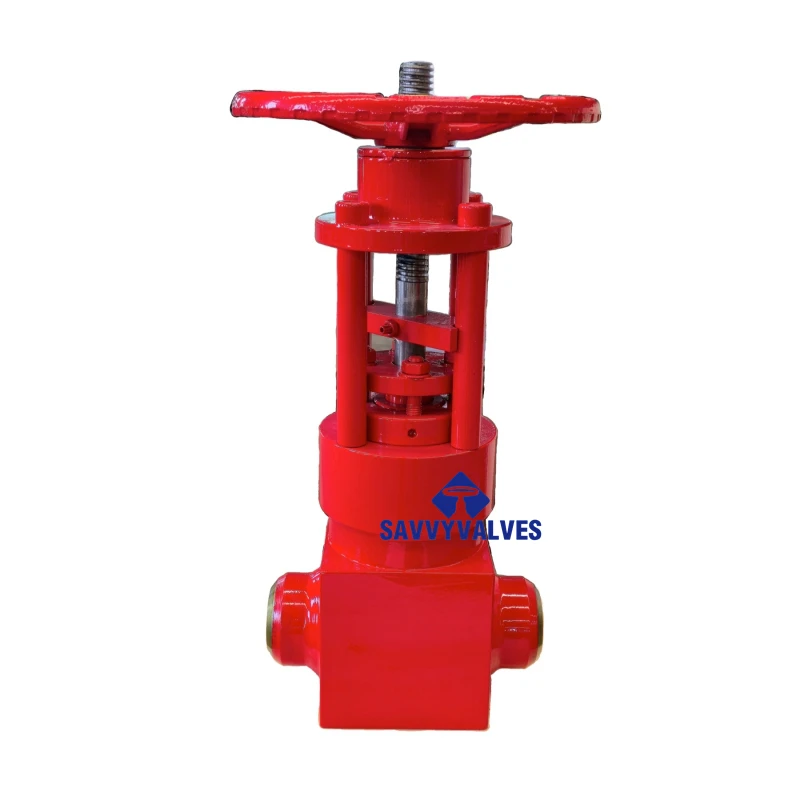

Actuation Options: Manual, electric, pneumatic, or hydraulic actuators can be integrated depending on control system needs. Automation capability enhances precision and responsiveness.

Pressure and Temperature Ratings: Ensure the valve can handle your system’s maximum operating pressure and temperature without compromising safety.

Compliance and Certification: Valves should meet international standards like API, ANSI, ISO, or NSF for quality assurance and regulatory compliance.

By prioritizing these features, you ensure your purchased butterfly valves for sale deliver reliable service, reduce downtime, and contribute to operational cost savings.

Why Source Your Butterfly Valve from Trusted Manufacturers and Suppliers

Selecting your butterfly valve from reputable manufacturers and suppliers is crucial for securing high-quality products and professional support. Trusted suppliers provide comprehensive product documentation, technical guidance, and customization services to match your unique system requirements.

Experienced manufacturers apply rigorous quality control throughout the production process, ensuring valves meet performance specifications and have consistent durability. They often invest in research and development to incorporate innovations such as improved sealing materials and corrosion-resistant coatings.

Reliable suppliers also offer after-sales services including installation assistance, maintenance training, and prompt spare parts availability, all of which contribute to reduced operational risks and longer valve lifespans.

Furthermore, working with certified suppliers helps guarantee compliance with environmental and safety regulations, mitigating liabilities and fostering sustainable operations.

butterfly valve FAQs

What advantages does a butterfly valve offer compared to other valve types?

Butterfly valves provide compact size, lightweight design, quick operation, and cost-effectiveness. They handle large pipe diameters efficiently and require less maintenance compared to gate or globe valves.

How do I choose the right type butterfly valve for my application?

Consider factors like pipe size, pressure, temperature, fluid type, and maintenance access. Wafer valves are good for space savings, lug valves for easier maintenance, and triple-eccentric valves for high-performance sealing needs.

Can butterfly valves for sale be automated?

Yes, many butterfly valves support manual and automated actuation using electric, pneumatic, or hydraulic actuators, allowing integration into modern control systems for precise flow management.

What sealing materials are commonly used in butterfly valves?

Common sealing materials include EPDM (good for water and chemicals), PTFE (excellent chemical resistance), and NBR (good oil and gas resistance). The choice depends on the media and temperature.

How do I ensure the quality of butterfly valves for sale?

Purchase from certified suppliers that comply with industry standards like API, ISO, and ANSI. Request test reports, certifications, and warranty details to verify quality assurance.