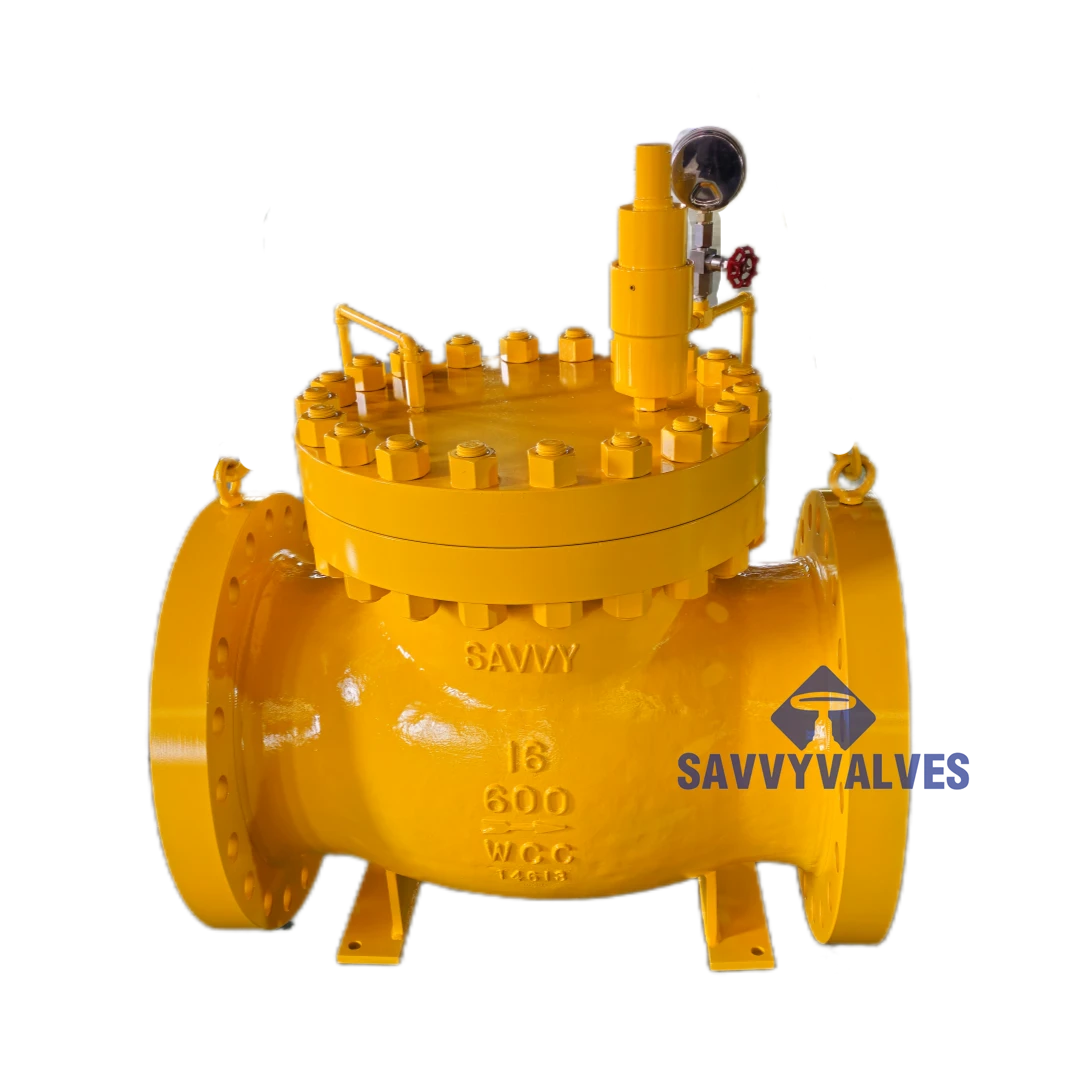

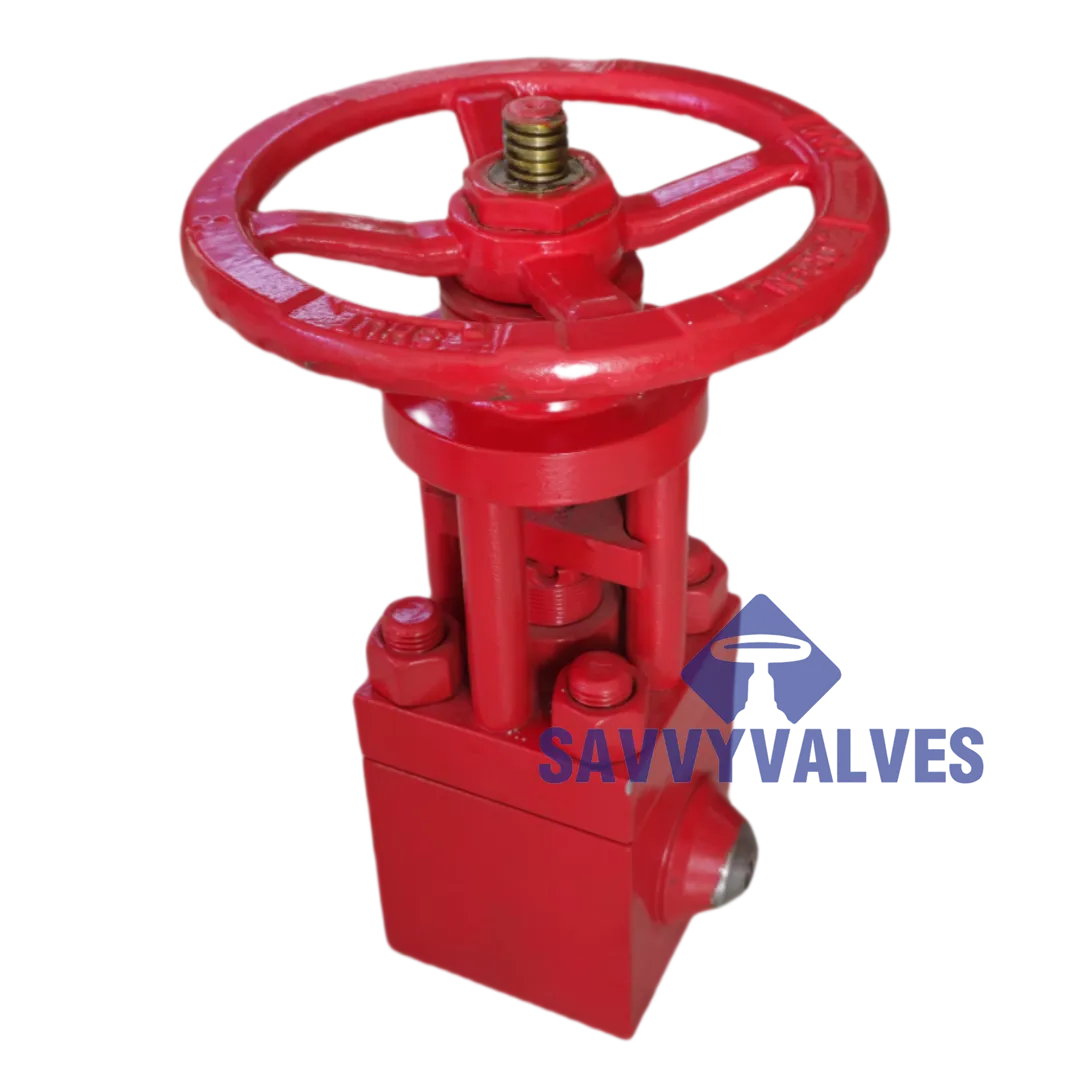

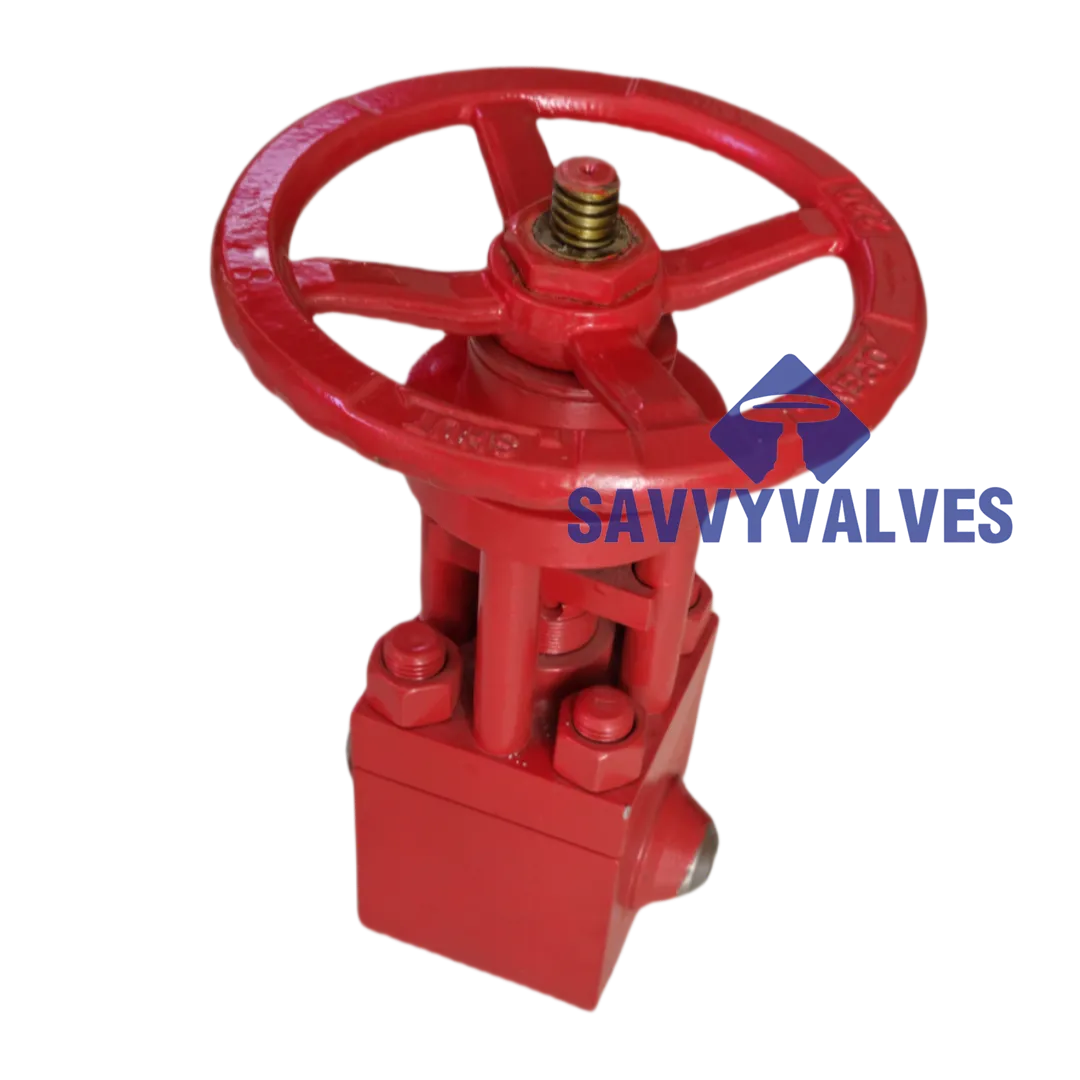

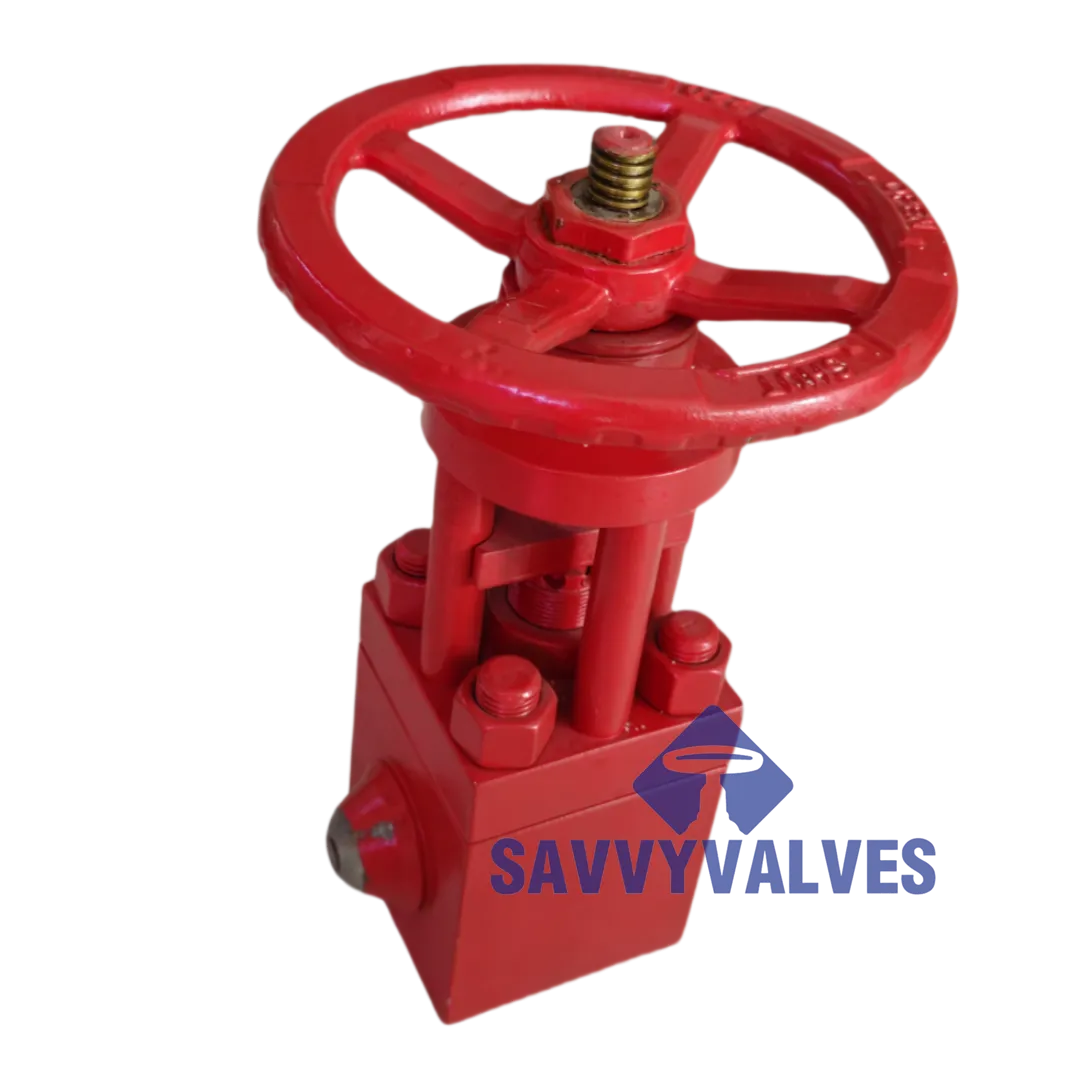

As industries worldwide demand unmatched flow control and operational safety, the globe valve has surged to prominence thanks to its reliability, precision regulation, and adaptability across sectors like petrochemicals, metallurgy, power generation, and water management. This comprehensive guide explores globe valves with a special focus on the 1/2" 4500lb Globe Valve, covering technical standards, production processes, application cases, authoritative certifications, product comparisons, visualized data, and practical engineering experience to help you select the optimal solution in a complex market.

Globe Valve Market: Growth, Trends & Key Data (2024)

According to ResearchAndMarkets, the global globe valves market is projected to reach USD 11.4 billion by 2028, growing at a CAGR of 4.2%. The demand is driven by infrastructure upgrades, rising petrochemical investments, and stricter safety standards (e.g., API 600/602, ISO 9001:2015).

Globe valve types (cast, forged, stainless & exotic alloys) are evolving with smart actuation, anti-corrosion materials (such as Hastelloy, Inconel), and high-pressure service for LNG, refinery, and hydrogen sectors. Top players focus on digital diagnostics and predictive maintenance to increase lifecycle value.

Globe Valve Technical Parameter Table

| Model | Size (DN) | Pressure (lb/PN) | Body Material | Ends | Seat Type | Temperature Range (°C) | Std. Compliance |

|---|---|---|---|---|---|---|---|

| 1/2" 4500lb Globe Valve | DN15 | 4500lb / PN320 | F316/F11 Alloy Steel | BW/SW/NPT | Metal/Hardfaced | -46 ~ +600°C | API 602, ISO 9001, CE |

| ANSI Globe Valve | DN50 | 600lb / PN100 | WCB/CF8/CF8M | RF/RTJ | Metal/SS | -29 ~ +450°C | API 600, EN 13709 |

| DIN Globe Valve | DN100 | PN40 | LCC/1.4462 | RF/Butt Weld | Soft/Hard | -60 ~ +540°C | DIN 3356, ISO |

Manufacturing Process of Globe Valve (with Flow Diagram)

- Materials: F316/F11 alloy steel for high strength and corrosion resistance (ASTM A182, ASTM A105 standards).

- Manufacturing: Precision forging/casting, CNC machining for tight tolerances (up to H7 fit), in-house hardfacing with Stellite 6 on seat/disc for superior wear.

- Testing: NDE (RT/UT/MT/PT), hydrostatic shell & seat test (per API 598, ISO 5208), helium leakage for fugitive emission compliance.

- Certifications: API 602, ISO 9001, CE/PED, traceable MTC EN10204 3.1.

Key Technical Parameters: 1/2" 4500lb Globe Valve

| Parameter | Value |

|---|---|

| Nominal Size (DN) | DN15 / 1/2" |

| Pressure Rating | 4500lb (PN320) |

| Body Material | ASTM F316 or F11, Customizable |

| Bonnet Type | Bolted, Pressure Seal |

| Trim | Stellite 6 /17-4PH SS / Hardfaced |

| End Connection | Butt Weld/SW/NPT |

| Operating Temp. | -46°C to +600°C |

| Applicable Standard | API 602, ISO 15848, BS 5352 |

| Cycle Life | >20,000 cycles tested |

Typical 1/2" 2500lb

Typical 1/2" 1500lb

F11 Alloy

Others

- Ultimate Pressure: 4500lb, designed for supercritical/high-pressure pipelines – outperforms standard 2500lb/1500lb offerings.

- Premium Materials: F316 (58%), F11 alloy (28%), others, optimized for corrosion/temperature.

- Lifecycle: >20,000 open/close cycles, tested per ISO/ANSI standards.

- Customizable: Trims, fugitive emission packing, cryogenic extended bonnets available upon request.

Application Scenarios & Field Case Studies

- Oil & Gas (Refinery, Cryogenic LNG): Used in high-pressure hot/cold lines, catalytic reformers, and hydrogenation, handling fluctuating loads while meeting API 607 fire-safety.

- Power Generation: Ideal for turbine bypass, steam lines, and feedwater systems requiring precision throttling and quick shutoff (Power Engineering Magazine).

- Metallurgy & Chemical: Handles aggressive chemicals (H2SO4, Cl2, NaOH) due to anti-corrosive body/trims. 316SS outlasts carbon steel by >70% per CorrosionPedia 2023 stats.

- Water & Wastewater Treatment: Offers fine flow regulation, low maintenance, and compliance with ISO 15848 fugitive emission norms.

Certifications, Authority & Client Endorsements

- Certifications: API 602, API 607, ISO 9001:2015, CE/PED, ISO 15848 FE, EN10204-3.1 MTCs on each delivery.

- Worldwide Clients: Serving Sinopec, Shell, POSCO, Aramco, and leading EPCs for >15 years.

- Industry Recognition: Cited in "China Valves Magazine", "Valve World Forum", and client acceptance audits (Example: Valve World).

- Support Pledge: 24-hour engineer hotline, 18-month warranty, in-stock spare parts.

Brand X

Avg. Market

Leading Globe Valve Manufacturers: Comparison Overview

| Manufacturer | Country | Main Standard | Cycle Life (1/2" 4500lb) | Material Range | Customization? |

|---|---|---|---|---|---|

| Savvy Valve Tech | China | API 602, ISO 9001 | 35,000+ | F316, F11, Special Alloys | Yes (Cryo, High-Temp, etc.) |

| Velan | Canada | API 600/602, CE | 31,000 | WCB, LCB, F91, Alloy 20 | Partial/Higher Models |

| Bonney Forge | USA | API 602, PED | 28,000 | F11, F22, Duplex | Limited |

| Kitz | Japan | JIS, ISO | 22,000 | CF8, CF3M | No |

Bespoke Globe Valve Solutions & Delivery

- Design Options: Custom trims (Stellite 21, 410S/Monel), extended bonnets (-196°C), fire-safe packings, NACE-compliant materials for sour service.

- Rapid Delivery: Standard sizes in stock for fast shipping; custom-engineered orders: 2-6 weeks from contract to FAT shipment.

- Quality Assurance: 100% NDT test (ultrasound, magnetic, dye), traceable batch records, third-party inspection (BV, SGS, TUV) on request.

- After-sales Support: 24/7 technical hotline, on-site assistance in over 65 countries, digital installation/troubleshooting manuals.

Expert FAQ: Globe Valve Technical FAQ

Conclusion & References

Modern globe valve designs are essential for safe, efficient, and reliable flow management in high-stakes industries. With stringent certifications, customization capability, and real-world operation longevity, the 1/2" 4500lb Globe Valve is a benchmark for future-ready engineering.

References:

Valve World |

CorrosionPedia |

ResearchAndMarkets |

Power Engineering Magazine