In the rapidly expanding landscape of industrial gases, liquefied natural gas (LNG), and petrochemicals, the safe and efficient handling of cryogenic fluids is paramount. These fluids, existing at extremely low temperatures (typically below -150°C or -238°F), demand specialized solutions for their containment and control. Among these, the cryogenic gate valve stands out as a critical component, engineered to maintain integrity and performance under the most challenging thermal conditions. This comprehensive guide delves into the world of **cryogenic gate valve** technology, focusing on the sophisticated engineering behind the CNG LNG LPG Pattern forged cryogenic gate valve, its vital applications, and its significant advantages in modern industrial operations.

Industry Trends and the Imperative of Cryogenic Solutions

The global energy transition and growing demand for cleaner fuels like LNG and LPG have propelled the cryogenic industry into a new era of growth. According to a report by Grand View Research, the global industrial gas market size was valued at USD 101.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030, driven largely by demand from metal fabrication, chemical, and healthcare sectors. The LNG market, in particular, is witnessing robust expansion, with global LNG trade reaching an estimated 400 million tonnes in 2023, up from 390 million tonnes in 2022 (Source: Shell LNG Outlook 2024). This growth necessitates advanced infrastructure for production, storage, transportation, and regasification, all of which rely heavily on robust cryogenic components. The integrity of these systems directly impacts safety, operational efficiency, and environmental compliance.

Cryogenic environments pose unique challenges for conventional valves, including material embrittlement, stem packing leakage due to thermal cycling, and ice formation. A properly designed cryogenic gate valve mitigates these risks, ensuring reliable on/off control in extreme low-temperature applications such as:

- LNG/LPG Terminals & Carriers: For loading, unloading, and distribution of liquefied gases.

- Air Separation Units (ASUs): Handling liquid oxygen (LOX), liquid nitrogen (LIN), and liquid argon (LAR).

- Petrochemical Plants: Processing cryogenic hydrocarbons.

- Aerospace & Research Facilities: Dealing with liquid hydrogen and helium.

- Biomedical & Pharmaceutical: For storage and transfer of biological samples and active pharmaceutical ingredients.

Product Spotlight: CNG LNG LPG Pattern Forged Cryogenic Gate Valve

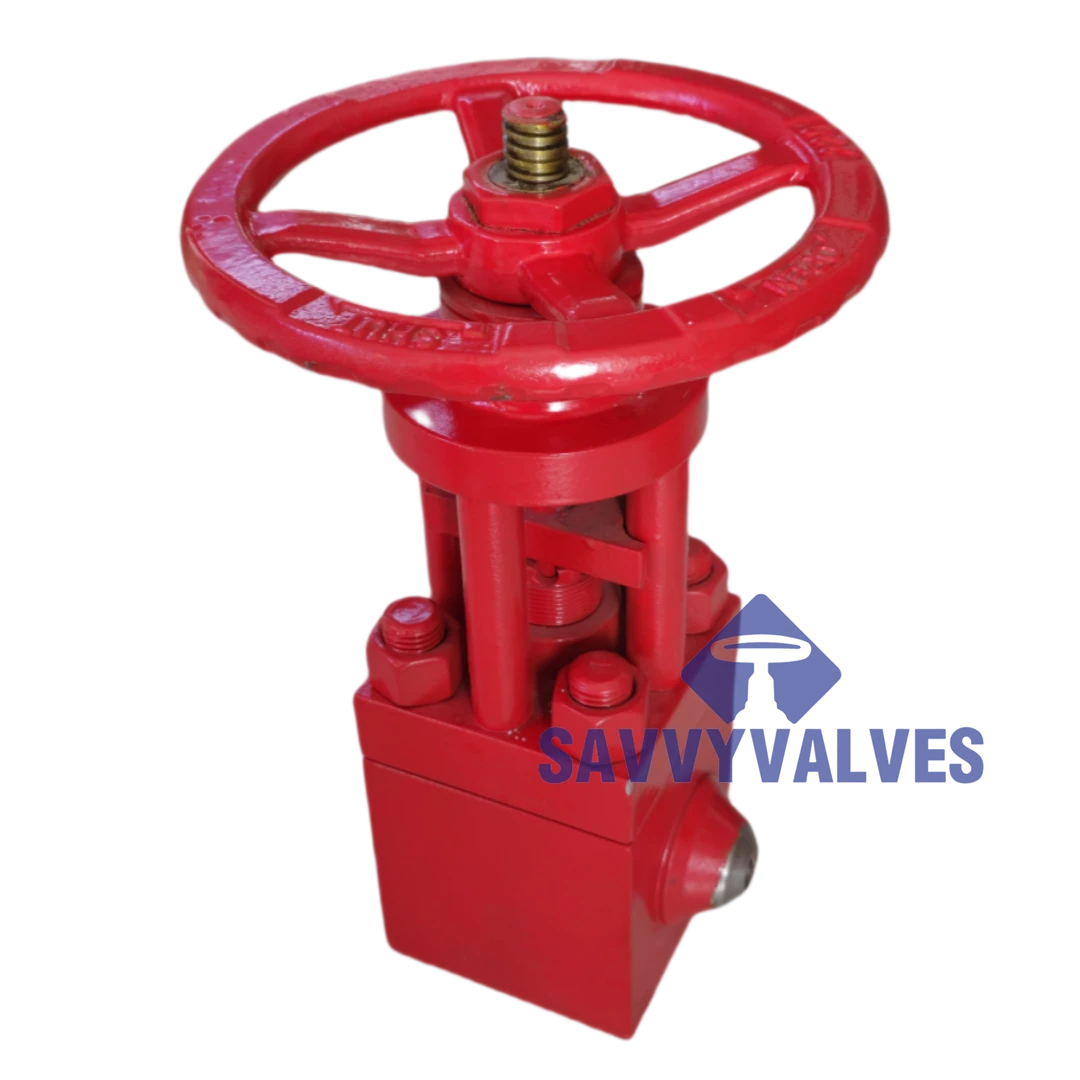

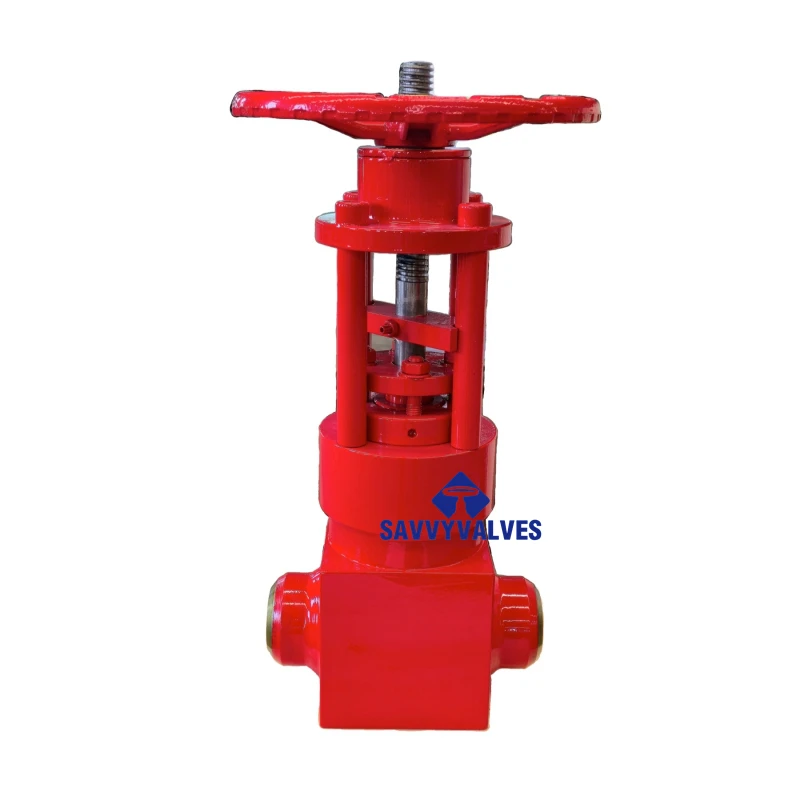

Our CNG LNG LPG Pattern **forged cryogenic gate valve** is meticulously engineered to excel in the most demanding cryogenic applications. Manufactured using state-of-the-art forging techniques, these valves offer superior mechanical properties and structural integrity compared to cast alternatives. The forging process compacts the metal, eliminating porosity and internal defects, resulting in a homogenous grain structure that enhances resistance to thermal shock, fatigue, and corrosion, crucial for maintaining zero fugitive emissions in cryogenic service.

This particular valve pattern is specifically optimized for the unique flow characteristics and stringent safety requirements of Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG), and Liquefied Petroleum Gas (LPG) systems, where reliability is non-negotiable. Its design incorporates features that prevent media leakage to the atmosphere, a critical concern for hazardous and valuable cryogenic fluids.

Key Technical Parameters and Specifications

Understanding the precise specifications of a cryogenic gate valve is essential for proper selection and application. Our CNG LNG LPG Pattern forged cryogenic gate valve boasts a robust set of parameters designed for optimal performance:

| Parameter | Specification | Description |

|---|---|---|

| Product Name | CNG LNG LPG Pattern Forged Cryogenic Gate Valve | Specifically designed for CNG, LNG, and LPG applications at cryogenic temperatures. |

| Size Range (NPS) | 1/2" (DN15) to 4" (DN100) | Common sizes for pipeline and equipment connections. Covers requirements including **3 4 800 gate valve** for smaller bore, high-pressure lines. |

| Pressure Class (ASME) | Class 150 to Class 2500 (e.g., Class 800, Class 1500, Class 2500) | Suitable for various pressure ratings, including high-pressure applications like a **3 4 800 gate valve**. |

| Temperature Range | -196°C to +120°C (-320°F to +250°F) | Capable of handling ultra-low cryogenic temperatures as well as ambient conditions during warm-up/cool-down. |

| Body/Bonnet Material | Forged Stainless Steel (ASTM A182 F304, F316, F316L), Forged Duplex/Super Duplex, Carbon Steel (LF2) with specific low-temperature treatments. | Selected for excellent low-temperature ductility and corrosion resistance. Forged gate valve construction ensures superior integrity. |

| Trim Material | ASTM A182 F304, F316, F316L (Typically 13% Cr for seat/wedge facing, or Stellite overlays) | Ensures durability and resistance to wear and galling. |

| End Connections | Flanged (RF, RTJ - ASME B16.5), Butt-weld (BW - ASME B16.25), Socket-weld (SW - ASME B16.11), Threaded (NPT - ASME B1.20.1) | Versatile connection options for different system requirements. |

| Bonnet Type | Extended Bonnet (typically ≥ 250mm extension) | Essential for creating a vapor column, keeping packing warm, and preventing ice formation around the stem. |

| Sealing & Packing | Graphite packing (e.g., expanded graphite) with live loading, bellow seal options for zero leakage. | Designed for tight sealing, minimizing fugitive emissions, and high cycle life under thermal cycling. |

| Actuation Options | Manual (handwheel), Gear operated, Pneumatic, Electric, Hydraulic | Adaptable for remote or automated control systems. |

| Design Standards | API 602 (forged steel valves), API 600 (steel gate valves), API 624 (fugitive emissions), MSS SP-134, ASME B16.34, BS 6364 (cryogenic valves) | Compliance with international standards ensures safety, quality, and interchangeability. |

| Testing Standards | API 598 (valve inspection and testing), Cryogenic Test (BS 6364, per customer requirement) | Rigorous testing, including liquid nitrogen testing, verifies performance at design cryogenic temperatures. |

Technological Advantages for Optimal Performance

The engineering excellence embedded in our **forged cryogenic gate valve** translates directly into tangible operational benefits:

- Superior Forged Body Construction: Unlike cast valves, the forged body eliminates potential casting defects such as porosity, shrinkage, and cold shuts. This results in a dense, uniform material structure with enhanced mechanical strength, pressure containment capabilities, and resistance to thermal shock, crucial for **cryogenic gate valve** applications. The superior grain flow aligns with the valve's geometry, maximizing its inherent strength.

- Extended Bonnet Design: A hallmark of any reliable cryogenic gate valve, the extended bonnet ensures that the stem packing remains outside the extremely cold zone. This creates a thermal barrier (a vapor column) that prevents the packing from freezing, thereby maintaining its sealing integrity and drastically reducing the risk of fugitive emissions, which are harmful, costly, and environmentally damaging.

- Low-Friction Stem & Packing System: Our valves feature polished stems and specialized live-loaded packing systems (often using graphite rings) designed for extreme temperatures. This minimizes operational torque, reduces wear on packing, and extends the valve's operational life, even with frequent thermal cycling. Compliance with API 624 for fugitive emissions is often a standard verification for these valves.

- Bubble-Tight Shut-off: Precision machining of the wedge and seats, coupled with specific seat designs (e.g., metal-to-metal or soft-seated for very low pressure drop requirements), ensures bubble-tight shut-off, preventing leakage of valuable or hazardous cryogenic media. This translates to significant cost savings and enhanced safety.

- Corrosion Resistance: Utilizing materials like ASTM A182 F316L (low carbon stainless steel) or Duplex stainless steels provides excellent resistance to corrosion from various media, especially when dealing with moisture or impurities within cryogenic fluids. This extends the valve's service life and reduces maintenance requirements.

- Enhanced Safety Features: Designed with safety in mind, these valves often incorporate features like anti-blowout stems and secure bolting, adhering to international safety standards for critical fluid handling.

The Meticulous Manufacturing Process of a Cryogenic Gate Valve

The production of a high-performance cryogenic gate valve is a complex process demanding precision, specialized equipment, and stringent quality control at every stage. Our manufacturing ethos emphasizes adherence to international standards (e.g., ISO 9001 quality management system) to ensure product reliability and longevity. Below is a detailed overview of the process:

Process Flow for Forged Cryogenic Gate Valves:

- Material Selection & Forging:

- Raw Material Acquisition: High-grade alloy steel billets (e.g., ASTM A182 F304, F316, F316L, or LF2 for low-temperature carbon steel) are sourced from approved suppliers, complete with Mill Test Certificates (MTCs) to verify chemical composition and mechanical properties. This ensures compliance with standards like ASTM A350 LF2 for impact testing at low temperatures.

- Forging Process: Billets are heated to their specific forging temperature and then shaped under immense pressure using forging presses or hammers. This process imparts a superior grain structure, making the valve body significantly stronger, denser, and more resistant to fatigue and thermal cycling than a cast equivalent. This is the defining characteristic of a **forged gate valve**.

(示意图/短视频链接 - Representation: Forging involves shaping hot metal under pressure, refining its grain structure and enhancing strength.)

- Rough Machining & Heat Treatment:

- Rough Machining: The forged valve body and bonnet undergo initial machining to remove excess material and prepare for subsequent precision operations.

- Heat Treatment: Depending on the material, specific heat treatments (e.g., solution annealing for stainless steels, normalizing for carbon steels) are performed to optimize mechanical properties, relieve internal stresses, and achieve the required metallurgical structure for cryogenic service. This step is crucial for preventing material embrittlement at low temperatures.

- Precision CNC Machining:

- Advanced CNC Machining: The valve body, bonnet, wedge (gate), stem, and other critical components are precisely machined using Computer Numerical Control (CNC) machines. This ensures high dimensional accuracy, fine surface finish, and precise geometry of critical sealing surfaces (seats) for bubble-tight shut-off. This includes machining the extended bonnet length according to BS 6364 guidelines.

- Seating Surface Preparation: Seating surfaces are meticulously machined and often overlaid with harder alloys (e.g., Stellite 6) to enhance wear resistance and longevity.

- Cleaning & Surface Treatment:

- Degreasing & Cleaning: All components are thoroughly cleaned to remove contaminants, oils, and particulates, especially critical for oxygen service to prevent ignition.

- Passivation (for Stainless Steel): Stainless steel components undergo passivation to enhance their natural corrosion resistance.

- Assembly:

- Component Assembly: The meticulously prepared components – body, bonnet, wedge, stem, packing, gland, and handwheel/actuator – are assembled in a clean environment. Particular attention is paid to the installation of the stem packing to ensure proper compression and sealing integrity.

- Lubrication: Cryogenic-compatible lubricants are sparingly used where necessary, ensuring no contamination of the fluid path.

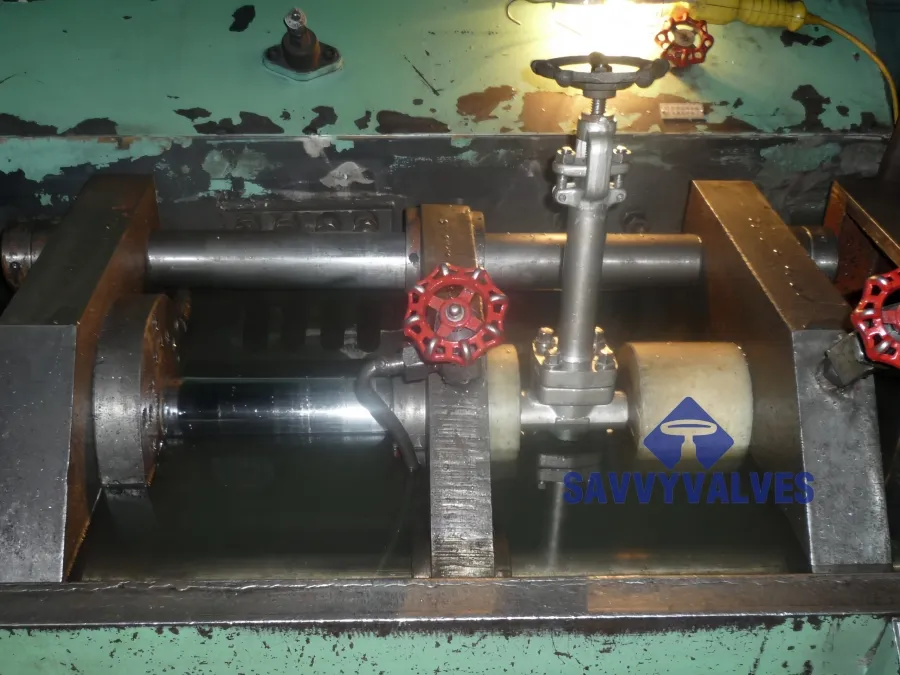

- Rigorous Testing & Inspection:

- Non-Destructive Testing (NDT): Prior to assembly, critical components may undergo NDT methods such as Magnetic Particle Testing (MPT) for ferromagnetic materials, Liquid Penetrant Testing (LPT) for surface defects, Ultrasonic Testing (UT) for internal flaws, and Radiographic Testing (RT) for internal volumetric defects. This ensures the integrity of the **forged gate valve** components.

- Hydrostatic Testing: The valve body is subjected to a hydrostatic pressure test (typically 1.5 times the rated pressure) to verify shell integrity and freedom from external leakage, as per API 598.

- Low Pressure Air Seat Test: A low-pressure air test verifies the initial seat tightness.

- Cryogenic Test (Mandatory): This is the most critical test for a cryogenic gate valve. The valve is submerged in a liquid nitrogen bath (-196°C) or tested with super-cooled helium/nitrogen gas, and then subjected to pressure testing to ensure seat and stem seal integrity at operating cryogenic temperatures. Leakage rates are measured against stringent standards like BS 6364 or specific customer requirements. This also verifies the performance of the extended bonnet and packing system under thermal contraction.

- Fugitive Emissions Test (API 624/ISO 15848-1): For critical applications, valves are tested to verify ultra-low emissions performance over thermal cycles and mechanical cycles.

- Visual Inspection: A final visual inspection checks for surface finish, marking, and overall conformity.

- Surface Treatment & Packaging:

- Corrosion Protection: The valve exterior is prepared and coated with corrosion-resistant paint suitable for industrial environments.

- Final Inspection & Documentation: Each valve undergoes a final inspection, and all test reports, material certificates, and quality documents are compiled.

- Packaging: Valves are carefully packaged to prevent damage during transit, often with protective end caps for flanges/connections.

This stringent process ensures that every CNG LNG LPG Pattern **forged cryogenic gate valve** meets or exceeds international quality and safety standards, providing an estimated service life of 20-30 years with proper maintenance, significantly longer than many conventional valves. They are widely used in petrochemical, metallurgy, power generation, and specialized industrial gas applications, offering advantages in energy efficiency (due to minimal leakage) and superior corrosion resistance.

Choosing the Right Partner: Manufacturer Comparison Criteria

Selecting the right manufacturer for **cryogenic gate valve** solutions is as crucial as the valve technology itself. It's not merely about purchasing a product; it's about securing a long-term partnership that guarantees reliability, support, and innovation. Here are key criteria for evaluating and comparing manufacturers:

- Expertise and Experience: Look for manufacturers with a proven track record (e.g., 15+ years in cryogenic valve manufacturing). They should demonstrate deep understanding of cryogenic fluid dynamics, material science at ultra-low temperatures, and specific industry challenges (e.g., LNG, industrial gases).

- Certifications & Compliance: Verify adherence to international quality management systems (ISO 9001), environmental standards (ISO 14001), and occupational health and safety (ISO 45001). Crucially, ensure their products comply with specific valve design and testing standards like API 602, API 600, ASME B16.34, and the essential BS 6364 for cryogenic service, as well as fugitive emissions standards like API 624.

- Manufacturing Capabilities: Assess their in-house capabilities for forging, CNC machining, welding, and especially cryogenic testing. A manufacturer with their own cryogenic test facility signifies robust quality control and commitment to product integrity.

- R&D and Innovation: A forward-thinking manufacturer invests in research and development to improve valve performance, develop new materials, and innovate solutions for emerging industry needs (e.g., new types of packing, smart valve technologies).

- Customization and Engineering Support: The ability to offer tailored solutions (e.g., specific materials, end connections, actuation, or specialized testing for a **3 4 800 gate valve**) and provide comprehensive engineering support before, during, and after project implementation is vital.

- After-Sales Service & Support: Availability of technical support, spare parts, and field service personnel for maintenance and troubleshooting ensures minimal downtime and extended valve life.

- Global Presence and Project Experience: A manufacturer with experience in diverse geographical markets and a portfolio of successful projects (e.g., major LNG terminals, air separation plants) demonstrates their capability to handle complex international requirements.

Tailored Solutions: Customization and Engineering for Your Project

While standard designs meet many requirements, critical or unique applications often demand customized cryogenic gate valve solutions. We offer extensive customization capabilities, ensuring that our CNG LNG LPG Pattern forged cryogenic gate valves seamlessly integrate into your existing infrastructure and perform optimally under your specific operating conditions. Our engineering team collaborates closely with clients to understand their precise needs, offering solutions that extend beyond off-the-shelf products.

Customization Options Include:

- Material Upgrades: Beyond standard stainless steels, we can provide valves in exotic alloys like Monel, Hastelloy, or Inconel for extreme corrosion resistance or enhanced mechanical properties at specific temperatures.

- Specific End Connections: While standard flanged, butt-weld, socket-weld, and threaded ends are available, we can accommodate less common or project-specific connection types.

- Actuation Systems: From simple handwheel operation to complex pneumatic, electric, or hydraulic actuators, including failsafe options (fail-open/fail-close) and sophisticated control accessories (limit switches, positioners).

- Instrumentation & Monitoring: Integration of pressure transducers, temperature sensors, or leakage detection systems for real-time monitoring and advanced process control.

- Bellows Seal Design: For applications demanding absolute zero fugitive emissions, we offer bellow seal designs as an alternative or enhancement to traditional packing.

- Special Testing Protocols: Beyond standard API 598 and BS 6364 cryogenic tests, we can perform additional non-destructive testing (e.g., 100% RT for critical welds), high-pressure gas tests, or cycle testing to meet specific project specifications.

- Surface Finishes & Coatings: Specialized internal or external coatings for enhanced corrosion resistance or friction reduction.

- Bespoke Design Modifications: Adapting valve dimensions, flow paths, or component configurations for unique installation envelopes or performance requirements.

Our commitment to engineering excellence ensures that every customized cryogenic gate valve retains the same high standards of quality, safety, and reliability as our standard products.

Real-World Application Cases & Success Stories

The reliability of our CNG LNG LPG Pattern **forged cryogenic gate valve** has been proven in numerous challenging applications worldwide. These examples highlight the product's adaptability and our commitment to client success.

Case Study 1: LNG Regasification Terminal Expansion Project

Challenge: A major energy company was expanding its LNG regasification terminal, requiring highly reliable shut-off valves for critical lines handling LNG at -162°C (-260°F) and high pressures. The primary concerns were preventing fugitive emissions, ensuring long-term operational integrity despite frequent thermal cycling, and minimizing maintenance downtime. They specifically needed robust **cryogenic gate valve** solutions that could withstand harsh coastal environments.

Solution: We supplied over 300 units of our CNG LNG LPG Pattern **forged cryogenic gate valve**, ranging from NPS 1" to NPS 12" (including several **3 4 800 gate valve** units for instrument lines), primarily in ASTM A182 F316L material with extended bonnets and live-loaded graphite packing. All valves underwent rigorous cryogenic testing at -196°C and certified to API 624 for ultra-low fugitive emissions. We provided comprehensive engineering support, including detailed CAD drawings and installation guidance.

Outcome: Two years post-installation, the client reported zero incidents of stem packing leakage or operational failures attributed to our valves. The superior forging quality and precise manufacturing contributed to reduced commissioning time and significantly lowered their long-term operational costs due to minimal maintenance requirements and avoided product loss from emissions. The project successfully met its environmental compliance targets.

Case Study 2: Industrial Gas Production Facility Upgrade

Challenge: An industrial gas producer needed to upgrade its air separation unit (ASU) for increased capacity of liquid oxygen (LOX) and liquid nitrogen (LIN). The existing valves suffered from frequent stem freezing and seat leakage, leading to inefficiencies and safety concerns. They required **cryogenic gate valve** solutions capable of consistent performance in LOX/LIN service, with specific requirements for cleanliness and oxygen compatibility.

Solution: We provided a tailored solution involving our CNG LNG LPG Pattern **forged cryogenic gate valve** in ASTM A182 F304 material, specially cleaned and prepared for oxygen service (e.g., hydrocarbon-free cleaning per ASTM G93/G94). The valves featured our optimized extended bonnet design and a unique stem sealing arrangement to combat freezing. Sizes ranged from NPS 1/2" to NPS 6", including many **forged gate valve** units with socket weld ends for compact piping configurations.

Outcome: The new valves demonstrated exceptional reliability, with no reported stem freezing issues or seat leakage. The client noted a significant improvement in process efficiency due to stable flow control and reduced product loss. Our ability to meet the stringent oxygen compatibility requirements was a key factor in the project's success, contributing to a safer working environment and higher product purity.

Enhancing Trust: FAQ, Delivery, Warranty & Support

Commitment to Trustworthiness (T in EEAT)

At Savvy Valve Tech, we understand that trust is built on transparency, reliability, and unwavering support. We are committed to providing not just high-quality products like our CNG LNG LPG Pattern cryogenic gate valve, but also a seamless experience from inquiry to post-installation support. Our adherence to international standards and our customer-centric approach are cornerstones of our operations.

Frequently Asked Questions (FAQ) about Cryogenic Gate Valves:

Industry Insight & Authoritative Citations

The specialized nature of cryogenic valve design is continuously evolving, driven by demands for increased safety, efficiency, and environmental compliance. Academic research and industry forums consistently highlight the importance of robust material selection and rigorous testing protocols for valves operating in extreme low-temperature environments. For instance, the challenges associated with stem packing integrity under thermal cycling are extensively discussed in publications from organizations like the Valve Manufacturers Association of America (VMA) and in academic journals focusing on fluid mechanics and materials science.

"The performance of a cryogenic valve's stem seal is paramount to preventing fugitive emissions and ensuring operational safety. Design features like the extended bonnet, coupled with advanced packing materials and live-loading mechanisms, are critical for maintaining seal integrity during temperature excursions and cycling." — Extract from a presentation at the Valve Manufacturers Association of America (VMA) Technical Conference.

Furthermore, research published in journals such as "Cryogenics" and "Industrial & Engineering Chemistry Research" often delves into the metallurgical properties of alloys at cryogenic temperatures, emphasizing why **forged gate valve** construction is inherently superior for these applications due to its refined grain structure and reduced susceptibility to brittle fracture. The continuous push for 'zero leakage' in LNG terminals, for example, is driving innovations in both valve design and testing methodologies, solidifying the need for highly engineered solutions like the CNG LNG LPG Pattern cryogenic gate valve.

"Achieving and maintaining ultra-low fugitive emissions in cryogenic systems is a complex engineering challenge, requiring a holistic approach to valve design, material selection, manufacturing precision, and validation through stringent type testing like ISO 15848-1 or API 624." — Reference from a technical paper on fluid sealing technologies in ASME Journal of Fluids Engineering.

These insights underscore the critical importance of selecting high-quality, expertly engineered **cryogenic gate valve** products that meet the evolving demands of the cryogenic industry, ensuring both operational excellence and environmental stewardship.