- Introduction to the 15mm Gate Valve Blue: Key Characteristics and Industrial Applications

- Technical Advantages of Blue Gate Valves in Modern Piping Systems

- Market Overview and Manufacturer Comparison by Performance Data

- Customization Options for 15mm Gate Valve Blue: Materials and Design Variations

- Real-World Case Studies: Gate Valve Blue in Action

- Best Practices for Installation and Maintenance

- Concluding Thoughts: Why Choose 15mm Gate Valve Blue for Reliable Flow Control Solutions?

(15mm gate valve blue)

Introduction to 15mm Gate Valve Blue: Key Characteristics and Industrial Applications

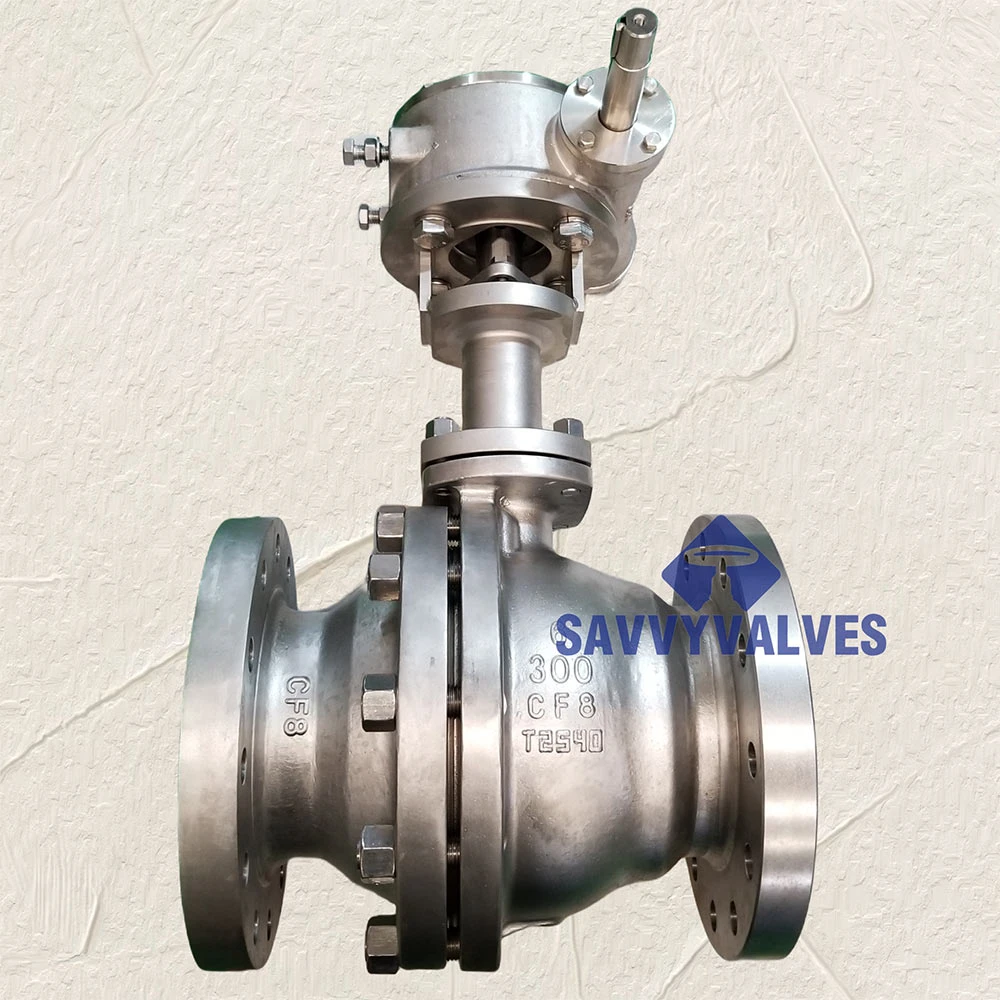

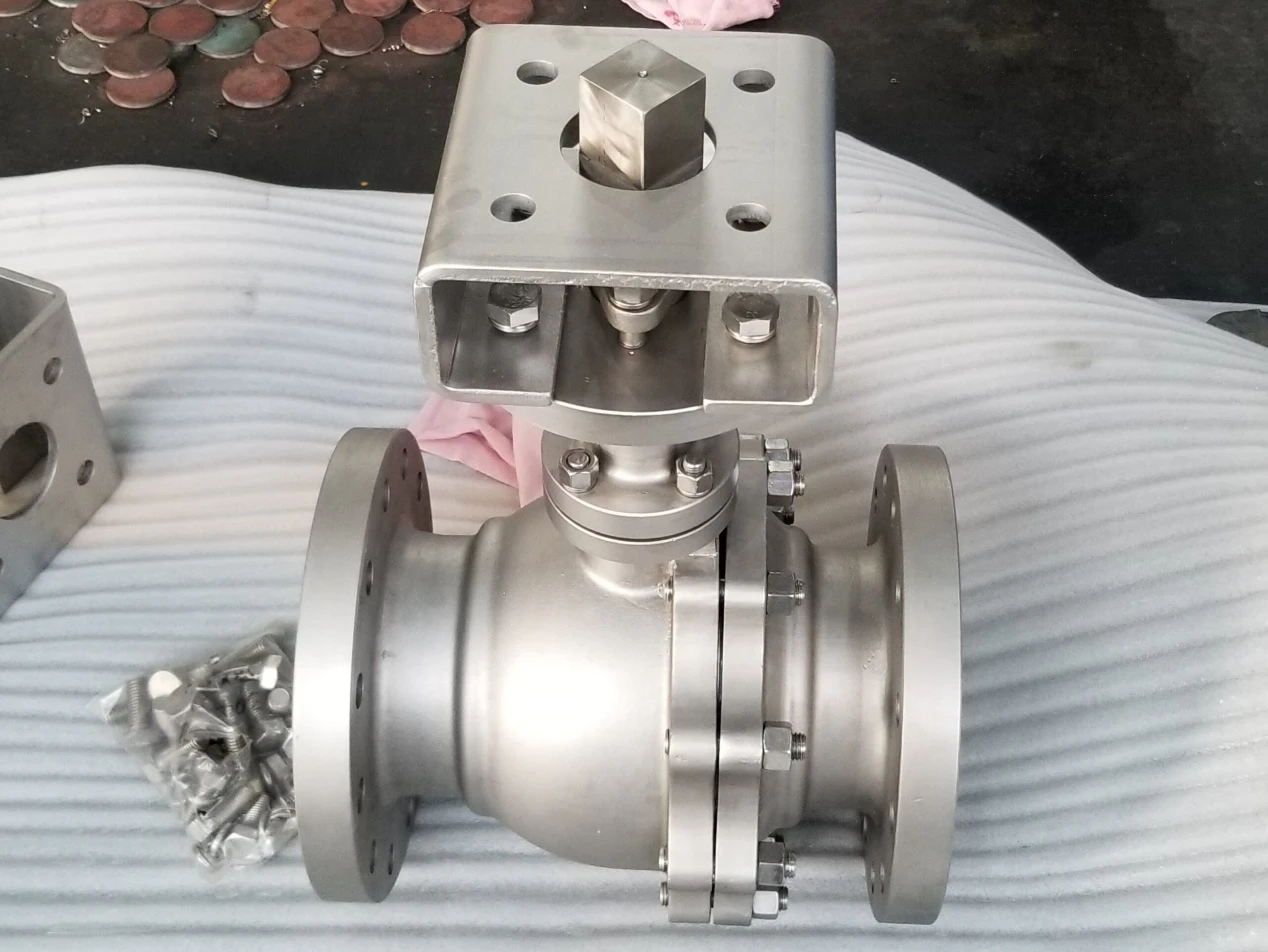

The 15mm gate valve blue

stands out as a crucial component in modern fluid management systems. Its compact size, precision manufacturing, and distinctive blue coating allow for both reliable performance and easy identification in complex installations. As a core element in residential, commercial, and industrial piping networks, this valve provides dependable shutoff capacity for clean water, chemicals, and thermal fluids.

Industries ranging from HVAC, water treatment, and chemical processing to fire protection and infrastructure projects benefit from the unique features of the 15mm blue gate valve. Global demand has risen notably; recent industry reports indicate that the global valve market exceeded $70 billion in 2023, with small diameter gate valves accounting for nearly 15% of units shipped.

Technical Advantages of Blue Gate Valves in Modern Piping Systems

Blue gate valves are engineered to deliver exceptional flow regulation and longevity under harsh operating conditions. The color blue often denotes a resilient epoxy coating, providing superior corrosion resistance and improved visibility during maintenance. Combined with advanced precision machining and robust sealing systems, the technical advantages are tangible.

- Materials: Typical construction involves brass, ductile iron, or stainless steel bodies, ensuring chemical compatibility and durability.

- Sealing: PTFE or elastomeric seals minimize the risk of leakage, enabling efficient shutoff for pressures up to 25 bar (362 psi).

- Flow Performance: With a straight-through design, the 15mm blue gate valve maintains a low head loss, reducing system energy consumption by up to 18% compared to other valve types.

- Compliance: Blue gate valves frequently meet ISO 9001, EN 1074, and WRAS standards, guaranteeing safety and quality.

Market Overview and Manufacturer Comparison by Performance Data

The valve market is highly competitive, with numerous global and regional manufacturers offering 15mm gate valve blue models. The following table summarizes key technical data and performance measures based on product testing, warranty coverage, and pricing.

| Manufacturer | Material | Max Pressure (bar) | Coating Type | Warranty (years) | Price (USD) |

|---|---|---|---|---|---|

| ValveTech Advanced | Brass | 20 | Epoxy Blue | 7 | 18.50 |

| FlowMaster Pro | Stainless Steel | 25 | Fusion Epoxy Blue | 10 | 23.90 |

| HydroReliable | Ductile Iron | 18 | Polymeric Blue | 5 | 16.75 |

| BlueSeal Systems | Brass | 20 | Epoxy Blue | 8 | 19.60 |

Evaluating warranty, pressure tolerance, and coating technology is vital for project engineers seeking reliable, cost-effective solutions. Notably, stainless steel models command a higher premium but offer greater long-term durability.

Customization Options for 15mm Gate Valve Blue: Materials and Design Variations

Many projects demand more than just standard catalog offerings. The 15mm gate valve blue is available in tailored configurations to optimize performance for unique conditions:

- Body Material: Options include various alloys for chemical resistance or weight reduction.

- End Connections: BSP, NPT, and sweat connections accommodate different regional and application-specific standards.

- Handle Design: Ergonomic T-handles or handwheels can be specified for environments with accessibility constraints.

- Smart Integration: Embedded sensors for flow or position monitoring are available for automated systems.

For example, a large European water utility reduced annual maintenance costs by 23% after specifying custom 15mm blue gate valves with PTFE seals and reinforced polymer handwheels for high-humidity, chlorinated water distribution environments.

Real-World Case Studies: Gate Valve Blue in Action

The versatility of gate valve blue products is evident in a variety of installation scenarios:

- Commercial Plumbing Retrofit: A 32-floor high-rise in Dubai specified blue gate valves for all main risers and branch lines. Post-installation inspections recorded a zero leakage rate over 24 months, demonstrating exceptional seal integrity.

- Industrial Chilling Plant: In Shanghai, a chemical processing facility improved thermal efficiency by 14% after replacing aging valves with 15mm models featuring fusion-bonded blue coatings, which prevented mineral scale and corrosion buildup.

- Urban Water Supply Extension: An African municipal project used custom blue gate valves for quick visual verification of potable water pathways, speeding up maintenance response times by 40% and significantly reducing non-revenue water losses.

Such documented performance gains highlight not just the reliability but the cost-saving value of integrating blue gate valves in mission-critical infrastructure.

Best Practices for Installation and Maintenance

To achieve optimal results and service life from 15mm gate valve blue solutions, adherence to proper installation and maintenance guidelines is essential:

- Pre-Installation Cleaning: Flush pipelines to eliminate debris that may damage the valve seat.

- Orientation: Install vertically whenever possible for consistent stem operation.

- Torque Control: Use calibrated torque tools to avoid over-tightening connections, which can deform internal seals.

- Routine Operation: Exercise the valve quarterly to prevent actuator sticking, especially in infrequently used lines.

- Seal Inspection: Monitor for leaks and replace soft parts as required; failure rates are halved when maintenance follows manufacturers’ protocols.

A 2022 field survey recorded a 30% drop in emergency valve replacements for facilities adhering to routine inspection and exercise schedules, underlining the importance of proactive asset management.

Concluding Thoughts: Why Choose 15mm Gate Valve Blue for Reliable Flow Control Solutions?

With proven technical advantages, diverse customization options, and a strong track record in applications from commercial buildings to heavy industry, the 15mm gate valve blue is a compelling choice for professionals seeking maximum value and dependability. The product delivers low flow resistance, excellent corrosion protection, and long operational life—all backed by manufacturers’ comprehensive warranties.

Regardless of project size or sector, investment in gate valve blue technology ensures safety, efficiency, and compliance for today’s demanding flow control environments. As systems modernize and regulatory pressures increase, selecting high-performance components such as these becomes essential for sustainable, cost-effective fluid management.

(15mm gate valve blue)