1. Overview

A ball valve is a quarter-turn rotary valve that controls flow by rotating a spherical disc. Key features include:

- Excellent sealing (metal seats achieve ANSI Class VI)

- Minimal flow resistance (full-bore design matches pipeline ID)

- Rapid operation (90° rotation for full open/close)

- Long service life (wear-resistant designs support 100,000+ cycles)

2. Main Components

| Component | Description |

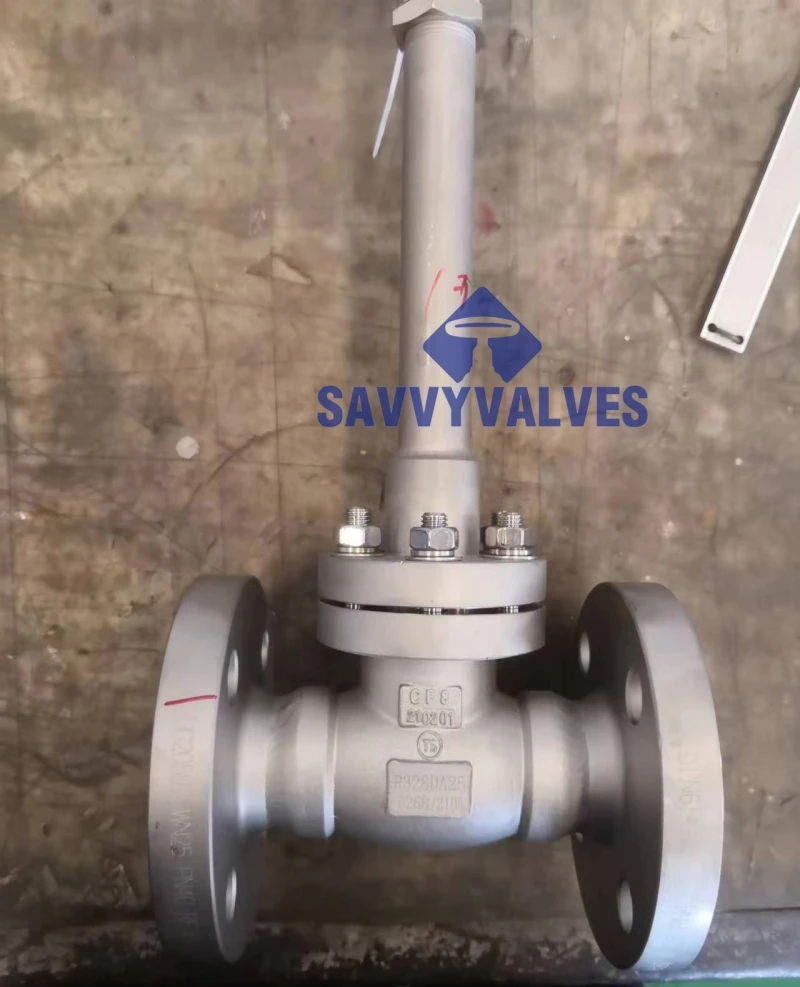

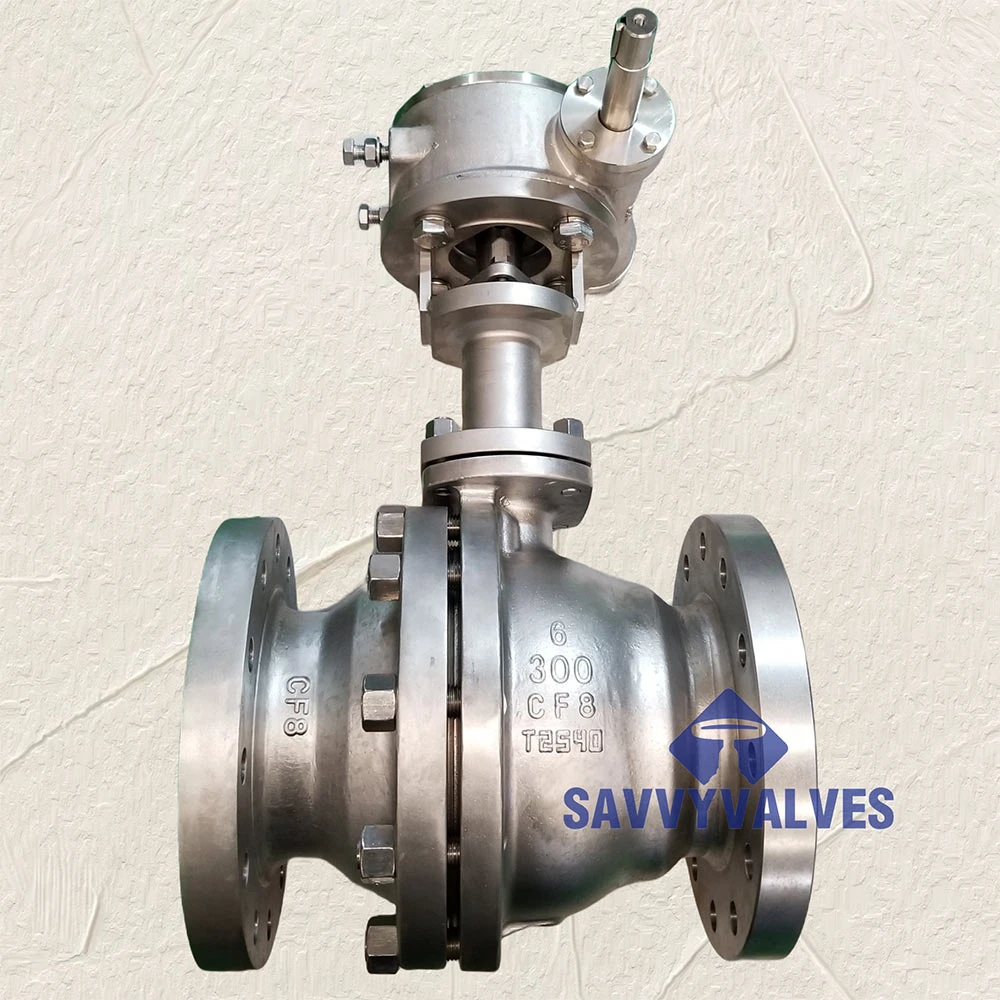

| Body | Cast/forged construction (WCB, CF8, duplex steel); connections: flanged/buttweld/threaded |

| Ball | Precision-polished sphere (Ra≤0.8μm); materials: 304/316 SS, Ni-plated carbon steel, ceramic-coated |

| Seat | Soft seal (PTFE/RPTFE) or metal seal (Stellite alloy) |

| Stem | Blowout-proof design; 17-4PH heat-treated; graphite packing with SS spring compensation |

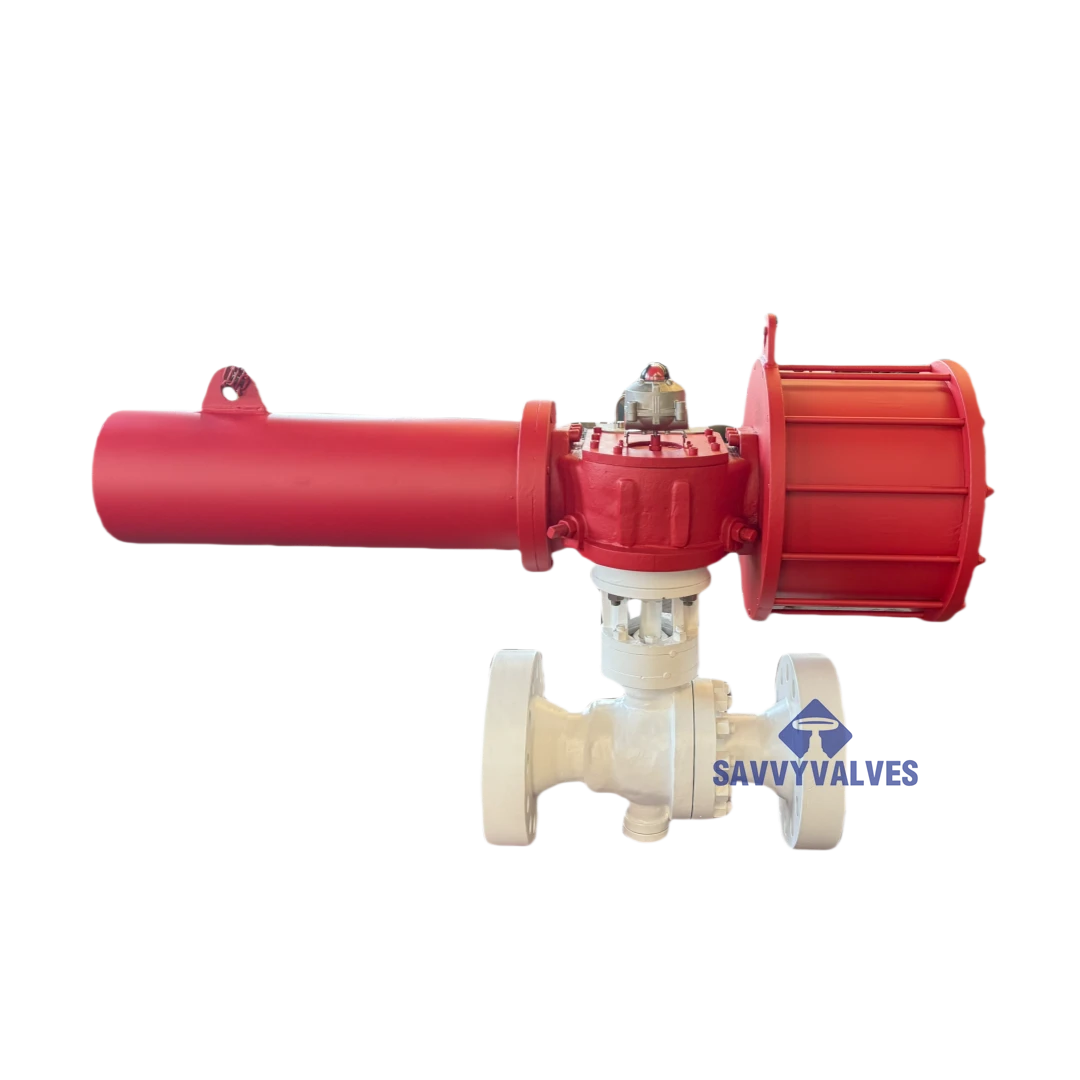

| Actuation | Manual/pneumatic/electric/hydraulic (ISO 5211 mounting pad) |

3. Types

(1) By Design

- Floating Ball

- Ball presses against seats via media pressure

- Size range: DN15~DN200

- Pressure: PN16~PN40

- Trunnion Mounted

- Ball fixed by upper/lower stems; seats absorb pressure

- Size range: DN50~DN1200

- Pressure: PN16~PN250 (ANSI 150~2500)

(2) By Bore

- Full Bore: ID = pipeline ID (for pigging)

- Reduced Bore: ID ≈ 80% pipeline ID (cost-effective)

(3) Special Types

- V-Port Ball: V-notch for precise control (≈equal percentage characteristic)

- Three-Piece Body: Removable for maintenance

- Top-Entry: In-line repairable design

4. Specifications

| Parameter | Range | Notes |

| Size (DN) | DN8~DN1200 | Custom designs for larger sizes |

| Pressure Rating | PN10~PN420 (ANSI 150~2500) | High-pressure trunnion valves up to 2500LB |

| Temperature | -196℃~550℃ | Cryogenic treatment for low temps |

| Media | Water/oil/gas/acids/slurries | Fluorine-lined for corrosive media |

| Leakage Class | ANSI Class IV/V/VI | Metal seats achieve Class VI |

| Operation Speed | Pneumatic: 0.5 sec (fastest) | Large electric valves: 10-30 sec |

5. Applications

① Oil & Gas

- Pipeline block valves (API 6D)

- LNG cryogenic valves (-196℃ austenitic SS)

② Chemical

- Corrosive media (PTFE-lined)

- High-pressure reactors (forged trunnion valves)

③ Power

- Boiler feedwater (hard-seal forged valves)

- Steam lines (bellows-sealed valves)

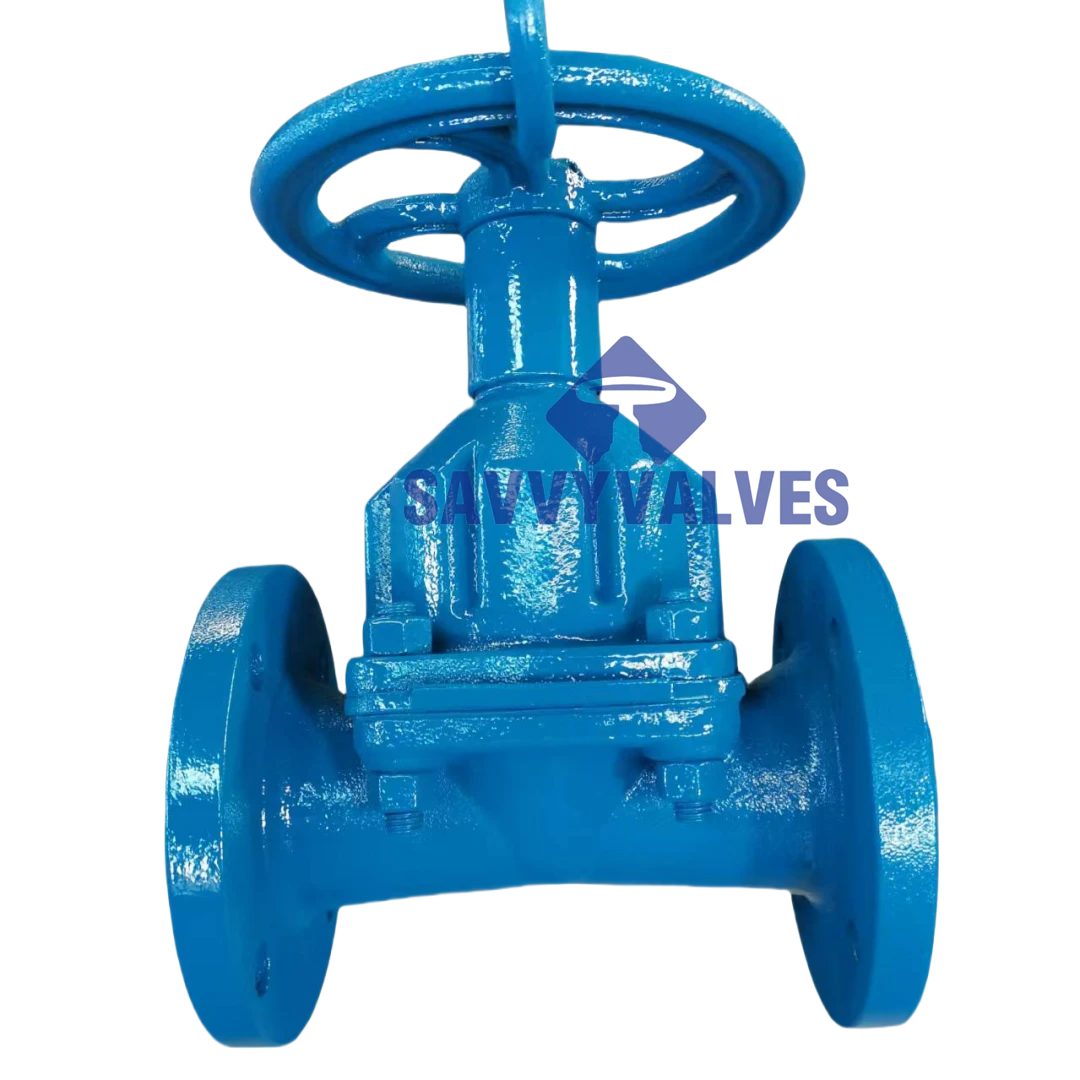

④ Water Treatment

- Municipal networks (full-bore epoxy-coated)

- Wastewater (wear-resistant ceramic-coated)

⑤ Specialized

- Semiconductor (ultra-high-purity gas)

- Marine systems (bronze seawater valves)

6. Selection Guide

| Application | Recommended Type |

| Water/gas (PN16) | Floating ball + PTFE seats |

| High-pressure oil (PN100) | Trunnion mounted + metal seats |

| Acids/alkalis | Fluorine-lined/Hastelloy ball |

| Cryogenic LNG (-196℃) | Cryogenically treated SS valves |

| Abrasive slurries | Hard-faced alloy-coated balls |

7. Pros & Cons

✔ Advantages

- Bubble-tight sealing (bidirectional)

- Easy maintenance (in-line seat replacement for some models)

- Fire-safe design (API 607 certified)

✖ Limitations

- Unsuitable for throttling (except V-port)

- High cost for large-diameter/high-pressure valves

8. Standards

- API 6D: Pipeline valves

- API 608: Flanged metal ball valves

- ISO 17292: Petroleum/petrochemical valves

- ASME B16.34: Pressure-temperature ratings

9. Maintenance

- Inspect stem packing quarterly

- Annual seal integrity tests for high-pressure valves

- Bellows-sealed designs for corrosive environments

Conclusion

Ball valves excel in sealing and low-flow resistance, making them essential for industrial piping systems. Proper selection based on media properties, pressure, and frequency ensures long-term reliability.