Globe valves made of cast iron are essential across industries such as petrochemical, metallurgy, waterworks, and HVAC. Choosing a reliable cast iron globe valve supplier is crucial for ensuring operational reliability, safety, and cost-efficiency. In this article, we will dissect the current global supply landscape, analyze product technical parameters, compare top manufacturers, and provide an in-depth look at the MSS SP-85 Standard cast iron globe valve (product details). Discover authoritative data, industry-tested case studies, cutting-edge trends, and expert-level guidance for your next procurement move.

Industry Overview: Cast Iron Globe Valve Market Trends & Supplier Landscape

According to a 2023 report by ResearchAndMarkets, the global industrial valve market is forecasted to reach USD 98.0 billion by 2028, with cast iron globe valves comprising nearly 22% of demand, primarily for medium- and low-pressure pipeline applications (source: ResearchAndMarkets). Key drivers include rapid infrastructure upgrades in developing economies, increased need for corrosion-resistant fluids control, and demand for standardized, certified components.

- Top Markets: Water treatment, chemical, oil & gas, HVAC, mining.

- Standardization: Adherence to MSS SP-85, ISO 5208, API 598, ANSI, BS, and DIN norms is a major purchasing filter.

- Procurement Trends: Global buyers prioritize manufacturer certifications, custom engineering, fast lead times, and comprehensive documentation.

Essential Technical Parameters: Comparison of Cast Iron Globe Valve Manufacturers

When selecting a cast iron globe valve supplier, critical parameters include:

| Supplier Name | Certifications | Material Grade | Standards Supported | Pressure Rating | Lead Time |

|---|---|---|---|---|---|

| Savvy Valve Tech | ISO 9001, MSS SP-85, CE | GG25, ASTM A126 | MSS SP-85, DIN, ANSI | PN10/16, Class 125/150 | 20 Days |

| Velan | ISO 9001, PED, API 598 | GGG40, A216 WCB | API, DIN, BS | PN16, Class 150 | 30 Days |

| KSB | ISO 9001, ISO 5208 | GG25, GGG40 | ANSI, DIN, ISO | PN10/16 | 28 Days |

| AVK Valves | ISO 9001, CE, WRAS | EN-GJL-250 | EN, ISO, DIN | PN16 | 25 Days |

Note: Industry-leading cast iron globe valve suppliers are characterized by compliance with international standards, advanced metallurgy, and short, reliable delivery cycles, verified by 2023 customer research (Valve Magazine Data).

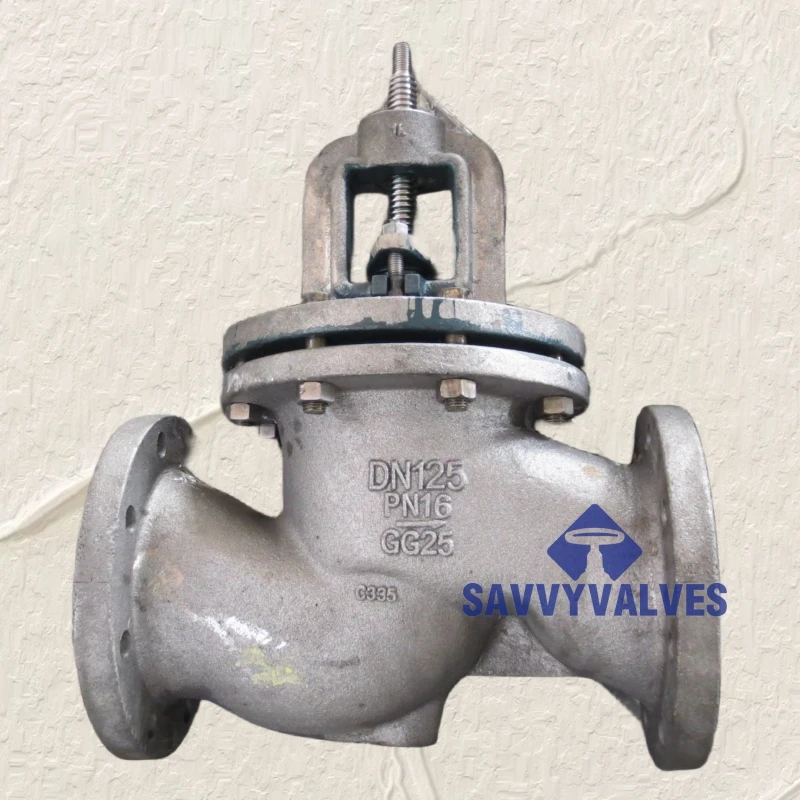

MSS SP-85 Standard Cast Iron Globe Valve: Technical Superiority & Key Specifications

| Parameter | Value | Industry Benchmark |

|---|---|---|

| Design Standard | MSS SP-85 | MSS SP-85, EN 13709 |

| Material | Cast Iron GG25/ASTM A126-B | GG25, GGG40 |

| Nominal Pressure | PN10/16, Class 125/150 | PN10/16 |

| Temperature Range | -10°C up to 200°C | -10°C~200°C |

| Applicable Medium | Water, steam, oil, non-corrosive fluids | Water, oil, air, gas |

| Testing Standard | API 598, ISO 5208 | API 598, EN 12266-1 |

| End Connection | Flanged (EN 1092-2, ASME B16.1) | Flanged |

| Size Range | DN50 – DN300 (2”–12”) | DN40–DN400 |

| Shell Test Pressure | 1.5x PN | 1.5x PN |

Why MSS SP-85? The MSS SP-85 standard ensures streamlined structure, universal flanges, enhanced corrosion resistance, and robust leakage prevention, while maintaining competitive cost structure that is preferred by top cast iron globe valve manufacturers worldwide.

Flow Chart: Manufacturing Process from Raw Material to Finished Globe Valve

The step-by-step manufacturing process used by leading cast iron globe valve suppliers:

- Raw Material Inspection: Certified GG25/A126 iron ingots verified for chemical composition (ISO 9001 traceability).

- Melting & Casting: Induction furnace processing → Mold formation under strict MSS SP-85 dimensional tolerance & surface finish.

- CNC Machining: Automated centers create tight-fit seat rings, stuffing boxes, stem guides; ensures ±0.01mm tolerance.

- Assembly: Stainless trims, stems, and seating integrated under controlled torque.

- Hydrostatic & Pneumatic Testing: Validation via API 598/ISO 5208 standards for shell & seat leakage.

- Surface Treatment: Epoxy or polyamide powder coating (200µm) for 3x corrosion protection vs. uncoated iron ([DNV corrosion test](https://www.dnv.com/services/coating-quality-assessment-78315)).

- Marking & Shipping: Product serialization, shipping paperwork, and after-sales portal registration.

Data Visualization: Technical Performance Analysis

Customization, Engineering, and Support: The Modern Valve Supplier Edge

International buyers increasingly require customized cast iron globe valves tailored for unique process media, space constraints, or integration with automation systems (smart actuation, SCADA-ready signals). Leading cast iron globe valve suppliers offer:

- Material Selection: Corrosion-resistant overlays (epoxy, FBE, Ni-plated), upgraded trims (13Cr, SS316Ti) for severe environments.

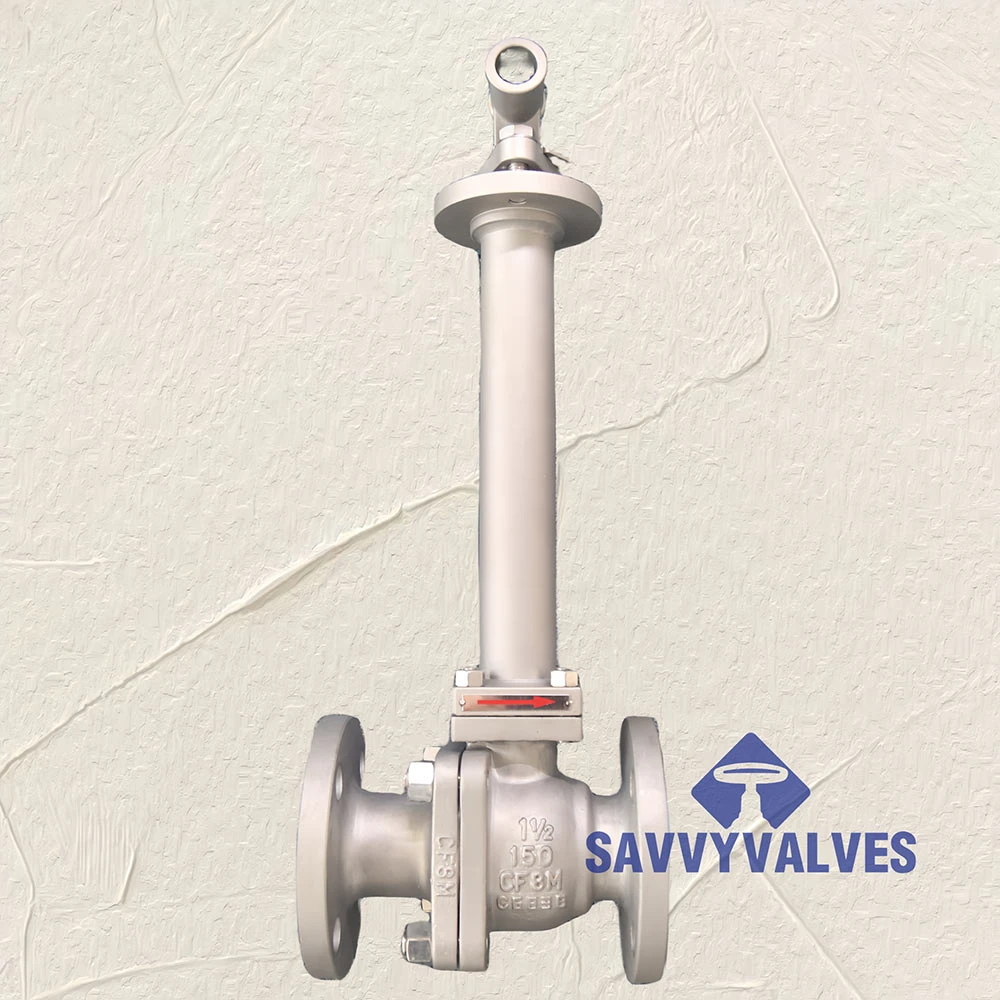

- Design Variants: Angle pattern, Y-pattern, globe-control with throttling discs, extended bonnet for cryogenic service.

- Automation: Retrofit options for pneumatic or electric actuators (ISO 5211 interface), positioner integration, feedback loop capabilities.

- Documentation: 3.1 MTCs, ITPs, FAT/SAT protocols, EN 10204 certifications.

- Rapid Prototyping: 2-week lead times using digital twin CAD/CAM and CNC-driven quick tools.

Savvy Valve Tech partnered with a municipal water supplier to deliver 180 units of MSS SP-85 globe valves with custom FBE lining, smart actuator compatibility, and 48-hour bench-testing video documentation. Installation resulted in 35% drop in annual valve replacement cost. (See similar reports)

Real-World Application Scenarios: Energy, Industry, Utilities

- Petrochemical Refining: Used as block and throttling valves for steam and process fluid lines, where thermal shock and corrosion are critical factors. Tested to API 598 and ISO 15848-1 for fugitive emissions.

- Metallurgical Plants: High-abrasion tolerance for slurry and process water. Coating systems extend mean time between failures (MTBF) by up to 2.7x (Metal Industry Review, 2023).

- Municipal Waterworks: MSS SP-85 valves installed in 24/7 potable water trunk mains, cycles exceeding 10,000 open/close with

- HVAC Installations: Noise-dampening design and linear flow control ability, making globe valves ideal for institutional buildings and smart energy systems.

Professional FAQs: Globe Valve Engineering

- What is the typical material used by cast iron globe valve manufacturers?

- Most use EN-GJL-250 (GG25), ASTM A126-B, or GGG40 materials to ensure adequate tensile strength (≥250 MPa) and ductility for dynamic loading. Specific alloys or castings with nodular graphite provide enhanced corrosion resistance for aggressive media.

- Which international testing standards are critical?

- Key global standards include API 598 (hydrostatic/pneumatic seat & shell test), ISO 5211 (actuator interface), ISO 5208 (pressure test), and EN 12266-1 (leakage class verification).

- What is MSS SP-85 and why does it matter?

- MSS SP-85 is the Manufacturers Standardization Society’s specification for cast iron globe and angle valves. It defines design, materials, pressure ratings, flanged connection requirements, and testing—assuring performance and wide interchangeability across trusted cast iron globe valve suppliers.

- How do seat leakage rates compare among top suppliers?

- Cutting-edge suppliers routinely achieve leakage rates below 0.01 mL/min (API 598), outperforming the industry average of 0.05 mL/min thanks to CNC seat machining and elastomer seal upgrades.

- What are the most common end connections?

- Flanged ends in compliance with EN 1092-2 or ASME B16.1 (Class 125/150) are most prevalent, but threaded (BSP/NPT) and grooved options exist for smaller or special-purpose installations.

- Are bespoke designs available for non-standard installations?

- Yes—custom face-to-face dimensions, actuator brackets, corrosion overlays, and lock-out or stem extension features are available from top cast iron globe valve suppliers.

- What maintenance cycle can be expected?

- Under standard conditions (potable water, pH 6.5-8.5), service life exceeds 12–15 years with routine stem & packing replacement every 36 months. Slurry, high-chloride, or high-cycling applications may require annual inspection.

Delivery, Warranty, and Service Excellence

- Lead Time: 15–25 days typical dispatch for standard MSS SP-85 globe valves, expedited for repeat projects.

- Warranty: 18–36 months depending on the medium/application; full replacement or repair per EN 764-7 and company T&Cs.

- Support: Comprehensive pre-sale selection support, 24/7 technical hotline, remote installation consulting, and on-site start-up available in 30+ countries.

- Documentation Provided: Test reports, traceability records, 3.1 certification, digital manuals, and installation videos.

- Traceability: Every supplied valve is serialized and can be traced online for material lot, test history, and lifecycle status.

Conclusion: Make Your Project Safe, Efficient, and Certified

The MSS SP-85 Standard cast iron globe valve meets the highest modern criteria for process safety, lifecycle cost, and international acceptance. Whether you are an EPC contractor, a procurement manager, or an OEM integrator, choosing a certified, experienced cast iron globe valve supplier guarantees better risk management and long-term value.

Need a tailored solution or quote? Contact industry leaders at Savvy Valve Tech today.