In the dynamic landscape of fluid control, the demand for robust, efficient, and long-lasting valve solutions is paramount. Among the various valve types, the NRS Resilient Seated Gate Valve stands out as a critical component, offering superior sealing capabilities and extended service life compared to traditional metal-seated gate valves. This comprehensive guide delves into the core aspects of these essential valves, from their foundational technology and manufacturing excellence to their diverse applications and market impact. We will explore how a high-quality NRS Resilient Seated Gate Valve, such as those offered by Savvy Valve Tech, represents a significant investment in operational integrity and sustainability.

Industry Trends: The Evolution of Fluid Control

The global valve market is experiencing significant growth, driven by increasing industrialization, urbanization, and the modernization of existing infrastructure. Projections indicate the global industrial valves market, valued at approximately USD 70 billion in 2023, is expected to reach over USD 90 billion by 2030, with a compound annual growth rate (CAGR) of around 4.5% (Source: Grand View Research, market reports). Within this growth, the demand for more advanced, low-maintenance, and corrosion-resistant valves is escalating. Resilient seated gate valves, in particular, are gaining traction due to their bubble-tight shut-off capabilities and minimal head loss, making them ideal for critical applications where leakage is unacceptable.

Key trends influencing the adoption of resilient seated gate valve technology include:

- Sustainability & Environmental Regulations: Stricter environmental policies necessitate zero-leakage solutions, reducing water loss and minimizing ecological impact.

- Smart Infrastructure Development: Integration with IoT and smart monitoring systems for predictive maintenance and optimized fluid management.

- Aging Infrastructure Replacement: The need to replace outdated, less efficient valve systems with modern, reliable alternatives.

- Emphasis on Lower Total Cost of Ownership (TCO): Users are increasingly prioritizing valves that offer lower operational and maintenance costs over their lifespan, aligning perfectly with the benefits of a nrs resilient seated gate valve.

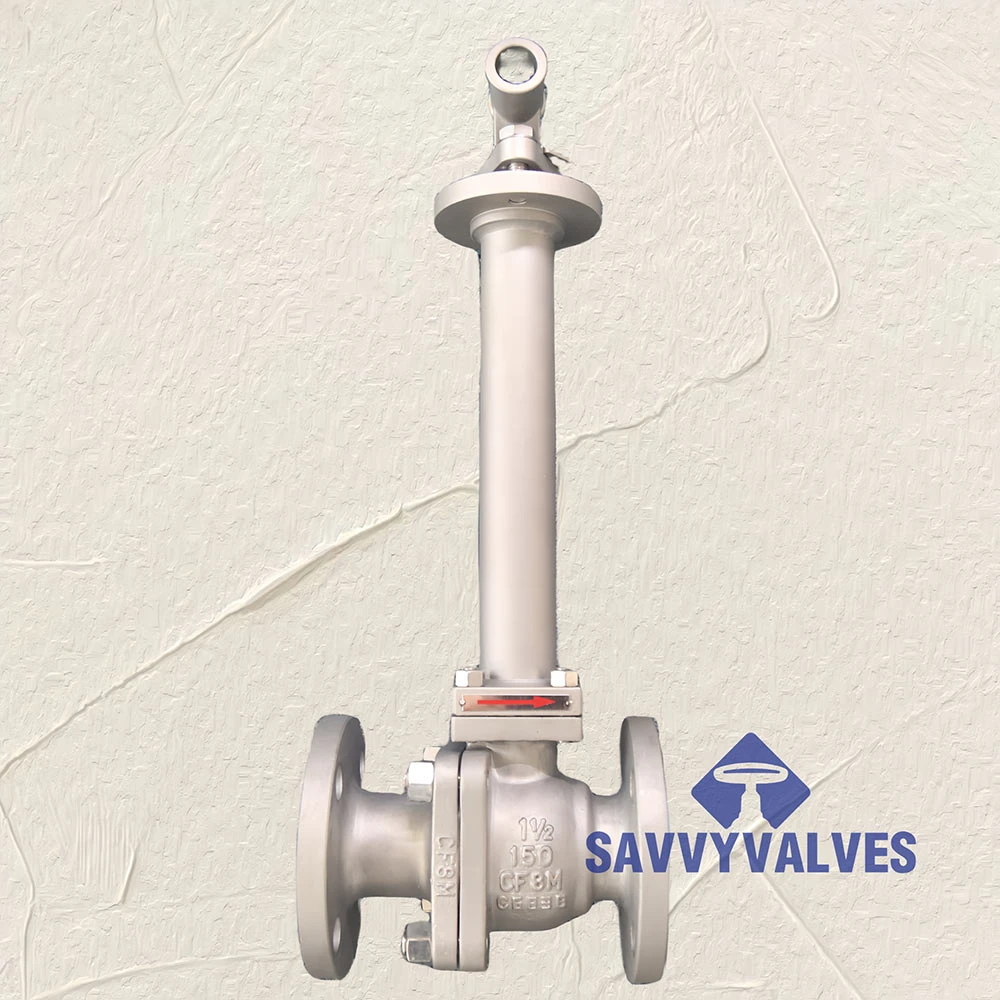

Figure 1: A typical NRS Resilient Seated Gate Valve in a municipal water treatment plant.

Technical Parameters and Superior Performance

The design and material selection are crucial for the performance of an NRS Resilient Seated Gate Valve. Unlike traditional wedge gate valves that rely on metal-to-metal seating, these valves feature a fully encapsulated wedge with an elastomeric material (typically EPDM or NBR), ensuring a bubble-tight seal even under varying pressure conditions. The "NRS" (Non-Rising Stem) design means the stem does not move up or down when the valve is operated, making it ideal for installations with limited overhead clearance.

Key Technical Specifications:

The following table provides typical specifications for a high-performance NRS Resilient Seated Gate Valve:

| Parameter | Specification | Description |

|---|---|---|

| Nominal Size Range | DN50 - DN600 (2" - 24") | Common sizes for municipal, industrial, and commercial applications. Larger sizes available upon request. |

| Pressure Rating | PN10 / 1.0 MPa (150 PSI) | Suitable for low to medium pressure applications. |

| PN16 / 1.6 MPa (232 PSI) | Common for municipal water and general industrial use. | |

| Temperature Range | -10°C to +80°C (14°F to 176°F) | Typical for EPDM seats, suitable for water and neutral liquids. Other elastomers for wider ranges. |

| Body Material | Ductile Iron (GGG50 / ASTM A536 65-45-12) | Provides excellent strength, ductility, and corrosion resistance. Often fusion-bonded epoxy coated. |

| Wedge Material | Ductile Iron core, fully encapsulated with EPDM/NBR | Ensures long-term sealing integrity and corrosion protection. |

| Stem Material | Stainless Steel (SS420 / SS304 / SS316) | High strength and corrosion resistance for reliable operation. |

| Sealing Standard | EN 1074-1 & 2, AWWA C509 / C515 | Ensures bubble-tight shut-off. Leakage rate: Class A (zero leakage). |

| Flange Drilling | EN1092-2 (PN10/PN16), ANSI B16.5 Class 150 | Compatibility with various piping systems. |

| Coating | Fusion-bonded Epoxy Powder Coating | Minimum 250 microns dry film thickness, resistant to corrosion and suitable for potable water (WRAS/NSF certified). |

| Operation | Handwheel, Gearbox, Electric Actuator | Versatile control options. |

Application Scenarios: Where Reliability Matters Most

The versatility and robust design of the NRS Resilient Seated Gate Valve make it indispensable across a wide array of industries and applications:

- Water Supply and Distribution: The primary application. These valves are critical for isolating sections of municipal water mains, controlling flow to residential areas, and preventing backflow. Their tight seal prevents water loss, a significant concern in aging urban infrastructure.

- Wastewater Treatment Plants: Handling non-potable water, often containing solids and chemicals. The robust design and corrosion-resistant materials ensure longevity in harsh environments.

- Fire Protection Systems: Essential for reliable shut-off and isolation in fire hydrants and sprinkler systems, where quick and dependable operation is critical for safety.

- Irrigation Systems: Managing water flow in agricultural settings, ensuring efficient water distribution to crops.

- Industrial Applications: Used in various industrial processes requiring precise fluid control, especially for water and neutral liquid lines. This includes cooling water systems, process water lines in food & beverage, and general utility lines in manufacturing.

- Building Services: HVAC systems, plumbing, and general water management within large commercial and residential buildings.

In all these scenarios, the zero-leakage capability and low maintenance requirements of a nrs gate valve translate directly into operational cost savings and improved system reliability.

Figure 2: Installation of an NRS Resilient Seated Gate Valve in a main water distribution line.

Technical Advantages: Why Choose a Resilient Seated Gate Valve?

The advantages of a NRS resilient seated gate valve over traditional metal-seated or other valve types are profound, impacting both performance and long-term cost of ownership:

- Bubble-Tight Shut-off (Zero Leakage): The elastomeric encapsulation of the wedge creates a perfect seal against the valve body, preventing any leakage. This is a significant improvement over metal-seated valves, which can experience minor leakage due to wear or trapped debris. This directly contributes to water conservation and reduced operational losses.

- Corrosion Resistance: The ductile iron body is typically coated with fusion-bonded epoxy, providing excellent protection against corrosion both internally and externally. The encapsulated wedge further isolates the metal components from the fluid, enhancing the lifespan, especially in harsh water or mild chemical environments.

- Reduced Operating Torque: The smooth, low-friction operation due to the resilient seating reduces the force required to open and close the valve, minimizing wear on internal components and potentially allowing for smaller, less expensive actuators.

- Self-Cleaning Mechanism: As the wedge moves, the resilient material scrapes the valve body, preventing the build-up of debris and scale. This self-cleaning action ensures reliable sealing over time, even with non-clean fluids.

- Long Service Life: With fewer wear parts and superior material compatibility, a well-manufactured resilient seated gate valve can offer decades of reliable service, significantly reducing replacement and maintenance costs. According to a study by the American Water Works Association (AWWA), properly maintained resilient seated gate valves can have an average service life exceeding 50 years in water distribution applications.

- Full Bore Design: When fully open, the valve offers an unobstructed flow path, minimizing pressure drop and energy loss. This translates to energy savings, particularly in large-scale pumping systems.

- Non-Rising Stem (NRS): Ideal for confined spaces as the stem does not extend above the handwheel when operated. This compact design is highly beneficial in underground installations or areas with limited headroom.

Manufacturing Process: Crafting Excellence in Every NRS Resilient Seated Gate Valve

The manufacturing of a high-quality NRS Resilient Seated Gate Valve involves a meticulous process, combining advanced material science with precision engineering. Here’s a simplified breakdown of the typical stages:

Phase 1: Material Preparation & Casting

Raw Materials (Ductile Iron, Stainless Steel, EPDM/NBR Granules)

Melting & Alloying (Precise composition control for Ductile Iron)

Sand Casting (Body & Wedge Casting) → High-precision molds

Cooling & Shakeout

Initial Cleaning & Deburring

Quality Inspection (Visual, Chemical Composition, Mechanical Properties)

Phase 2: Machining & Surface Treatment

CNC Machining of Body (Flanges, Bore, Gland Area, Seat Pocket)

CNC Machining of Wedge (Core for Rubber Encapsulation)

Machining of Stem & Other Components (Spindle, Gland, Bushings)

Cleaning & Phosphating (Preparation for Coating)

Fusion-Bonded Epoxy Coating (Body & Bonnet) → Electrostatic application, curing at high temperature (e.g., 200°C)

Coating Thickness & Adhesion Testing (e.g., Holiday Detection, Cross-Cut Test)

Phase 3: Rubber Encapsulation (Wedge)

Pre-treatment of Ductile Iron Wedge Core

Rubber Injection Molding (EPDM/NBR onto the wedge core) → High pressure, controlled temperature

Vulcanization (Curing the rubber for optimal elasticity and bonding)

Deflashing & Trimming

Wedge Quality Inspection (Visual for defects, Durometer for hardness, Adhesion Test)

Phase 4: Assembly

Installation of Stem into Wedge

Assembly of Stem Seals (O-rings, Gland Packing)

Insertion of Wedge-Stem Assembly into Body

Bonnet Assembly (Gasket, Bolts)

Handwheel/Gearbox/Actuator Attachment

Phase 5: Testing & Quality Assurance

Hydrostatic Pressure Testing (Body & Seat, according to EN 1074, AWWA C509/C515)

- Body Test: 1.5 times PN rating (e.g., 24 bar for PN16)

- Seat Test: 1.1 times PN rating (e.g., 17.6 bar for PN16) with zero leakage.

Operational Torque Test

Dimensional Verification

Final Visual Inspection & Documentation

Packaging & Shipping

Throughout this process, adherence to international standards like ISO 9001 (Quality Management), EN 1074, AWWA C509/C515, and BS 5163 is rigorously maintained to ensure every resilient seated gate valve meets the highest performance and durability benchmarks.

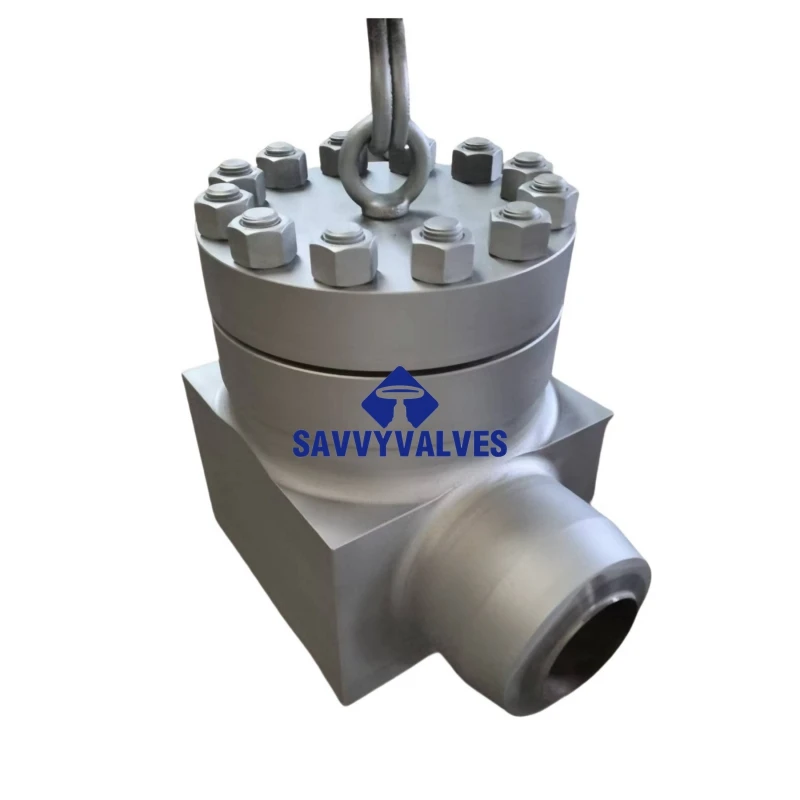

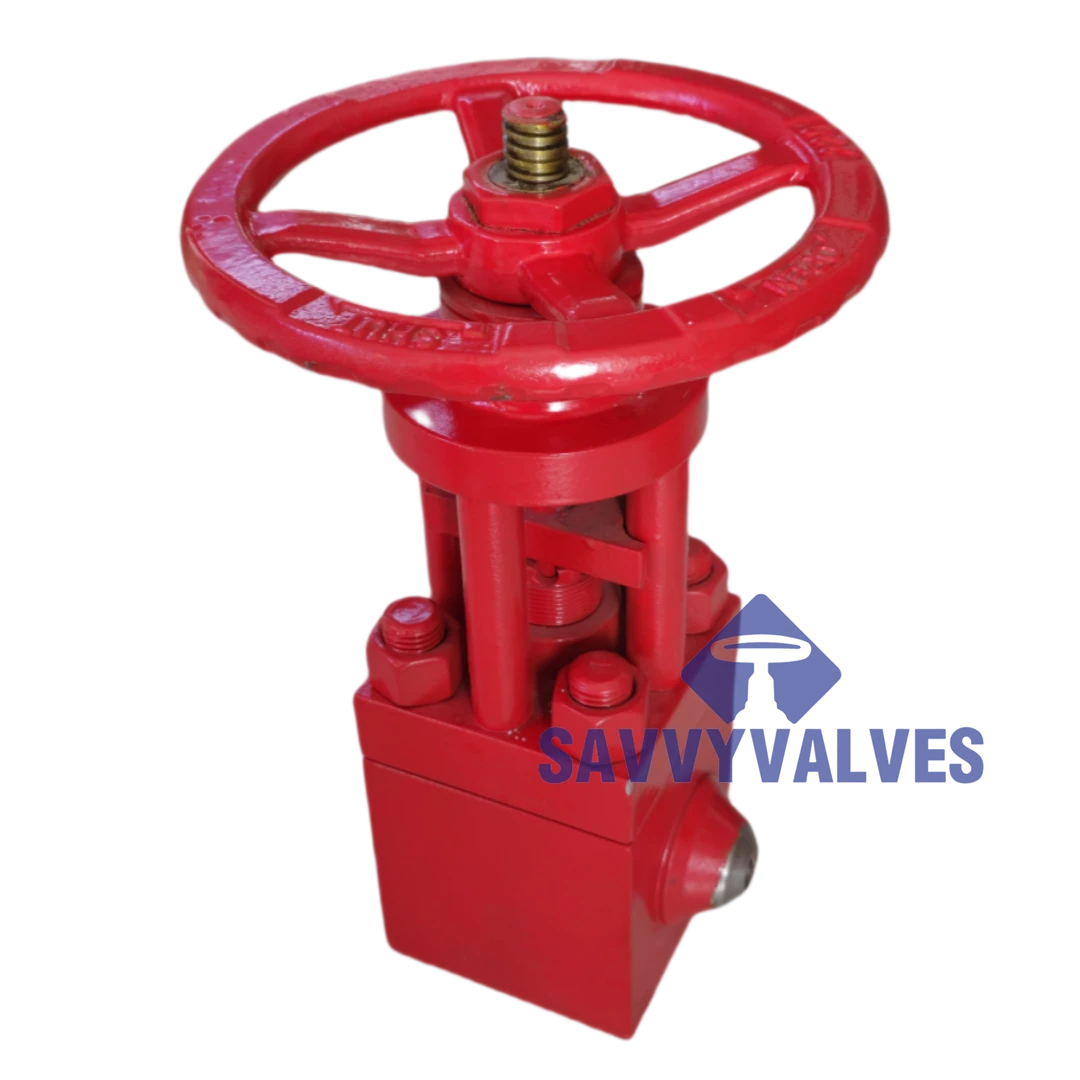

Figure 3: Precision CNC machining of valve components during manufacturing.

Manufacturer Comparison: Choosing the Right Partner

When selecting a supplier for NRS Resilient Seated Gate Valves, it’s crucial to look beyond just the price tag. A reliable manufacturer will offer a combination of technical expertise, quality assurance, and comprehensive customer support. Below is a comparative overview of what to consider:

| Feature / Criteria | Leading Manufacturers (e.g., Savvy Valve Tech) | Standard Manufacturers | Budget Manufacturers |

|---|---|---|---|

| Quality Certifications | ISO 9001, CE, WRAS/NSF (for potable water), AWWA, BSEN | ISO 9001, possibly CE | Basic QC, limited external certifications |

| Material Traceability | Full material traceability certificates (MTCs) for all components | Limited or partial traceability | Often none |

| Coating Quality | Minimum 250 microns fusion-bonded epoxy, holiday-free, WRAS/NSF approved | 150-200 microns epoxy, may not be certified for potable water | Thin paint or basic epoxy, prone to flaking |

| Wedge Encapsulation | High-pressure injection molded EPDM/NBR, excellent adhesion, durable | Compression molded or lower quality injection, potential for delamination | Poor adhesion, thin rubber, high risk of failure |

| Testing Procedures | 100% hydrostatic body & seat test, operational torque test, third-party inspection options | Batch testing, basic hydrostatic tests | Minimal testing, reliance on sample checks |

| Warranty & Support | Extensive warranty (e.g., 2-5 years), dedicated technical support, spare parts availability | Standard 1-year warranty, basic support | Limited to no warranty or support |

| Customization | High flexibility for specific dimensions, materials, or actuator types | Limited customization options | Standard products only |

| Experience & Reputation | Decades of industry experience, strong client testimonials, project case studies | Newer entrants or smaller scale, less established reputation | Focus on low cost, minimal long-term reputation |

Choosing a reputable manufacturer like Savvy Valve Tech ensures that your investment in an NRS Resilient Seated Gate Valve translates into reliable performance and a lower total cost of ownership, avoiding costly failures and downtime.

Customization Solutions and Expertise

While standard configurations of the NRS Resilient Seated Gate Valve meet most common requirements, certain projects demand tailored solutions. Leading manufacturers offer extensive customization options to precisely fit unique application needs:

- Material Variations: Beyond standard ductile iron and EPDM, options include specific stainless steels for aggressive media, or alternative elastomers (e.g., Viton for higher temperatures or chemical resistance, Hypalon for strong oxidizers).

- Actuation Types: Manual handwheels can be replaced or supplemented with gearboxes for larger sizes, electric actuators for remote control and automation, or pneumatic/hydraulic actuators for rapid response.

- Flange and End Connections: While standard flange drillings are common, custom drilling patterns, grooved ends, or plain ends for welding can be provided.

- Bypass Arrangements: For very large valves or high-pressure systems, a bypass can be integrated to equalize pressure before opening, reducing operating torque and wear.

- Indicator Posts & Extensions: For underground installations, indicator posts or extended operating stems can be supplied to allow for easy operation and visual confirmation of valve position from ground level.

- Special Coatings: For highly corrosive environments or submerged applications, specialized multi-layer coating systems or additional cathodic protection features can be incorporated.

Savvy Valve Tech's engineering team works closely with clients from conceptualization to deployment, ensuring that every customized nrs gate valve adheres to the same stringent quality controls as our standard products, guaranteeing seamless integration and optimal performance.

Figure 4: Specialized NRS Resilient Seated Gate Valve with an extended stem for underground installation.

Application Cases: Real-World Impact

The practical benefits of NRS Resilient Seated Gate Valves are best illustrated through real-world applications and customer feedback:

Case Study 1: Municipal Water Main Upgrade, City of AquaFlow

Facing significant water loss due to aging, leaking cast-iron gate valves, the City of AquaFlow initiated a major infrastructure upgrade. They replaced over 500 traditional metal-seated valves with Savvy Valve Tech's PN16 NRS Resilient Seated Gate Valves (DN200-DN400). Post-installation data revealed a remarkable reduction in non-revenue water (NRW) by 18% within the first year, attributed directly to the bubble-tight seal of the new valves. Maintenance calls for valve leaks decreased by 70%, leading to substantial operational savings. The smooth operation and compact NRS design also simplified installation in crowded utility corridors. "The Savvy Valve Tech nrs resilient seated gate valve has been a game-changer for our water conservation efforts," stated the city's Public Works Director.

Case Study 2: Industrial Cooling Water System, GreenTech Manufacturing

GreenTech Manufacturing, a large-scale industrial facility, experienced frequent downtime due to corrosion and valve leakage in their cooling water circuits. Traditional valves required annual replacement in some high-stress areas. By switching to fusion-bonded epoxy-coated resilient seated gate valves from Savvy Valve Tech, GreenTech achieved unprecedented reliability. After three years of continuous operation, there have been zero reported valve failures or leaks, even in sections where chemical dosing is applied. The full-bore design also contributed to a measurable 3% reduction in pumping energy consumption across the system. This demonstrates the energy-saving advantage and robust anti-corrosion properties of these valves.

Customer Feedback Spotlight:

"We've relied on Savvy Valve Tech for our critical water infrastructure projects for over a decade. Their NRS Resilient Seated Gate Valve consistently performs above expectations, and their technical support is unparalleled. It’s not just a product; it’s a long-term partnership built on trust." - Chief Engineer, Global Infrastructure Solutions Inc.

Ensuring Trustworthiness: Our Commitment to You

At Savvy Valve Tech, we understand that purchasing critical infrastructure components requires absolute trust. Our commitment to trustworthiness is embedded in every stage of our process:

- Comprehensive Quality Assurance: Every NRS Resilient Seated Gate Valve undergoes rigorous testing, including hydrostatic body and seat tests, according to international standards (EN 1074, AWWA C509/C515). Our quality management system is ISO 9001 certified, ensuring consistent excellence.

- Transparent Delivery & Logistics: We provide clear communication on manufacturing lead times and delivery schedules. Our global logistics network ensures timely and secure delivery of your order, whether it's a single unit or a bulk shipment. Typical lead times range from 4-8 weeks for standard products, with expedited options available.

- Robust Warranty & After-Sales Support: All our resilient seated gate valves come with a comprehensive warranty against manufacturing defects (typically 2-5 years, depending on product series). Our dedicated technical support team is available to assist with installation queries, troubleshooting, and maintenance advice, ensuring the longevity and optimal performance of your valves.

- Expert Technical Documentation: We provide detailed product datasheets, installation manuals, and operation & maintenance guides, empowering our customers with the knowledge to maximize their valve's performance.

- Sustainable Practices: We are committed to environmentally responsible manufacturing, minimizing waste, and utilizing energy-efficient processes. Our products are designed for durability, reducing the need for frequent replacements and contributing to sustainable infrastructure.

Figure 5: Final quality inspection and pressure testing of an NRS Resilient Seated Gate Valve.

Professional FAQ (FAQ)

Conclusion: A Pillar of Modern Fluid Control

The NRS Resilient Seated Gate Valve is not merely a component; it is a fundamental pillar of modern, efficient, and sustainable fluid management systems. Its technical superiority, marked by bubble-tight sealing, exceptional corrosion resistance, and low maintenance, positions it as the preferred choice across municipal, industrial, and commercial applications. By understanding the intricate manufacturing processes, adhering to stringent quality standards, and partnering with experienced manufacturers like Savvy Valve Tech, industries can unlock unparalleled reliability and operational longevity.

Investing in a high-quality NRS Resilient Seated Gate Valve is an investment in the future of infrastructure, ensuring efficient resource management, environmental protection, and sustained operational integrity. As industries continue to evolve, the demand for such robust and reliable solutions will only grow, cementing the resilient seated gate valve's irreplaceable role in the global fluid control landscape.

Further Reading and References:

- American Water Works Association (AWWA) C509/C515 Standards: These standards provide detailed specifications for resilient-seated gate valves for water supply service. Access through AWWA publications or relevant engineering libraries.

- The Valve World Magazine: A leading international journal for valve and actuation technology. Often features articles on new valve designs, materials, and applications. https://www.valve-world.net

- Hydraulics & Pneumatics Magazine: Provides insights into fluid power systems, including valve technology and industry trends. https://www.hydraulicspneumatics.com

- Water Technology Magazine: Focuses on innovations and challenges in water and wastewater management, frequently covering valve applications. https://www.watertechonline.com