Navigating Industrial Flow Control: The Essence of Gear Operated Wafer Type Butterfly Valves

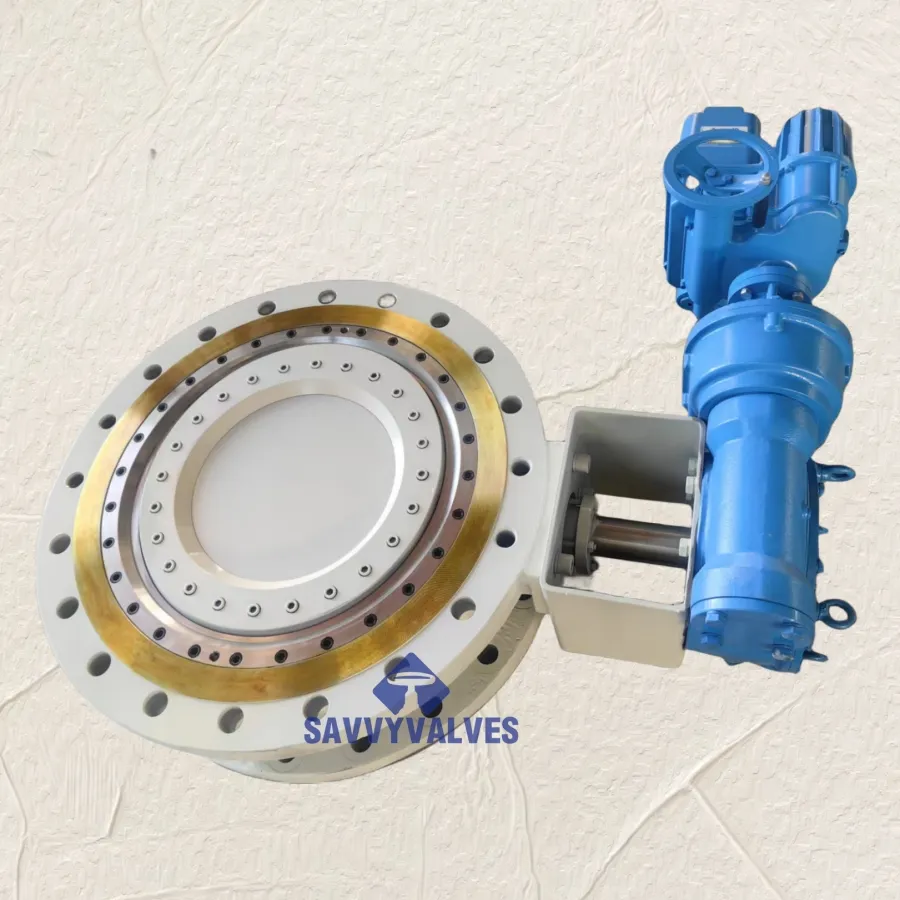

In the intricate world of industrial fluid management, the choice of a valve is paramount, directly influencing operational efficiency, safety, and cost-effectiveness. Among the myriad valve types, the butterfly valve stands out for its quarter-turn operation, lightweight design, and compact footprint, making it a preferred solution across numerous sectors. When precision and significant torque are required, especially for larger sizes or high-pressure applications where manual levers are insufficient, a gear operated wafer type butterfly valve emerges as the optimal choice. This valve type integrates a robust gear mechanism, providing substantial mechanical advantage for smooth, controlled opening and closing, even under demanding conditions where high differential pressures or abrasive media are present. Its inherent design minimizes pressure drop across the valve when fully open, ensuring efficient fluid flow and contributing significantly to energy conservation in pipeline systems. The global market for industrial valves, particularly sophisticated gear operated butterfly valves, is experiencing robust growth, propelled by the relentless expansion and modernization of infrastructure in key sectors such as chemical processing, oil and gas exploration and refining, water and wastewater treatment, power generation, and pulp and paper. This growth is further accelerated by an increasing emphasis on stringent environmental regulations, demanding advanced sealing technologies for zero fugitive emissions, and the drive towards greater automation and digitalization in industrial processes. Manufacturers are continuously innovating, focusing on advanced material science for enhanced corrosion and erosion resistance, superior sealing mechanisms for bubble-tight shut-off (even with metal seats), and smart integration capabilities for remote monitoring, predictive maintenance, and seamless operation within Industrial Internet of Things (IIoT) ecosystems. This strategic evolution underscores the critical role these engineered flow control solutions play in optimizing productivity, ensuring safety, and extending the operational life of vital industrial infrastructures.

The Genesis of Precision: Manufacturing the Gear Operated Wafer Type Butterfly Valve

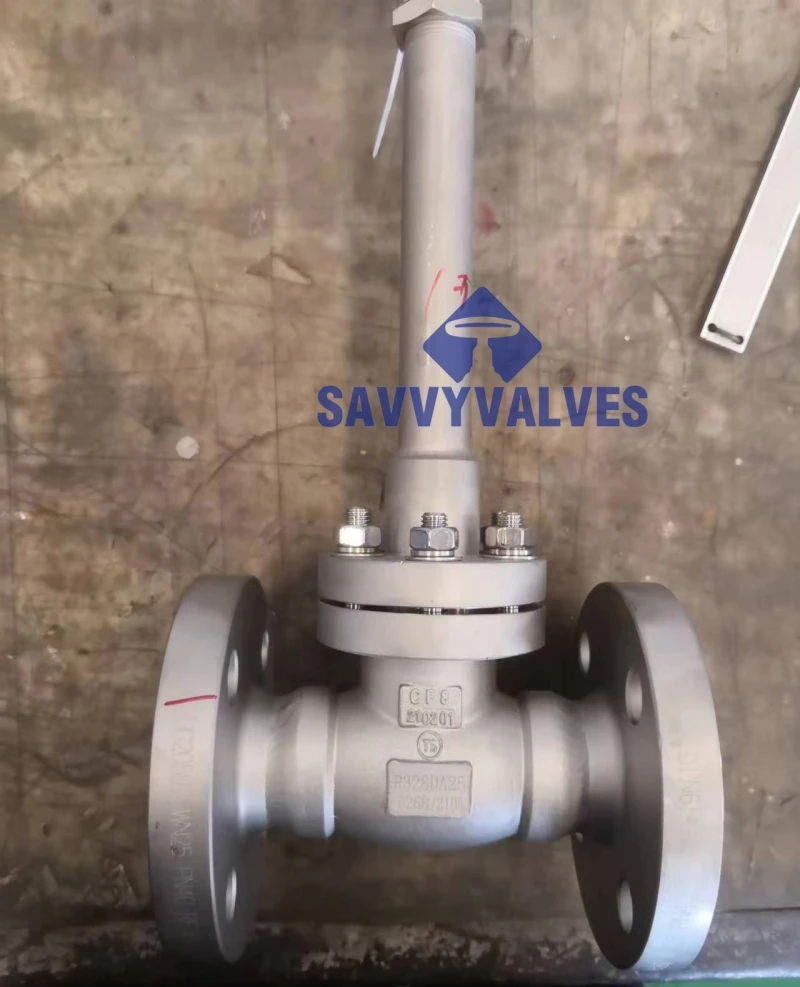

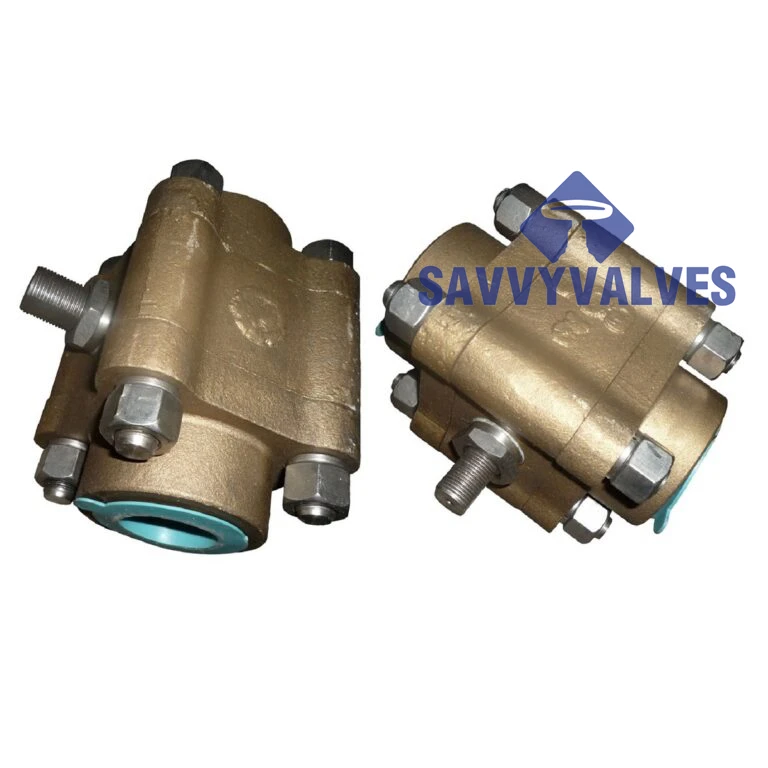

The manufacturing of a high-performance gear operated wafer type butterfly valve is a testament to precision engineering, involving a multi-stage process that ensures unparalleled durability, unwavering reliability, and optimal functionality across diverse industrial applications. The journey commences with meticulous material selection, where the body, disc, and stem materials are carefully chosen based on the intended application's specific temperature, pressure, and media compatibility requirements. Common body materials include robust cast iron (e.g., ASTM A126 Class B), ductile iron (e.g., ASTM A536 65-45-12), carbon steel (e.g., ASTM A216 WCB for general service), various grades of stainless steel (e.g., 304, 316, 316L for corrosion resistance), Duplex Stainless Steel (e.g., 2205 for high strength and pitting resistance), and specialized alloys like Monel or Hastelloy for highly corrosive or abrasive services. Discs often mirror these body materials or feature advanced coatings like Electroless Nickel Plating (ENP) or ceramic coatings for enhanced wear and corrosion resistance. The manufacturing journey typically begins with either casting or forging processes, which form the rough valve body and disc components. Casting provides remarkable flexibility for producing complex shapes and accommodating larger valve sizes, while forging offers superior mechanical properties, including enhanced grain structure and internal integrity, which are crucial for high-pressure and high-stress applications.

Following the initial forming, these components undergo rigorous CNC machining to achieve the precise dimensions, tight tolerances, and superior surface finishes required for critical interfaces, particularly for the valve seat, disc sealing surface, and stem bore. Sealing components, such as resilient seats made from advanced elastomers like EPDM, NBR, Viton, or high-performance polymers like PTFE and PFA, are meticulously molded or machined to ensure bubble-tight shut-off, complying with leakage classes like ANSI/FCI 70-2 Class VI. For metal-seated triple offset designs, the intricate conical seating surface on both the disc and body is machined with extreme precision to achieve superior metal-to-metal sealing, often reaching Class V or even Class VI leakage rates for critical isolation applications. The gear operator itself is a critical sub-assembly, comprising a hardened worm gear, a robust worm shaft, and an ergonomic handwheel, all encased within a sturdy housing, typically cast iron or ductile iron. These components are machined to stringent specifications, assembled, and thoroughly lubricated to ensure smooth, low-friction operation, exceptional durability, and sufficient mechanical advantage, typically providing a torque ratio that significantly reduces the manual effort required to operate the valve, especially large gear operated wafer type butterfly valve units. The final integration of the gear operator with the valve stem demands precision alignment, ensuring that the rotary motion translates accurately and efficiently to the disc's quarter-turn movement. Throughout the entire manufacturing process, stringent quality control measures are rigorously implemented. This comprehensive approach includes raw material verification and spectroscopic analysis, in-process dimensional checks using advanced metrology tools, non-destructive testing (NDT) such as ultrasonic testing (UT), radiographic inspection (RT), or magnetic particle inspection (MPI) for castings and welds, and ultimately, final hydrostatic and pneumatic shell and seat leakage tests in strict accordance with international standards like API 598, ISO 5208, and ASME B16.34. Adherence to overarching quality management systems such as ISO 9001 ensures consistency, traceability, and unwavering performance. A well-manufactured gear operated wafer type butterfly valve is engineered for an extended service life, often exceeding 20 years, depending on the application severity and consistent maintenance, offering exceptional longevity and reliability in demanding sectors like petrochemicals, power generation, oil & gas, water and wastewater treatment, HVAC, and pulp and paper industries, where their compact design, efficient operation, and precise control contribute significantly to energy savings and reduced unscheduled maintenance downtime.

Technical Specifications: Unpacking the Performance of Gear Operated Wafer Type Butterfly Valves

Understanding the detailed technical parameters of a gear operated wafer type butterfly valve is absolutely crucial for discerning engineers and procurement specialists to ensure optimal system integration, long-term operational efficiency, and unwavering reliability. These valves are meticulously engineered to manage substantial flow rates with minimal pressure loss, making them inherently efficient for a wide array of industrial applications. Key parameters include the nominal diameter (DN or NPS), which typically ranges from DN50 (2 inches) up to DN1200 (48 inches) or even larger for highly specialized projects, thus accommodating a vast spectrum of pipeline sizes and flow requirements. Pressure ratings are of paramount importance, strictly adhering to international standards such as PN10, PN16, PN25, PN40 (European standards), or ASME Class 150, Class 300, and Class 600 (American standards), which precisely define the maximum allowable operating pressure at a specific temperature. The selection of materials for the valve body, disc, and stem dictates the valve's resistance to corrosion, abrasion, erosion, and extreme temperatures; common robust selections include WCB Carbon Steel for general utilities, CF8M Stainless Steel (equivalent to 316) for corrosive environments, Duplex Stainless Steel (e.g., CD3MN) for enhanced strength and resistance to stress corrosion cracking, and various bronze alloys (e.g., C95800 Aluminium Bronze) for seawater or brackish water applications. The seat material, whether resilient (e.g., EPDM, NBR, Viton, PTFE) or metallic, profoundly influences the valve's shut-off class and suitability for various media, with resilient seats typically achieving bubble-tight Class VI, and advanced metal seats (especially in triple offset designs) consistently reaching Class V or even Class VI in specialized, critical applications, significantly minimizing undesirable seat leakage and ensuring product integrity.

Temperature range capabilities for a gear operated wafer type butterfly valve vary significantly based on the chosen material combination, often spanning from -29°C to +200°C for soft-seated valves, and extending considerably higher, sometimes up to +600°C, for high-performance metal-seated designs. The gear operator ratio is a vital specification, indicating the mechanical advantage it provides; higher ratios mean substantially less manual effort is required to operate the valve, which is particularly beneficial for very large diameter valves or those subjected to high differential pressures that generate significant torque. Furthermore, understanding flow coefficients (Kv for metric or Cv for imperial units) is essential for accurately sizing the valve for a specific desired flow rate and permissible pressure drop. For instance, a properly sized gear operated wafer type butterfly valve typically exhibits high Kv/Cv values, signifying its exceptional efficiency in allowing fluid passage when fully open, minimizing energy consumption. Stem sealing is another critical aspect, with options ranging from standard gland packing systems (e.g., graphite or PTFE based) to more advanced live-loaded packing or hermetically sealed bellows seals, all essential for preventing fugitive emissions and ensuring strict compliance with increasingly stringent environmental regulations like ISO 15848-1. These detailed technical specifications collectively enable precise valve selection and configuration, ensuring that the chosen gear operated wafer type butterfly valve not only meets the most demanding operational parameters but also contributes significantly to the overall integrity, safety, and long-term efficiency of the fluid control system, preventing costly downtime and ensuring seamless regulatory adherence.

Typical Specifications for Gear Operated Wafer Type Butterfly Valves

| Parameter | Details/Range |

|---|---|

| Nominal Diameter (DN/NPS) | DN50 - DN1200 (2" - 48") and larger upon request |

| Pressure Rating | PN10, PN16, PN25, PN40, ANSI Class 150, 300, 600 |

| Body Materials | Cast Iron (GG25), Ductile Iron (GGG50), WCB Carbon Steel, CF8M Stainless Steel (316), Duplex SS (2205), Aluminium Bronze |

| Disc Materials | Ductile Iron (Nickel Plated), CF8M SS (316), Duplex SS, Aluminium Bronze, Hastelloy, Titanium |

| Seat Materials | EPDM, NBR, PTFE, Viton, Metal-to-metal (Hard-faced with Stellite/Chrome Carbide) |

| Temperature Range | -29°C to +200°C (Soft Seated), up to +600°C (Metal Seated) |

| Applicable Standards | API 609, ISO 5752, ASME B16.5, ASME B16.34, ISO 5211 (Actuator Mounting), API 598 |

| Leakage Class | API 598, ANSI/FCI 70-2 Class VI (Soft Seated), Class V or IV (Metal Seated) |

| Operation | Manual Gear Operated, Electric Actuated, Pneumatic Actuated (with Gearbox for manual override) |

Applications and Advantages: Where Gear Operated Wafer Type Butterfly Valves Excel

The inherent versatility and robust design of the gear operated wafer type butterfly valve make it an indispensable component across a vast array of critical industrial applications, demonstrating superior performance in diverse operational environments. Its compact wafer-style body allows for remarkably easy installation between two pipe flanges, significantly saving valuable space and reducing overall weight in critical pipeline layouts, making it an ideal choice for systems where structural footprint and weight are primary design considerations. In the vast water and wastewater treatment sectors, these valves are extensively utilized for efficiently controlling flow in large-diameter pipes, facilitating seamless operation in raw water intake, advanced filtration processes, chemical dosing, and clean water distribution networks. Their exceptional ability to handle suspended solids without clogging, combined with their robust sealing capabilities, makes them particularly beneficial for challenging media. The chemical and petrochemical industries heavily rely on these valves for general service, handling highly corrosive media, and even some abrasive slurries, leveraging advanced materials like high-grade stainless steel or duplex alloys to rigorously withstand harsh chemical environments, while the integrated gear operator ensures precise and reliable control of critical process flows. Furthermore, in large-scale HVAC systems, they are widely employed for regulating hot and chilled water flow in commercial and industrial buildings, where their high flow capacity and remarkably low pressure drop contribute significantly to energy-efficient building management and reduced operational costs. The power generation sector, encompassing thermal, nuclear, and renewable energy plants, extensively utilizes these valves for essential cooling water lines, complex flue gas desulfurization (FGD) systems, and various auxiliary utility services, benefiting immensely from their unwavering reliability and exceptional longevity under the most demanding and often high-temperature or high-pressure conditions.

The primary technical advantage of a gear operated wafer type butterfly valve lies in the substantial mechanical advantage provided by its integrated gearbox. This sophisticated mechanism significantly reduces the manual torque required to open or close the valve, effectively enabling the precise manual operation of even very large diameter valves (typically 6 inches and above) that would otherwise necessitate expensive, complex, and power-intensive actuation systems. This feature is particularly valuable in remote locations, in emergency bypass lines, or where reliable power supply for electric or pneumatic actuators might be intermittent or unavailable. Moreover, their fundamental quarter-turn operation ensures rapid open-to-close or close-to-open cycles, a crucial factor in applications demanding quick shut-off for safety or rapid diversion of fluid streams. Compared to traditional heavy gate or globe valves, gear operated butterfly valves are considerably lighter and more compact, leading to significantly lower installation costs, reduced structural support requirements for piping systems, and much easier access for routine maintenance and inspection. When equipped with a triple offset design (TOV), these valves achieve bi-directional bubble-tight shut-off (Class V or VI), making them exceptionally suitable for critical isolation services where zero leakage is paramount, thereby significantly enhancing process safety, preventing product loss, and minimizing environmental impact. The inherent design of butterfly valves also minimizes internal resistance to flow when fully open, resulting in a substantially lower pressure drop across the valve compared to other valve types, and consequently, reduced pumping energy consumption throughout the system, directly contributing to substantial operational cost savings and supporting critical environmental sustainability goals by reducing the carbon footprint. Their long service life, typically exceeding two decades, and minimal maintenance requirements further bolster their economic appeal, offering a compellingly low total cost of ownership (TCO) over their entire operational lifespan, making the gear operated wafer type butterfly valve an economically astute investment for long-term industrial efficiency.

Strategic Procurement: Manufacturer Comparison and Custom Solutions for Optimal Performance

When strategically sourcing a gear operated wafer type butterfly valve, the selection of a manufacturer extends far beyond merely evaluating product specifications; it deeply encompasses the manufacturer's overarching reliability, the comprehensiveness of their after-sales support, and their demonstrated ability to provide highly tailored solutions for unique industrial challenges. Industry leaders are prominently distinguished not only by their strict adherence to stringent international standards, such as ISO 9001 for quality management systems and API 609 for specific valve design and rigorous testing protocols, but also by their verifiable proven track record, extensive service history spanning decades, and an unwavering commitment to continuous innovation in valve technology. Effectively evaluating potential manufacturers involves assessing crucial factors such as their material traceability systems, the robustness of their internal manufacturing process controls (e.g., whether they have in-house casting, forging, and advanced CNC machining capabilities), and the sophistication of their testing facilities, including specialized fire-safe testing (to API 607/6FA standards) and cryogenic testing where applicable for low-temperature applications. A truly reputable manufacturer will readily provide comprehensive and transparent documentation, including detailed technical datasheets, certified performance curves, material test reports (MTRs), and all relevant certifications, unequivocally demonstrating their deep expertise and industry authority in the field of gear operated wafer type butterfly valve production.

Furthermore, the capacity for delivering highly customized solutions is a significant and often overlooked key differentiator in the competitive valve market. While standard gear operated butterfly valves can efficiently meet a multitude of common industrial requirements, numerous specific industrial applications often demand unique and bespoke configurations. This might encompass requirements for specialized high-performance alloys for extreme corrosion or severe abrasion resistance, extended stem designs for underground installations or insulated pipelines, specific hygienic coatings for food-grade or pharmaceutical applications, or custom actuation interfaces to seamlessly integrate with existing plant control systems. A strong and experienced manufacturing partner excels in offering comprehensive engineering support, collaborating closely with clients to design and produce these bespoke solutions, thereby ensuring that the customized gear operated wafer type butterfly valve perfectly integrates into complex process systems and precisely handles unique, challenging process parameters with utmost effectiveness. The competitive landscape for industrial valves is incredibly diverse, with numerous manufacturers offering varying levels of product quality, technical specialization, and customer support. When comparing different options, it is imperative to consider critical factors such as the manufacturer's documented experience in similar challenging applications, their global reach for logistical and technical support, and their proactive approach to predictive maintenance services and the guaranteed availability of spare parts over the valve's lifespan. For instance, a vendor specializing exclusively in Triple Offset Butterfly Valves Gear Operated might offer superior and more focused expertise for high-temperature, high-pressure, or critical isolation duties compared to a more general valve supplier. Look for companies that openly share authentic customer feedback, detailed successful service cases, and demonstrate a proactive, long-term approach to addressing post-installation needs. Ultimately, a strategic partnership with a manufacturer demonstrably committed to unwavering quality, relentless innovation, and comprehensive customer support, all robustly backed by rigorous testing data and industry certifications, ensures that your investment in a gear operated wafer type butterfly valve delivers maximum operational value, enhanced safety, and long-term peace of mind, significantly contributing to the overall success of your industrial operations.

Assurance of Excellence: Quality, Support, and Customer Trust for Gear Operated Wafer Type Butterfly Valves

Building and steadfastly maintaining trust in the highly competitive B2B sector, especially for mission-critical infrastructure components like the gear operated wafer type butterfly valve, hinges on an unwavering commitment to exceptional quality, transparent operational processes, and robust, responsive customer support. Reputable manufacturers demonstrably embody this commitment through their strict adherence to internationally recognized quality management systems like ISO 9001:2015, which ensures consistent product quality and process control from the initial design phase through manufacturing, testing, and final delivery. Furthermore, specific product certifications such as API 609 for butterfly valves, comprehensive CE marking for compliance within European markets, and sometimes even specialized FDA compliance for sanitary or pharmaceutical applications, provide independent and authoritative verification of product performance, safety, and suitability for specific environments. A truly comprehensive quality assurance program for a gear operated wafer type butterfly valve encompasses rigorous raw material testing, meticulous in-process inspections at every stage of manufacturing, and exhaustive final functional tests, including hydrostatic shell tests to verify body integrity and pneumatic or hydrostatic seat leakage tests to ensure tight shut-off, all performed in accordance with specified performance parameters and leakage class requirements (e.g., API 598 for testing and API 609 for design). Beyond initial quality, the provision of detailed and accessible documentation, including material test reports (MTRs), comprehensive certification of compliance (COC), and user-friendly operation and maintenance manuals, empowers clients with all the necessary information for efficient installation, optimized operation, and prolonged, trouble-free service life of their gear operated butterfly valves.

Effective customer support and transparent business policies are equally vital for fostering deep and enduring trustworthiness in the industrial valve supply chain. This foundational aspect includes clear and precise communication regarding lead times and delivery schedules; while standard delivery periods for common configurations of a gear operated wafer type butterfly valve might typically range from 4 to 8 weeks, highly customized or very large-diameter valves could necessitate a longer lead time, sometimes extending to 12-20 weeks or more, but these expectations should always be communicated upfront and managed proactively. Furthermore, a strong and comprehensive warranty commitment, typically ranging from 12 to 24 months from installation or 18 to 36 months from shipment, provides clients with substantial financial protection against any potential manufacturing defects, unequivocally underscoring the manufacturer's profound confidence in their product's durability and performance. Post-sales support, encompassing readily available technical assistance, expert troubleshooting services, and the guaranteed availability of genuine spare parts, is indispensable for ensuring minimal operational downtime and extending the effective operational life of the valve. Many leading suppliers for gear operated wafer type butterfly valve units offer dedicated technical hotlines, deploy highly skilled field service engineers for on-site support, and provide comprehensive training programs for client staff, ensuring that operators and maintenance personnel are fully equipped to manage the valves effectively. An easily accessible and well-structured Frequently Asked Questions (FAQ) section on their website, addressing common queries regarding installation procedures, routine maintenance practices, and material compatibility, further enhances transparency and user confidence, solidifying the manufacturer's position as a reliable, experienced, and deeply trustworthy partner in industrial fluid control solutions, fostering long-term relationships built on proven performance and mutual respect.

Frequently Asked Questions (FAQ)

-

Q: What is the primary benefit of a gear-operated butterfly valve over a lever-operated one?

A: The gear operator provides significant mechanical advantage, dramatically reducing the torque required to open or close the valve. This is crucial for larger diameter gear operated wafer type butterfly valve units (typically 6 inches and above) or high-pressure applications where manual lever operation would be impractical, excessively difficult, or even impossible. It allows for highly precise control and remarkably smoother operation, especially when dealing with high differential pressures. -

Q: Can a wafer type butterfly valve be used for end-of-line service?

A: While a wafer type gear operated wafer type butterfly valve is typically clamped securely between two pipeline flanges, some specialized designs can withstand minor differential pressure when one side is open to the atmosphere. However, for true end-of-line service or applications requiring complete and safe isolation without a downstream pipe, lug type butterfly valves are generally preferred as they can be bolted directly to a pipeline flange, allowing for downstream piping removal without system depressurization or additional support. -

Q: How does a Triple Offset Butterfly Valve (TOV) differ from a standard resilient-seated butterfly valve, especially for gear operated units?

A: A standard resilient-seated butterfly valve relies on the compression of an elastomer seat against the disc for sealing, suitable for general service and tight shut-off at moderate temperatures and pressures. A Triple Offset Butterfly Valve (TOV), such as a Triple Offset Butterfly Valves Gear Operated, features three distinct offsets (two in the shaft/disc geometry and one in the conical seating surface) which eliminate all friction between the disc and seat during the critical opening and closing cycles. This innovative design allows for metal-to-metal seating, making TOVs exceptionally ideal for high-temperature, high-pressure, or abrasive applications, frequently achieving superior Class V or even Class VI shut-off. Gear operators are particularly beneficial and often essential for TOVs due to the significantly higher seating torque required to achieve their robust metal-to-metal seal. -

Q: What are the common inspection and testing standards for these valves?

A: Key industry standards governing the design, manufacture, inspection, and testing of gear operated wafer type butterfly valve units include API 609 for general design and rigorous testing of butterfly valves, API 598 for comprehensive valve inspection and pressure testing (encompassing hydrostatic shell and seat leakage tests), ISO 5208 for pressure testing of industrial valves, and ISO 5211 for standardizing actuator mounting flanges. Adherence to these international standards ensures that the valve meets stringent performance, safety, and reliability requirements for diverse industrial applications.

Conclusion: The Enduring Value of Precision Flow Control

The gear operated wafer type butterfly valve stands as a robust cornerstone in modern industrial fluid control, embodying a powerful and indispensable combination of compact design, exceptional operational efficiency, and unwavering performance across the most demanding applications. Its widespread and ever-increasing adoption across diverse industrial sectors, from the rigorous and safety-critical demands of petrochemical processing and large-scale power generation to the essential infrastructure of water treatment facilities and sophisticated HVAC systems, unequivocally underscores its remarkable adaptability and intrinsic value as a primary flow control solution. The seamless integration of a precision-engineered gear mechanism offers unparalleled ease of operation for even the largest valve sizes and under the highest pressure differentials, ensuring incredibly precise flow modulation and consistently reliable shut-off without the need for complex, power-intensive, or expensive automated actuation systems. This inherent mechanical advantage, coupled with continuous and significant advancements in material science, sophisticated sealing technologies, and advanced manufacturing processes, has propelled these gear operated butterfly valves to the forefront of solutions specifically aimed at enhancing overall system efficiency, minimizing energy consumption through remarkably low pressure drop, and rigorously safeguarding against hazardous fugitive emissions, thereby aligning with global sustainability objectives.

Ultimately, investing in a high-quality gear operated wafer type butterfly valve from a reputable and experienced manufacturer is not merely a tactical procurement decision but a profound strategic commitment to achieving long-term operational excellence, enhanced safety, and sustainable industrial growth. By meticulously prioritizing vendors who consistently demonstrate exceptional engineering expertise, strictly adhere to stringent international manufacturing standards, offer comprehensive and responsive after-sales support, and are genuinely capable of delivering highly customized solutions tailored to specific project requirements, B2B decision-makers and technical stakeholders can confidently ensure that their critical fluid control systems are not only robust, inherently reliable, and exceptionally durable but also inherently future-proof against evolving industry challenges. The continuous refinement of manufacturing processes, from advanced casting and precision forging techniques to intricate CNC machining and rigorous multi-stage testing protocols, collectively guarantees the production of valves that offer an extended service life and significantly reduced maintenance overhead, translating directly into lower total cost of ownership. In an era where operational efficiency, unwavering reliability, and environmental stewardship are paramount industrial imperatives, these sophisticated gear operated wafer type butterfly valve units stand as essential enablers of seamless, safe, and economically viable industrial operations, contributing significantly to both economic prosperity and critical environmental protection. The ongoing journey of industrial progress will undoubtedly continue to rely heavily on the precise, dependable, and durable flow control afforded by these indispensable engineering marvels.

Authoritative References

- American Petroleum Institute (API) Standard 609, "Butterfly Valves: Double-Flanged, Lug- and Wafer-Type."

- International Organization for Standardization (ISO) 9001, "Quality Management Systems – Requirements."

- American Society of Mechanical Engineers (ASME) B16.34, "Valves—Flanged, Threaded, and Welding End."

- Fluid Controls Institute (FCI) Standard 70-2, "Control Valve Seat Leakage."

- International Organization for Standardization (ISO) 15848-1, "Industrial valves – Measurement, test and qualification procedures for fugitive emissions – Part 1: Classification system and qualification procedures for type testing of valves."

- American Society for Testing and Materials (ASTM) A216/A216M, "Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service."