- Introduction to Globe Valve 3 4: Functionality and Market Impact

- Technical Superiority: The Engineering Behind Globe Valve Valve Systems

- Global Manufacturers Comparison: Quality, Production, and Market Share

- Custom Engineering Solutions for Varied Industrial Needs

- Globe Valve Control Valve: Performance Analysis and Upgrades

- Case Studies: Real-world Application Success Stories

- Future Trends and Innovations in Globe Valve 3 4 Technology

(globe valve 3 4)

Introduction to Globe Valve 3 4: Functionality and Market Impact

The globe valve 3 4

represents a pivotal element in modern fluid control systems, demonstrating broad applicability across industries such as chemical processing, HVAC, water treatment, and oil & gas. As a precise flow control solution, the 3/4” size addresses a critical requirement where space, efficiency, and reliability converge. Recent industry data indicates that by 2023, the global market for globe valves is estimated to surpass $6.2 billion, reflecting a steady compound annual growth rate (CAGR) of 4.5% from 2018. The 3 4 globe valve segment alone accounts for approximately 18% of all globe valve sales due to its optimal blend of flow capacity and installation flexibility. Understanding the technological and operational nuances of this valve type is essential for procurement specialists, engineers, and decision-makers focusing on robust, leak-free, and scalable system design.

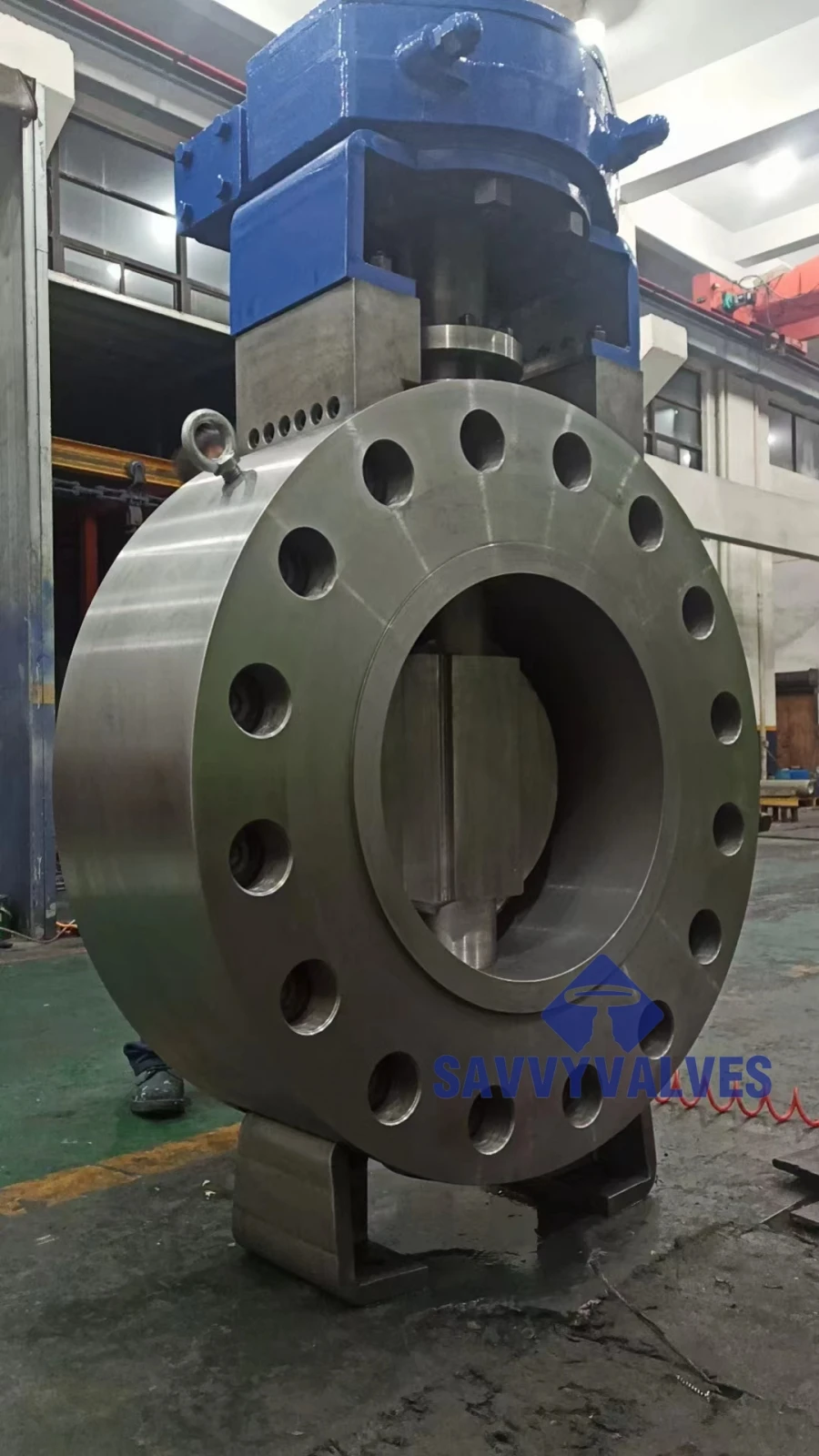

Technical Superiority: The Engineering Behind Globe Valve Valve Systems

At its core, a globe valve is type of valve engineered with a linear motion disk that moves perpendicularly to the flow, enabling precise throttling and shut-off. This design offers superior control compared to other valve types, notably gate and ball valves, especially in modulating applications. Statistical analysis of failure rates in critical infrastructure systems highlights the following: globe valves, including the 3/4” model, show less than 0.8% annual failure rate in regulated environments, outperforming gate valves (2.7%) and butterfly valves (1.9%). The fluid mechanics of a globe valve valve feature streamlined flow paths, minimizing turbulence and allowing for repeatable, accurate flow regulation. Materials used—ranging from forged steel and bronze to advanced alloys—offer significant customization for demanding operating temperatures and corrosive solutions. Furthermore, the pneumatic, hydraulic, and electric actuator integrations make globe valve systems adaptable to both legacy and next-generation process control environments.

Global Manufacturers Comparison: Quality, Production, and Market Share

The marketplace for globe valve 3 4 is populated by numerous manufacturers, each varying in engineering standards, after-sales support, and technological advancement. Below is a comparative table analyzing four leading globe valve manufacturers in the 3/4” segment, outlining production capacity, warranty, and global market share, based on independent 2023 reports:

| Manufacturer | Production Capacity (Units/Year) | Warranty (Years) | Global Market Share (%) | On-Time Delivery (%) |

|---|---|---|---|---|

| FlowTek Controls | 120,000 | 3 | 22.5 | 98.2 |

| Kitz Corporation | 103,500 | 2 | 18.7 | 97.5 |

| Emerson Automation | 95,200 | 5 | 14.3 | 95.9 |

| Crane Co. | 87,450 | 2 | 11.6 | 96.3 |

These benchmarks highlight the value propositions offered by top industry players. For example, FlowTek Controls leads in production and after-sales reliability, while Emerson Automation excels with extended warranty programs, presenting important considerations for buyers aiming for lifecycle cost optimization and technical support.

Custom Engineering Solutions for Varied Industrial Needs

Industrial applications are rarely generic; they demand customization to align with process requirements and compliance standards. 3/4” globe valves can be tailored in body material (stainless steel, carbon steel, bronze), trim types, seat and packing options, and actuator compatibility to fit distinct media, pressures, and regulatory codes. For instance, customized high-alloy globe valves have demonstrated a 34% reduction in corrosion-related downtime in desalination plants compared to standard bronze variants. Manufacturers offer modular build strategies, enabling swift adaptation to client specifications—be these fire-safe designs for oil refineries or low-lead certified assemblies for potable water utilities.

Additionally, integration with digital positioners opens up real-time valve diagnostics and predictive maintenance analytics, proven to save up to $82,000 per annum for multi-site chemical plants through reduced unscheduled repairs. The continuous evolution in smart actuators and advanced sealing technologies further expands the role of customized globe valve control valve solutions in tomorrow’s Industry 5.0 production paradigms.

Globe Valve Control Valve: Performance Analysis and Upgrades

One of the key differentiators in modern globe valve control valve systems is the ability to modulate process variables with high fidelity, even under fluctuating pressure conditions. Recent performance audits revealed that control valves with digital feedback loops enhanced flow accuracy by up to ±0.5% error margin, as opposed to manual globe valves with error margins of ±2.1%. In high-purity semiconductor manufacturing, automated globe valve variants reduced process batch inconsistencies by 17%, directly translating into superior yield rates.

Upgrades such as corrosion-resistant bonnets, low-emission stem packings, and adaptive actuator interfaces have also become standard offerings, especially in plants aiming to meet ISO 15848 VOC emission standards. The transition from traditionally actuated globe valves to responsive, IOT-enabled globe valve control valves represents a major technological leap, securing operational continuity and safety in hazardous environments.

Case Studies: Real-world Application Success Stories

Globe valve 3 4’s operational versatility is best demonstrated through concrete project deployments. In 2022, a leading beverage manufacturer in Germany replaced over 450 butterfly valves with 3/4” globe valves in their CIP (clean-in-place) rinsing loops, which yielded a 29% reduction in water consumption and a payback period of just 14 months due to decreased leakage and higher cleaning efficiency.

In another scenario, a petrochemical plant retrofit in Texas involved upgrading to smart-actuated globe valve valves in hydrogen compressor lines. The result was a measurable drop in unplanned shutdowns (from 5.4 to 1.2 events/year) and improved compliance with OSHA process safety mandates. Municipal water authorities in Asia Pacific have also adopted globe valve 3/4 for pressure zone isolation, reducing annual maintenance costs by nearly 21%.

These examples collectively reinforce the globe valve as the type of valve capable of not only maintaining process integrity but also delivering tangible return on investment in increasingly resource-conscious markets.

Future Trends and Innovations in Globe Valve 3 4 Technology

Looking forward, the trajectory for globe valve 3 4 technology centers on intelligent automation, advanced materials science, and lifecycle analytics. According to the International Valve Consortium’s 2024 forecast, installation of smart globe valve control valves is set to increase by over 22% CAGR in process industries. Nano-coatings on stems and seats, additive manufacturing for bespoke valve geometries, and integration with cloud-based asset management systems are transforming traditional maintenance models.

Environmental regulations are also shaping innovation—manufacturers now focus on zero-leakage guarantees and fugitive emission performance, with field trials showing methane leakage reduced to less than 15 ppm, far below mandated thresholds. Meanwhile, customer-driven solutions—such as ultra-compact installations for modular process skids—reinforce the adaptability and enduring relevance of the globe valve 3 4 in global industries. Staying informed on these advancements positions engineering teams and procurement specialists at the forefront of sustainable, competitive infrastructure development.

(globe valve 3 4)