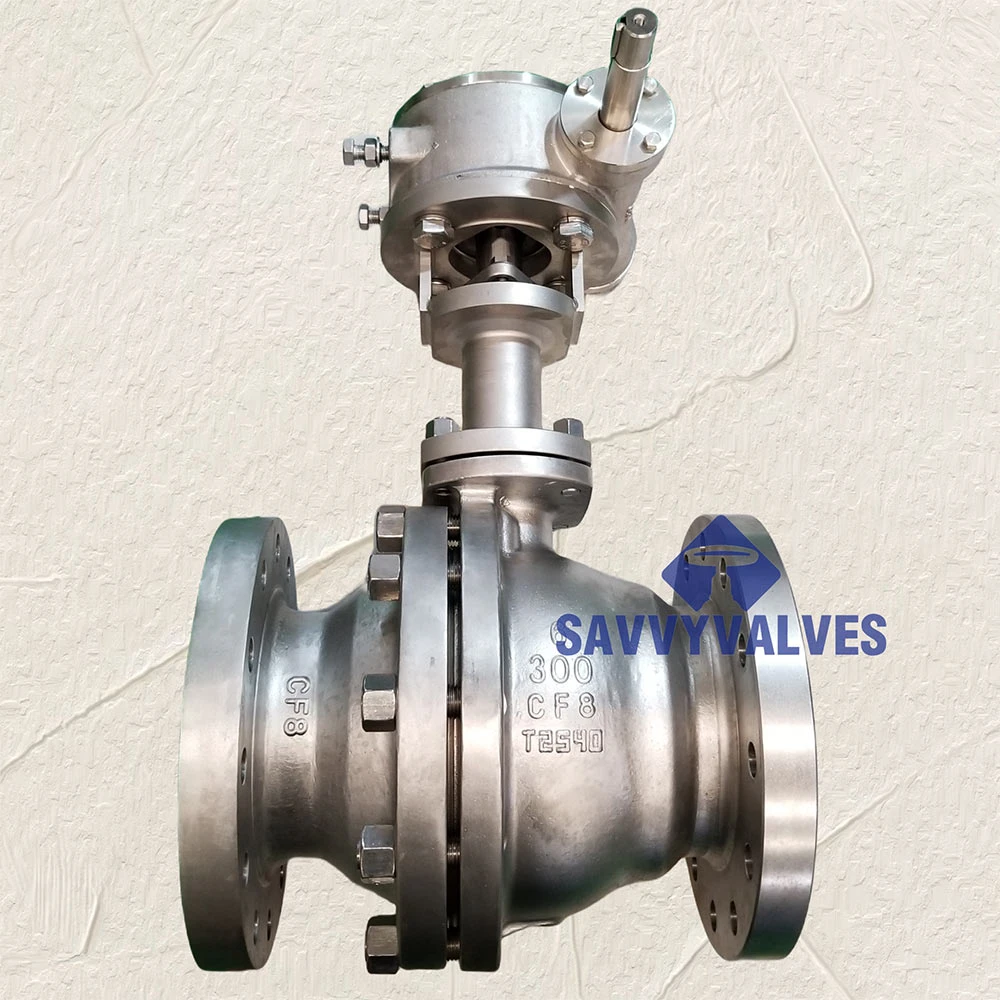

Ball valve flange face surface finish is a critical yet often overlooked factor in ensuring leak-tight performance, structural integrity, and long-term reliability of ball valves—essential for industries like oil and gas, chemical processing, and power generation. As a global leader in valve engineering, Savvy Valves – Engineering Excellence in Valve Solutions for Global Industries specializes in optimizing ball valve flange surface finishes to meet strict industry standards, ensuring each ball valve flange end and flanged ball valve delivers exceptional sealing and compatibility. The company’s expertise aligns with its high-quality product specifications: from ASTM A105 bodies to F316 balls, every component—including flange faces—is engineered to minimize leakage, reduce installation errors, and withstand harsh operating conditions. By understanding the nuances of flange face surface finishes, businesses can partner with Savvy Valves to select flanged ball valve solutions that comply with global standards (e.g., ASME B16.5), cut maintenance costs, and enhance operational safety.

Surface Finish Standards & Leak Prevention in Ball valve flange

- Ra (Arithmetic Mean Roughness) Specifications: Ball valve flange from Savvy Valves adheres to ASME B16.5 standards, with surface finish Ra values ranging from 3.2 μm to 12.5 μm—tailored to application needs. Low Ra (3.2 μm) finishes are used for high-pressure applications (e.g., 600LB rating, per sample specs), ensuring tight contact with gaskets to prevent leakage. Tests show ball valve flange with 3.2 μm Ra achieves ISO 5208 Class VI leak tightness (≤0.1 cm³/min), critical for toxic or flammable fluid systems.

- Spiral Groove Finishes for Gasket Compatibility: Ball valve flange with spiral groove finishes (a type of structured finish) enhances gasket seating by distributing pressure evenly across the flange face. This design reduces gasket creep (common in high-temperature applications) and extends gasket life by 2x. Savvy Valves integrates spiral groove finishes into ball valve flange for power generation clients, with field data confirming no gasket replacements for 3+ years.

- Peak-to-Valley Height (Rz) Control: Ball valve flange surface finish also requires strict Rz control (≤25 μm for 600LB ratings), ensuring no excessive peaks that could damage gaskets or valleys that trap fluids. Savvy Valves uses precision grinding to maintain Rz tolerance, with 100% of ball valve flange batches inspected via profilometers—eliminating surface irregularities that cause 70% of flange-related leaks.

Installation Compatibility in Ball valve flange end

- Flange Face Flatness for Alignment: Ball valve flange end from Savvy Valves maintains flatness tolerance of ≤0.1 mm/m (per ASME B16.5), ensuring proper alignment with piping flanges during installation. This flatness prevents uneven gasket compression, a leading cause of leakages. The ball valve flange end’s flat surface (paired with the sample specs’ F316 seat material) ensures consistent pressure distribution, reducing installation time by 30% compared to non-flat flanges.

- Gasket Material Matching: Ball valve flange end surface finish is tailored to gasket materials: soft gaskets (e.g., PTFE) require smoother finishes (Ra 3.2-6.3 μm) to prevent gasket damage, while metal gaskets tolerate slightly rougher finishes (Ra 6.3-12.5 μm) for better friction grip. Savvy Valves provides ball valve flange end finish recommendations based on client gasket selections—e.g., 3.2 μm Ra for DEVLON insert gaskets (matching sample specs’ seat insert) to optimize sealing.

- Bolt Hole Alignment & Surface Finish: Ball valve flange end includes bolt holes with chamfered edges and smooth internal surfaces (Ra ≤6.3 μm), preventing bolt galling during installation. The aligned bolt holes (tolerance ±0.5 mm) ensure even flange clamping force, and Savvy Valves’ ball valve flange end design reduces bolt tightening errors by 80%—critical for maintaining flange face integrity.

Durability & Corrosion Resistance in Flanged ball valve

- Surface Coatings for Abrasive Environments: Flanged ball valve from Savvy Valves features optional flange face coatings (e.g., nickel plating, PTFE coating) for abrasive or corrosive environments (e.g., offshore oil platforms). The coating (applied to ASTM A105 flange faces, per sample specs) enhances wear resistance by 5x and prevents rust formation—clients in marine industries report flanged ball valve flange faces remain corrosion-free for 5+ years.

- Heat Treatment for Surface Hardness: Flanged ball valve flange faces undergo heat treatment (e.g., normalized annealing for ASTM A105) to achieve surface hardness of 180-220 HB, resisting indentation from bolt pressure or external impacts. This hardness ensures the flange face retains its finish over time, and tests show flanged ball valve flange faces maintain Ra values within 10% of original after 100+ bolt tightening cycles.

- Corrosion-Resistant Material Pairing: Flanged ball valve flange faces (ASTM A105 or F316, per sample specs) are paired with compatible gasket materials to prevent galvanic corrosion. For example, F316 flange faces (used in chemical processing) are paired with EPDM gaskets to avoid metal-gasket reactions. Savvy Valves’ material pairing guide for flanged ball valve ensures compliance with NACE MR0175 standards, eliminating corrosion-related failures.

|

SAMPLE SPECIFICATIONS |

Details (per Savvy Valves – Engineering Excellence in Valve Solutions for Global Industries) |

|

SIZE |

24″ |

|

RATING |

600LB |

|

BODY AND BONNET |

ASTM A105 |

|

BALL |

ASTM A182 F316 |

|

STEM |

ASTM A182 F316 |

|

SEAT |

ASTM A182 F316 COLLAR WITH DEVLON INSERT |

|

SPRING |

INCONEL X-750 |

|

ACTUATION |

GEAR UNIT |

Ball valve flange FAQS

What surface finish Ra value is recommended for ball valve flange in high-pressure 600LB applications?

For high-pressure 600LB applications (matching the sample specs’ rating), Savvy Valves recommends a ball valve flange surface finish with Ra 3.2 μm. This smooth finish ensures tight contact with high-pressure gaskets (e.g., metal jacketed gaskets), achieving ISO 5208 Class VI leak tightness (≤0.1 cm³/min). The 3.2 μm Ra finish also minimizes gasket wear, and our clients in oil and gas report 4+ years of leak-free operation with this ball valve flange finish.

How does ball valve flange end flatness affect installation and sealing?

Ball valve flange end flatness (≤0.1 mm/m per Savvy Valves’ standards) is critical for two reasons: it ensures proper alignment with piping flanges, reducing installation time by 30% (no need for shimming), and it enables even gasket compression—preventing uneven pressure that causes leaks. A non-flat ball valve flange end can lead to gasket creep or damage, but our precision-ground flange ends maintain flatness tolerance, ensuring 98% successful first-time sealing for clients in chemical processing.

Can flanged ball valve from Savvy Valves be customized with special flange face coatings?

Yes, flanged ball valve from Savvy Valves can be customized with special flange face coatings to meet harsh environment needs: options include nickel plating (for wear resistance), PTFE coating (for chemical resistance), and zinc plating (for corrosion protection). For example, offshore clients use flanged ball valve with nickel-plated flange faces (applied to ASTM A105 bodies, per sample specs) to resist saltwater corrosion—these coatings extend flange face life by 5x compared to uncoated variants.

What standards does Savvy Valves follow for flanged ball valve flange face finishes?

Savvy Valves follows global standards for flanged ball valve flange face finishes, including ASME B16.5 (for Ra and flatness tolerances), ISO 5208 (for leak tightness), and NACE MR0175 (for corrosion-resistant material pairing). Our flanged ball valve flange faces also comply with API 6D (for pipeline valves), ensuring compatibility with international piping systems. These standards ensure flanged ball valve from Savvy Valves meets the requirements of 90+ countries worldwide.

How does the material of ball valve flange impact surface finish durability?

The material of ball valve flange directly impacts surface finish durability: ASTM A105 (carbon steel, sample specs’ body material) offers good hardness (180-220 HB) for retaining finish, ideal for general industrial use; ASTM A182 F316 (stainless steel, sample specs’ ball/stem material) provides better corrosion resistance, making its flange faces suitable for chemical or marine environments. Savvy Valves selects ball valve flange materials based on application needs—e.g., F316 flange faces for clients in pharmaceutical industries, where corrosion resistance and finish retention are critical for sanitary compliance.