Precision Flow Control: The V Notch Ball Control Valve Explained

In industrial process control, the precise regulation of fluid flow is paramount for operational efficiency, safety, and product quality. Traditional on/off valves often fall short in applications requiring nuanced modulation. This is where the v notch ball control valve emerges as a critical component. Designed specifically for throttling and accurate flow control, these valves offer a unique V-shaped or contoured opening in the ball, providing a precise, repeatable, and linear flow characteristic. This allows for superior control over a wide range of flow rates, making them indispensable across various demanding sectors. Their robust design, coupled with advanced actuation, positions them as a cornerstone of modern automation systems, ensuring optimal performance even in challenging environments.

The demand for sophisticated control solutions is escalating with the increasing complexity of industrial processes. Industries are moving towards higher levels of automation and integration, driving the need for valves that can offer not just reliability but also enhanced diagnostic capabilities and connectivity. The evolution of the v port ball control valve reflects this trend, incorporating smart features and advanced materials to meet stringent performance requirements. From petrochemical refining to water treatment, these valves are instrumental in maintaining critical process variables, highlighting their pivotal role in industrial infrastructure. Understanding their capabilities and applications is key for engineers and procurement specialists seeking optimal control solutions.

Manufacturing Process and Quality Assurance of V-Notch Ball Valves

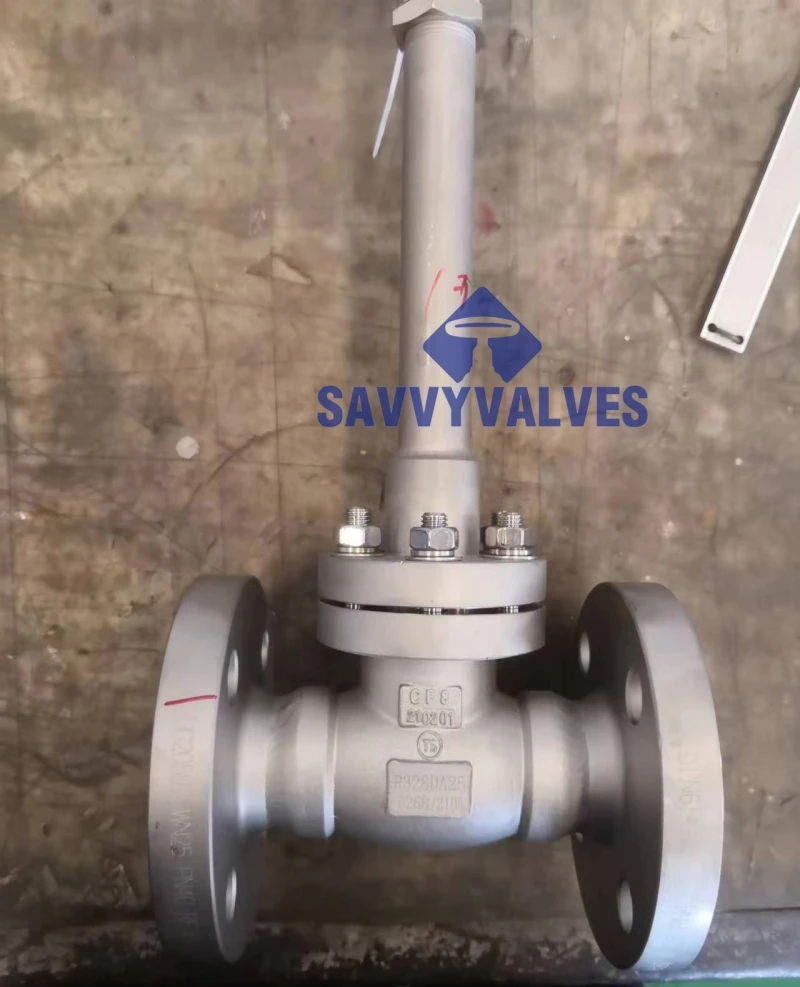

The manufacturing of a high-performance v port ball valve involves a meticulous multi-stage process, ensuring durability, precision, and adherence to international standards. It typically begins with material selection, where high-grade stainless steel (such as SS304, SS316, Duplex 2205), carbon steel (WCB), or specialized alloys are chosen based on the intended application's temperature, pressure, and corrosive environment. The primary components—body, ball, stem, and seats—undergo rigorous manufacturing techniques. For valve bodies, casting or forging processes are employed to create robust structures capable of withstanding high pressures. Castings are often preferred for complex shapes, while forgings offer superior mechanical properties due to grain flow alignment.

Following initial forming, sophisticated CNC machining centers meticulously shape the components to tight tolerances, particularly the V-notch or contoured port in the ball, which is critical for precise flow control. Surface finishes are carefully controlled to minimize friction and wear. Heat treatment processes are applied to enhance material strength and corrosion resistance. Throughout the assembly, each valve component is subjected to stringent quality control checks, including dimensional inspection, material traceability, and non-destructive testing (NDT) such as ultrasonic testing and liquid penetrant inspection to detect any internal flaws. Hydrostatic and pneumatic tests, conforming to standards like API 598 or EN 12266-1, verify leak-tightness and pressure integrity. Certification to ISO 9001 ensures a consistent quality management system, and compliance with industry standards like ANSI/ASME B16.34 for valves, ensures interoperability and safety. This comprehensive approach guarantees an extended service life and reliable performance in critical applications such as chemical processing, power generation, and municipal water treatment, offering significant advantages like reduced energy consumption through optimized flow and enhanced corrosion resistance.

Key Technical Parameters and Specifications

Selecting the right v notch ball control valve necessitates a thorough understanding of its technical specifications. These parameters dictate the valve's suitability for specific process conditions and overall performance. Key considerations include valve size, pressure rating, material compatibility, temperature range, and flow characteristics. The V-port design allows for a nearly equal percentage flow characteristic, meaning that for a given percentage change in valve opening, there is an equal percentage change in flow, which is ideal for precise control applications. This ensures stable operation and prevents hunting, a common issue with less precise control valves. The following table provides a general overview of typical parameters found in high-quality V-notch ball valves, such as the Electric hydraulic V port control ball valve offered by Savvy Valvetech.

| Parameter | Description / Range |

|---|---|

| Nominal Size (DN/NPS) | DN15 - DN600 (NPS 1/2" - 24") |

| Pressure Rating | PN16 - PN100 (Class 150 - 600) |

| Body Material | WCB (Carbon Steel), CF8/304, CF8M/316, Duplex 2205, Hastelloy, Monel |

| Ball Material | SS304, SS316, Duplex, with hard chrome plating or HVOF coating for wear resistance |

| Seat Material | PTFE, RPTFE, PEEK, Metal Seated (Stellite overlay) |

| Temperature Range | -29°C to 250°C (depending on seat material) |

| End Connections | Flanged (RF, RTJ), Wafer, Threaded, Welded |

| Actuation Type | Pneumatic, Electric, Hydraulic (e.g., Electric Hydraulic) |

| Flow Characteristic | Nearly Equal Percentage |

| Leakage Class | ANSI/FCI 70-2 Class IV or Class V (metal seats) |

These specifications are crucial for ensuring the valve’s compatibility with the process fluid and operating conditions, preventing premature failure, and guaranteeing efficient control. The choice of materials, for instance, directly impacts the valve's resistance to corrosion and erosion, which is vital in aggressive chemical environments. Furthermore, understanding the pressure-temperature (P-T) ratings is essential to prevent over-pressurization or material degradation at elevated temperatures. Always consult the manufacturer’s specific product data sheets for precise details on the Electric hydraulic V port control ball valve or any other control valve.

Applications and Industry Trends

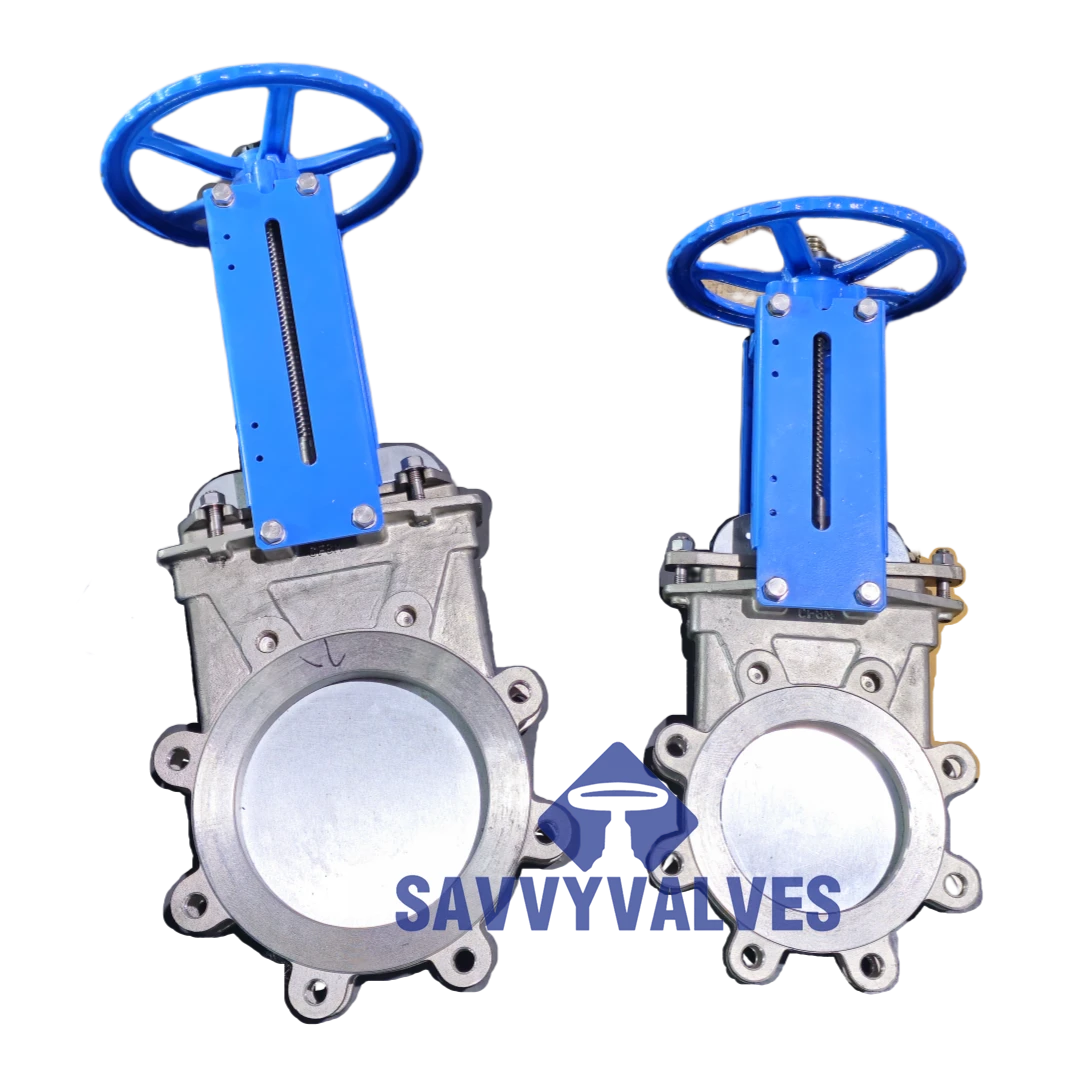

The versatility and precision of the v notch ball control valve make it indispensable across a multitude of industrial applications where accurate flow modulation is key. In the petrochemical sector, these valves are critical for controlling reactor feed, managing product streams, and ensuring precise blending, often handling corrosive or high-temperature fluids. In the power generation industry, particularly in thermal and nuclear plants, they regulate boiler feedwater, steam flow, and cooling water, contributing to energy efficiency and operational stability. The metallurgy industry relies on them for controlling process gases, cooling water, and slurry flows, where robust construction and wear resistance are paramount.

Furthermore, in the water and wastewater treatment industry, v port ball control valve technology is utilized for controlling aeration, chemical dosing, and sludge handling, ensuring environmental compliance and operational efficiency. The pulp and paper industry, known for its abrasive slurries and fibrous suspensions, also benefits from the non-clogging and precise control capabilities of these valves. The food and beverage sector employs them for regulating product flow, clean-in-place (CIP) systems, and utility services, requiring hygienic designs and precise control. A significant trend is the increasing integration of these valves into Industrial Internet of Things (IIoT) ecosystems, enabling predictive maintenance, real-time data analysis, and remote control, enhancing overall plant productivity and reducing downtime. Manufacturers like AT Controls Ball Valves are focusing on developing intelligent actuators and digital positioners that offer enhanced diagnostics and communication protocols, further solidifying the role of the v notch ball control valve in smart factory initiatives.

Advantages of Electric Hydraulic V Port Control Ball Valves

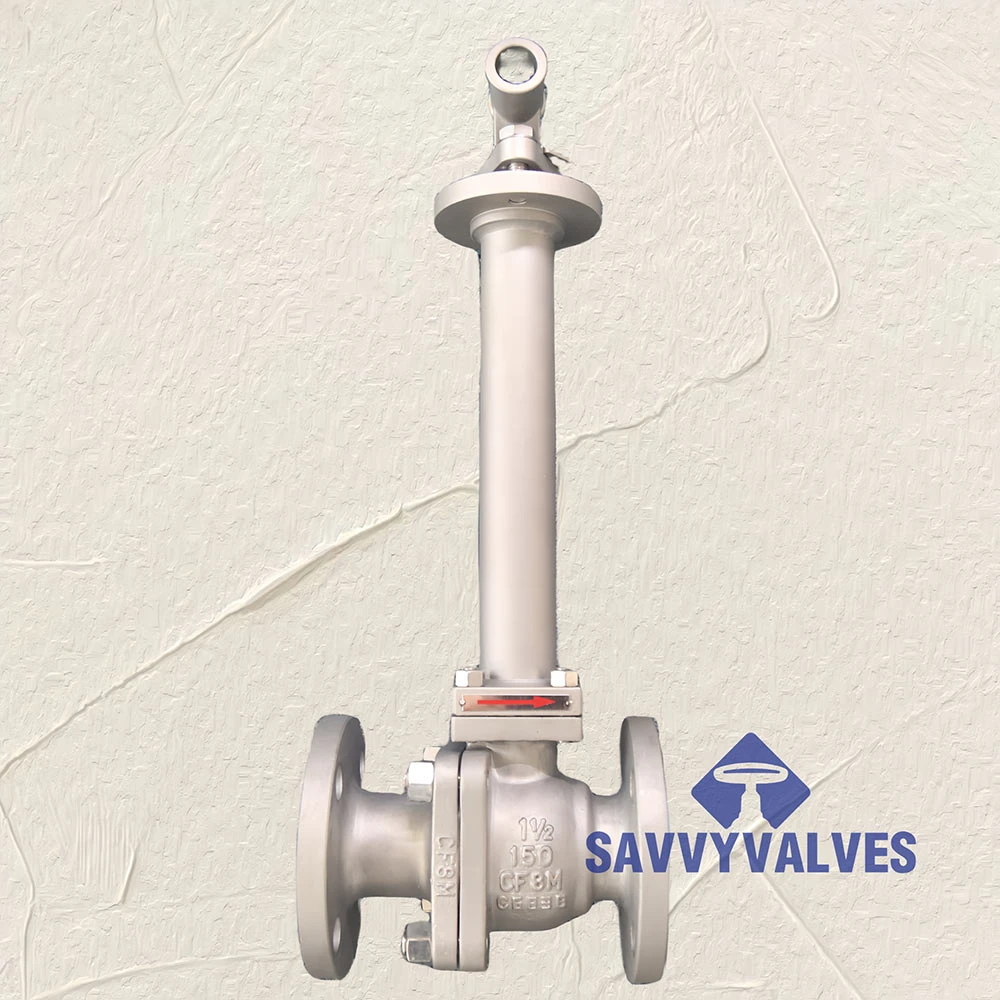

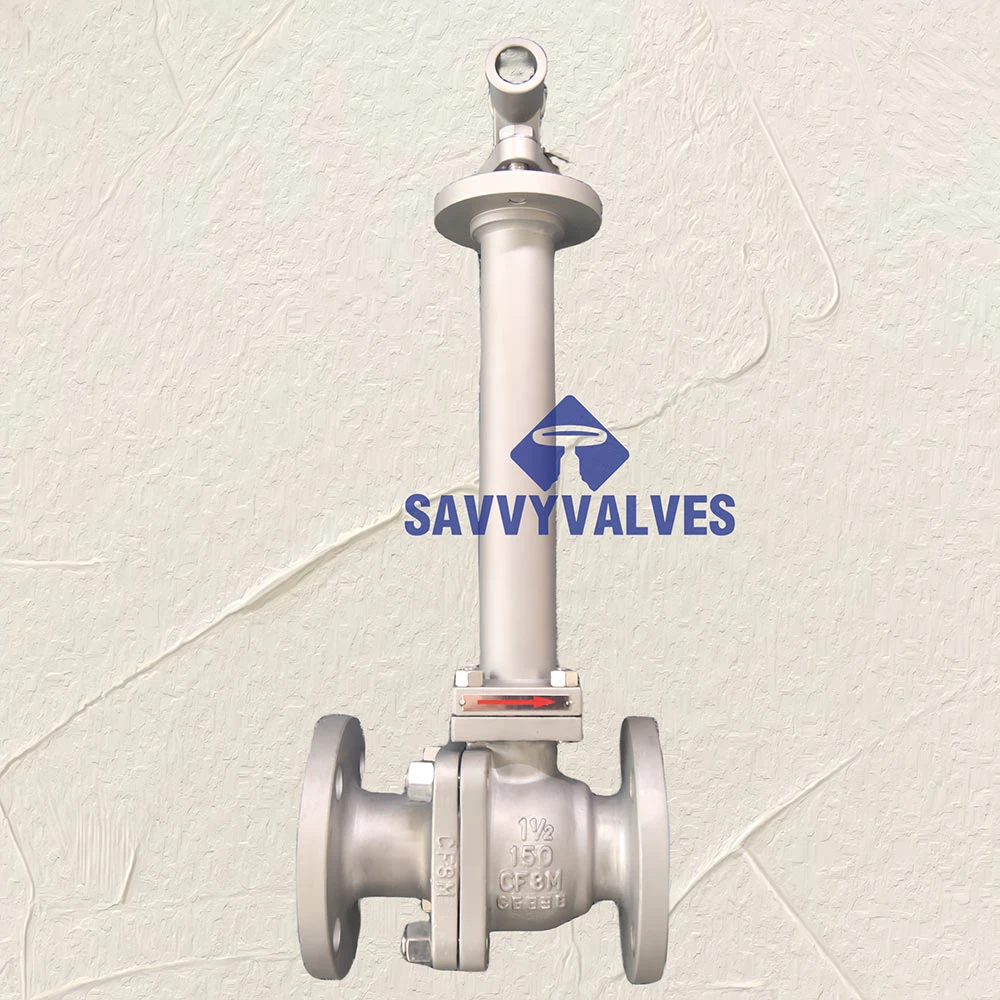

The Electric hydraulic V port control ball valve represents a pinnacle of control technology, combining the robust precision of a v port ball valve with the power and accuracy of electric hydraulic actuation. This combination offers several distinct advantages over traditional pneumatic or purely electric actuators. Electric hydraulic systems provide high torque output, enabling the valve to operate smoothly even against high differential pressures, reducing the risk of stick-slip phenomena. They also offer exceptional stiffness and positioning accuracy, crucial for maintaining precise flow rates and preventing process upsets. The electric power input makes them suitable for remote locations where compressed air might not be readily available, and their energy efficiency can be significant compared to continuously operating pneumatic systems.

The integrated design often includes fail-safe mechanisms, where the valve can be programmed to open, close, or hold position upon power failure, enhancing operational safety. For instance, in an emergency shutdown scenario, the hydraulic accumulator can ensure the valve completes its full stroke. Furthermore, these actuators typically offer sophisticated control options, including local or remote control, analog or digital signaling (e.g., 4-20mA, HART, Modbus), and diagnostic capabilities. This allows for seamless integration into Distributed Control Systems (DCS) or Supervisory Control and Data Acquisition (SCADA) systems, providing real-time feedback on valve position, status, and potential issues. This predictive maintenance capability reduces unplanned downtime and extends the lifespan of the v notch ball control valve, translating into lower operational costs and improved process reliability for facilities in critical industries like oil & gas, pharmaceuticals, and infrastructure.

Manufacturer Comparison and Custom Solutions

When selecting a v notch ball control valve, comparing manufacturers is essential, as their offerings can vary significantly in terms of material options, design features, quality certifications, and after-sales support. Reputable manufacturers such as Savvy Valvetech, known for its Electric hydraulic V port control ball valve, and other global players in industrial valves, typically adhere to strict international standards like ISO, API, and ASME, which provide a baseline for quality. Key differentiating factors often include the specific V-port geometry, which influences flow characteristics, the robustness of the sealing mechanism (e.g., metal-seated for severe service), and the precision and reliability of the accompanying actuator (e.g., electric hydraulic vs. pneumatic).

A manufacturer's ability to provide custom solutions is also a significant advantage. Many industrial processes have unique requirements that cannot be met by off-the-shelf products. This might involve special material constructions for highly corrosive or abrasive media, extended bonnets for cryogenic applications, specific connection types, or integrated smart instrumentation for advanced diagnostics. For instance, a client in the mining industry might require a v port ball valve with specialized wear-resistant coatings for handling highly abrasive slurries, while a pharmaceutical company might need a valve with ultra-high purity materials and polished internal surfaces for sterile processes. Reputable suppliers, including those specializing in AT Controls Ball Valves and similar control solutions, offer extensive engineering expertise to design and fabricate valves tailored to exact specifications, ensuring optimal performance and compliance with industry-specific regulations. This collaborative approach from design to delivery ensures that the control valve solution perfectly aligns with the operational demands and long-term objectives of the client.

Application Cases and Customer Testimonials

The real-world performance of a v notch ball control valve is best demonstrated through successful application cases. In one instance, a major chemical plant faced challenges in precisely controlling the flow of a highly viscous polymer solution, leading to product inconsistencies and frequent clogging with their existing globe valves. Upon implementing Electric hydraulic V port control ball valves, the plant reported a 15% improvement in process stability and a 20% reduction in downtime due to clogging. The unique V-port design allowed for a smoother flow path, minimizing material accumulation and providing the fine-tuned control needed for the polymerizing reaction.

Another compelling case involved a municipal wastewater treatment facility that required accurate control of air flow to their aeration basins to optimize biological treatment processes and reduce energy consumption. Traditional butterfly valves struggled to provide stable control at low flow rates. By replacing them with v port ball control valve units, the facility achieved superior oxygen transfer efficiency, resulting in a 10% decrease in energy usage for aeration and improved effluent quality. A customer feedback from the plant manager stated, "The precision and reliability of the Savvy Valvetech Electric hydraulic V port control ball valve has been a game-changer for our aeration system. It has significantly reduced our operating costs and improved our environmental performance." These examples underscore the tangible benefits and proven reliability of the v notch ball control valve in demanding industrial environments, providing a testament to their value in critical control applications.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of a V-notch ball valve over a standard ball valve for control applications?

A1: The primary advantage lies in its specialized V-shaped or contoured port. Unlike standard ball valves which are designed for on/off service, the V-notch design provides a characterized flow path, offering precise and linear flow control over a wide range of valve openings. This ensures stable regulation, prevents cavitation at low flows, and makes the v notch ball control valve ideal for throttling applications where accurate modulation is required.

Q2: Can V-notch ball valves handle abrasive or slurry applications?

A2: Yes, they are highly capable. The design of the v port ball valve minimizes areas where particles can accumulate and offers a shearing action as the ball closes, reducing clogging. For highly abrasive or slurry services, specific material enhancements like hardened trim, ceramic inserts, or specialized coatings (e.g., HVOF tungsten carbide) are often applied to the ball and seat to extend the valve's service life and maintain performance.

Q3: What are the typical delivery times for custom-engineered Electric hydraulic V port control ball valves?

A3: Delivery times for custom-engineered Electric hydraulic V port control ball valves can vary significantly based on complexity, material availability, and manufacturing queue. For standard configurations, lead times typically range from 4-8 weeks. However, for highly specialized materials, larger sizes, or unique design modifications, it could extend to 12-20 weeks or more. We recommend consulting directly with our sales team for an accurate project-specific delivery schedule to ensure your project timelines are met. Our commitment includes clear communication regarding lead times and transparent order tracking.

Why Choose Our Electric Hydraulic V Port Control Ball Valve?

Choosing the right control valve is a critical decision that impacts your operational efficiency and long-term costs. Our Electric hydraulic V port control ball valve stands out due to its superior engineering, robust construction, and commitment to precision control. Each valve is designed and manufactured to meet stringent international standards (e.g., ISO 9001 certified manufacturing facilities, compliance with ASME/ANSI, API, EN norms), ensuring reliability and performance even in the most demanding industrial environments. We leverage decades of experience in valve technology to deliver products that consistently exceed expectations.

Our commitment extends beyond product quality to comprehensive customer support. We offer detailed pre-sales consultation to help you select the optimal v notch ball control valve configuration for your specific application, ensuring perfect compatibility and peak performance. Our standard warranty for the Electric hydraulic V port control ball valve typically covers 12 to 18 months from installation or 24 months from shipment, whichever comes first, against manufacturing defects. Furthermore, our dedicated technical support team is available to provide post-installation assistance, troubleshooting, and maintenance guidance. With established global distribution channels and efficient logistics, we strive for reliable delivery cycles, minimizing project delays. We believe in building long-term partnerships, providing not just a product, but a complete solution backed by expertise, reliability, and unparalleled service.

References

- International Organization for Standardization (ISO).

- American Petroleum Institute (API).

- American Society of Mechanical Engineers (ASME).

- Fluid Controls Institute (FCI).

- European Committee for Standardization (CEN).