The cryogenic floating ball valve represents a critical component in low-temperature fluid control systems across petrochemical, natural gas, metallurgy, and LNG industries. As global demand for clean energy and advanced materials grows, the market for cryo ball valve solutions has surged, driven by efficiency, reliability, and safety requirements under extreme conditions.

- Global cryogenic valve market is projected to reach $4.1 billion by 2028, growing at a CAGR of 5.4% (Source: MarketsandMarkets).

- Cryogenic floating ball valves are pivotal in LNG storage/distribution, air separation, and hydrogen industry infrastructure.

- Key demand drivers: Stringent safety regulations (ISO 28921, ANSI B16.34), increased process automation, and cryogenic energy transport.

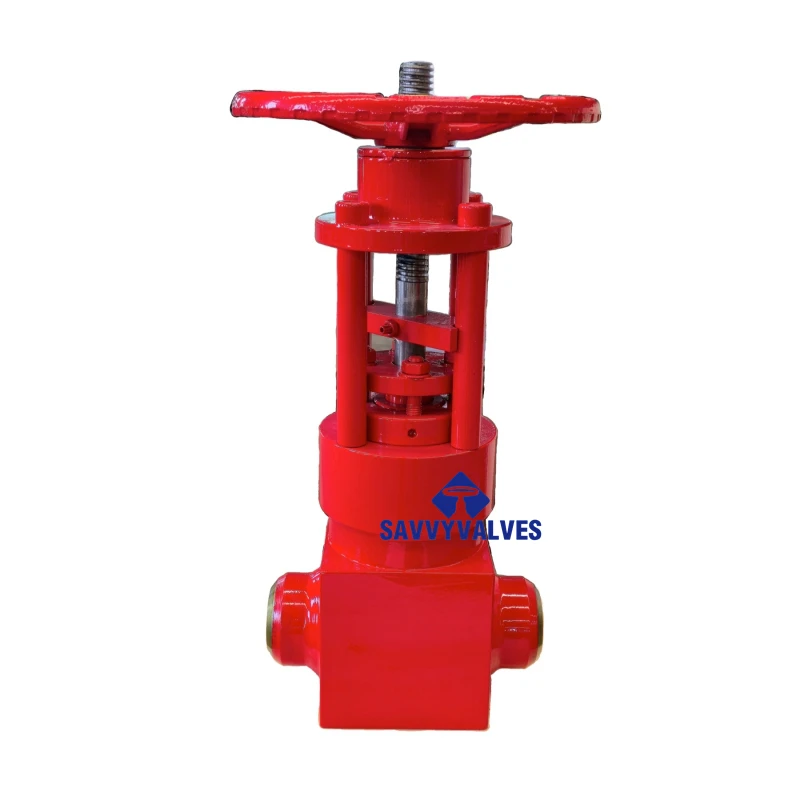

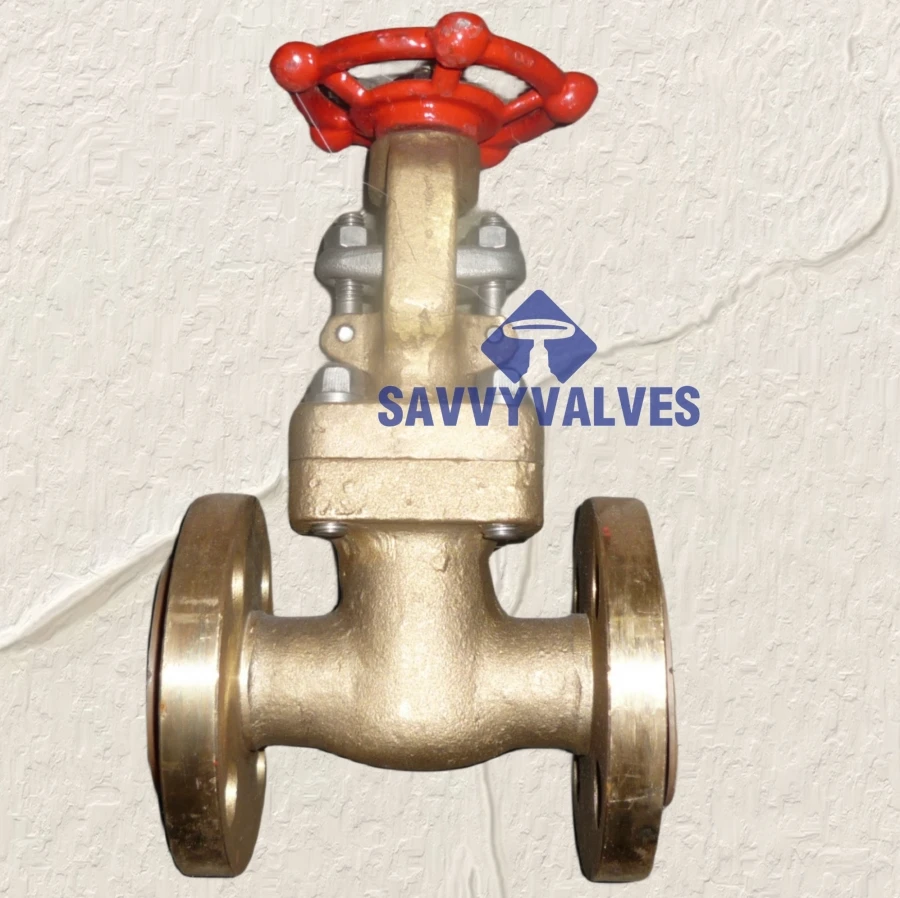

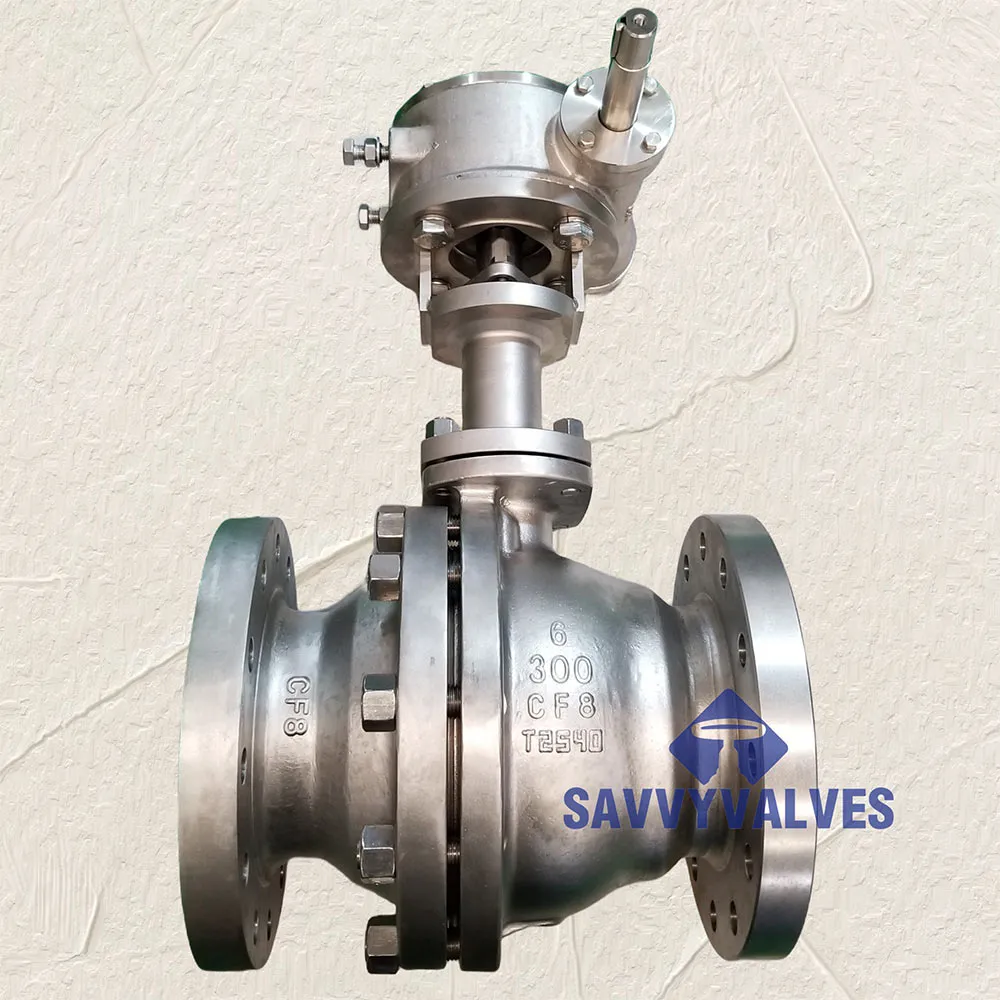

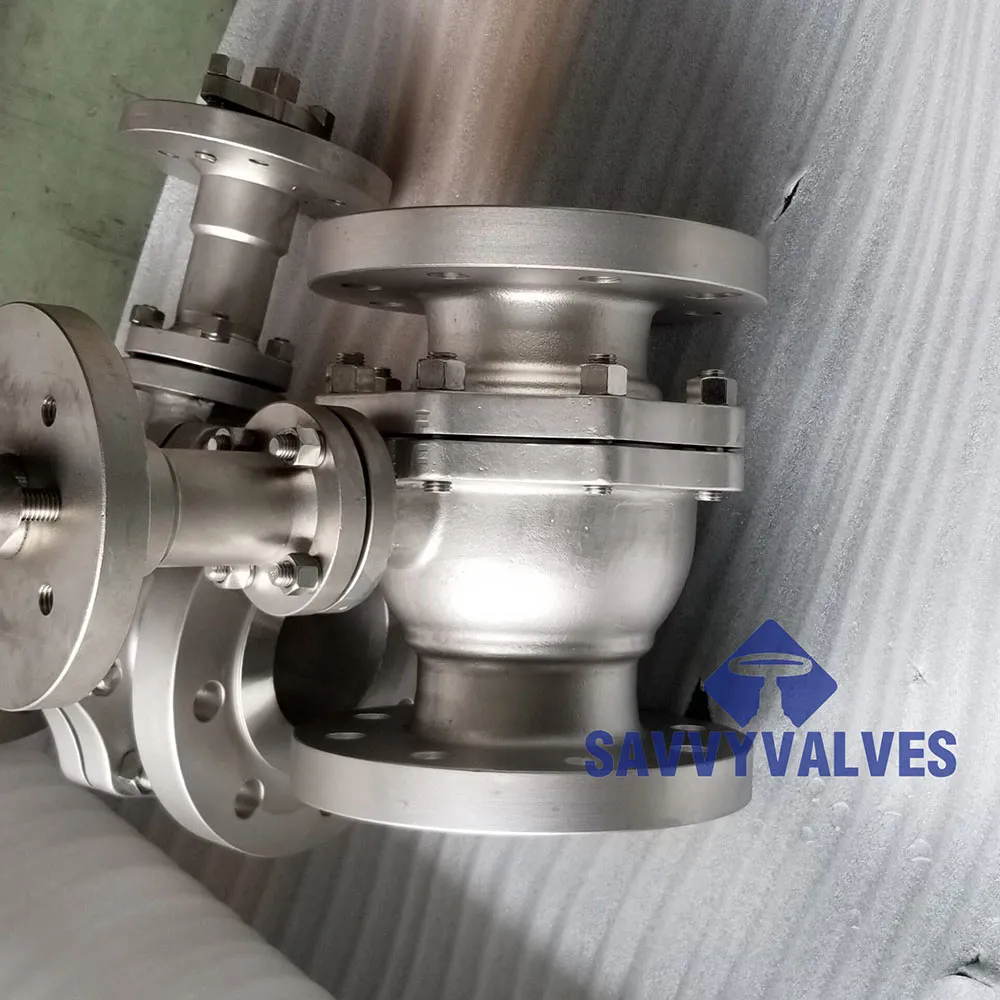

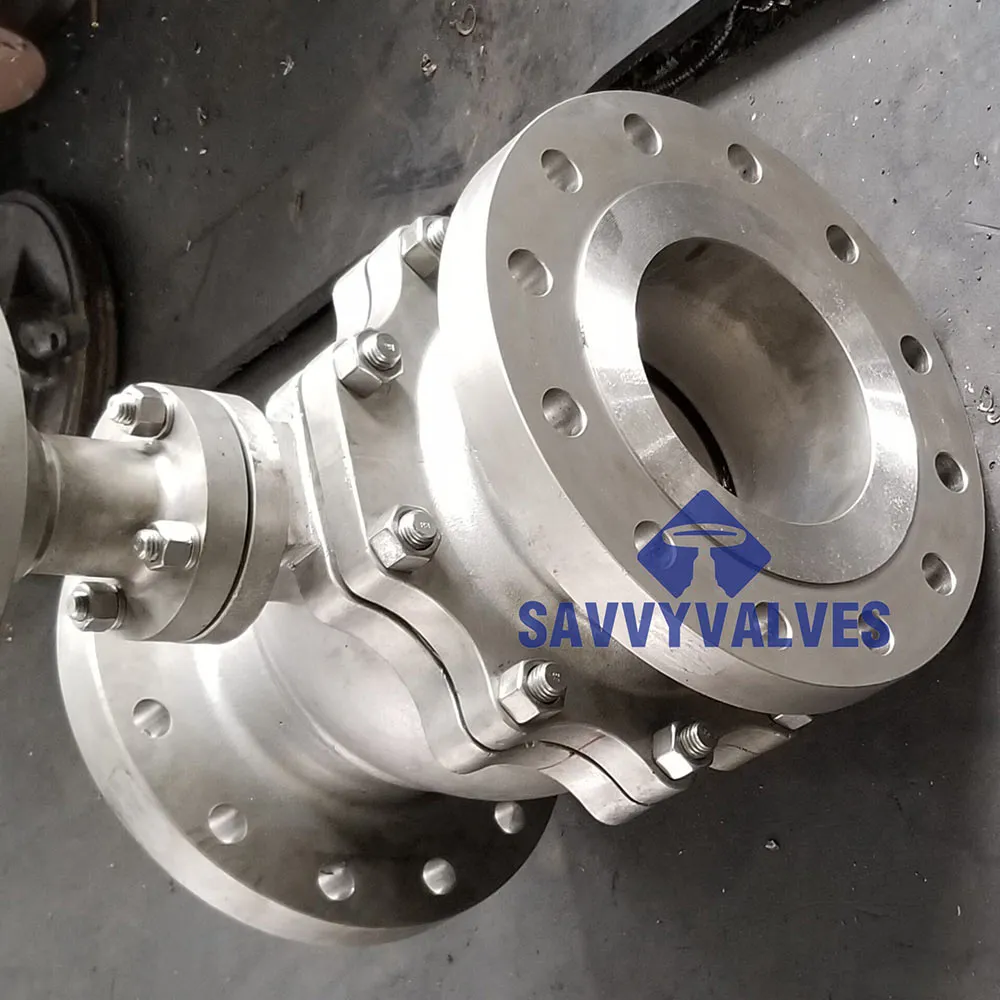

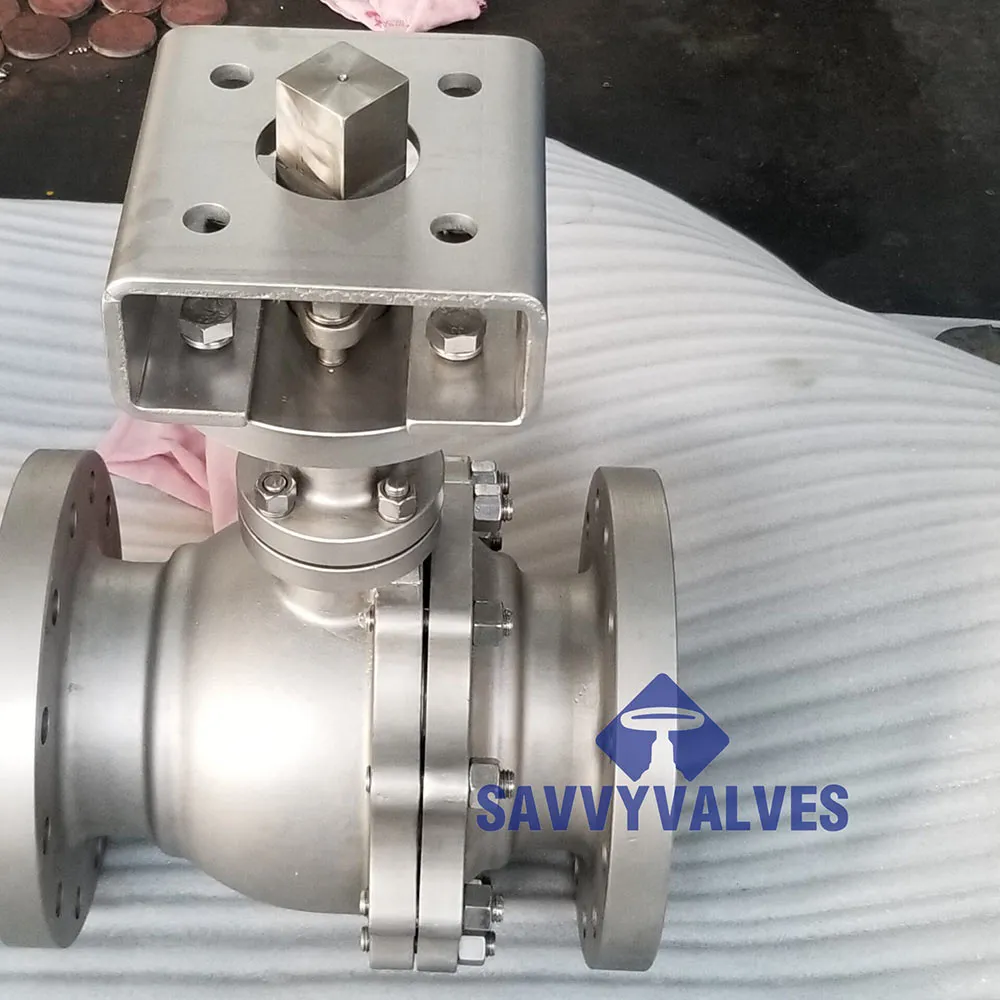

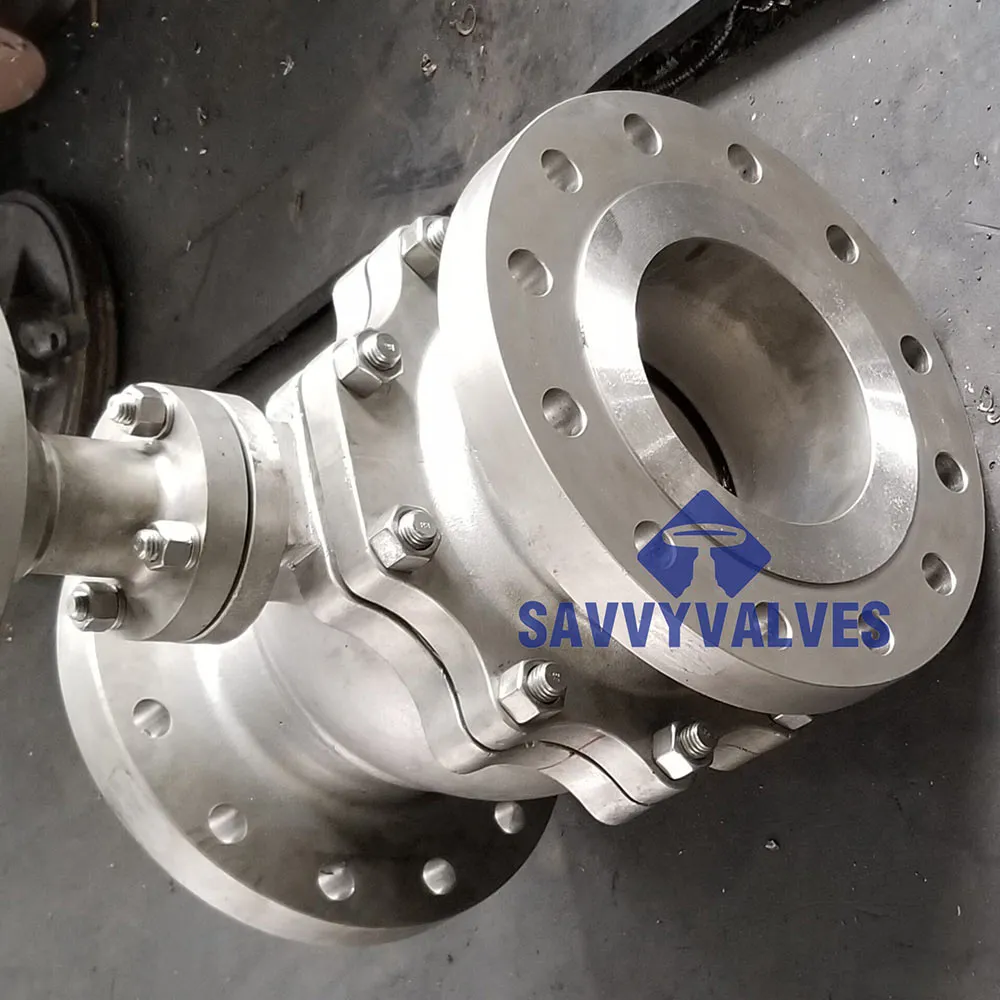

2-Piece Cryogenic Floating Ball Valve: Technical Overview & Key Features

The 2-Piece Cryogenic Floating Ball Valve is meticulously engineered for leak-proof sealing, extended durability, and compliance with international cryogenic standards (ISO, BS6364).

- Body Material: Stainless Steel (CF8M, ASTM A351), Forged Steel, Special Alloys (Monel, Inconel)

- Seat Materials: PTFE, PCTFE, Devlon (cryogenic rated soft/hard seats)

- Temperature Range: -196°C (~-320°F) to +80°C

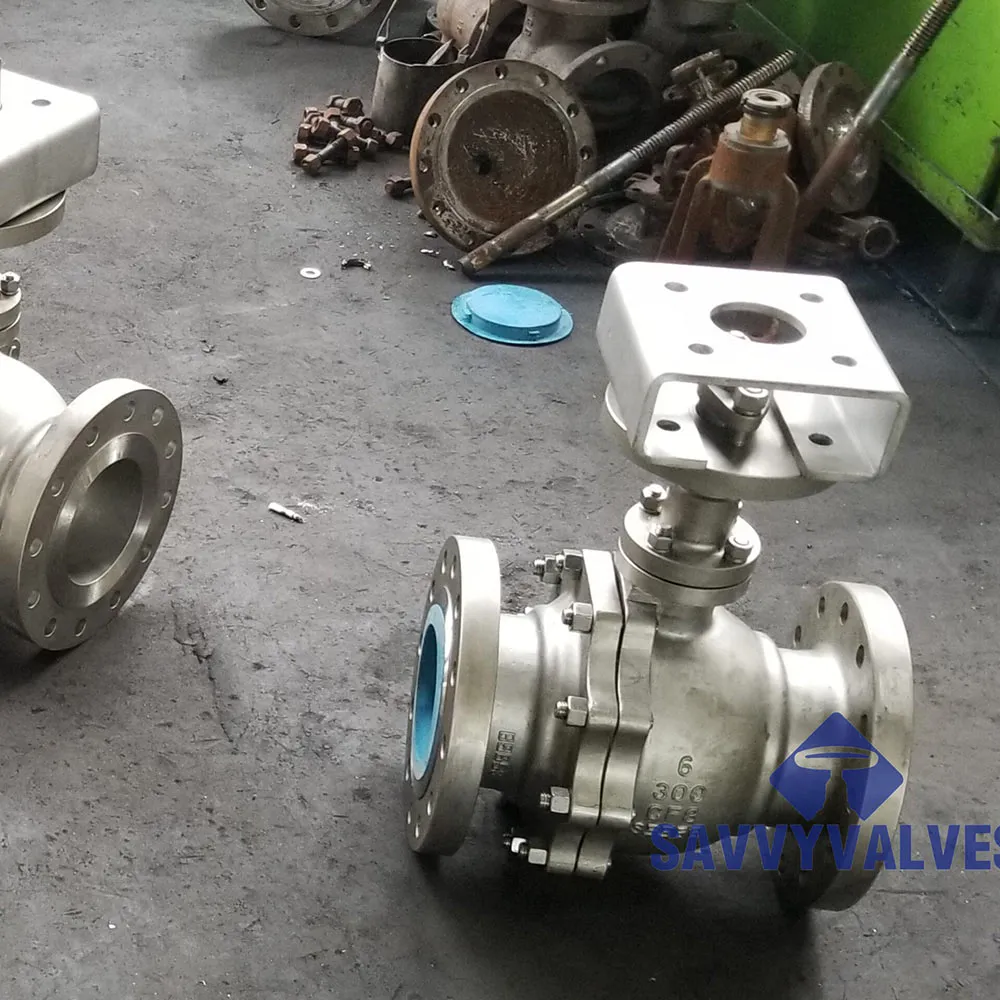

- Pressure Ratings: Class 150/300/600/900, PN16–PN64

- Size Range: DN15–DN300 (1/2"–12")

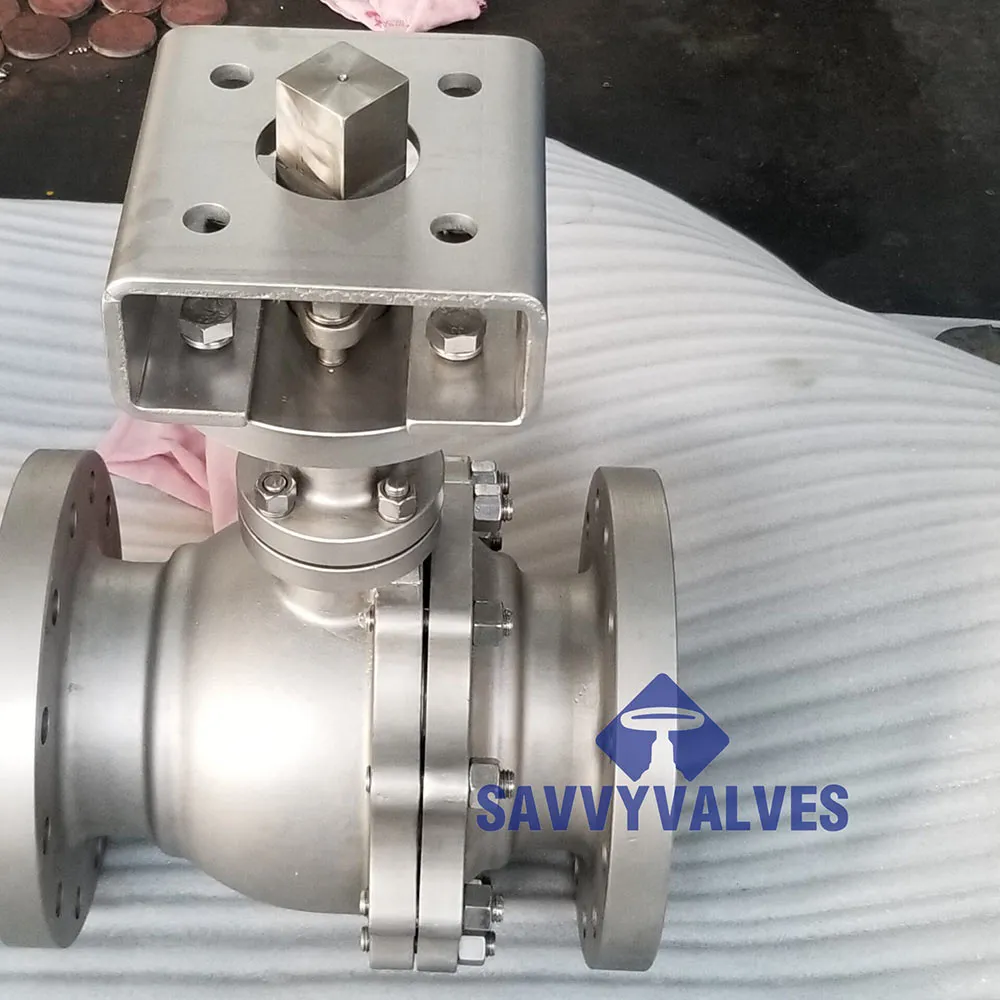

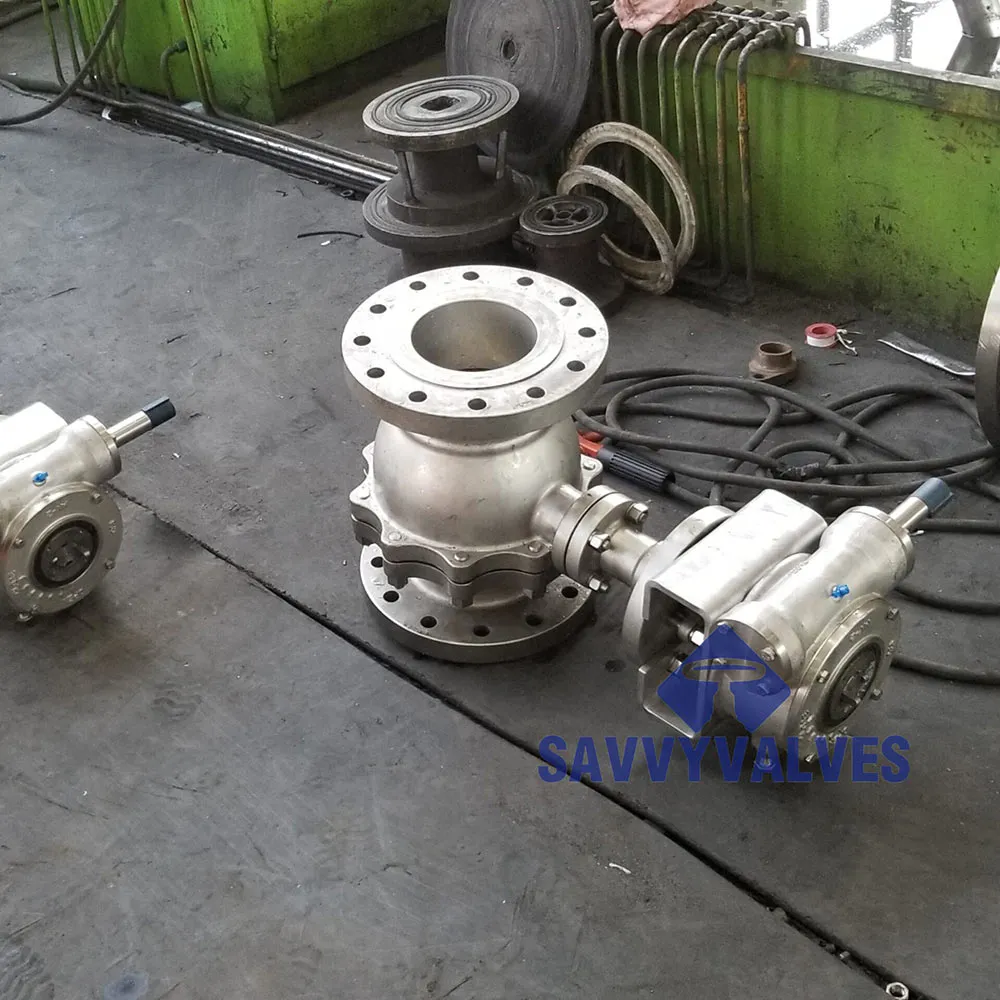

- Operation: Manual, Pneumatic/Electric Actuator compatible

Key Technical Parameters: Cryogenic Floating Ball Valve Market Overview

| Parameter | Industry Range | 2-Piece Model (Savvy ValveTech) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|---|

| Design Standard | ISO 28921, BS6364, ANSI B16.34 | ISO 28921-1:2013, BS6364:2014 | ISO 28921, API 6D | BS6364, ANSI B16.34 |

| Body Material | CF8M, ASTM A351, Forged Steel | CF8M, A351, Monel | A216 WCB, A351 CF8 | SS316, Inconel |

| Seat Material | PTFE, PCTFE, Devlon | PCTFE, Devlon | PTFE, RPTFE | PCTFE |

| Min Temp | -196°C | -196°C | -196°C | -196°C |

| Max Pressure | PN64 / 900LB | PN64 / 900LB | PN40 / 600LB | PN40 / 600LB |

| Size Range | DN8–DN300 | DN15–DN300 | DN15–DN200 | DN20–DN250 |

| Leakage Class | Class VI (ISO), API 598 | Class VI, API 598 | BS6755, API 598 | Class VI |

| Fire-Safe Cert. | API 607, ISO 10497 | API 607, ISO 10497 | API 607, ISO 10497 | API 607 |

Industry Trends and Technology Innovations in Cryogenic Ball Valves

- Automation: Integration with smart plant systems and IoT for remote diagnostics in LNG terminals.

- Advanced Alloys: Enhanced corrosion resistance and mechanical strength (use of super duplex, Inconel).

- Low-Emission Stem Packings: Fugitive emission rates below 50 ppm as per ISO 15848 (test-proven data).

- 3D Design Validation: CAD/CAM and FEA simulation for optimizing valve sealing geometry.

- Extended Warranty: Top suppliers like Savvy ValveTech offer 36 months warranty and post-sale maintenance.

Cryogenic Ball Valve Market Share by Application, 2023

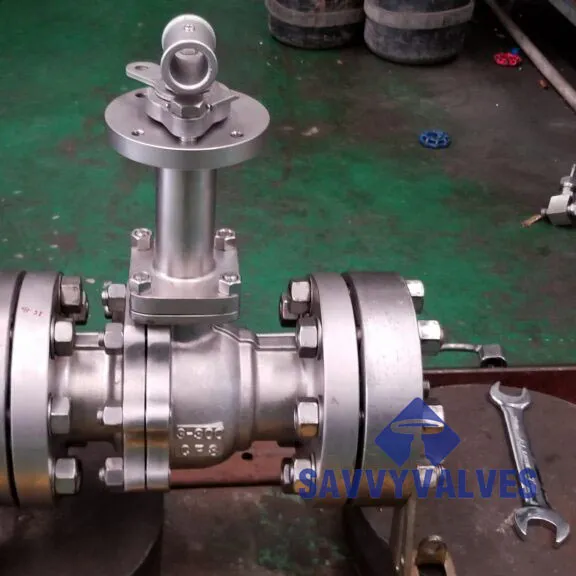

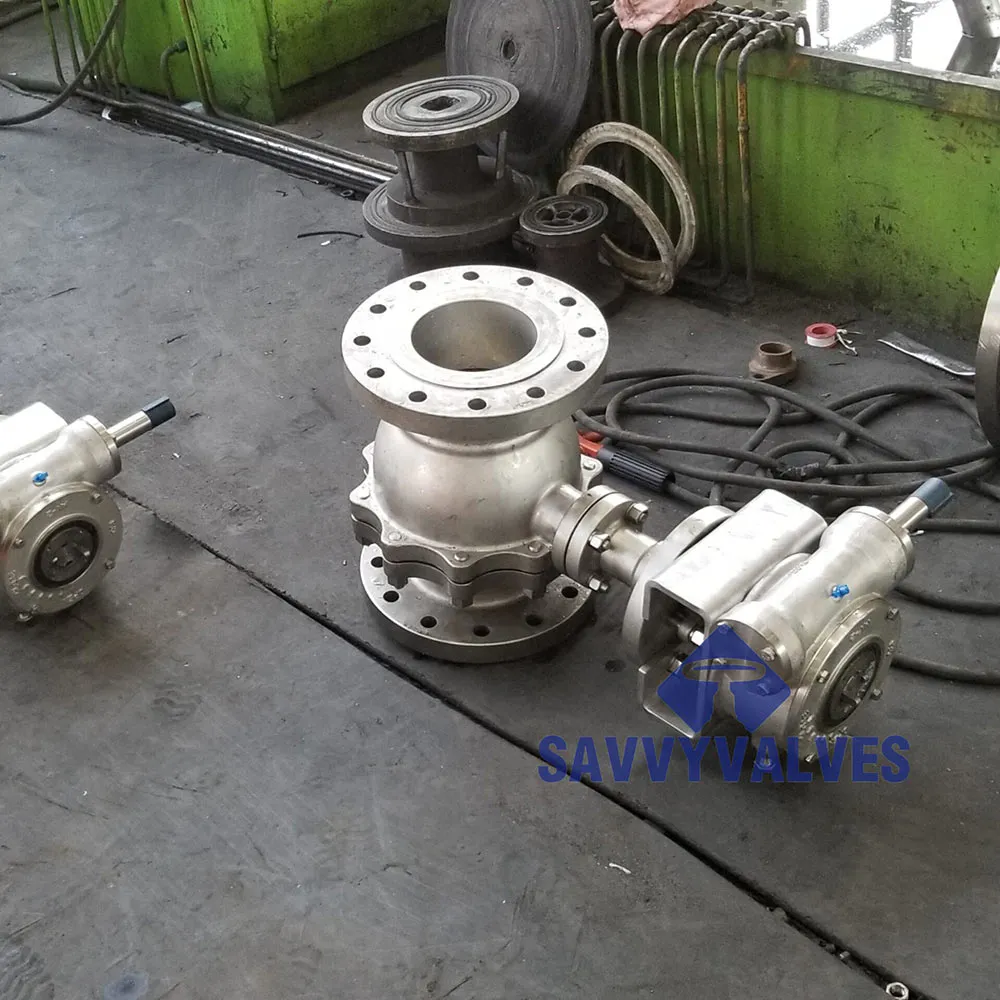

Manufacturing Process of Cryogenic Floating Ball Valve

Material selection ensures the valve body, ball, and stem meet minimum impact values and chemical requirements (see ASTM/EN standards). The precision casting or forging process provides high-density, low-porosity components. Advanced CNC machining ensures critical tolerances (<0.01mm).

- All cleaning and assembly are performed in clean rooms to avoid grease and particulate contamination.

- Cryogenic valves undergo helium leak testing with maximum leak rates <6×10⁻⁶ mbar·l/s (ISO 28921-1 certified).

- Traceable identification (nameplate + unique valve number) is standard for QA.

Example: Technical Specifications of 2-Piece Cryogenic Floating Ball Valve

Why Choose Cryogenic Floating Ball Valve? Technical Advantages

- Extended Bonnet Design: Prevents cold transmission, avoids stem icing, and ensures actuator stability.

- Zero-Leakage Class VI: Soft/hard-seat combinations guarantee <10 bubbles/min leakage, tested per API 598.

- Lip-Seal Stem: Dual/sealed low-temperature stem packing provides fugitive emission control (per ISO 15848).

- Modular Construction: Facilitates easier onsite maintenance/replacement.

- Fire-Safe Certified: Verified to API 607 7th Ed. / ISO 10497 (tested at 760°C and cycled for valve integrity).

- Global Approvals: Compliant with CE (PED), SIL3, TA-Luft, and direct vendor approval for major gas companies.

- LNG Loading Skids (Singapore, 2022): 212 units supplied to LNG terminal with zero site rejections.

- Hydrogen Refueling Stations (EU, 2023): 2-piece floating ball valves qualified for -196°C repeated cycling, 98% customer satisfaction (users: H2 Mobility Europe).

- ASU Plants (India, 2022): 134 valves for air separation units, in-service for >44,000 cycles with no maintenance required.

Product Comparison: 2-Piece Cryogenic Floating Ball Valve vs. Competitors

| Feature | 2-Piece Cryogenic Floating Ball Valve | Competitor A | Competitor B |

|---|---|---|---|

| Material Traceability | EN10204 3.1/3.2 full traceability | Partial | Partial |

| Production Lead Time | 5-7 Weeks | 7-10 Weeks | 8-12 Weeks |

| Cryogenic Leak Test | 100% per ISO 28921-1 | Spot Check API 598 | API 598 only |

| Warranty | 36 Months | 18 Months | 12 Months |

| Repair Kit Availability | Standard, Immediate | Request based | Not standard |

| Fire-Safe Approval | API 607/ISO 10497 | API 607 | No |

Service Commitment and Delivery Timelines

- Standard Lead Time: 5–7 weeks after order confirmation

- Expedited Delivery: 15–20 working days for select sizes

- Quality Assurance: All valves fully traceable and backed by 36-month warranty

- Support Channels: 24/7 technical assistance, on-site commissioning, and repair

Customization Options & Typical Application Scenarios

Cryogenic floating ball valves can be customized to fit diverse requirements across sectors:

- Bonnet Extension: Custom lengths to suit insulation thickness and operator access

- Material: Special alloys for high-chlorine/hydrogen services

- Seat Design: Replaceable/metal seats for abrasive or high-flow duties

- Operator Interface: ISO 5211 mounting pads for smart actuators

- Cryogenic Testing: Optional ultrasonic/NDT for nuclear or ultra-pure applications

Real-World Application Cases

Project: National LNG Terminal upgrade

Scope: 162 valves (1"–6", Class 300)

Outcome: No leakage after 480 pressure cycles at -162°C; operational with auto-actuator system.

Hydrogen Mobility (Europe, 2023)

Project: H2 station network pilot

Scope: Engineered extended bonnet for fast-cycling (-192°C, DN25–DN100)

Outcome: 99.6% uptime; positive field reports; maintenance interval 27,000+ cycles

Performance by Size - CV Value Line Chart

EEAT: Experience, Authority, and Customer Trust

- All cryogenic floating ball valves compliant with ISO 9001, ISO 14001, PED, CE

- 3rd party inspection: SGS, TUV, Bureau Veritas

- Industry partners: Sinopec, Linde, Air Liquide, Shell

End-User Testimonials

"We had over 20,000 cycles without a single seal failure, even under -190°C duty intensity." — LNG Terminal Maintenance Supervisor

Expert FAQ: Cryogenic Floating Ball Valve Selection & Use

Quality, Service, and Support

- Warranty: Industry-leading 36 months

- Delivery: 5–7 weeks (with expedited options)

- Support: 24/7 technical hotline, remote and on-site service in over 20 countries

- Documentation: All test/traceability reports supplied (EN10204 3.1/3.2 possible)

For detailed technical questions or to request a quote for customized cryogenic floating ball valve solutions, visit: 2-Piece Cryogenic Floating Ball Valve

References & Further Reading

- ISO 28921-1:2013 — Cryogenic valves standard

- Valve Magazine: Design Considerations for Cryogenic Valves

- Gulf Coast Energy Forum: The Global Cryogenic Valve Market: Next Steps

- Journal of Natural Gas Science & Engineering: Temperature Effects on Cryogenic Valve Performance

- Valve World Forum: Latest Trends in Cryogenic Valves