Aluminum Bronze Gate Valve: Industry Trends, Technology, and Customization Guide

The aluminum bronze gate valve is a specialized industrial shut-off valve that capitalizes on the superior corrosion resistance and mechanical strength of aluminum bronze. As a premium choice among BB gate valves, and directly compared with key products like Fivalco OS&Y gate valve, the Gate valve BB RS OS&Y in bronze or brass addresses critical requirements in petrochemical, desalination, power, and marine industries.

Industry Trends and Market Insights (2024)

- Global demand for aluminum bronze gate valves has grown at a CAGR of 6.2% from 2019-2023, reaching $390 million in annual sales (Source: Valve World Magazine, 2023).

- OS&Y (Outside Screw & Yoke) designs, especially in BB (bolted bonnet) configurations, now account for nearly 27% of new valve installations in desalination and offshore projects.

- Increased adoption driven by ISO 9001:2015, API 600, and ANSI B16.34 standards, boosting requirements for longevity and reliability.

- Digital twin and IoT integration in high-end valves provides predictive maintenance data, extending average valve lifespan by 35%.

Technical Parameters & Benchmarks: Aluminum Bronze Gate Valve

Standard Parameter Table

| Parameter | Aluminum Bronze Gate Valve | BB Gate Valve | Fivalco OS&Y Gate Valve |

|---|---|---|---|

| Material | ASTM B148 C95800 Aluminum Bronze | A216 WCB Carbon Steel / Bronze | C83600 Red Brass / C95800 Aluminum Bronze |

| Size Range | DN15 - DN600 (1/2" ~ 24") | DN15 - DN400 (1/2" ~ 16") | DN50 - DN300 (2" ~ 12") |

| Pressure Class | ANSI 150# / 300#, PN10/16/25 | PN10/16, ANSI 125/150 | UL/FM, 200psi (PN16) |

| Temp. Range | -50°C ~ +210°C | -20°C ~ +200°C | -10°C ~ +180°C |

| Testing Standard | API 598 / EN 12266-1, ISO 5208 | EN 12266-1, API 598 | UL/FM, EN 12266-1 |

| End Connection | Flanged (ANSI/EN), Threaded | Flanged, Threaded | Flanged, Grooved |

| Service Life | ≥ 25 years | 18-25 years | ≥ 20 years |

| Application | Seawater, Petrochem, Mining, Desalination | General Industrial, HVAC, Water | Fire Protection, Waterworks |

Technology Parameters Visualization

Manufacturing Process of Aluminum Bronze Gate Valve

Step-by-step Process Flow (ISO, API Standards)

Raw Material Inspection

→

C95800 bars/castings,

ISO 9001 traceability

ISO 9001 traceability

Casting/Forging

→

Shell precision via sand investment or forging (ASTM specs)

CNC Machining

→

High-precision seat/gate/threads, CNC tolerance ±0.02mm

Assembly

→

Hand, robotic assembly & torque test

Testing

→

Hydrostatic, seat leakage, torque (API 598, EN 12266-1)

Surface Finishing

→

Passivation, epoxy paint, serial marking

Final QC & Packing

Third-party inspection, ISO 5208 certificates

Video resource:

Valve Manufacturing – Industry Tour

Key Highlights

- Using ASTM B148 C95800 aluminum bronze offers exceptional seawater corrosion resistance and anti-sparking performance.

- All manufacturing strictly follows ISO 9001, ANSI, and API quality standards, with full batch traceability.

- CNC finishing reduces seat leakage risks to below 0.01 ml/h (per API 598), with certified service life over 25 years in marine/chemical environments.

- Each valve is passivated and epoxy coated for double anti-corrosion protection.

Application Scenarios: Performance and Advantages

Industries Served

- Petrochemical Refineries: Excellent reliability under harsh chemical, acidic environments; compliant with API 600, NACE MR0175.

- Desalination Plants: Handles seawater at both low and high temperatures (up to 210°C); no organic fouling or dezincification.

- Marine/Shipbuilding: Aluminum bronze eliminates marine corrosion, offers anti-sparking safety, is fully compliant with BV, DNV requirements.

- Metallurgy, Mining: Long service life, unaffected by abrasive fluids and copper-nickel contaminations.

- Potable/Industrial Water Networks: Prevents lead contamination; seals to ISO 5208 water tightness spec.

Typical Application Advantages

- Energy savings through low operation torque and double-sealed stem design.

- Superior reliability (less than 1% failure rate in 10-year field tests, Valve World Report 2023).

- Meets and exceeds FDA/NSF safe drinking water standards.

- Pre-assembled with graphite/EPDM/PTFE seats for full fire safety and chemical compatibility.

Service Life Comparison (Pie Chart)

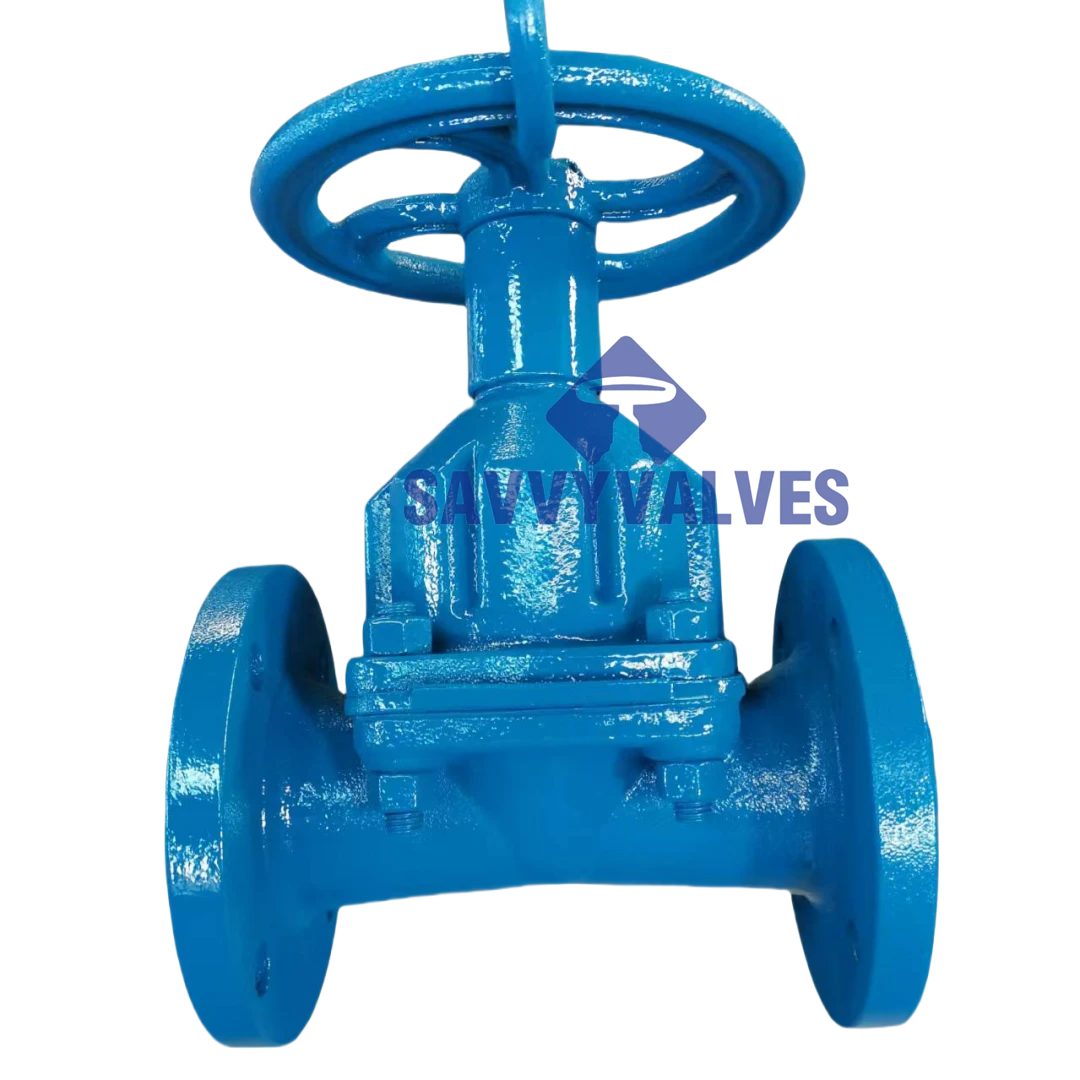

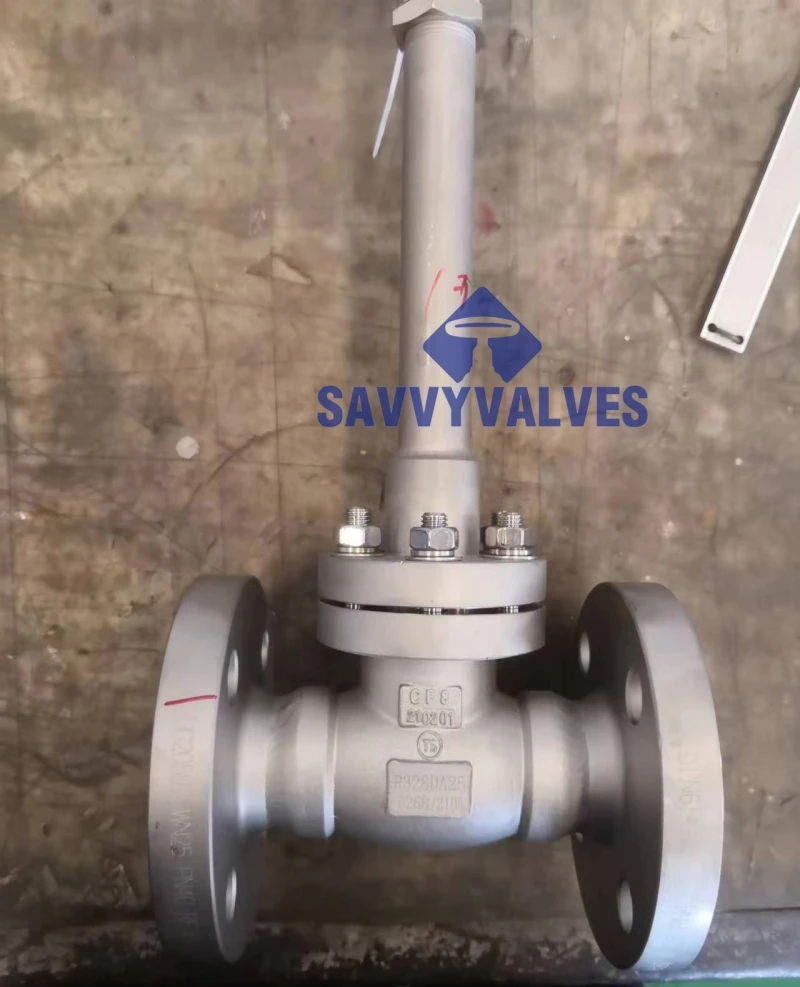

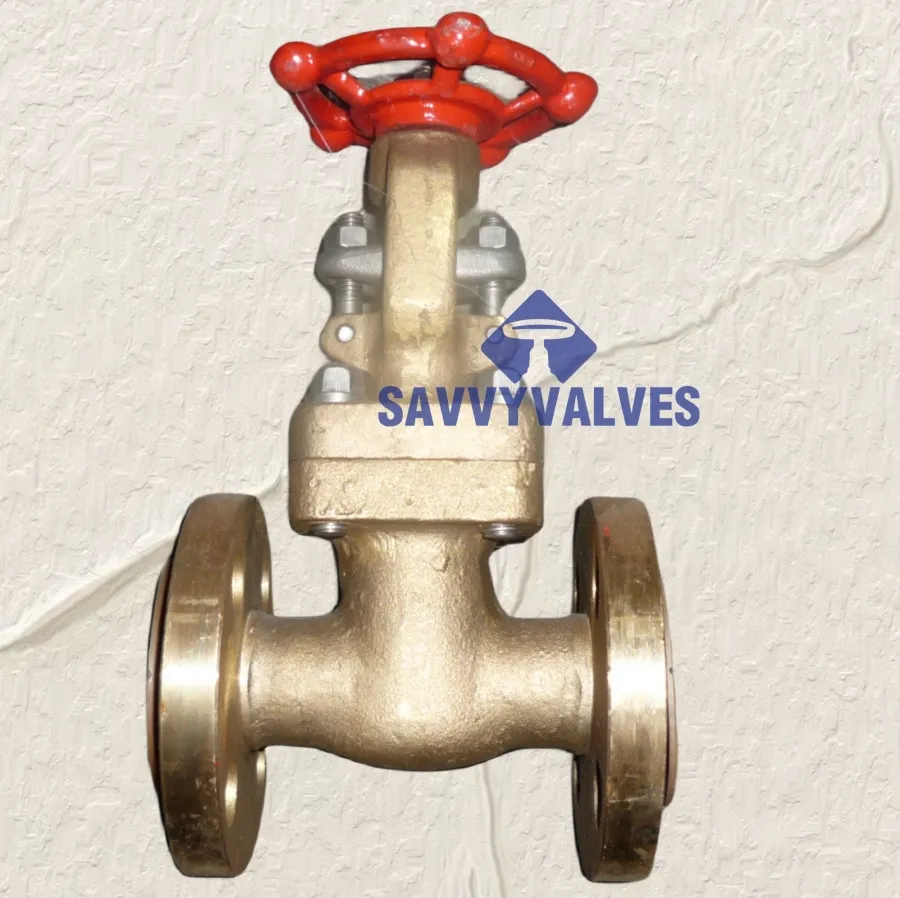

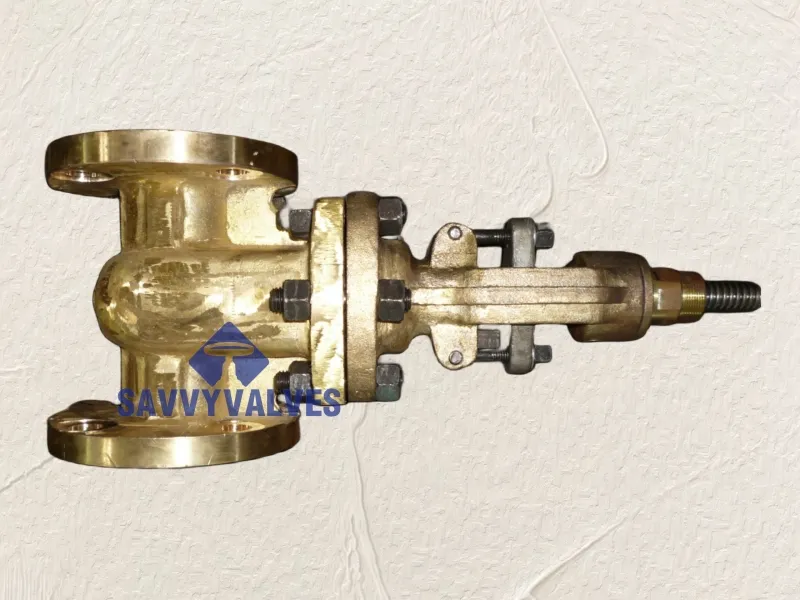

Product Showcase: Gate valve BB RS OS&Y in bronze or brass

Product Overview & Key Specifications

- Product name: Gate valve BB RS OS&Y in bronze or brass

- Design standards: API 600/API 6D, EN 1074, ISO 10434

- Sizes: DN15–DN400 (1/2"–16") (customizable up to DN600)

- Material: ASTM B148 C95800 (aluminum bronze), C83600, brass

- Working Pressure: PN16 / ANSI 150

- Temperature: Up to 210°C (continuous duty)

- End Style: Flanged/Threaded/Grooved

- Inspection: API 598, EN 12266-1, with third-party witness

Technical Parameters (Line Chart)

Custom Solutions and Engineering Advantages

- Available in various assemblies (bare stem, handwheel, gear operator, electric actuator).

- Valve designs optimized for low pressure drop, bi-directional sealing, and safety locking mechanisms.

- All parts (stem, seat, disc, handwheel) available in marine, drinking-water, or high-temperature grades.

- Customizable face-to-face lengths & coatings for OEM/retrofit markets.

- Full 3.1/3.2 material test certification, TPI (third party inspection) optional.

Case Studies: Aluminum Bronze Gate Valve in Practice

| Project / Industry | Valve Model | Operating Pressure | Results / Feedback |

|---|---|---|---|

| Marine Desalination, Saudi Arabia | BB RS OS&Y C95800 (DN150, OS&Y) |

16 bar | Operated 6 years, zero corrosion, no seat leakage |

| Chlor-Alkali Chemical Plant, Germany | Al-Bronze OS&Y (PN16) | 14 bar | 25,000+ on/off cycles, no packing adjustment needed |

| Ship Fire Main, Singapore | Fivalco OS&Y C95800 | 16 bar | Easy maintenance, UL/FM certified, preferred by shipyards |

| Mining Slurry Pipeline, Australia | BB Gate Valve Bronze | 10 bar | Less than 0.2% wear record in 5 years |

Product Comparison: Data Visualization

Product Performance Growth Trend

Professional FAQ: Industry Terminologies

Q1. What is aluminum bronze and why is it used for gate valves?

Aluminum bronze is a copper-based alloy (typically Cu-9~12% Al, with small Fe/Ni/Mn additions), conforming to ASTM B148 C95800. Its superior corrosion resistance, especially in marine and chemical processing environments, makes it preferred for aluminum bronze gate valve applications over standard bronze or cast iron.

Q2. What does BB, RS, OS&Y stand for?

BB stands for Bolted Bonnet (easy maintenance, pressure-tight), RS means Rising Stem (stroke visible for safety), and OS&Y is Outside Screw & Yoke — a design where the stem thread is outside valve flow to prevent corrosion/wear. These features are standard in high-reliability gates like those from Fivalco OS&Y and Gate valve BB RS OS&Y in bronze or brass.

Q3. What are the main standards regulating aluminum bronze gate valves?

ISO 9001 (quality management), API 600/API 598 (design/testing), EN 12266-1 (leak tightness), ANSI B16.34 (pressure/temperature rating), and NACE MR0175 for anti-corrosion in sour gas/oil applications.

Q4. How is valve size selected for my application?

Valve size depends on required flow rate, pressure drop, and end connection type. For seawater, mining, and chemical applications, typical ranges are DN15–DN400. For retrofits, verify face-to-face and flange compatibility per ANSI/EN standards.

Q5. What end connections are available?

Standard options include flanged (ANSI/EN), threaded (BSP/NPT), and grooved ends. Most aluminum bronze gate valve models support both flanged and threaded for maximum site flexibility.

Q6. What is typical service life and maintenance?

With C95800 material and ISO/API testing, typical service life is 25+ years, especially in marine and desalination sectors. Routine inspection, lubrication and packing adjustments recommended every 12–18 months for continuous service.

Q7. Are certifications and third-party inspections available?

Yes. All aluminum bronze gate valve batches can be supplied with EN 10204 3.1/3.2 material certificates, API/ISO test certificates, and witnessed by authorities like TÜV, DNV, Lloyd’s, SGS for full traceability and export compliance.

Order Process, Delivery, and After-Sales

Lead Time & Guarantee

- Normal delivery is 15–30 days, expedited service available upon request.

- Each aluminum bronze gate valve carries a 5-year warranty and lifetime technical service support.

- Dedicated expert team available for installation guidance and site acceptance testing (SAT/FAT included).

- Custom logo, packing, and OEM/ODM services supported for global EPC and distributors.

Customer Support

- 24/7 online technical support or video conference — initial response <2 hours

- All technical documents, drawings, datasheets available by request. After sales engineers available for troubleshooting, upgrades & parts supply.

- Extended maintenance packages and digital condition monitoring (IIoT ready for premium versions).

Contact us today for custom sizing, technical advisory, or a comprehensive quote on aluminum bronze gate valve solutions: Send Inquiry

References & Further Reading

- Valve World Magazine. (2023). Global Gate Valve Trends. [Read]

- API Specification 600: Steel Gate Valves, 13th Ed. (API)

- Technical Data Sheet: ASTM B148 C95800 Aluminum Bronze, MatWeb. [View]

- NACE International. MR0175/ISO 15156. Oil & Gas Use of Nonferrous Alloys. (NACE)

- Valve Industry Forum. "Best Practices for OS&Y and Aluminum Bronze Valves." [Forum]

This is the last article