Understanding the Critical Role of Lug-Type Pneumatic Knife Gate Valve in Industrial Processes

In the demanding landscape of industrial fluid control, the Lug-Type Pneumatic Knife Gate Valve stands as a paramount component, crucial for efficient and safe operations across numerous sectors. These valves are specifically engineered to handle challenging media, including slurries, viscous liquids, corrosive chemicals, and abrasive materials, where conventional valves often fail due to clogging or wear. Their design, characterized by a sharp, thin gate that slices through the media, ensures effective shut-off and minimal resistance to flow when fully open. The integration of pneumatic actuation allows for rapid, precise, and remote control, significantly enhancing operational safety and automation capabilities. Current industry trends emphasize enhanced automation, predictive maintenance, and the integration of smart technologies, all of which are perfectly complemented by the inherent design and capabilities of pneumatic knife gate valves. As industries strive for greater efficiency, reduced downtime, and improved environmental compliance, the demand for robust, reliable, and intelligently controlled flow solutions like this valve continues to surge, underpinning its essential position in modern industrial infrastructure. This shift necessitates valves that not only perform under extreme conditions but also offer seamless integration into complex control systems, highlighting the enduring relevance and evolving design of these specialized valves for critical applications.

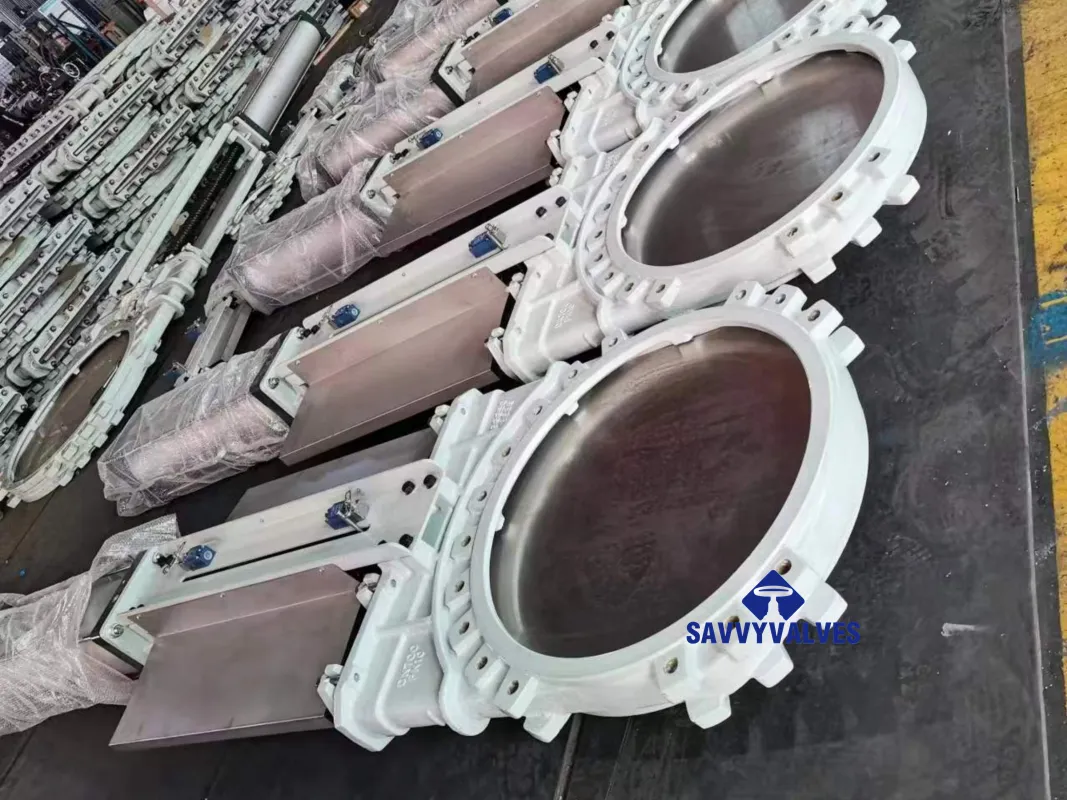

The robust construction of a Lug-Type Pneumatic Knife Gate Valve, often featuring a lugged body for direct bolting to pipelines, simplifies installation and maintenance while ensuring a secure, leak-free connection. This design is particularly advantageous in applications where space is at a premium or frequent valve removal might be necessary for pipeline maintenance. Key components typically include a cast or fabricated body, a resilient seat, a polished gate, a packing gland for stem sealing, and the pneumatic actuator itself, comprising a cylinder, piston, and solenoid valves for air control. The material selection for these components is critical and varies widely based on the intended application, ranging from stainless steel and ductile iron for general industrial use to specialized alloys like Hastelloy or Super Duplex for highly corrosive or abrasive environments. Understanding these material specifications is fundamental to ensuring the longevity and optimal performance of the valve under specific operating conditions. The drive for increased operational uptime and reduced lifecycle costs further propels the adoption of these high-performance valves, making them an indispensable asset in modern processing facilities. The reliability offered by their straightforward design, coupled with the power of pneumatic control, positions them as a go-to solution for challenging fluid management tasks globally.

The Meticulous Manufacturing Process of a High-Performance Lug-Type Pneumatic Knife Gate Valve

The production of a reliable Lug-Type Pneumatic Knife Gate Valve is a sophisticated process that begins with the selection of premium raw materials. For the valve body and gate, common materials include ASTM A216 WCB (Carbon Steel), ASTM A351 CF8M (316 Stainless Steel), ASTM A351 CF8 (304 Stainless Steel), or specialized alloys like Duplex Stainless Steel (e.g., ASTM A890 4A/5A/6A) or Hastelloy C-276, chosen specifically for their chemical resistance and mechanical properties relevant to the intended application. The manufacturing journey typically commences with precision casting or forging processes for the main body and gate, ensuring structural integrity and dimensional accuracy. Following this, advanced CNC machining is employed to achieve the precise tolerances required for optimal sealing and smooth operation. This critical step shapes the valve's internal cavities, gate guides, and flange connections to stringent international standards like ASME B16.5 for flanges and ASME B16.10 for face-to-face dimensions, guaranteeing interchangeability and reliability in diverse piping systems. Surface treatments, such as polishing or specialized coatings (e.g., hard chrome plating on the gate), are applied to enhance wear resistance and improve media flow characteristics, particularly for abrasive or sticky substances.

Subsequent stages involve the meticulous assembly of various components, including the seat (often made of EPDM, Viton, PTFE, or metal-to-metal), packing (PTFE, graphite, or braided), stem, and yoke. The pneumatic actuator, which is typically a double-acting or spring-return cylinder, is then integrated and precisely calibrated. Each Lug-Type Pneumatic Knife Gate Valve undergoes rigorous quality control inspections at every phase of its manufacturing. This includes material composition verification (PMI testing), non-destructive testing (NDT) such as radiographic (RT) or ultrasonic (UT) inspections for castings, hydrostatic pressure testing (Shell and Seat testing) according to API 598 or ISO 5208 standards to ensure leak-tightness, and functional testing of the actuator for smooth operation and rapid response. Compliance with international standards such as ISO 9001 (Quality Management Systems), ANSI/AWWA C504, and MSS SP-81 for design and testing is not just a regulatory requirement but a cornerstone of ensuring long-term reliability and safety. The typical service life of a well-maintained knife gate valve can exceed 15-20 years, depending on the application severity and material selection, making it a sustainable investment. These valves are extensively used in industries such as petrochemicals, metallurgy, pulp and paper, mining, power generation, and water/wastewater treatment, demonstrating their versatility and robust performance in energy-saving and corrosion-resistant applications.

Key Technical Specifications and Performance Parameters of Lug-Type Pneumatic Knife Gate Valve

Understanding the technical specifications of a Lug-Type Pneumatic Knife Gate Valve is paramount for proper selection and optimal performance in industrial applications. These valves are engineered to meet stringent operational demands, with critical parameters influencing their suitability for specific media and environments. Sizes typically range from DN50 (2 inches) up to DN1200 (48 inches) or larger for custom applications, accommodating a wide spectrum of flow requirements. Pressure ratings are standardized to classes such as PN10, PN16, ANSI Class 150, or even higher for specialized designs, dictating the maximum allowable operating pressure. The valve body materials are selected based on process fluid corrosivity and temperature, encompassing Ductile Iron (ASTM A536), Cast Steel (ASTM A216 WCB), 304/316 Stainless Steel (ASTM A351 CF8/CF8M), and more exotic alloys like Duplex/Super Duplex Stainless Steel for aggressive chemical or high-chloride environments. Gate materials often mirror the body materials but are sometimes hardened or coated for enhanced abrasion resistance. Sealing materials, crucial for leak-tightness, include EPDM, NBR, Viton, PTFE, and various metal seats, each offering different temperature and chemical compatibility ranges, with operating temperatures typically spanning from -29°C to +180°C depending on the material combination.

The pneumatic actuation system is a defining feature, typically operating with instrument air pressure of 4-7 bar (60-100 psi) and offering rapid open/close cycles, crucial for emergency shut-off or high-frequency operation. The choice between double-acting (air-to-open, air-to-close) and spring-return (air-to-open/close, spring-to-close/open) actuators depends on fail-safe requirements. Face-to-face dimensions typically comply with MSS SP-81 for wafer or lugged types, ensuring interchangeability. Flow characteristics are generally excellent when fully open, offering minimal pressure drop due to the full-bore design, which is highly beneficial for energy efficiency in large pipeline systems. When closed, the gate effectively shears through solids, preventing accumulation and ensuring positive shut-off. This design minimizes the risk of clogging and provides superior sealing even with high-solid content media. Maintenance requirements are relatively low, primarily involving periodic inspection of packing and pneumatic components. The table below provides a representative overview of typical specifications, but it's essential to consult specific product data sheets for precise application matching.

Typical Technical Parameters of Lug-Type Pneumatic Knife Gate Valve

| Parameter | Typical Range/Value |

|---|---|

| Nominal Size (DN) | DN50 - DN1200 (2" - 48"), larger available upon request |

| Pressure Rating | PN10, PN16, ANSI Class 150 (up to 250 PSI) |

| Body Materials | Ductile Iron (DI), Cast Steel (WCB), 304/316 SS, Duplex SS, Hastelloy |

| Gate Materials | 304/316 SS, Duplex SS, Hard Chrome Plated SS |

| Seat Materials | EPDM, NBR, Viton, PTFE, Metal-to-Metal |

| Operating Temperature | -29°C to +180°C (depending on seal material) |

| Actuation Type | Double-Acting Pneumatic Cylinder, Spring-Return Pneumatic Cylinder |

| Pneumatic Supply Pressure | 4 - 7 Bar (60 - 100 PSI) |

| Design Standard | MSS SP-81, ASME B16.34, API 609 (for specific types) |

| Testing Standard | API 598, ISO 5208 |

Diverse Application Scenarios and Proven Advantages of Lug-Type Pneumatic Knife Gate Valve

The versatility and robust design of the Lug-Type Pneumatic Knife Gate Valve make it indispensable across a multitude of challenging industrial applications where traditional ball, butterfly, or globe valves would quickly fail. In the mining industry, for instance, these valves are critical for controlling highly abrasive ore slurries, tailings, and process water, where their ability to cut through solids and prevent clogging significantly extends operational uptime. Similarly, in the pulp and paper sector, they excel in managing pulp stock, waste paper slurries, and chemical recovery lines, preventing fiber accumulation and ensuring consistent flow. Wastewater treatment plants rely on them for handling raw sewage, sludge, and grit, where their robust sealing against solids and ease of maintenance are invaluable. The chemical processing industry benefits from specific material configurations of these valves for controlling corrosive and hazardous media, ensuring safety and integrity of the system. In power generation, particularly in coal-fired plants, they manage ash slurries and flue gas desulfurization (FGD) processes, enduring high wear and corrosive conditions. Even in the food and beverage industry, specialized sanitary versions of these valves are used for bulk material handling of powders and viscous food products.

Beyond their broad applicability, the Lug-Type Pneumatic Knife Gate Valve offers distinct technical advantages. Their full-bore design, when fully open, ensures minimal pressure drop, leading to significant energy savings, particularly in high-volume applications where pump efficiency is critical. The precise pneumatic actuation allows for rapid open/close cycles, enhancing process control and safety, especially during emergency shutdowns. The sharp-edged gate, combined with a resilient or metal seat, provides excellent sealing capabilities even with high-solid content, effectively preventing downstream leakage. Furthermore, the design inherently resists clogging, as the gate shears through any accumulated media during closure, preventing common issues faced by other valve types. This inherent self-cleaning action contributes to reduced maintenance requirements and lower operational costs. Their robust construction, often utilizing corrosion-resistant materials, provides exceptional longevity even in harsh environments, reducing the frequency of replacements and minimizing total cost of ownership. The lugged body design also simplifies installation and removal, facilitating pipeline maintenance without disturbing adjacent piping, further adding to their operational efficiency.

Manufacturer Comparison and Customization Solutions for Lug-Type Pneumatic Knife Gate Valve

When selecting a supplier for Lug-Type Pneumatic Knife Gate Valve, distinguishing between manufacturers is crucial, as quality, expertise, and support vary significantly. Reputable manufacturers differentiate themselves through adherence to international standards (e.g., ISO 9001 certification for quality management, API specifications for valve design), robust R&D capabilities, extensive material inventories for rapid customization, and comprehensive after-sales support. Key factors to consider include the manufacturer's experience in similar applications, their track record of successful installations, and the transparency of their testing and certification processes. A comparative analysis often reveals variations in valve body casting quality, precision of CNC machining, the effectiveness of their gate sealing mechanisms, and the reliability of their pneumatic actuators. For example, a manufacturer with extensive experience in the mining sector might offer specialized hard-facing options for gates to combat extreme abrasion, while one focusing on chemical processing might emphasize exotic alloy availability and superior packing designs for fugitive emissions control. It is vital to assess not just the initial cost, but the total cost of ownership, which includes potential maintenance, downtime, and replacement expenses over the valve's lifecycle.

One of the significant advantages offered by leading manufacturers is the provision of highly specialized customization solutions for Lug-Type Pneumatic Knife Gate Valve. Recognizing that standard off-the-shelf valves may not fully address unique process requirements, customization allows for tailoring specific parameters. This can include bespoke body materials (e.g., Titanium for extreme corrosives, specific ductile iron grades for low-temperature service), unique dimensions for tight space constraints, specialized coatings for enhanced abrasion or chemical resistance (e.g., ceramic-lined, PTFE-lined), and integration with specific automation systems (e.g., intelligent positioners, fieldbus communication, precise flow control through V-port gates). For example, in a highly viscous media application, a manufacturer might propose a flush-bottom design or a heating jacket. For applications requiring precise flow modulation rather than just on-off control, a V-port gate design with a precise pneumatic positioner can be engineered. A manufacturer's ability to offer comprehensive engineering support, from initial design consultation to post-installation troubleshooting, is a hallmark of a trustworthy partner. This collaborative approach ensures that the final valve solution is perfectly aligned with the client's operational demands, maximizing efficiency and minimizing risks in complex industrial environments, thereby building long-term trust and reliability.

Manufacturer Comparison Factors for Lug-Type Pneumatic Knife Gate Valve

| Factor | Leading Manufacturer Qualities | Average Manufacturer Qualities |

|---|---|---|

| Quality Certifications | ISO 9001, API, CE, PED, SIL Rating options | Basic ISO or regional certifications |

| Material Availability | Extensive stock, exotic alloys, quick sourcing | Limited standard materials only |

| Customization Capability | Full engineering support, bespoke designs, special coatings | Minor modifications to standard products |

| Testing & QA | 100% Hydrostatic, PMI, NDT, functional testing per international standards | Basic functional tests, limited material verification |

| After-Sales Support | Global service network, spare parts availability, technical assistance | Limited or local support |

Real-World Application Case Studies and Trust-Building Elements for Lug-Type Pneumatic Knife Gate Valve

Real-world application case studies vividly illustrate the transformative impact of the Lug-Type Pneumatic Knife Gate Valve in solving complex industrial challenges. Consider a large-scale copper mine in South America that faced constant clogging and premature wear in its tailings disposal lines due to highly abrasive slurry. Traditional globe valves required weekly maintenance and frequent replacement. Upon implementing 20 units of custom-engineered 316L SS knife gate valves with ceramic-coated gates, the mine reported an average increase in valve lifespan from 3 months to over 2 years, coupled with a 90% reduction in unplanned downtime related to valve issues. This transition not only yielded substantial cost savings in maintenance and replacement parts but also significantly improved overall operational efficiency. Another compelling example is a municipal wastewater treatment plant upgrading its sludge dewatering facility. Faced with challenges in reliably isolating high-solids content sludge, they adopted lug-type pneumatic knife gate valves. The precise pneumatic control allowed for automated, synchronized operation with dewatering equipment, leading to a 15% increase in dewatering efficiency and elimination of manual intervention, demonstrating how the right valve technology can directly impact process throughput and safety.

To further build trust and demonstrate authoritative experience, a comprehensive FAQ section, transparent delivery cycles, and robust warranty commitments are essential.

Frequently Asked Questions (FAQ) about Lug-Type Pneumatic Knife Gate Valve

Q1: What types of media can a Lug-Type Pneumatic Knife Gate Valve handle?

A1: These valves are exceptionally well-suited for abrasive slurries, corrosive liquids, viscous media, powders, granular materials, and wastewater. Their design allows the gate to shear through solids effectively.

Q2: What are the primary advantages of pneumatic actuation over manual or electric?

A2: Pneumatic actuation offers rapid opening and closing speeds, crucial for emergency shut-off or quick process changes. It also allows for precise remote control, integration into automated systems (DCS/PLC), and is intrinsically safe in hazardous environments compared to electric actuators. They also provide high torque for seating and unseating the gate.

Q3: How do you select the correct material for a specific application?

A3: Material selection is critical and depends on the process fluid's corrosivity, temperature, pressure, and abrasiveness. Common choices include ductile iron, 304/316 stainless steel, and specialized alloys like Duplex SS for extreme conditions. Consulting with our technical team is recommended for optimal material pairing.

Q4: What maintenance is typically required for these valves?

A4: Lug-Type Pneumatic Knife Gate Valve are designed for low maintenance. Regular checks include inspecting the packing for leaks, ensuring the pneumatic actuator is receiving adequate, clean air supply, and lubricating moving parts as per manufacturer guidelines. The self-cleaning action of the gate minimizes internal clogging issues.

Delivery Cycle and Quality Assurance

Our commitment to efficiency extends to our delivery protocols. Standard delivery for common configurations of Lug-Type Pneumatic Knife Gate Valve typically ranges from 4-6 weeks from order confirmation, subject to current production schedules and material availability. For urgent requirements, expedited manufacturing and shipping options are available, which can reduce lead times significantly. Custom-engineered solutions or valves requiring exotic materials may extend this period; however, precise timelines are provided at the quotation stage. Each valve undergoes stringent quality assurance protocols certified by ISO 9001:2015 standards, encompassing raw material inspection, in-process quality checks, and comprehensive final functional and hydrostatic testing. This meticulous process ensures every valve shipped meets or exceeds international performance and safety standards before leaving our facility.

Warranty and Customer Support

We stand behind the quality and reliability of our Lug-Type Pneumatic Knife Gate Valve products with a comprehensive warranty. All valves are typically covered by a 12-month warranty from the date of installation or 18 months from the date of shipment, whichever comes first, against defects in material and workmanship. This commitment underscores our confidence in the durability and performance of our products. Our dedicated customer support team is available to provide technical assistance, troubleshooting, and spare parts support throughout the lifecycle of the valve. We offer expert guidance on installation, operation, and maintenance, ensuring that our clients receive continuous value and optimal performance from their investment. Our long-standing service record and numerous client partnerships globally attest to our unwavering dedication to customer satisfaction and product excellence.

References:

- Valves, Piping, and Fittings Handbook for Process Engineers.

- Fluid Mechanics: Fundamentals and Applications.

- Industry Standards: ISO 9001, API 609, MSS SP-81, ASME B16.34.

- Process Control and Automation: A Practical Guide.

- Corrosion Engineering and Science.