Understanding Double Flanged Dual Plate Check Valves: Industry Trends and Technical Evolution

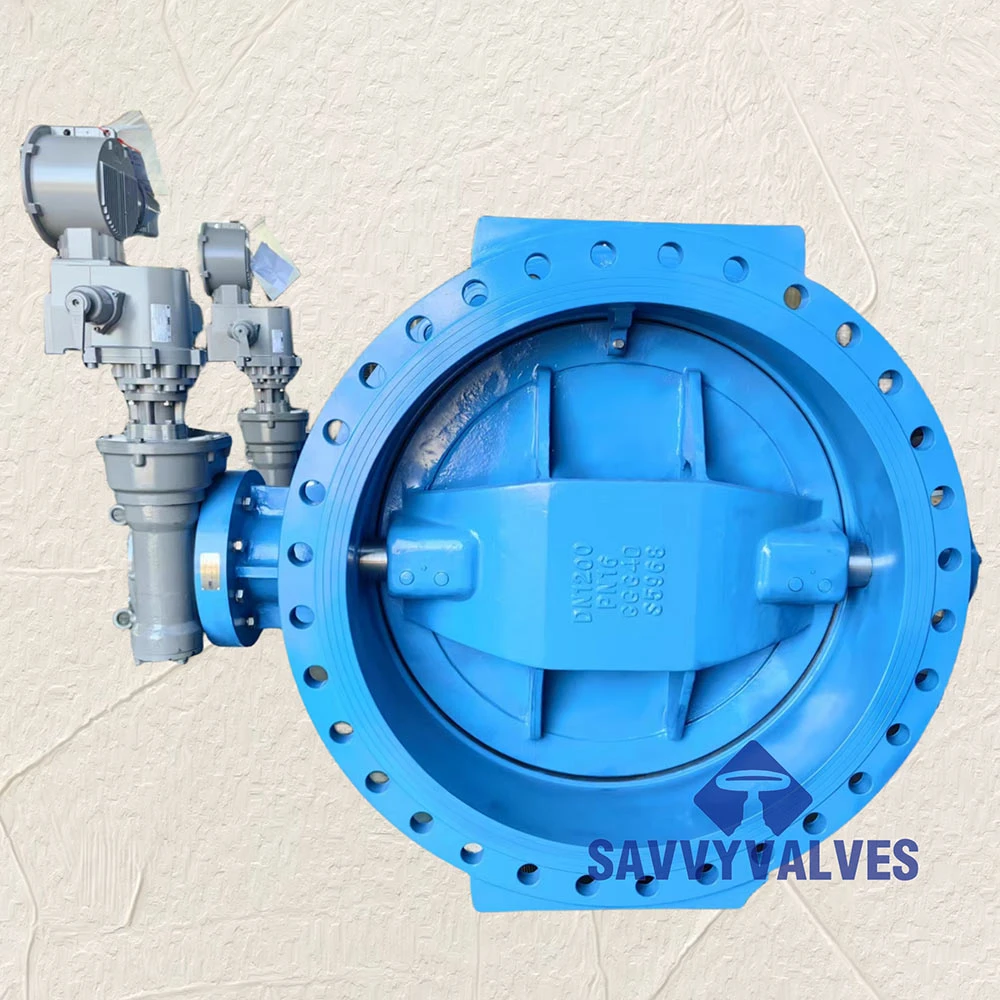

The industrial landscape's relentless pursuit of efficiency, reliability, and safety has fundamentally reshaped valve technology, particularly within critical fluid handling systems. At the forefront of this evolution stands the double flanged dual plate check valve, an indispensable component designed to prevent backflow in pipelines. This engineering marvel, characterized by its compact design and high-performance capabilities, is gaining increasing traction across diverse sectors. Current industry trends point towards a growing demand for valves that not only meet stringent operational parameters, such as higher pressure and temperature resistance, but also contribute to overall system energy efficiency and reduced maintenance overhead. Manufacturers are continuously innovating, incorporating advanced materials like specialized alloys and employing sophisticated computational fluid dynamics (CFD) to optimize valve performance, minimize pressure drop, and enhance sealing integrity. Furthermore, the integration of smart monitoring capabilities, though nascent for passive devices like check valves, is an emerging trend in broader valve infrastructure, enabling predictive maintenance and improving operational uptime. This forward momentum underscores the critical role of robust and intelligently designed check valves in modern industrial infrastructure, providing essential protection against costly equipment damage and operational disruptions while ensuring seamless fluid control.

As industries strive for sustainable operations and enhanced productivity, the focus intensifies on components that offer long-term value and consistent performance. The inherent advantages of a double flanged dual plate check valve, such as its minimal space requirement compared to traditional swing check valves and its superior performance in pulsating flow conditions, align perfectly with these objectives. The dual-plate design, often featuring independent torsion springs, facilitates quick closure, effectively mitigating the damaging effects of water hammer and transient pressures. This rapid response mechanism is crucial in protecting sensitive upstream equipment and maintaining system stability. Moreover, advancements in sealing technologies, including metal-to-metal seating for high-temperature and abrasive media applications or resilient seats for bubble-tight shutoff, expand the applicability of these valves across a wider range of challenging fluid services. The emphasis on standardized manufacturing practices and rigorous testing protocols further reinforces user confidence, making the double flanged dual plate check valve a preferred choice for engineers and procurement specialists seeking reliability and cost-effectiveness over the valve's operational lifecycle. The market is also seeing a shift towards suppliers offering comprehensive technical support and tailored solutions, recognizing that a generic product might not always meet the unique demands of highly specialized industrial processes, thus elevating the importance of deep technical expertise from valve manufacturers.

The Art of Precision: Manufacturing Process and Quality Assurance

The production of a high-quality dual plate check valve double flanged is a meticulous process demanding precision engineering and rigorous quality control at every stage. It typically begins with the careful selection of raw materials, which are paramount to the valve's performance and longevity. For demanding applications, materials like stainless steel (e.g., 304, 316, Duplex, Super Duplex), carbon steel (WCB, LCB), or specialty alloys (Monel, Hastelloy) are chosen based on the media, temperature, and pressure requirements. These materials undergo stringent chemical analysis and mechanical testing to ensure compliance with international standards such as ASTM or ASME. The manufacturing process often involves a combination of advanced techniques: casting or forging for the valve body and plates to achieve superior strength and integrity, followed by sophisticated CNC machining. CNC (Computer Numerical Control) machining ensures precise dimensions and smooth finishes for critical components like the valve seat, disc, and hinge pins, which directly impact sealing capability and operational efficiency. Each component is meticulously crafted to tight tolerances, ensuring seamless integration and optimal functionality within the assembled valve. This initial phase sets the foundation for a robust and reliable product, designed to withstand the harsh conditions prevalent in industrial environments.

Post-machining, components undergo various surface treatments, and for metal-seated valves, precision lapping ensures a superior sealing surface. Assembly is carried out in controlled environments to prevent contamination. Crucially, every double flange check valve is subjected to a comprehensive battery of tests before leaving the factory. These include hydrostatic shell testing to verify the integrity of the valve body under pressure, pneumatic seat testing to ensure bubble-tight shutoff (or specified leakage rates for metal seats), and low-pressure air tests. Non-destructive testing (NDT) methods like radiographic inspection, ultrasonic testing, or magnetic particle inspection may be employed for critical components to detect internal flaws. Manufacturers strictly adhere to international quality management systems such as ISO 9001 and product-specific standards like API 594 (for check valves), ASME B16.34 (for valves-flanged, threaded, and welding end), and ANSI B16.5 (for pipe flanges and flanged fittings), guaranteeing that the valve's design, materials, and testing meet or exceed industry benchmarks. This rigorous quality assurance process not only validates the valve's performance but also projects an expected service life extending over decades, even in continuous operation. The application scope for such precisely engineered valves spans petrochemical plants, power generation facilities, metallurgical operations, and municipal water and wastewater treatment plants, where their reliable backflow prevention and corrosion resistance capabilities are paramount for safe and efficient operations.

Technical Specifications and Performance Parameters

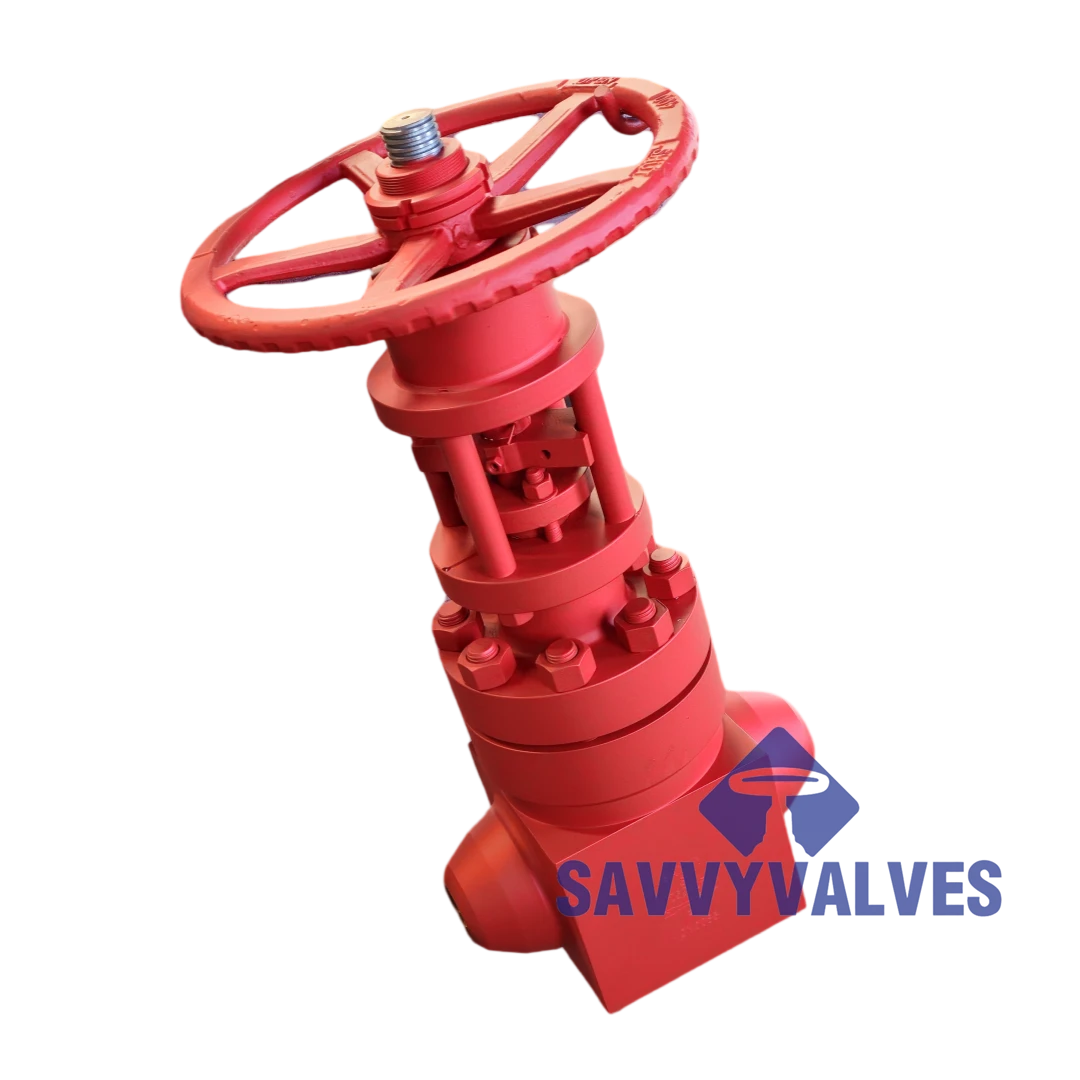

Selecting the appropriate double flanged dual plate check valve hinges on a thorough understanding of its technical specifications and performance parameters. These detailed metrics dictate the valve's suitability for specific applications, ensuring both operational efficiency and long-term reliability. Key parameters typically include the Nominal Pipe Size (NPS) or DN, which defines the valve's diameter, and the pressure class rating (e.g., ANSI Class 150, 300, 600, or PN10, PN16, PN25, PN40), indicating the maximum allowable working pressure at a given temperature. The valve's body and trim materials, such as the specific grade of stainless steel, carbon steel, or high-nickel alloys, are selected based on the corrosiveness and temperature of the fluid media. For instance, a metal-seated design, like the 24″ 600lb Metal Seated Wafer Double Flange Dual Plate Check Valve, is specifically engineered for high-temperature and abrasive services where soft seats would degrade rapidly. Furthermore, face-to-face dimensions, dictated by standards like API 594 or ASME B16.10, ensure interchangeability and ease of installation within existing piping systems. Understanding these parameters is critical for engineers designing pipeline systems, as they directly impact flow dynamics, safety margins, and maintenance schedules, making informed selection paramount for system integrity and operational success.

| Parameter | Description/Value |

|---|---|

| Nominal Size | DN600 (24 Inch) |

| Pressure Rating | ASME Class 600 LB (PN100) |

| Body Material | WCB (Carbon Steel), LCB, CF8, CF8M, Duplex Stainless Steel (e.g., ASTM A216 WCB for body) |

| Disc/Plate Material | ASTM A351 CF8M (Stainless Steel) or equivalent |

| Seat Material | Metal Seated (e.g., Stellite Overlay, Hard Faced) |

| End Connection | Double Flanged (RF/RTJ) to ASME B16.5 |

| Face-to-Face | API 594 Short Pattern or Custom |

| Applicable Temperature Range | -46°C to 425°C (depending on materials) |

| Sealing Mechanism | Metal-to-Metal with Torsion Springs |

| Design Standard | API 594, ASME B16.34 |

| Testing Standard | API 598 |

| Coefficient of Flow (Cv/Kv) | Specific to design, typically very high to minimize pressure drop. |

Unlocking Value: Application Scenarios and Operational Advantages

The versatility and robust design of the double flanged dual plate check valve make it a preferred solution across an extensive array of industrial applications where reliable backflow prevention is non-negotiable. In the oil and gas sector, particularly in pipelines and offshore platforms, these valves are critical for preventing reverse flow in multi-phase fluid transportation, protecting compressors and pumps from damage. Petrochemical processing plants utilize them in various stages of refining and chemical production, handling corrosive and high-temperature media with their specialized material construction and metal seats. Power generation facilities, including thermal, nuclear, and combined-cycle plants, deploy these valves in steam, condensate, and cooling water lines to maintain unidirectional flow and safeguard valuable turbine and boiler equipment. Furthermore, in municipal water and wastewater treatment plants, they ensure the integrity of pumping stations and distribution networks, preventing contamination and maintaining flow efficiency. The compact, wafer-style design with double flanges makes installation simpler in tight spaces, offering significant advantages over traditional swing check valves which require more inline length. This broad applicability underscores the valve's adaptability and essential role in maintaining operational stability and safety across critical infrastructure.

Beyond their wide range of applications, the operational advantages of a dual plate check valve double flanged are compelling for B2B decision-makers. One primary benefit is their remarkably low pressure drop compared to conventional check valves. The streamlined flow path and lightweight, spring-loaded dual discs allow for minimal resistance to forward flow, directly translating into significant energy savings for pumping systems. For instance, in a large-scale water distribution network, even a marginal reduction in pressure drop across numerous valves can accumulate into substantial annual energy cost reductions, enhancing the overall operational efficiency of the system. Another critical advantage is the rapid closure of the dual plates, driven by torsion springs, which minimizes the potential for damaging water hammer. This phenomenon, caused by sudden flow stoppage, can exert immense pressure surges on pipelines and equipment. The quick, non-slamming action of these valves effectively cushions these surges, protecting vital components and extending the lifespan of the entire piping system. Their robust construction, often with corrosion-resistant materials and specialized coatings, ensures superior long-term performance in aggressive media, reducing the frequency of maintenance and replacement. Case studies from large chemical complexes have demonstrated that switching to high-performance dual plate check valves has led to documented reductions in maintenance downtime by up to 20% and an increase in pipeline system longevity by over 15%, validating their long-term economic benefits and reinforcing their value proposition in demanding industrial environments.

Strategic Sourcing: Manufacturer Comparison and Custom Solutions

In the complex world of industrial procurement, the choice of manufacturer for a double flange check valve is as critical as the valve's technical specifications. A reputable manufacturer differentiates itself through several key attributes that directly impact product quality, reliability, and long-term cost of ownership. These include a proven track record of adherence to international standards like ISO 9001 for quality management, API certifications for specific product lines, and robust R&D capabilities that drive innovation in material science and valve design. Furthermore, a manufacturer's commitment to comprehensive testing protocols, including third-party verification, provides an additional layer of assurance. While direct comparison tables of specific manufacturers might be proprietary, evaluating a supplier based on their global presence, extensive service network, and readiness to provide comprehensive technical documentation (such as performance curves, material certifications, and maintenance manuals) offers invaluable insights. For instance, a leading valve technology company might leverage decades of engineering expertise, holding numerous patents for innovative sealing technologies or specialized coatings that extend valve life in corrosive environments, distinguishing them from generic suppliers. This holistic evaluation process is essential for strategic sourcing, ensuring that the selected valve not only meets immediate project requirements but also offers sustained performance and reliable support over its entire lifecycle, a critical factor for operational continuity and safety in high-stakes industrial applications where failure is not an option.

| Factor | Description/Importance |

|---|---|

| Certifications & Standards | ISO 9001, API (e.g., API 6D, 594), CE Mark, ensuring adherence to global quality and safety standards. |

| Engineering & R&D Capabilities | Ability to innovate, conduct CFD analysis, and develop advanced material solutions for specific challenges. |

| Customization & Tailored Solutions | Capacity to design and manufacture valves for unique pressure, temperature, or media conditions. |

| Quality Control & Testing | In-house testing facilities (hydrostatic, pneumatic, NDT), adherence to API 598 for consistent product performance. |

| After-Sales Support & Service Network | Availability of technical support, spare parts, and field service globally or regionally. |

| Track Record & Reputation | Years in business, significant project references, and positive industry reputation from peers and customers. |

Furthermore, the concept of custom solutions is rapidly becoming a cornerstone for advanced industrial projects. While standard off-the-shelf double flanged dual plate check valve options serve many applications, highly specialized industries, such as those dealing with extremely corrosive chemicals, abrasive slurries, or ultra-high pressures, often require valves engineered to specific, often unique, performance envelopes. Savvy manufacturers offer bespoke engineering services, working closely with clients from initial design conceptualization through to manufacturing and testing. This collaborative approach ensures that the valve's material composition, seating configuration (e.g., specific hard-facing overlays like Tungsten Carbide for maximum abrasion resistance), spring mechanism, and overall structural integrity are precisely tailored to the application's most demanding parameters. For example, a project involving hydrogen sulfide in a sour gas application would necessitate specific NACE MR0175/ISO 15156 compliant materials and design to prevent sulfide stress cracking, which is a key area for customization. Such tailored solutions not only optimize performance but also significantly extend the valve's service life, minimize downtime, and reduce total cost of ownership, thereby demonstrating the manufacturer's expertise and commitment to solving complex engineering challenges and solidifying trust in their capabilities.

Trust and Reliability: Customer Support and Assurance

In the B2B landscape, trust and reliability are not just marketing buzzwords; they are fundamental pillars that underpin long-term partnerships, particularly when dealing with critical components like the double flanged dual plate check valve. A truly trustworthy supplier distinguishes itself through comprehensive customer support, transparent delivery schedules, robust warranty commitments, and responsive after-sales service. Understanding that queries can arise at any stage, from pre-purchase technical specifications to post-installation troubleshooting, a dedicated customer support team with deep product knowledge is indispensable. This support extends to assisting with valve sizing, material selection for specific media, and understanding pressure-temperature ratings. Moreover, in an era of complex global supply chains, clear communication regarding delivery lead times, shipping logistics, and tracking information provides peace of mind to project managers and procurement teams, enabling accurate project scheduling and preventing costly delays. Manufacturers committed to excellence will also have a well-defined quality assurance protocol, which includes rigorous internal testing as mentioned earlier, often complemented by independent third-party inspections to validate product compliance and performance. This holistic approach to customer assurance fosters confidence and establishes the supplier as a reliable partner in critical industrial operations, ensuring that the deployed valve solutions operate flawlessly from day one and throughout their extensive operational life.

A key component of this trust-building process is the FAQ (Frequently Asked Questions) module, which proactively addresses common concerns, from installation guidelines to operational limits. For example, FAQs might cover: "What is the minimum pressure required for the valve to open fully?" (Answer relates to cracking pressure), "Can this double flanged dual plate check valve be installed vertically?" (Yes, with specific flow direction considerations), or "What maintenance is required for a metal-seated check valve?" (Typically minimal, focusing on periodic inspection for wear). Beyond FAQs, a strong warranty commitment is a testament to the manufacturer's confidence in their product's durability and performance. Standard warranties typically cover manufacturing defects for a specified period, offering repair or replacement. Furthermore, for specialized industrial applications, comprehensive customer support extends to providing detailed product documentation, offering training sessions for installation and maintenance teams, and providing readily available spare parts to minimize downtime. The proactive engagement with clients, coupled with a robust framework for addressing inquiries and resolving issues promptly, positions a manufacturer as a reliable and authoritative partner. This comprehensive support system ensures that companies investing in a dual plate check valve double flanged receive not just a product, but a complete solution backed by expertise and an unwavering commitment to operational success and long-term customer satisfaction, vital for complex B2B engagements.

References

- American Petroleum Institute (API) Standards: API 594, API 598, API 6D.

- American Society of Mechanical Engineers (ASME) Standards: ASME B16.5, ASME B16.10, ASME B16.34.

- International Organization for Standardization (ISO) Standards: ISO 9001.

- Valve Manufacturers Association of America (VMA) publications and technical papers on check valve design and application.

- Industry reports on fluid control technologies and market trends in the oil & gas, power generation, and water treatment sectors.