In industrial systems, valves regulate, direct, or control the flow of fluids, gases, or slurries. Among these, control valves play a pivotal role in managing flow rates, pressures, and temperatures to maintain operational stability and safety. Partnering with reliable control valve manufacturers is essential to ensure that your process controls operate flawlessly under demanding conditions.

Leading control valve manufacturers leverage advanced materials, precision engineering, and cutting-edge technologies to produce valves that offer accurate modulation, quick response times, and durability. Whether you need valves for chemical processing, oil and gas, power generation, or water treatment, the right manufacturer will provide customized solutions tailored to your specific requirements.

High-quality control valves reduce downtime, improve energy efficiency, and extend the lifespan of your equipment. Investing in trusted control valve manufacturers also guarantees compliance with industry standards, certifications, and safety regulations critical for modern industrial operations.

Selecting a Reliable Check Valve Supplier for Leak-Free and Maintenance-Friendly Solutions

Check valves are crucial components designed to allow fluid flow in one direction while preventing backflow, protecting pumps, compressors, and other equipment from damage. Finding a dependable check valve supplier ensures you receive products that meet rigorous quality standards and function reliably in your system.

A trustworthy check valve supplier offers a diverse range of valves, including swing check, lift check, dual plate, and wafer check valves. Each type caters to different pressures, flow rates, and media, providing you with flexible options that fit your application perfectly.

Durability and low maintenance are key factors when sourcing check valves. Suppliers with robust quality control, advanced manufacturing processes, and materials like stainless steel, bronze, or cast iron can deliver valves that withstand corrosive environments and extreme temperatures.

Additionally, a good supplier provides technical support, assisting in valve selection, installation guidance, and troubleshooting, ensuring long-term operational reliability.

How to Choose the Best Gate Valve Supplier for Industrial Applications

Gate valves are widely used for on/off control in pipelines, offering minimal pressure drop when fully open. Choosing the right gate valve supplier is vital to get valves that are not only durable but also precise in sealing, with smooth operation.

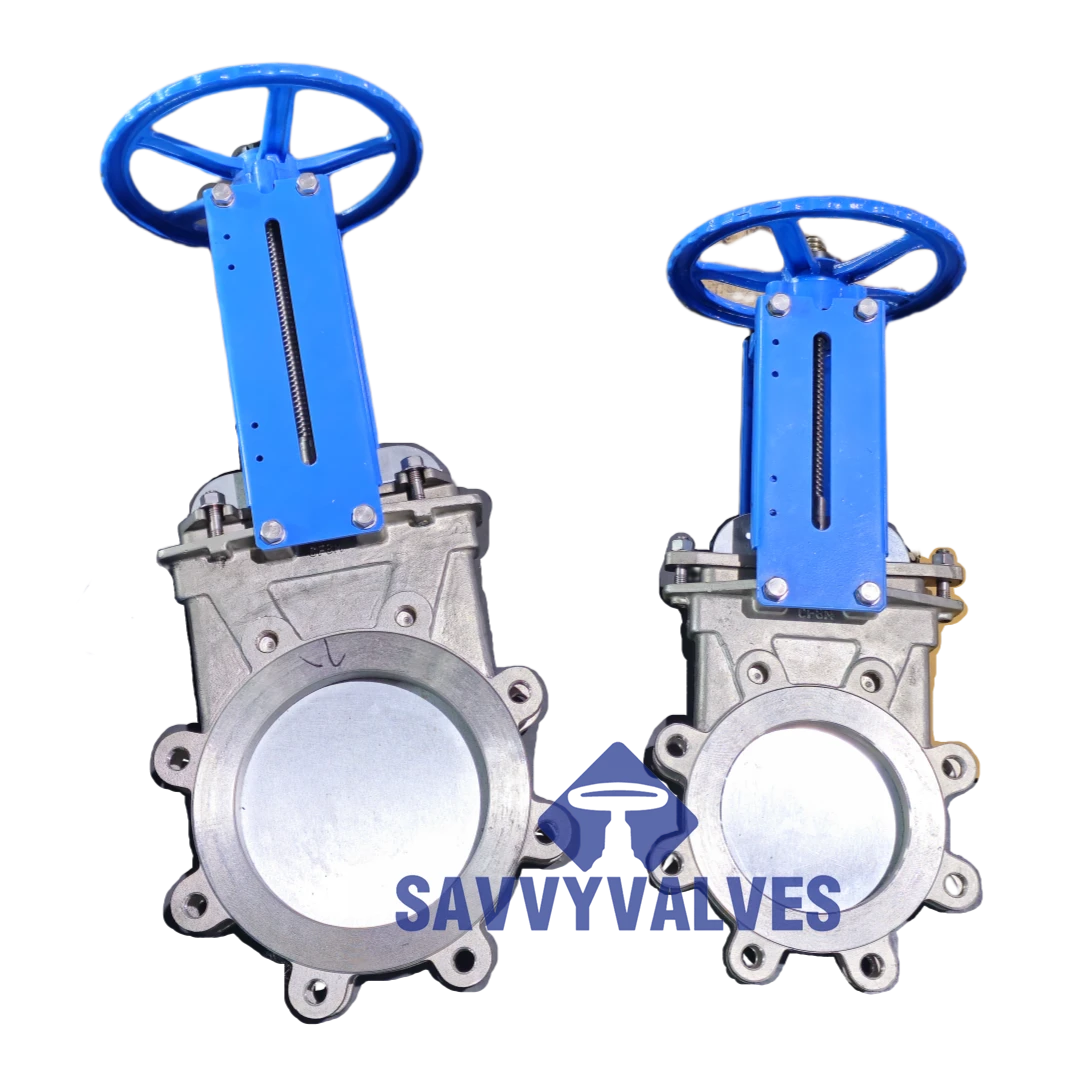

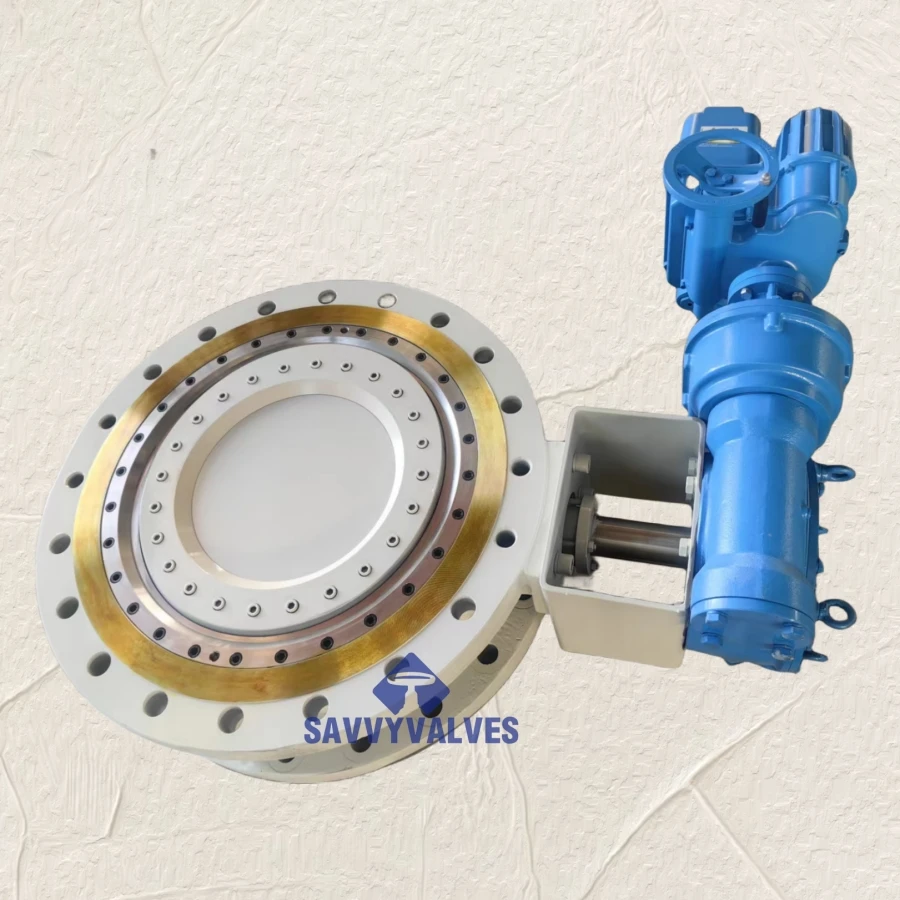

Top gate valve suppliers provide a variety of valve designs, including rising stem, non-rising stem, and knife gate valves, suitable for different industries like petrochemical, water treatment, and mining. Their products comply with international standards such as API, ANSI, and ISO.

Material selection is another important consideration. Reputable suppliers use cast steel, stainless steel, or alloy materials to ensure resistance against corrosion and wear. Furthermore, offering customization for flange types, end connections, and pressure ratings allows you to procure valves that perfectly integrate with your systems.

An excellent gate valve supplier also supports with after-sales service, spare parts availability, and timely delivery, helping you maintain uninterrupted operations.

Benefits of Partnering with Experienced Control Valve Manufacturers, Check Valve Suppliers, and Gate Valve Suppliers

Working with experienced control valve manufacturers, check valve suppliers, and gate valve suppliers brings many advantages that improve system reliability and cost efficiency. These suppliers bring expertise in engineering, production, and quality assurance, which translates to high-performance products tailored to your needs.

Consolidating your valve procurement with trusted partners reduces complexity, simplifies logistics, and enhances technical communication. This integrated approach ensures compatibility between valves and system components, reducing installation challenges and improving maintenance routines.

Experienced suppliers also stay updated with industry innovations, offering products that optimize energy use, reduce emissions, and meet evolving safety standards. Access to technical training, documentation, and responsive customer service enhances your operational capacity.

Ultimately, these partnerships contribute to lowering lifecycle costs and maximizing uptime across industrial operations.

Tips to Verify the Quality and Authenticity of Valves from Control Valve Manufacturers and Valve Suppliers

Ensuring the quality and authenticity of valves is critical for safety and performance. When sourcing from control valve manufacturers, check valve suppliers, and gate valve suppliers, look for certifications such as ISO 9001, API 6D, and CE marking. These certifications indicate compliance with internationally recognized standards.

Inspect the supplier’s manufacturing processes, including material sourcing, machining precision, and quality control testing such as pressure tests, leakage tests, and non-destructive examinations. Requesting detailed product datasheets and test reports helps verify valve specifications.

Warranty and after-sales service policies provide additional assurance, indicating supplier confidence in their products. Moreover, supplier reputation, customer reviews, and industry references are valuable indicators of reliability.

By rigorously evaluating these factors, you can confidently select valves that deliver safe, efficient, and long-lasting service.

control valve manufacturers FAQs

What distinguishes control valves from other types of valves like check and gate valves?

Control valves regulate flow, pressure, or temperature dynamically by adjusting the valve position based on process signals, enabling precise control. In contrast, check valves prevent backflow automatically, and gate valves primarily serve as on/off isolation devices.

How do I choose the right type of check valve for my system?

Consider the fluid type, pressure, flow direction, and installation space. Swing check valves are suitable for low-pressure systems, while lift check valves handle higher pressures. Wafer check valves save space in compact pipelines.

Can gate valves be used for throttling purposes?

Gate valves are designed for full open or closed positions and are generally not recommended for throttling as partial opening can cause damage and reduce valve lifespan. For throttling, control valves are preferred.

What materials are commonly used by control valve manufacturers?

Materials range from stainless steel, carbon steel, brass, and bronze to specialized alloys depending on fluid compatibility, temperature, and pressure requirements.

How important is after-sales support from valve suppliers?

After-sales support is crucial for troubleshooting, maintenance, spare parts availability, and ensuring valve longevity. Good suppliers offer technical guidance and timely assistance, minimizing downtime.