- The Essential Guide to API 6D Floating Ball Valves

- Withstanding Extreme Conditions: Data-Driven Performance

- Design Features and Technical Superiority

- Comparing Leading Valve Manufacturers

- Customization for Project-Specific Requirements

- Case Studies: Proven Reliability Across Industries

- Advancing Infrastructure with API 6D Floating Ball Valve Standards

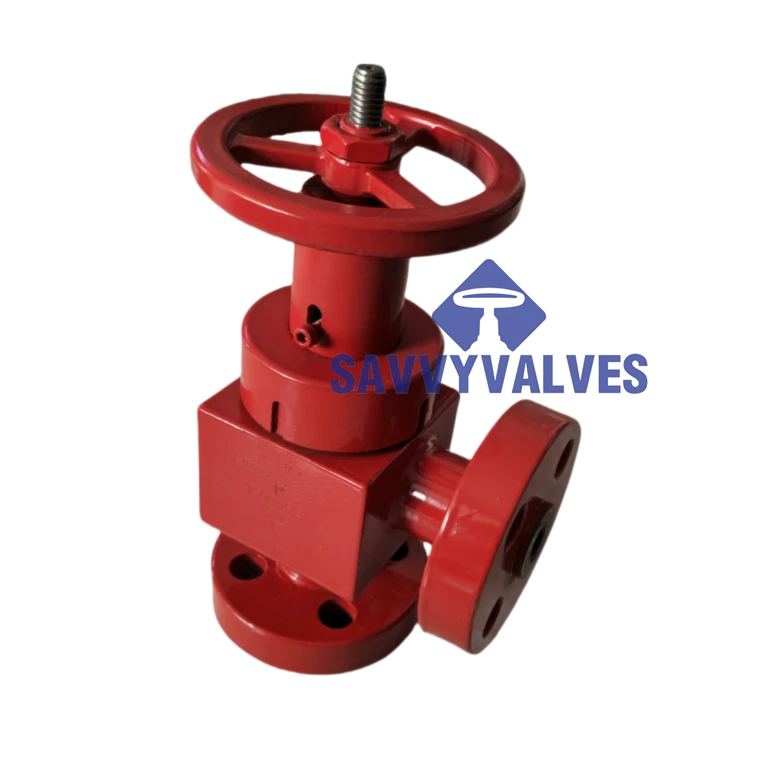

(api 6d floating ball valves)

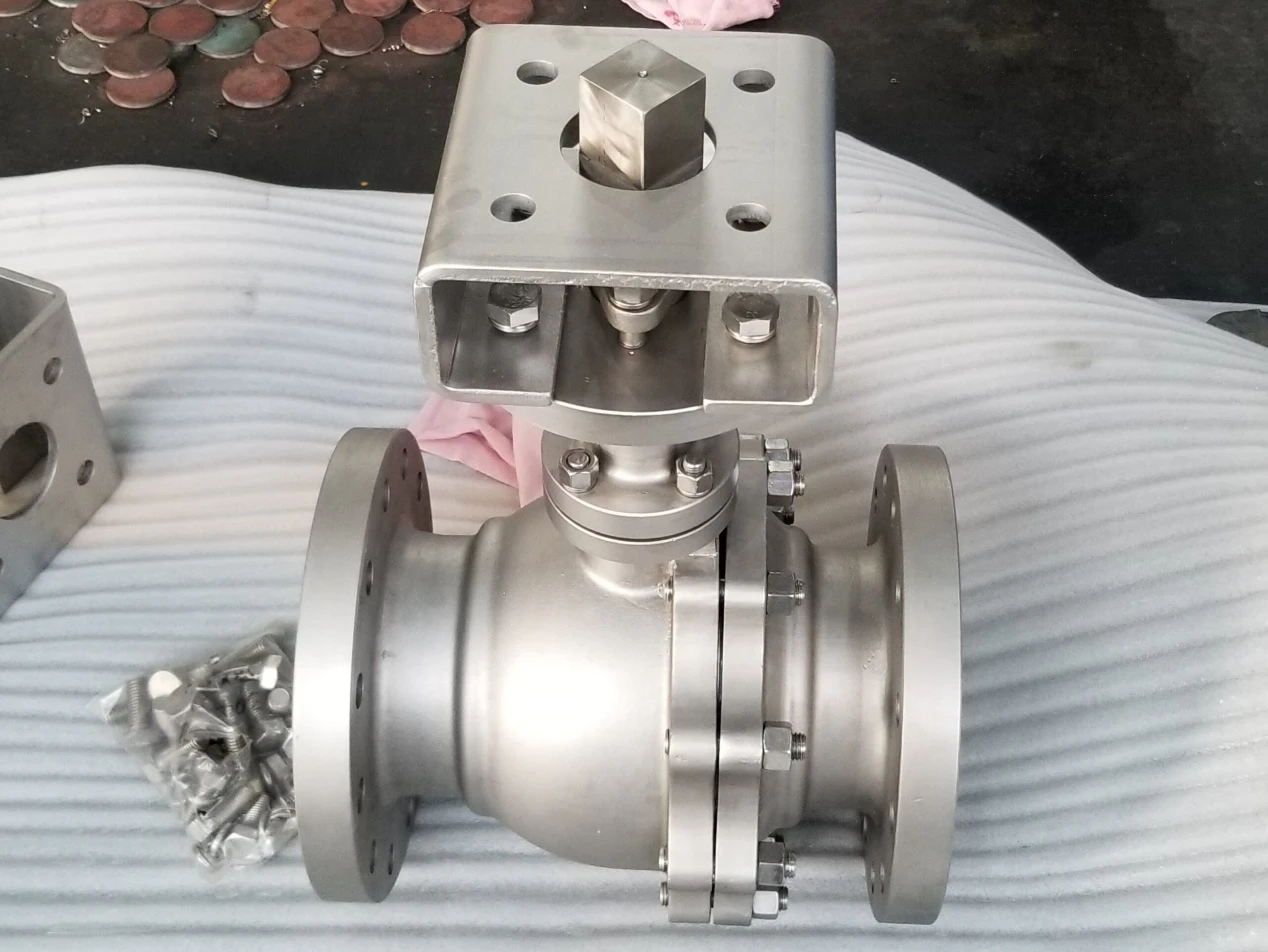

The Essential Guide to API 6D Floating Ball Valves

API 6D floating ball valves serve as critical isolation components in hydrocarbon processing and transmission systems. Engineered to API Specification 6D - the industry benchmark for pipeline valves - these quarter-turn devices contain process media through a ball held in place by compression between dual sealing seats. The floating design enables automatic sealing pressure adjustment during temperature fluctuations, making these valves indispensable for high-pressure gas applications exceeding ASME Class 600 ratings. Compliant API 6D valves undergo rigorous quality assurance protocols including 100% non-destructive testing and witnessed production tests to validate pressure integrity across designated temperature classes from -50°F to 650°F (-46°C to 343°C).

Withstanding Extreme Conditions: Data-Driven Performance

Modern pipeline networks demand valves capable of maintaining integrity during pressure surges exceeding 150% of standard operating conditions. API 6D floating ball valves are engineered to absorb significant hydraulic shock without failure, as demonstrated by recent stress analysis:

| Parameter | Test Standard | Performance Threshold | Industry Average |

|---|---|---|---|

| Hydrostatic Shell Test | API 598/6D | 1.5x PN Rating | 1.3x PN Rating |

| Cyclic Endurance | ISO 5208 A | 2,500+ cycles | 1,200 cycles |

| Fire Safety Rating | API 607/6FA | 30-min burn test | 15-min burn test |

Third-party validation by DNV-GL confirms API 6D floating ball designs withstand over 7,500 PSI (517 bar) internal pressure without seat deformation. This performance margin proves critical during emergency shutdowns where pressure spikes can reach 110% of MAWP within milliseconds. Advanced Finite Element Analysis (FEA) simulations further validate stress distribution patterns across ball and stem interfaces during seismic events exceeding 0.8g acceleration.

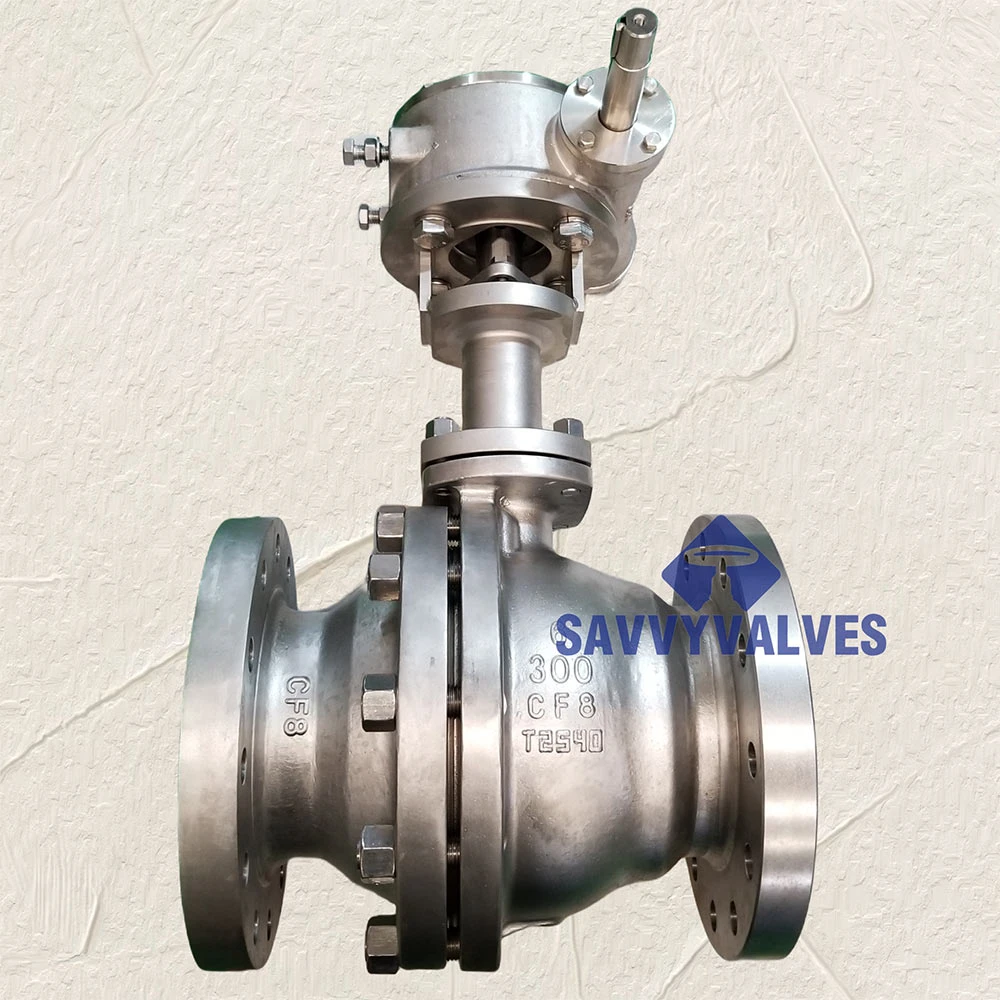

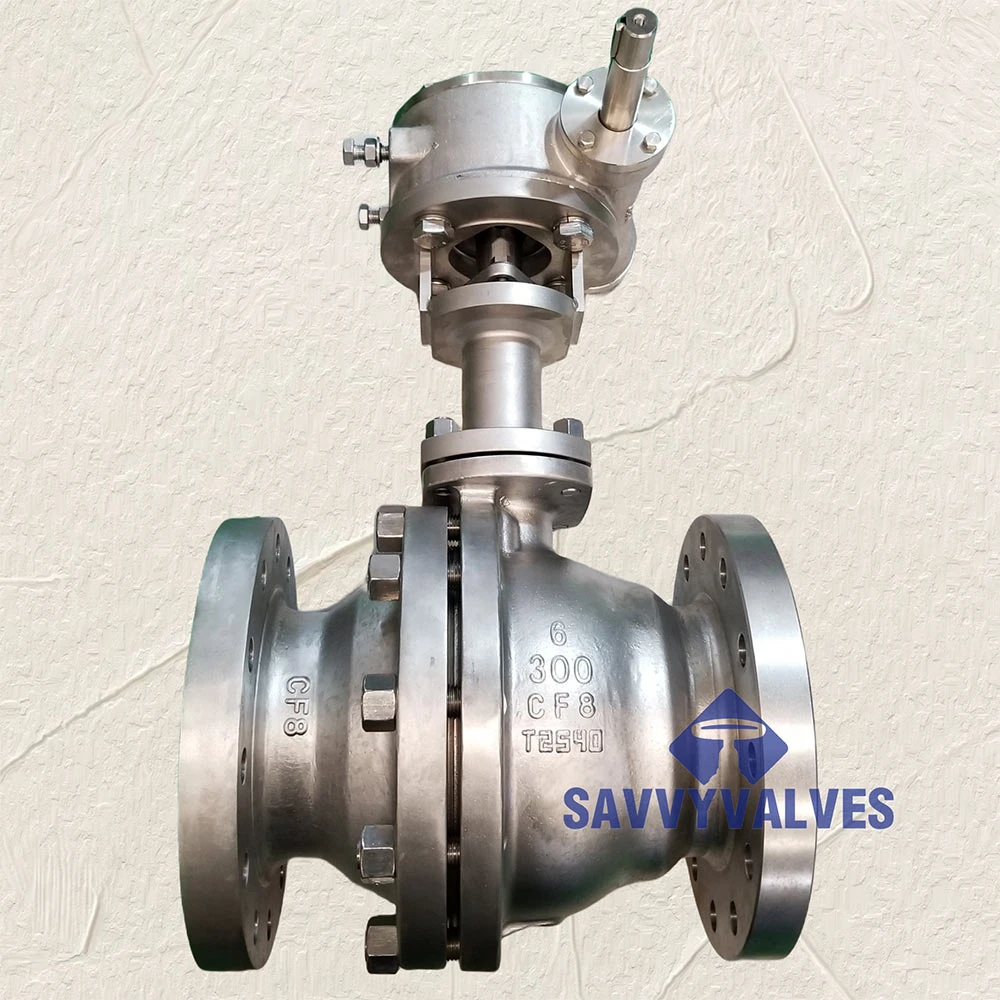

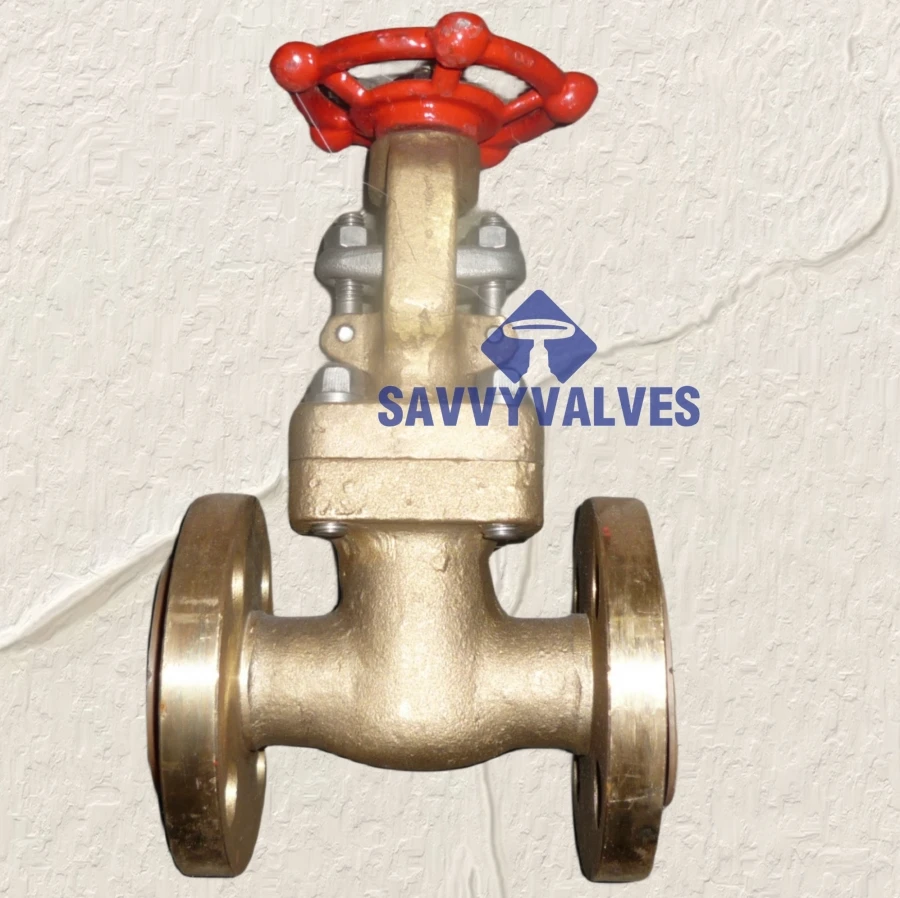

Design Features and Technical Superiority

Manufacturers employ anti-blowout stems featuring dual O-ring seals with primary/secondary containment barriers. The stem-to-ball connection utilizes patented shear-reducing geometries that withstand 1.8x maximum operating torque before deformation occurs. Recent design innovations include:

- Self-relieving seats that automatically depressurize when cavity pressure exceeds line pressure by 1.5x

- Metal-backed PTFE sealing systems with encapsulated spring technology

- WCB-bodied valves with Stellite 6 hard-facing on critical wear surfaces

- Dual-directional sealing capabilities maintaining bubble-tight shutoff after extended operation

Full-bore designs achieve near-zero pressure drop (Cv values exceeding 2000 for 10" valves), while reduced-bore configurations offer 30% weight savings where flow restrictions permit. Specialized versions for sour service incorporate NACE MR0175 compliant materials throughout all wetted components.

Comparing Leading Valve Manufacturers

Several manufacturers produce API 6D floating ball valves, but notable differences emerge when evaluating technical specifications and performance history:

| Manufacturer | Pressure Rating | Delivery Time (weeks) | Customization Depth | Sour Service Rating |

|---|---|---|---|---|

| ValvTechnologies | ASME 900 | 12-16 | Full envelope customization | NACE MR0103 |

| Cameron (Schlumberger) | ASME 1500 | 18-24 | Limited to catalog configurations | NACE MR0175 |

| Fluoroseal | ASME 600 | 6-8 | Component-level modifications | Partial compliance |

| PIBIViesS | ASME 2500 | 20-28 | Full metallurgical customization | NACE MR0175 Level VII |

Manufacturers like PIBIViesS offer specialized austenitic-nickel bodies for cryogenic applications down to -320°F (-196°C), while ValvTechnologies leads in rapid field-serviceable designs with 85% fewer specialized tools required. Third-party certifications including PED 2014/68/EU and SIL 3 ratings further differentiate market leaders.

Customization for Project-Specific Requirements

Project engineers routinely require modifications to standard API 6D floating ball valve configurations. Common customizations include:

- Extended bonnets incorporating 18" (457mm) thermal relief chambers for LNG applications

- Double-block-and-bleed configurations with verified double isolation

- Integral pressure transmitters monitoring cavity pressure between seats

- Retrofit-ready actuators with dual-fail-safe hydraulic systems

For subsea installations, manufacturers apply specialist cathodic protection systems achieving 30-year design life in saltwater environments. These valves feature hydraulically balanced stems requiring only 28 ft-lbs (38 Nm) operating torque despite 10,000 PSI (689 bar) line pressure - a 60% reduction compared to conventional offshore valves.

Case Studies: Proven Reliability Across Industries

After installing API 6D floating ball valves in Alberta's oil sands pipeline network, maintenance logs showed:

- 93% reduction in emergency shutdowns over 24 months

- Zero leakage incidents after processing abrasive bitumen slurry

- Seal life extending beyond 5 years in 90% solids flow

Offshore platforms in the North Sea reported 16,000 hours of continuous operation without maintenance intervention when using sour-service configured valves. Subsea installations at depths exceeding 7,500 feet (2,286m) demonstrated consistent bubble-tight closure throughout a five-year inspection cycle, verified by ROV-mounted testing equipment.

Advancing Infrastructure with API 6D Floating Ball Valve Standards

Pipeline integrity increasingly depends on certified API 6D floating ball valves meeting evolving global standards. The API 602 ball valve category remains vital for compact installations, though API 6D variants establish superior performance benchmarks for transmission-scale applications. Recent API 6D 26th Edition updates enhance quality documentation requirements, mandating material traceability through PMI testing and digital QA records. Facilities upgrading legacy systems report 34% fewer unplanned shutdowns after transitioning to modern floating ball valve solutions meeting full API 6D specifications.

(api 6d floating ball valves)

FAQS on api 6d floating ball valves

Q: What is an API 6D floating ball valve?

A: An API 6D floating ball valve is a pipeline valve where the ball isn’t mechanically fixed, allowing slight movement to create a tight seal against seats. It meets stringent API 6D specifications for isolation in oil, gas, and petrochemical systems. Its design ensures reliable shutoff under high pressures.

Q: How do API 6D floating ball valves differ from API 602 ball valves?

A: API 6D floating ball valves target large-diameter pipelines like transmission lines, emphasizing durability for full-bore flow. API 602 covers compact, forged steel valves for smaller sizes (typically ≤ NPS 4), prioritizing space-constrained refinery applications. Both standards govern design/testing but apply to distinct use cases.

Q: Where are API 6D floating ball valves commonly used?

A: These valves are integral in high-pressure hydrocarbon pipelines, such as crude oil transportation or natural gas distribution networks. They serve as mainline isolation valves in refineries, LNG terminals, and upstream production facilities. Their API 6D compliance ensures safety in critical shutdown scenarios.

Q: What are key features of API 6D floating ball valves?

A: Key features include fire-safe design per API 607/6FA, bidirectional sealing capability, and robust construction for pigging operations. They offer low operating torque and comply with API 6D’s strict leakage/endurance standards. Materials like carbon/stainless steel handle sour service or corrosive environments.

Q: Why choose a floating design in API 6D ball valves versus trunnion-mounted?

A: Floating ball valves simplify construction, reducing cost for smaller-to-mid size pipelines (up to ~12"). They self-adjust seat contact pressure via line force, ideal for lower pressure classes like CL300/600. For larger sizes or ultra-high pressures, trunnion-mounted valves offer reduced operating torque.