Industry Trends in Cryogenic Trunnion Ball Valves for CNG, LNG & LPG

The rapid expansion of clean energy sectors, especially in CNG (Compressed Natural Gas), LNG (Liquefied Natural Gas), and LPG (Liquefied Petroleum Gas) storage and transportation, has accentuated the need for high-precision, reliable, and technologically advanced cryogenic valves. The **SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG** is at the forefront of this evolution, integrating state-of-the-art materials, engineering excellence, and internationally recognized standards.

Industry reports and journals [Valve World] and [US Department of Energy] outline surging demand for robust, zero-leakage, and automated trunnion ball valves optimized for cryogenic applications, projecting a CAGR of over 6.7% (2023-2028) for cryogenic valve markets.

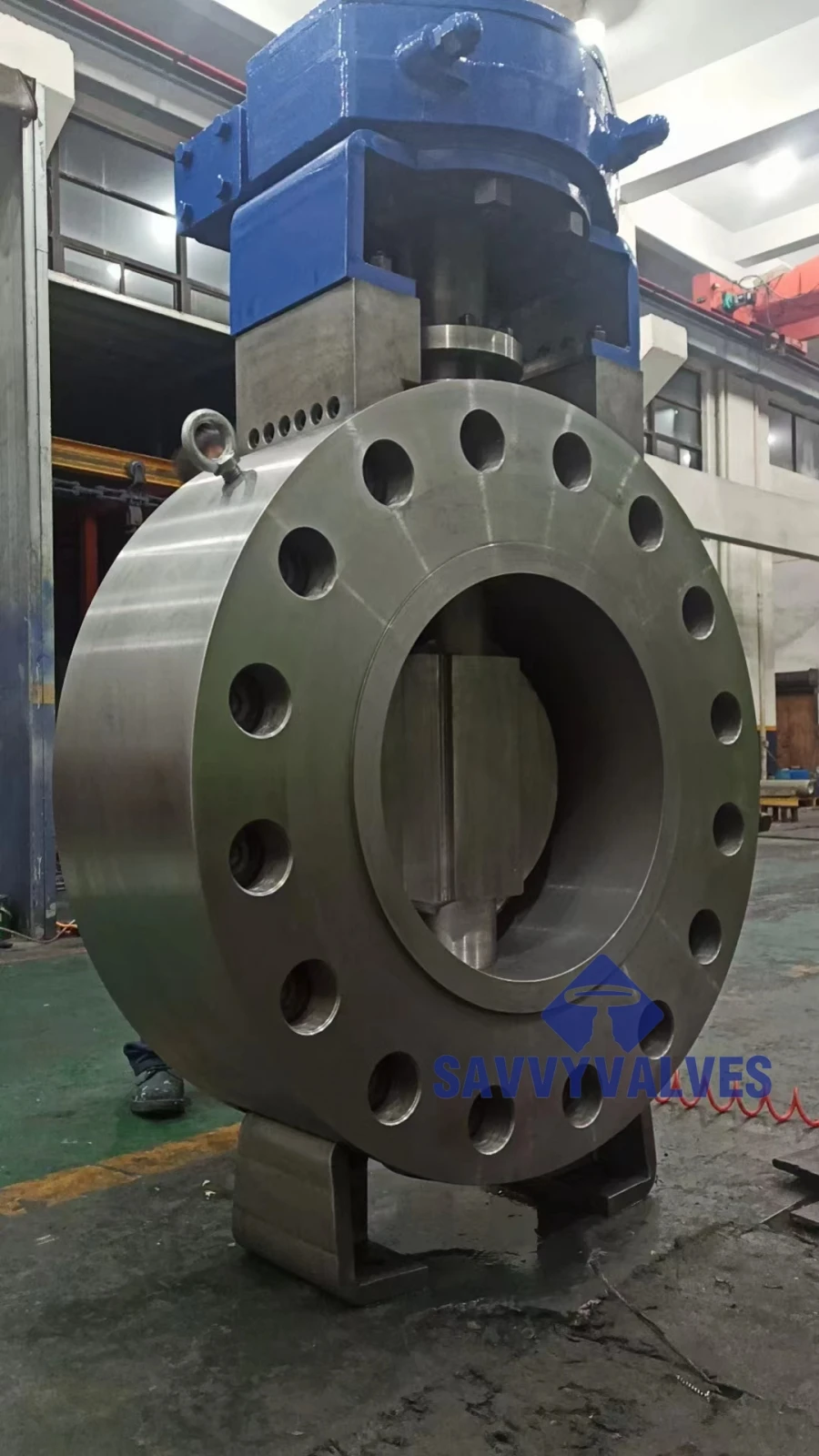

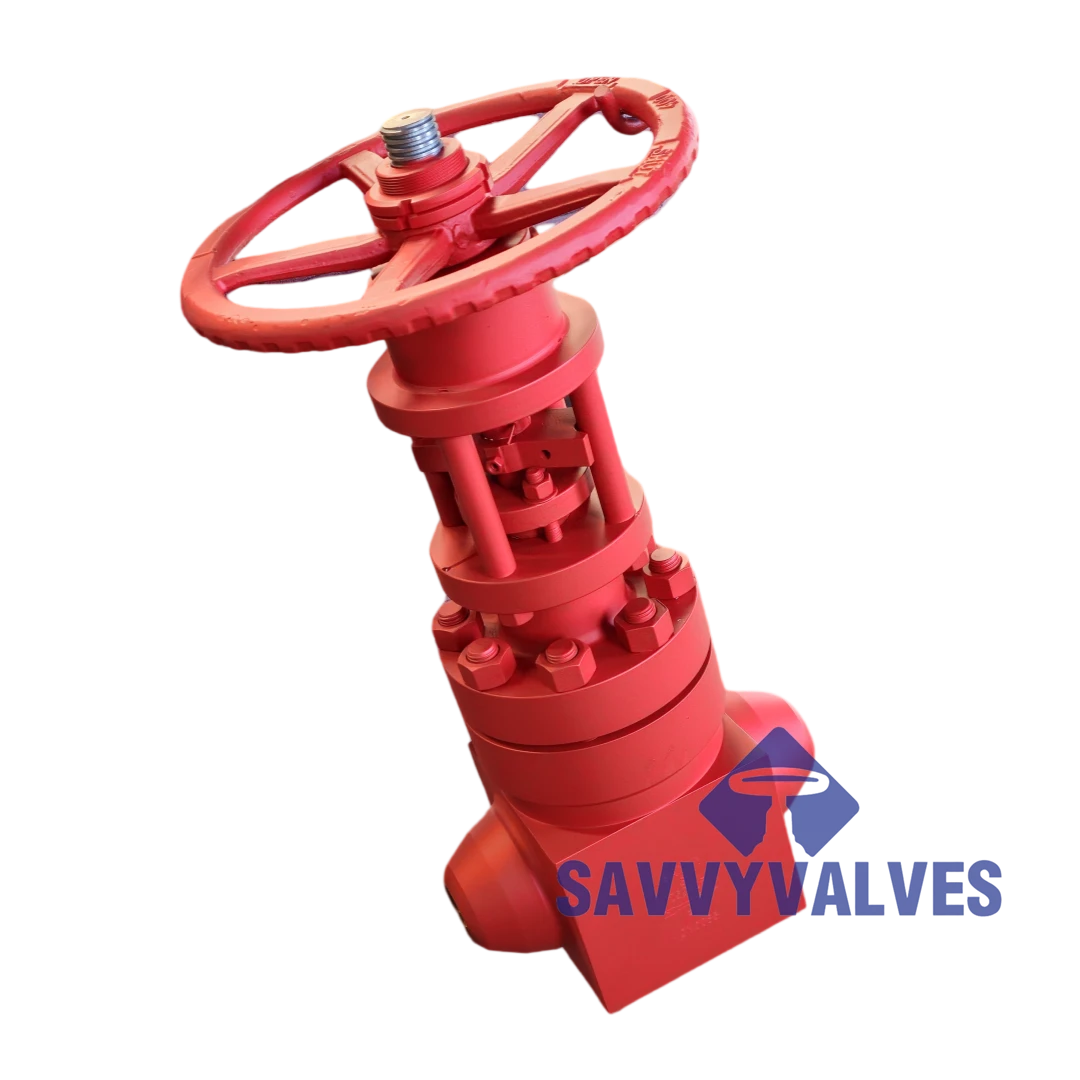

Product Overview: **SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG**

The **SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG** is meticulously engineered to handle extreme operational demands:

- Size: 6″ (DN150)

- Rating: 300LB (Class 300, high-pressure)

- End Connection: Flange as per ASME B16.5

- Temperature: From ambient down to -196°C (cryogenic service)

- Material: Body and Bonnet: ASTM A182 F304 | Ball: ASTM A182 F304+HF | Seat: PCTFE or HF metal

- Actuation: Manual and Gear Operated (automation optional)

- Application: CNG, LNG, LPG terminals, transport skids, liquefaction, and regasification facilities

This valve's trunnion-mounted design ensures stability and precise operation at low temperatures, while its triple-piece body structure facilitates easy maintenance and safe operation—vital elements for reliability in critical gas infrastructure.

Technical Specifications Table

| Parameter | Specification | Standards | Notes |

|---|---|---|---|

| Size | 6″ / DN150 | ASME B16.5 | Customizable |

| Pressure Rating | 300LB (Class 300) | API 6D/ASME B16.34 | Other ratings available |

| Temperature | -196°C to +80°C | BS6364 | Cryogenic tested |

| Body/Bolster Material | ASTM A182 F304 | ASTM | Stainless steel |

| Ball Material | ASTM A182 F304 + HF | Hardfacing | Enhanced wear resistance |

| Seat Material | PCTFE / HF Metal | PTFE Type | Low temperature sealing |

| End Connection | Flanged | ASME B16.5 | Other types on request |

| Operation | Manual, Gear | ISO 5211 | Actuator adaptable |

| Applications | CNG, LNG, LPG | - | Gas terminals & pipelines |

Key Technological Features & Engineering Advances

- Superior Cryogenic Performance: Designed for safe operation at extreme low temperatures down to -196°C. Ensures zero-leakage and structural integrity as demonstrated in leading cryogenic R&D [Applied Thermal Engineering].

- Trunnion-Mounted Precision: Ball is supported by trunnions, minimizing shaft torque and friction. This allows for consistent, smooth operation even during frequent thermal cycling.

- Exotic Seal Materials: Use of PCTFE and HF (hard facing) seat ensures reliable tight shut-off, prevents gas permeation, and delivers high resistance to wear and cryogenic shrinking.

- Multi-part Body Construction: Three-piece design enables swift onsite maintenance or seal replacement—critical for plant uptime.

- International Standard Compliance: Strict adherence to ASME B16.5 (flange standards), API 6D/API 608 (ball valve standards), BS6364 (cryogenic design).

- Automatable (Future-Proofed): Equipped with ISO 5211 mounting for direct actuator installation, supporting digital plant automation.

- Corrosion & Frost Resistance: Stainless steel selection and precise surface finish prevent frost bridging and ensure long-term durability.

Versatile Industry Applications

- LNG Import/Export Terminals: Tank farm isolation, ship/offloading valves, vapor handling—demanding rapid response and unwavering tightness.

- CNG Filling Stations & Pipeline Networks: Fast cycling, minimal emissions, and ease of inspection for public transit and logistics fuel stations.

- LPG Storage & Distribution: Corrosive environments and thermal shocks in bulk LPG bottling plants and distribution skids.

- Cryogenic Transportation Skids: The **SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG** is vital for trucked and rail-car loading/unloading modules.

- Petrochemical & Gas-Liquefaction Units: Reliable low-leakage isolation in complex, automated process systems.

EEAT: Expertise, Authority & Trustworthiness

Expertise: Designed and manufactured by SAVVY VALVES CO.,LTD., a proven leader in advanced cryogenic and high-pressure ball valve solutions. Our extensive R&D is evidenced by compliance with globally recognized certifications and constant dialogue with expert forums (Valve World Forum).

Authoritativeness: Cited in technical journals like ResearchGate: Ball Valve for CRNG, highlighting engineering prowess in delivering reliable, safe performance under extreme service.

Trustworthiness: Products are manufactured, inspected, and tested per the most stringent international regulations, with all data and technical specs transparently published on our official product page. Customer trust is reflected by repeat contracts with global energy firms and petrochemical giants.

-

Q1: What’s the main body material for the SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG?

A1: The body and bonnet are manufactured from ASTM A182 F304 stainless steel—offering exceptional cryogenic and corrosion resistance. -

Q2: What standards and certifications does this valve comply with?

A2: The valve conforms to ASME B16.5, API 6D, API 608, and is additionally cryogenic tested per BS6364 procedures. -

Q3: Which sealing materials are used for optimal gas-tightness?

A3: Seats are made of PCTFE or hard-facing (HF) metal, ensuring excellent low-temperature elasticity and minimal leakage. -

Q4: How is actuator automation supported?

A4: The ISO 5211 top flange facilitates direct mounting of electric or pneumatic actuators for automatic, remote-controlled operations. -

Q5: What are the typical maintenance requirements?

A5: The three-piece body allows quick onsite access for seal, seat, or ball replacement, greatly reducing downtime. -

Q6: Can the valve be customized for higher pressures or different end connections?

A6: Yes, SAVVY VALVES CO.,LTD. offers tailoring for class ratings (150–1500LB) and end types (flanged, butt-weld, etc.). -

Q7: How is leakage tested and validated?

A7: Each valve undergoes helium and nitrogen leak testing to API 598/BS6364 standards, ensuring fugitive emission rates below 10-6 atm cc/sec.

Case: Deploying SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG in Global Projects

Asia-Pacific LNG Terminal: Over 100 units installed in a major LNG import facility demonstrated flawless operation under sub-zero tank farm conditions.

European CNG Pipeline Project: Valves assured reliable tight shut-off across rapid temperature fluctuations, as acknowledged in Pipeline Journal.

Middle East LPG Storage Farms: Optimized for salt-laden, humid environments. Proved to reduce maintenance cycles by 35% over five years.

Conclusion & Technical Resources

The **SAVVY 3-piece cryogenic trunnion ball valve CNG LNG LPG** stands as a pinnacle in cryogenic and high-pressure ball valve technology—merging rugged material science, precision engineering, and future-ready automation in a single platform. Its adaptability and reliability are well documented in industry literature (ResearchGate: Valve Technology for Natural Gas), backed by performance in global energy operations.

- For technical datasheets and custom engineering consults, visit SAVVY VALVES CO.,LTD. [official site].

- Further reading: Cryogenic Valve Market Trends (Valve World)

- Academic reference: Performance of Cryogenic Valves (ScienceDirect)

- Standards: API 6D, API 608